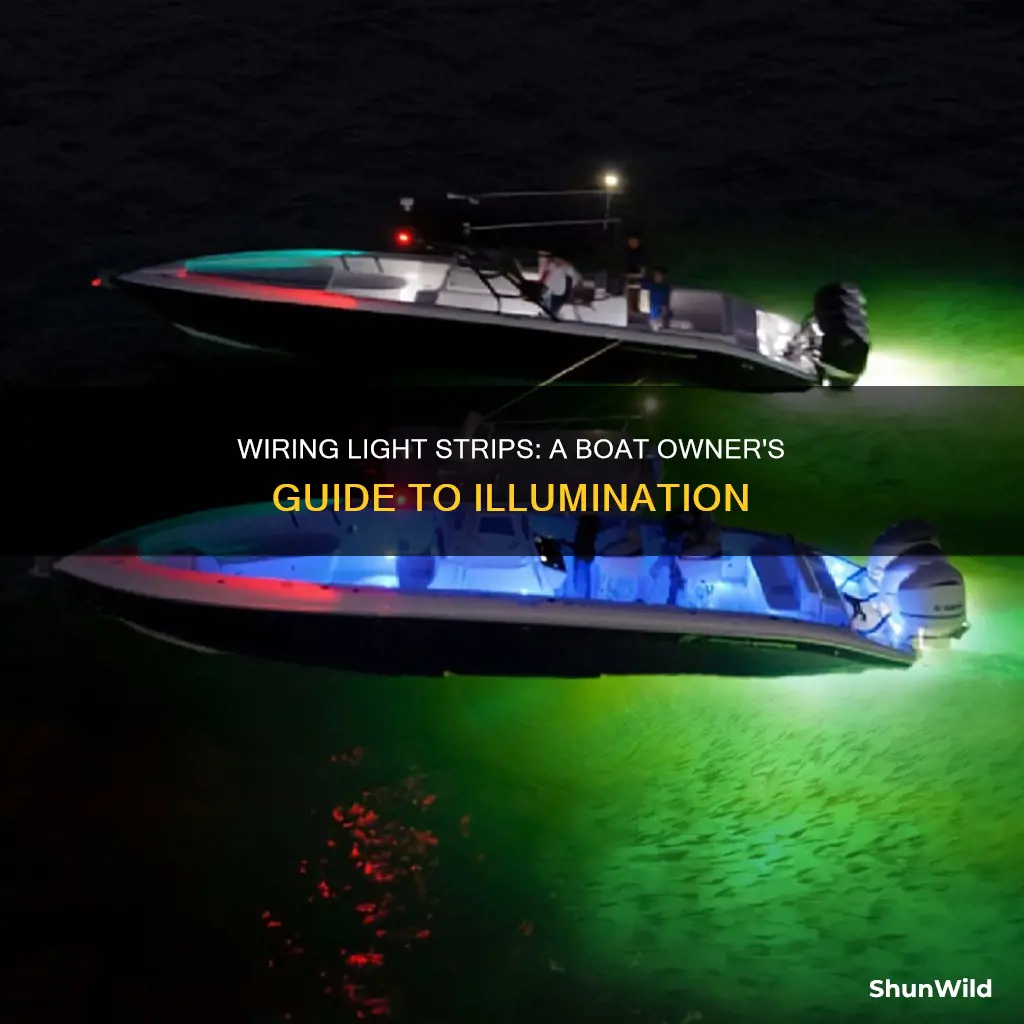

Wiring light strips to a battery on a boat is a complex task that requires careful planning and execution. The process involves several steps, including disconnecting the battery, scoping out the wiring route, measuring and cutting wires, soldering and crimping connections, and testing the lights before mounting them. It is important to use the correct type of wire and connectors, and to ensure that the power source is compatible with the lights. Additionally, there are different wiring methods to consider, such as powering lights on a main trunk line or running wires to each light individually.

What You'll Learn

Connecting to a power source

Before you begin, disconnect the negative cable of the boat's battery using a 5/16-inch box-end wrench. Lift the cable from the battery, move it outside the battery box, and close the box. This will keep you and your equipment safe in case anything goes wrong.

The best way to power your LED lights is to wire them directly into your boat's 12V battery. Most boats have a fuse box or breaker panel, which makes this task simple. However, it is crucial to ensure that the power source is 12V. Many boats have regulators built-in to prevent power spikes, but if yours does not, you can protect your LEDs with a DC voltage regulator. This is important because without it, your LEDs may experience issues such as dimming, loss of hearing, fading, light pattern baldness, or even burnouts.

If you are using a 12V battery, you will need to connect the positive wires (usually red) and the negative wires (usually black or yellow) to the battery. For current to flow and power your lights, a complete circuit must be made from positive back to the negative. Any break in the circuit will stop the lights from working.

