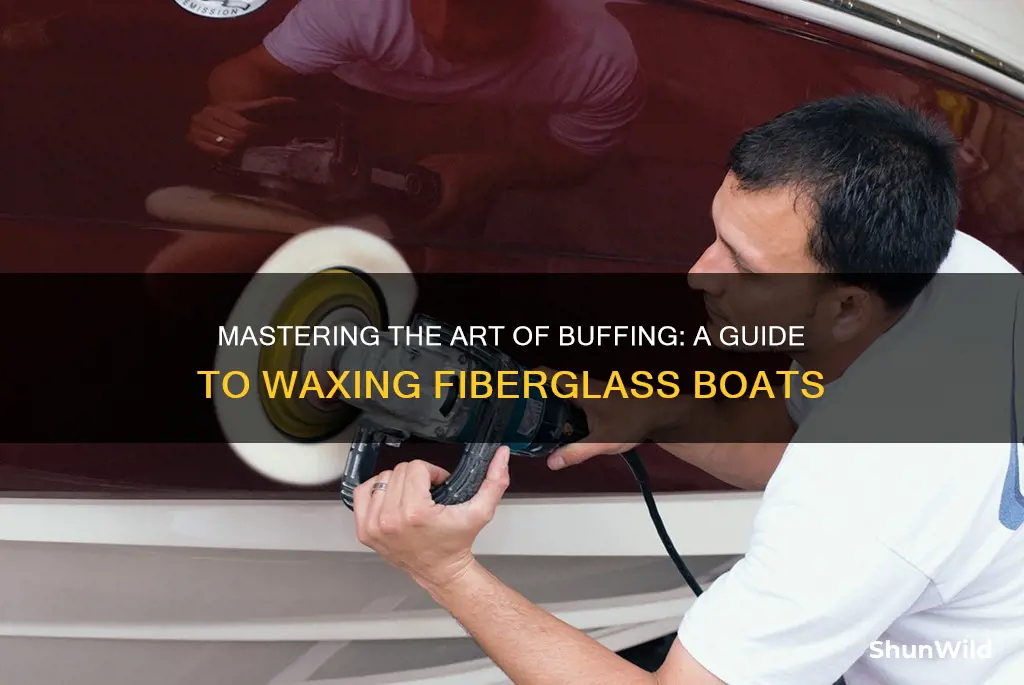

Waxing a fiberglass boat is an essential maintenance task that not only enhances the boat's appearance but also protects its surface from damage. Using a buffer can make the process more efficient and effective. This guide will provide a step-by-step tutorial on how to wax a fiberglass boat using a buffer, ensuring a smooth and glossy finish. It will cover the necessary tools and materials, the preparation process, and the application technique to achieve the best results.

| Characteristics | Values |

|---|---|

| Preparation | Clean the boat's surface thoroughly, removing dirt, grime, and old wax. Ensure the fiberglass is dry and free of any contaminants. |

| Wax Choice | Select a high-quality fiberglass boat wax specifically designed for marine use. Look for waxes that offer UV protection and long-lasting shine. |

| Buffer Selection | Use a soft, non-abrasive buffer pad suitable for fiberglass. A wool or foam buffer is ideal for this process. |

| Application Technique | Apply the wax in a thin, even layer using circular motions. Start at the bow and work your way back, ensuring complete coverage. Allow the wax to dry slightly before buffing. |

| Buffing Process | Buff the waxed area in a straight line using gentle, consistent pressure. This will create a smooth, glossy finish. Continue until the surface is free of any wax residue. |

| Drying Time | Allow sufficient time for the wax to dry and cure. This may vary depending on the wax product, but typically takes a few hours. |

| Reapplication | Reapply the wax every 3-4 months or as needed to maintain the shine and protect the fiberglass. |

| Safety Precautions | Wear gloves and protective eyewear during the process. Ensure proper ventilation in the workspace. |

| Maintenance | Regularly inspect the boat's surface for any signs of damage or wear, and address issues promptly to ensure the wax remains effective. |

What You'll Learn

- Prepare the Boat: Clean and inspect the fiberglass surface, ensuring no debris or contaminants interfere with the waxing process

- Choose the Right Wax: Select a high-quality, marine-grade wax suitable for fiberglass to ensure optimal protection and shine

- Buffing Technique: Use a buffer with a moderate speed and apply gentle, circular motions to evenly distribute the wax

- Remove Excess Wax: Buff the wax until it's completely removed, leaving a smooth, glossy finish without any residue

- Final Touches: Inspect the boat for any remaining wax and polish it to enhance the shine and protect the fiberglass

Prepare the Boat: Clean and inspect the fiberglass surface, ensuring no debris or contaminants interfere with the waxing process

To ensure a successful waxing process, the first step is to thoroughly prepare your fiberglass boat. Begin by giving the entire surface a good clean. This initial step is crucial as it removes any dirt, grime, or contaminants that could hinder the waxing process. Use a mild detergent mixed with water to gently clean the boat's exterior. Pay close attention to areas prone to dirt accumulation, such as the hull, deck, and any crevices or nooks. Rinse the boat thoroughly to eliminate any soap residue, ensuring the surface is completely dry before proceeding.

