Welding cracks in an aluminium boat requires careful preparation and execution to ensure a successful repair. The process involves several steps, including cleaning the crack, identifying the type of boat construction (welded or riveted), and choosing the appropriate welding technique and filler material. It is essential to assess the extent of the damage, as cracks may extend further than initially visible. Proper cleaning and preparation of the crack area are crucial, and drilling small holes at each end of the crack is often recommended to prevent further propagation. The choice between welding and riveting depends on the construction of the boat, with welded boats being more suitable for welding repairs. When welding, it is important to use the correct filler material, such as 5356 filler for anodized aluminium and 4043 filler for non-anodized aluminium. Additionally, techniques like TIG welding and MIG welding are commonly used for aluminium boat repairs.

| Characteristics | Values |

|---|---|

| Welding technique | TIG |

| Filler | 5356 for anodized aluminium, 4043 for non-anodized aluminium |

| Crack detection method | Dye penetrant |

| Crack treatment | Drill holes at each end, V out the crack |

| Welding technique | MIG |

What You'll Learn

Welding an aluminium boat crack: when to do it and when to walk away

Welding an aluminium boat crack is a repair job that can be done, but it's important to know when to attempt it and when to walk away. Here are some things to consider:

When to Do It

If the crack is in a welded aluminium boat, then welding is an appropriate repair method. Drilling small holes at each end of the crack and using a skinny wheel to cut a groove along its length can help ensure a successful weld. It's also crucial to have sufficient welding experience, especially with thin-gauge aluminium, and to understand the variables involved in the welding process.

When to Walk Away

If you have no experience welding boats, it's best to walk away and leave the repair to a professional. Welding a crack in an aluminium boat requires specific knowledge and skills, and an inexperienced welder could cause further damage. For example, if the boat is riveted rather than welded, a patch may be riveted over the crack instead. Additionally, the crack may be a sign of more serious underlying issues, such as fatigue or impact damage, which a competent welder will be able to assess.

Before attempting any repair, it's essential to gather detailed information about the boat and the crack. This includes the location and cause of the crack, the thickness of the material to be welded, the age and condition of the boat, and whether it has been exposed to saltwater. Providing this information to a professional welder will enable them to recommend the best course of action.

In conclusion, while welding an aluminium boat crack is possible in some cases, it's important to recognise when the job is beyond your skill level and to seek professional assistance.

Paddle Boat Registration: Illinois Law Requirements

You may want to see also

How to prepare an aluminium boat crack for welding

Before attempting to weld a crack in an aluminium boat, it is important to assess whether you have the necessary skills and equipment to carry out the repair. If you are inexperienced, it is recommended that you seek the help of a professional welder. Welding aluminium can be challenging and requires knowledge of the various variables that can affect the welding process and the integrity of the repair.

If you decide to proceed with the repair, the first step is to clean the aluminium surface thoroughly. Pre-weld cleaning of aluminium requires two main operations: the removal of oil, grease, and water vapour, followed by the removal of surface oxides. Use an organic solvent such as acetone or a mild alkaline solution like strong soap to remove any oil, grease, or water vapour from the crack and the surrounding area. Rinse and dry the area before proceeding to the next step.

Next, use a stainless steel wire brush (dedicated solely for use on aluminium) to remove surface oxides from the crack and the surrounding area. Alternatively, you can use a strong alkaline or acid solution, or a commercial oxide-removal solution sold by welding suppliers. Again, be sure to rinse and dry the area after this step.

Once the crack and surrounding area are clean, you can begin preparing for the welding process. If the joint will not be welded immediately, cover it with brown Kraft paper to prevent dirt and grit from contaminating the joint. Keep the aluminium dry and at room temperature, and try to weld within a few days. If welding is delayed, clean the joint again before proceeding.

Finally, inspect the crack to determine if any additional steps are needed. For example, if the crack is due to impact damage, reinforcement may be required to prevent future cracking. Consult with an experienced welder or marine repair specialist to ensure that all necessary steps are taken to ensure a safe and effective repair.

Boat Trailer Titles in Georgia: What's the Deal?