To wire your lights, follow these steps:

- Measure the length of the route from the battery to the light switch, and from the switch to the farthest light. Keep the wiring as high in the boat as possible to minimise exposure to water.

- Use No. 3 tinned BC5W2 boat cable to connect to the battery. Trim 12 inches of the cover from the cable to expose the red power wire and the yellow ground wire. Strip a half inch of insulation from the end of each wire and crimp a 3/8-inch ring connector to the red wire and a 5/16-inch ring connector to the yellow wire.

- Move to the light switch panel. Trim the cover of the safety duplex cable to expose the red and yellow stranded wires. Clip the red wire and solder one end to each of the two lugs on the fused navigation light switch.

- Pull the boat cable from the switch to the first navigation light. Clip the red wire, strip a half inch of insulation, and crimp a three-wire connector onto both ends. Push the navigation light's red wire into the remaining opening and crimp the connector.

- Repeat the above step for the yellow wire, using a three-way connector. Push the navigation light's green wire into the third opening and crimp the connector.

- Move on to the next navigation light and repeat the process until you reach the final light.

- Return to the battery and connect the red wire to the positive terminal and the yellow wire to the negative terminal.

- Reconnect the negative battery cable.

Now you know how to connect your light strips to a power source on your boat!

The Perfect Family Ski Boat: Best Options for Fun

You may want to see also

Wiring to a switch

Understanding the Basics:

Before starting, it's important to understand the basics of boat wiring. The electrical source in a boat is typically one or more batteries, usually a starting battery and a deep cycle battery. The positive wires are usually red, while the negative wires are black or yellow. It's crucial to ensure that the power source is 12V to avoid damaging the LED lights.

Wiring Process:

- Disconnect the Battery: Before beginning any wiring work, it's essential to disconnect the negative cable of the boat's battery. This is a safety precaution to protect you and your equipment in case anything goes wrong.

- Plan the Wiring Route: Measure the length of the route from the battery to the switch. Keep the wiring as high in the boat as possible to minimise exposure to water.

- Prepare the Wires: Trim and strip the insulation from the wires to expose the conductors. Use wire strippers to ensure a clean cut. You will need to work with both the power wire (red) and the ground wire (yellow or black).

- Connect to the Switch: Connect the wires to the switch, ensuring proper polarity. The red wire connects to the positive terminal of the switch, while the yellow or black wire connects to the negative terminal.

- Fuse the Circuit: It is important to fuse the circuit to protect against electrical overloads. Run a wire from the positive side of the battery to the switch, and ensure this wire is fused.

- Connect the Lights: Connect the positive wires from the lights to the other side of the switch. Ensure that all connections are secure and properly insulated.

- Test the Lights: Once the wiring is complete, reconnect the battery and test the lights to ensure they are functioning properly.

Safety Considerations:

- Always use marine-grade wiring and components that are designed for use in boats.

- Ensure that all connections are properly insulated and sealed to prevent exposure to water.

- Use a voltage regulator to protect your LED lights if your boat doesn't have a built-in regulator to prevent voltage spikes.

- Consult a professional marine electrician if you are unsure about any part of the process.

Get Started With Boat-Towed Surfing: A Beginner's Guide

You may want to see also

Connecting to negative wires

Connecting to the negative wires is a crucial step in wiring light strips to a battery on a boat. Here's a detailed guide on how to do it:

Firstly, it's important to understand the colour coding of wires. In most cases, negative wires are black, but they can sometimes be yellow. Before beginning any wiring work, it's essential to disconnect the negative cable of the boat's battery for safety. Use a 5/16-inch box-end wrench to lift the cable from the battery, move it outside the battery box, and close the lid. This will ensure that you're working with a safe, power-free system.

Now, let's get into the wiring process. You'll need to run all the negative leads directly to the negative side of the battery. This will create a complete circuit, allowing current to flow from positive to negative and power your lights. It's crucial to ensure that all connections are secure and insulated to prevent any short circuits or electrical issues.

When connecting the negative wires, it's good practice to twist the wires into a pigtail before soldering or crimping them together. This creates a secure connection that can withstand vibrations and movements on the boat. After twisting the wires, use heat shrink butt splices or connectors to join the negative wires from the lights to the boat's existing negative wires. Make sure to match up the wires correctly—black (negative) with black and, if present, yellow (ground) with yellow.

Once you've made the connections, apply heat to the connectors using a lighter or heat gun. This will cause the plastic around the connectors to shrink and seal, providing insulation and protection. After that, it's a good idea to wrap electrical tape around the connections for added security and to prevent rattling or pulling.