Once the cleaning is complete, a thorough inspection of the fiberglass surface is essential. Look for any signs of damage, such as scratches, chips, or cracks. These imperfections can affect the wax's ability to adhere and protect the surface. If you notice any damage, address it before applying the wax. Minor scratches can often be filled with a suitable fiberglass repair compound, following the manufacturer's instructions. Ensure the surface is smooth and level after any repairs to guarantee an even wax application.

Pay attention to the boat's nooks and crannies, as these areas can accumulate dirt and contaminants over time. Use a soft-bristled brush or a small cleaning tool to carefully remove any debris from these hard-to-reach places. This meticulous cleaning ensures that no foreign particles interfere with the waxing process, allowing the wax to bond effectively with the fiberglass.

After cleaning and inspecting, the boat's surface should be free of any contaminants, ensuring optimal conditions for waxing. This preparation step is vital as it sets the foundation for a smooth and effective waxing process, ultimately enhancing the boat's appearance and protection. Remember, a well-prepared surface will result in a longer-lasting wax job and a more aesthetically pleasing finish.

Boat Paddle Purpose: Steering and Propulsion Explained

You may want to see also

Choose the Right Wax: Select a high-quality, marine-grade wax suitable for fiberglass to ensure optimal protection and shine

When it comes to waxing your fiberglass boat, choosing the right wax is crucial for achieving a high-quality finish and ensuring the protection of your vessel. The market offers a wide range of wax options, but not all are created equal, especially when it comes to marine applications. Here's a guide to help you select the ideal wax for your fiberglass boat:

Marine-Grade Wax: Opt for a wax specifically designed for marine environments. These products are formulated to withstand the harsh conditions of saltwater, UV rays, and varying temperatures. Marine-grade waxes are typically more durable and provide long-lasting protection compared to general-purpose waxes. Look for brands that specialize in marine care, as they often have a deeper understanding of the unique challenges faced by boat owners.

Fiberglass Compatibility: Fiberglass is a delicate material that requires careful treatment. Ensure the wax you choose is specifically formulated for fiberglass surfaces. Some waxes may be too aggressive or contain harsh chemicals that can damage the finish. Check the product labels and opt for waxes that are known to be safe and effective for fiberglass boats. This will help maintain the integrity and appearance of your boat's surface.

High-Quality Ingredients: Invest in a wax with high-quality, premium ingredients. Look for products that contain natural or synthetic polymers, which provide excellent bonding and protective properties. These ingredients create a smooth, shiny finish and help fill in minor scratches and imperfections. Avoid waxes with harsh chemicals or those that may leave a residue, as they can negatively impact the boat's appearance and performance.

UV Protection: Marine environments expose boats to intense sunlight, which can cause fading and damage over time. Choose a wax with built-in UV protection to shield your fiberglass boat from the sun's harmful rays. UV-protective waxes help maintain the color and luster of your boat, ensuring it remains vibrant and attractive for years to come.

Application and Buffing: The chosen wax should be easy to apply and buff, ensuring a smooth and streak-free finish. Follow the manufacturer's instructions for the best results. Using a high-quality buffer will help you achieve a professional-looking shine and ensure the wax is evenly distributed. Proper application and buffing techniques will also ensure that the wax adheres well to the fiberglass surface, providing maximum protection.

By selecting a high-quality, marine-grade wax specifically formulated for fiberglass, you'll ensure that your boat receives the best possible care. This simple step will contribute to the longevity of your boat's finish, keeping it looking its best while providing essential protection against the elements. Remember, the right wax is a key component in maintaining and enhancing the beauty of your fiberglass boat.

Replacing Formula Boat Cabin Windows: A Step-by-Step Guide

You may want to see also

Buffing Technique: Use a buffer with a moderate speed and apply gentle, circular motions to evenly distribute the wax

When it comes to waxing a fiberglass boat, using a buffer is an excellent method to ensure a smooth and professional finish. The key to successful buffing is to maintain a steady hand and a moderate speed to avoid any unwanted scratches or imperfections. Here's a detailed guide on the buffing technique:

Start by ensuring your buffer is set to a moderate speed. This speed allows for controlled and precise movements without causing excessive heat or damage to the fiberglass surface. A buffer with a variable speed setting is ideal, as it gives you the flexibility to adjust the speed as needed. Before beginning, make sure the buffer is clean and free of any debris. A clean tool will prevent any unwanted residue or scratches during the process.