You may want to see also

Welding techniques for repairing an aluminium boat crack

Before attempting to repair a crack in an aluminium boat, it is important to assess the extent of the damage and determine the appropriate repair method. If the boat is welded together, you can weld the crack. If it is riveted, it is recommended to rivet a patch over the crack.

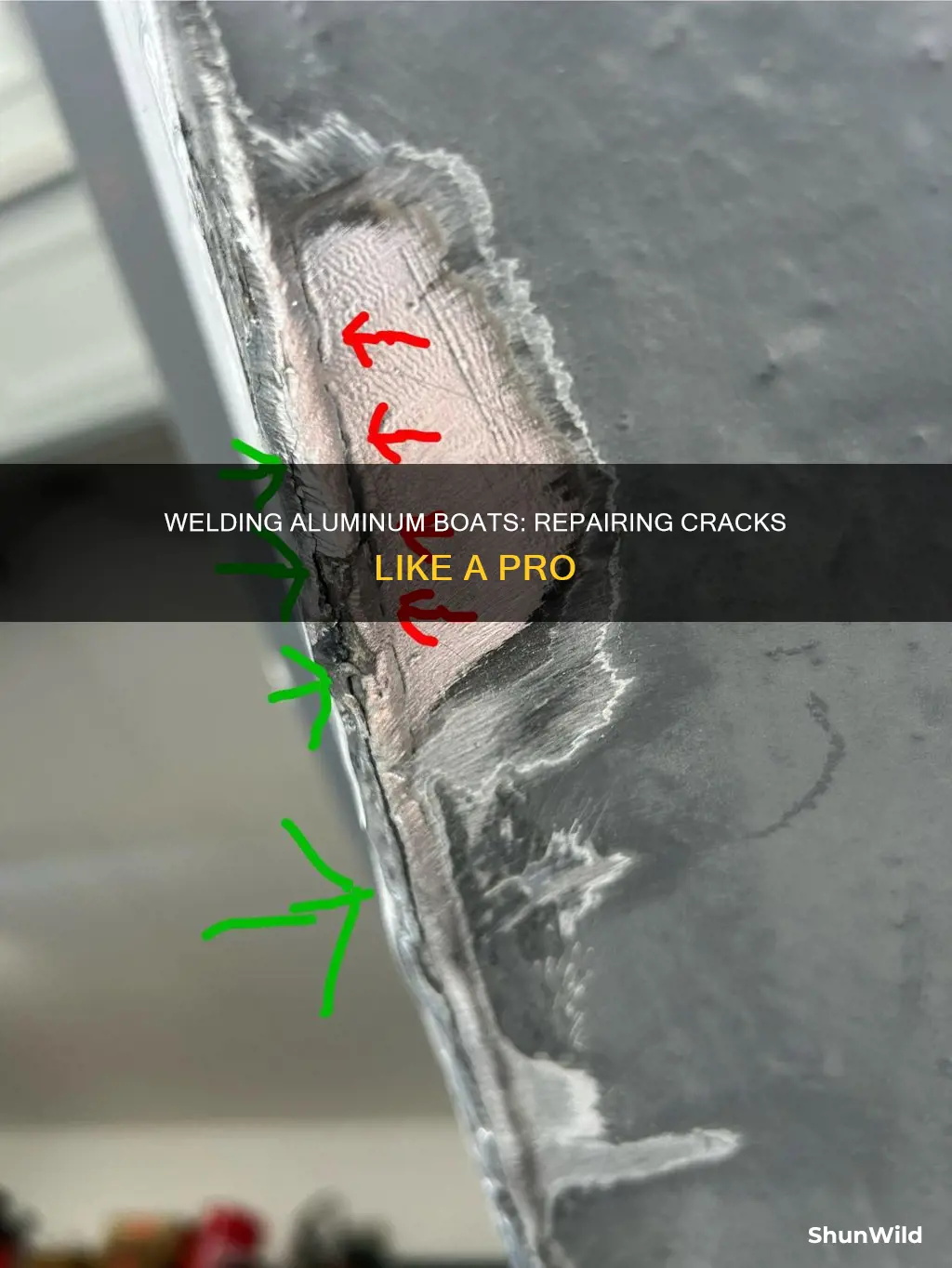

- Clean the area around the crack: Use a stainless steel brush to remove any oxide layer, and wipe the area with acetone to ensure it is free from contaminants.