Finally, remember to reconnect the negative battery cable once all the wiring work is complete. This will restore power to your boat's electrical system, and your light strips should be ready to illuminate your vessel.

Connecting to the negative wires is a crucial step in ensuring your boat's lighting system functions correctly and safely. Always take your time, follow safety procedures, and ensure that all connections are secure and properly insulated.

The Auberdine Ferry: A Guide to Boat Travel

You may want to see also

Using a fuse

Understanding Fuses:

- Fuses are sacrificial devices designed to interrupt the circuit and prevent excessive current flow.

- In the event of an overload or short circuit, the fuse will "blow," disrupting the current flow and safeguarding the electrical components.

- Fuses are typically colour-coded, with each colour indicating a specific amperage rating. Common ratings include 3-5 amps for smaller loads and higher ratings for more powerful applications.

Selecting the Right Fuse:

- Choose a fuse with an amperage rating that matches or exceeds the expected current draw of your light strips. This ensures the fuse can handle the normal current without tripping unnecessarily.

- Refer to the manufacturer's instructions or specifications for your light strips to determine the required amperage rating for the fuse.

Installing the Fuse:

- Locate the positive wire coming from the battery's positive terminal. This is typically a red wire.

- Connect the fuse to this positive wire as close to the battery as possible. The fuse should be easily accessible for inspection and replacement if needed.

- Use appropriate tools and connectors to securely attach the fuse to the wire, following the instructions provided with the fuse.

- Ensure that all connections are secure and insulated to prevent short circuits or exposure to moisture.

Maintaining the Fuse:

- Regularly inspect the fuse for any signs of damage or corrosion, especially after extended use or exposure to harsh conditions.

- If the fuse blows, it must be replaced. Keep spare fuses with the appropriate amperage rating on hand to facilitate quick replacement.

- When replacing a fuse, always address the underlying cause of the problem before installing a new one. A blown fuse indicates an issue that needs to be resolved to prevent further damage.

By following these steps and incorporating a fuse into your wiring setup, you can enhance the safety and reliability of your boat's lighting system, protecting both the lights and the boat's electrical components.

Usaa's Boat Insurance: What You Need to Know

You may want to see also

Selecting the right wire type

- Compatibility with battery size and conductor gauge: Ensure that the wire type you select is compatible with the size of your battery and the conductor gauge. Using incompatible wire types can lead to unsafe conditions and potentially damage your boat's electrical system.

- Ampacity considerations: Different wire types have varying ampacity, or current-carrying capacity. It is important to select a wire type that can safely handle the amount of current flowing through it. As a general rule, you should never go below #16 AWG (American Wire Gauge) on a boat, as smaller wire types are more fragile and can pose a safety risk.

- Length of wiring run: The length of the wiring run from the battery to the switch panel will impact the voltage drop. Longer wiring runs tend to result in higher voltage drops. To mitigate this, consider using larger-gauge wires, as they can help reduce voltage drop.

- Insulation and protection: Given the marine environment, it is essential to select wire types that have adequate insulation and protection against moisture and corrosion. Look for marine-grade wiring that is specifically designed for use in boats and can withstand the harsh conditions at sea or on freshwater bodies.

- Ease of installation and maintenance: Some wire types may be easier to install and maintain than others. Consider the availability of connectors, terminals, and other accessories that are compatible with the wire type you choose. This will make it easier to work with and maintain your boat's electrical system.

- Compliance with regulations: Ensure that the wire type you select complies with marine electrical standards and regulations. Using non-compliant wire types can lead to safety hazards and may void any warranties on your boat's electrical components.

Remember, electrical work on a boat can be complex and potentially dangerous. If you are unsure or uncomfortable with any aspect of the wiring process, it is always best to consult a professional marine electrician for guidance or assistance.

Strategic Vent Placement for Boat Covers

You may want to see also

Frequently asked questions

First, ensure the power source is 12V. Then, disconnect the negative cable of the boat battery before modifying the electrical system. Next, run all negative leads directly to the negative side of the battery. After that, run a wire from the positive side of the battery to a switch, and then run all positive wires from the lights to the other side of the switch. Finally, reconnect the negative battery cable.

Wire your lights directly into your boat's 12V battery.

A DC voltage regulator ensures DC power doesn't exceed 12V. Without one, your LED lights may experience dimming, loss of hearing, fading, light pattern baldness, and even burnouts.

Marine safety duplex cable combines the "hot" power wire and the ground wire in a single cable, allowing you to make the run from battery to all the running lights without a cumbersome return loop of wire to the battery.

Utilize a Plug and Play Building Block Power Wire Harness. This option is super easy and fast to install, and troubleshooting lights down the road is a breeze.