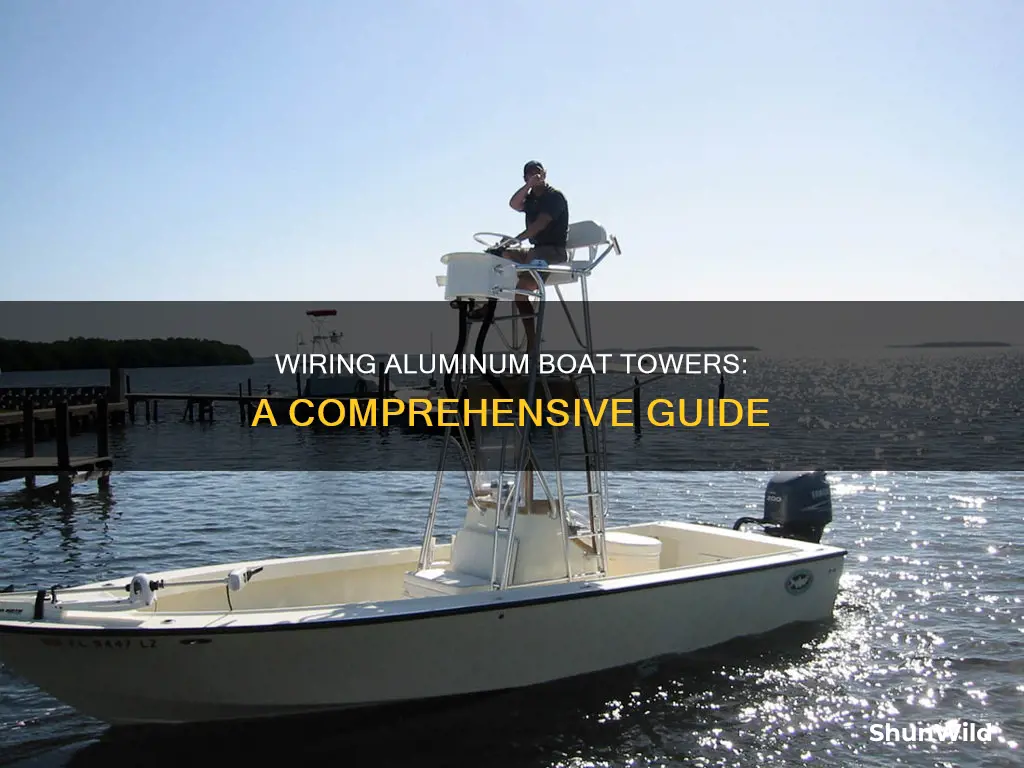

Wiring an aluminium boat tower is a complex task that requires careful planning and execution. The process involves running wires to connect various accessories, such as speakers, lights, and other electrical components. It is important to count the number of accessories and determine their power requirements before starting the installation process.

One crucial aspect of wiring an aluminium boat tower is ensuring proper grounding. It is recommended to connect the ground to the negative battery post instead of the boat body to prevent issues like electrolisis and potential safety hazards.

Additionally, it is essential to use the correct wire gauge to handle the current draw and length of the wire run. The wiring process includes drilling holes in the tower for wires to pass through, feeding wires through the tower, and connecting them to the battery and accessories.

While wiring an aluminium boat tower can be a challenging task, with proper planning, attention to safety, and following manufacturer instructions, it is possible to successfully complete the wiring installation.

What You'll Learn

Plan the wiring and drilling

Planning the wiring and drilling of your aluminium boat tower is a crucial step in ensuring a successful installation. Here is a step-by-step guide to help you through the process:

Step 1: Identify Your Accessories

First, determine the number and type of accessories you plan to install, such as speakers, lights, or other electrical components. This will help you understand the wiring requirements and ensure you have the necessary components.

Step 2: Plan Wire Routing

Decide on the optimal route for the wires to travel from the battery to the accessories. Consider the location of the battery and the placement of the accessories. The path should be as direct as possible, minimising the length of wire needed.

Step 3: Determine Drilling Locations

Identify the exact locations where you will need to drill holes for the wires to pass through. Mark these spots clearly, ensuring they align with the planned wire route. Remember to choose spots that will provide easy access to the wires for future maintenance or upgrades.