- Drill small holes at each end of the crack: This helps to prevent the crack from spreading further.

- Cut a groove along the length of the crack: Use a skinny wheel or a carbide burr to create a V-shaped groove, which will provide a clean surface for welding.

- Choose the appropriate filler metal: For anodized aluminium, use 5356 filler. For non-anodized aluminium, use 4043 filler.

- Preheat the area: Preheating can help reduce the risk of cracking during welding. Use a torch or an oven to slowly heat the area around the crack.

- Weld the crack: Use a TIG welding technique with AC (alternating current) to take advantage of its cleaning action. Make sure to add filler material to the weld, as fusing alone may not be sufficient for aluminium.

- Post-weld cleaning: After welding, clean the area with a stainless steel brush and wipe it down with acetone to remove any residue or contaminants.

It is important to note that welding aluminium can be challenging due to its crack-prone nature. Ensure proper preparation and cleaning before and after welding to minimize the risk of cracks. Additionally, be cautious when welding near rivets, as excessive heat can affect the integrity of the riveted joints.

Succession's Yacht Owner: Unveiling the Mystery of 'Succession

You may want to see also

Repairing an aluminium boat crack without welding

Another method is to use marine epoxy, which is a rubbery substance that works for minor, temporary repairs. However, this is not a long-term solution as it is unreliable and will eventually need to be redone.

If you are looking for a more permanent solution without welding, you can also try a product like Gluvit or Flex Seal, which are coatings made specifically for boat repair and have been known to last for years without issues.

Additionally, if your boat is riveted, you can rivet a patch over the crack. You should drill a small hole at each end of the crack and use a skinny wheel to cut a groove along its length. Then, you can rivet a patch of aluminium over the crack, sealing it with a product like 5200.

Unpacking the Racist Origins of "Fresh Off the Boat

You may want to see also

How to prevent further cracking after repairing an aluminium boat crack

To prevent further cracking after repairing an aluminium boat crack, it is important to understand the underlying cause of the crack. If the crack is due to fatigue or impact damage, the repair method and materials used will be crucial to ensuring the boat's structural integrity. Here are some detailed instructions to prevent further cracking:

- Assess the Extent of the Damage: Before attempting any repairs, it is essential to thoroughly inspect the boat and identify all cracks and their potential causes. Look for signs of impact damage, corrosion, or metal fatigue. Take note of the location and orientation of the cracks, as this will influence the repair process.

- Prepare the Area: Use a grinder with a wire wheel attachment to clean the area around the crack thoroughly. Remove any paint, dirt, or debris to expose bare aluminium. This step is crucial, as a clean and prepared surface will ensure a strong weld or adhesive bond.

- Drill and Groove: At each end of the crack, drill a small hole. This step helps to prevent the crack from spreading further. Next, use a skinny wheel to cut a groove along the length of the crack. This groove will provide a guide for your weld and help ensure a straight and controlled repair.

- Welding Technique: When welding the crack, use a technique suitable for aluminium, such as TIG welding. Ensure that you are familiar with welding aluminium, as it requires specific skills and parameters different from welding steel. Avoid excessive heat input, as this can distort the metal and affect nearby rivets or seals.

- Reinforcement: Consider adding structural reinforcement to the repaired area. This could involve welding or riveting additional aluminium plates or sections to provide extra strength and prevent future cracking.

- Post-Weld Treatment: After welding, allow the repair to cool gradually and naturally. Avoid abrupt cooling, as this can cause stress cracks. Clean the weld and apply a suitable marine-grade sealant or paint to protect the repair from corrosion.

- Regular Maintenance: To prevent future cracking, maintain your aluminium boat properly. Regularly inspect for signs of damage or corrosion, especially in high-stress areas. Keep the boat clean and free from debris, and store it properly when not in use.

By following these detailed instructions and taking a thoughtful, methodical approach to repairing your aluminium boat crack, you can help prevent further cracking and ensure the safety and longevity of your vessel.

Spotting Rot in Aluminum Boats: What to Look For

You may want to see also