Step 4: Consider Joint and Pivot Points

When planning the wire route, pay special attention to any joint or pivot points on the tower. Wiring around solid joints is recommended, as it provides the path of least resistance. For pivoting joints, ensure you allow for sufficient wire slack to accommodate the full range of motion when the tower is folded or adjusted.

Step 5: Waterproofing

To prevent water ingress and potential electrical issues, it is crucial to use rubber grommets or similar waterproofing measures at each hole where the wires exit or enter the tower or boat's hull. This will safeguard your electrical system and protect against water damage.

Step 6: Measure Twice, Drill Once

As the saying goes, "measure twice, cut once." Before you start drilling, double-check all your measurements and markings to ensure they are accurate. Drilling into your boat's structure can be nerve-wracking, so take your time and be confident in your placement before proceeding.

Step 7: Plan for Future Expansion

Consider the possibility of adding more accessories in the future. Allow for extra wires or capacity in your initial wiring setup to accommodate future expansion. This way, you won't have to redo your wiring if you decide to enhance your boat tower with additional features later on.

Otto Kilcher's Boat: The Constructor's Fate Explored

You may want to see also

Avoid grounding to the boat body

When wiring an aluminium boat tower, it is crucial to avoid grounding to the boat body. Here are some detailed instructions and considerations to ensure safe and effective wiring:

Firstly, it is essential to understand the different ground systems in a boat's electrical system. These include the DC ground, AC ground (neutral), AC grounding or bond, and the boat's bonding system. The DC ground is connected to the negative terminal of the battery, while the AC ground and grounding systems are "free-floating," meaning they do not ground on the vessel but only to the shore. The AC grounding wire, often green, is a safety measure to divert current in the event of a short circuit. The bonding system, also typically green, involves wiring underwater metals together to equalise potential differences between various metal components.

Now, to avoid grounding to the boat body, follow these guidelines:

- Do not connect grounds to the aluminium boat body. Always connect the ground to the negative battery post. Grounding to the boat body can cause electrolysis, leading to the formation of pin holes over time.

- Run a separate ground wire directly to a terminal block or fuse block. This simplifies troubleshooting and reduces the risk of short circuits.

- Ensure that all ground connections are solid and free from corrosion. Corroded connections can lead to electrical issues and increase troubleshooting complexity.

- Use a large gauge ground wire to connect to the ground bus bar or terminal at the top of the tower. This will reduce the number of wires running into the frame.

- If you have electronics on the tower, such as lights or speakers, it is recommended to run both positive and negative return wires to the battery instead of utilising the tower as a ground block.

- Consult a galvanic chart to ensure that the metals in direct contact or close proximity are compatible and will not result in galvanic corrosion.

- If you live in an area with lightning storms, consider grounding tall metal structures, such as the tower, to provide a safe path for lightning to discharge into the water and away from people on the boat.

By following these instructions and considerations, you can effectively avoid grounding to the boat body when wiring an aluminium boat tower, ensuring a safer and more reliable electrical system.

The Open Boat: Evolving Correspondents, Changing Perspectives

You may want to see also

Use a fuse block

When wiring an aluminium boat tower, using a fuse block is a safer and more reliable way to install additional accessories. It is important to install a fuse block correctly, ensuring that you do not drill into the aluminium. One option is to use double-sided tape to stick the fuse block in place, ensuring it is the outdoor variety. Alternatively, you can glue a chunk of plastic cutting board to the aluminium and screw the fuse block into that.

It is also important to consider the placement of your fuse block. Good places to mount fuse blocks include under the console, behind the bow switch panel, or on a transom support. Remember to locate the wiring, splices, connections, and the fuse blocks themselves high enough so that they will never be submerged.

When wiring the fuse block, the positive wire should go from the battery to the fuse block and then to the switch, ending at the light or load. A fuse or circuit breaker should be installed in the positive power wire as close to the battery as possible. This will protect as much of the wiring as possible between the battery and the device being powered.

In addition, it is recommended to use marine-grade, dual-conductor cable between the battery and the fuse panel. The outer sheath of this type of cable resists chafing, fatigue, and damage from grease, oil, battery acid, and sunlight. It also makes snaking the cable through tight spots quicker and easier than trying to run separate wires.

By following these guidelines, you can ensure that your aluminium boat tower is wired correctly and safely when using a fuse block.

The Black Pearl: A Boat's Owner Mystery

You may want to see also

Use grommets to prevent water entry

When wiring an aluminium boat tower, it is important to prevent water from entering the tower's tubing or the boat's hull. This can be achieved by using rubber grommets at the holes where wires exit and enter the tower.

Grommets are metal rings that protect holes in materials and any cords or wires that run through them. Spur grommets, which are designed for maritime use, are recommended for this purpose as they can withstand greater loads than plain grommets and are made of thicker metal. They also have a longer barrel to accommodate thicker materials.

To install spur grommets, you will need a hole punch, a mallet or hammer, and a setting tool with an anvil. First, use the hole punch to create a hole in the rubber grommet. Then, insert the barrel of the grommet through the hole in the tower. Use the mallet or hammer to drive the setting tool into the grommet, securing it in place.

It is important to ensure that the grommets are tight and securely fitted to prevent water ingress. Silicone or another type of sealant can also be applied around the wires to provide an additional barrier against water entry.

By following these steps and using the appropriate tools, you can effectively prevent water from entering your aluminium boat tower through the wiring holes.

The Thrill of Sailboat Racing: Competitive Sailing Explained

You may want to see also

Use a backing plate kit to reinforce the hull

Reinforcing the hull of an aluminium boat with a backing plate kit is a crucial step to ensure the boat's longevity and safety. Here are some detailed instructions on how to do it:

Materials and Preparation:

- Backing plates can be made from plywood, aluminium, stainless steel, or G10 fibreglass board. For aluminium boats, aluminium or stainless-steel backing plates are ideal choices.

- The backing plate should be at least 1/4-inch thick. A common size is 3-by-6-by-3/8-inch, which provides ample support.

- If using plywood, ensure it has multiple thin plies with no voids and is made with waterproof glue. Coat the plywood with epoxy to seal it and prevent moisture ingress.

- Drill the fastener holes in the backing plate oversized and fill them with epoxy to prevent leaking.

- Backing plates should be tapered or curved to fit the hull shape and prevent hard spots or uneven bearing surfaces.

Installation:

- Before drilling into your boat's hull, use painter's tape on the intended area to protect the gel coat from scratches and the fiberglass from splintering.

- Drill pilot holes first, then the final-sized holes. Run the drill in reverse at medium speed to protect the gel coat.

- Chamfer the edges of the holes to prevent spider cracking. Use a chamfer bit, a rat tail file, or a conical sanding bit to create a 45-degree angle.

- Apply a generous amount of sealant around the area where the backing plate will be mounted, as well as on the fastener heads.

- Place the backing plate in position and bolt it in place. Ensure the bolts are only tight enough to spread the epoxy evenly.

- Coat the bolts with petroleum jelly to prevent them from being epoxied in place.

- Once the epoxy has cured, mount the fitting by tracing its outline and cutting away the tape underneath for easy cleanup.

- Place the fasteners in the fitting and tighten the nuts from underneath, being careful not to overtighten.

Additional Tips:

- Always use large fender washers to reinforce the installation and distribute the load more effectively.

- If you're drilling and tapping the backing plate to accept bolts, stainless steel is a good choice due to its strength. If using nuts and washers, aluminium is sufficient.

- The backing plate should be as large as possible while still fitting within the available space.

Boat Ramps in Connecticut: Are They Accessible?

You may want to see also

Frequently asked questions

Here are some general tips for wiring an aluminum boat tower:

- Plan the wiring and drilling before starting any work.

- Use a wire harness to connect accessories.

- Drill holes in the tower to feed the wires through, ensuring there is enough slack to accommodate any folding or pivoting joints.

- Use rubber grommets at the holes to prevent water from entering the tower's tubing or boat's hull.

- Consult a professional marine electrician if you are unsure about the wiring process.

Common accessories that are wired to an aluminum boat tower include:

- Speakers

- Lights

- Light and speaker combination bars

- Wakeboard tower lights

- Bilge pumps

- Fish finders

- Stereos

Some important safety considerations when wiring an aluminum boat tower include:

- Always connect the ground to the negative battery post, never to the boat body.

- Use the correct wire gauge to avoid overheating and fire hazards.

- Use circuit protection to prevent excessive current flow, which can lead to electrical fires.

- Ensure proper ventilation and avoid contact with water to mitigate the risk of electrical shocks and short circuits.