Now, it's time to apply the wax. Hold the buffer in your dominant hand and the wax in the other. Start with a small amount of wax to avoid overloading the surface. Dip the buffer's pad into the wax, ensuring it's evenly coated. Begin buffing in gentle, circular motions, covering the entire surface area of the boat you're working on. Keep the movements consistent and avoid any abrupt stops or starts, as this can lead to uneven wax distribution.

The goal is to create a smooth, glossy finish by evenly distributing the wax. Circular motions help in this regard, as they allow the wax to melt and blend seamlessly with the fiberglass. Take your time and be thorough, ensuring every inch of the boat's surface is treated. Remember, the wax should be applied in a thin, even layer, and you can always add more if needed.

As you buff, you'll notice the wax melting and creating a smooth, shiny appearance. This process might take a bit of practice, but with a steady hand and a moderate speed, you'll achieve excellent results. Keep the buffer moving across the surface, and if you encounter any stubborn spots, slightly increase the speed to remove any remaining imperfections.

In summary, the buffing technique is all about control and precision. By using a buffer at a moderate speed and applying gentle, circular motions, you can evenly distribute the wax, creating a beautiful and protective finish for your fiberglass boat. This method ensures a professional-looking result, making your boat shine and last longer.

Best Paint Options for Boat Windows

You may want to see also

Remove Excess Wax: Buff the wax until it's completely removed, leaving a smooth, glossy finish without any residue

To ensure a flawless finish when waxing a fiberglass boat, it's crucial to remove any excess wax thoroughly. This step is often overlooked, but it's essential to achieve a smooth, glossy surface without any residue. Here's a detailed guide on how to accomplish this:

Start by inspecting the waxed areas. Look for any visible residue or uneven patches where the wax might have built up. These areas will need extra attention. Use a clean, soft cloth or a specialized wax removal tool to gently rub the waxed surfaces. Work in small sections to avoid overwhelming yourself and to maintain control over the process. Apply light, circular motions, ensuring you cover the entire area. The goal is to melt and lift the excess wax from the surface without scratching the fiberglass.

As you work, you'll notice the wax softening and becoming easier to manipulate. Continue this process until you've removed as much wax as possible. You might find that some areas require more effort than others, especially around curves and contours. Take your time and be patient; rushing this step could lead to an uneven finish.

Once you've removed the excess wax, it's time to buff the surface. Grab a high-quality microfiber cloth or a dedicated buffing pad. These materials are ideal for this task as they provide a gentle yet effective clean. Apply a small amount of clean water to the cloth or pad, ensuring it's damp but not soaking wet. Then, gently buff the waxed areas in the same circular motions you used for removal. This step will help to smooth out the surface and create a beautiful, glossy appearance.

Continue buffing until you're satisfied with the result. The goal is to have a surface that is free of any wax residue, looking smooth and shiny. Remember, the key to success here is taking your time and being meticulous. A thorough buffing process will ensure your fiberglass boat maintains its pristine condition and appears as good as new.

Pulling Power: Can a Toyota Tacoma Handle a Bass Boat?

You may want to see also

Final Touches: Inspect the boat for any remaining wax and polish it to enhance the shine and protect the fiberglass

After completing the initial waxing process, it's crucial to inspect the boat thoroughly to ensure no excess wax remains on the fiberglass surface. This step is essential to avoid any potential issues that could arise from over-waxing, such as a sticky or tacky feel, which can be unsightly and uncomfortable.

Start by examining the entire boat, paying close attention to the areas where wax might accumulate more easily, such as the sides, bottom, and any curves or contours. Use a soft cloth or a clean, dry towel to gently wipe down the surface, removing any visible wax residue. Be thorough but gentle to maintain the integrity of the fiberglass.

Once you've removed any excess wax, it's time to polish the boat to enhance its shine and protect the fiberglass. Polishing will also help to remove any minor scratches or imperfections, further improving the boat's appearance. Use a high-quality marine polish suitable for fiberglass, ensuring it is specifically designed for this material to avoid any adverse effects.

Apply the polish generously to a clean cloth, ensuring it is damp but not overly so. Then, carefully rub the polish onto the boat's surface in a circular motion, covering all areas. Allow the polish to dry according to the manufacturer's instructions, which may vary depending on the product. This process will leave the boat with a stunning, deep shine while providing an additional layer of protection against the elements.

Finally, inspect the boat once more to ensure no wax or polish remains on the surface. This final inspection is key to achieving a professional-looking finish and ensuring the boat is ready for its next adventure on the water. With these final touches, your fiberglass boat will be protected, shiny, and ready to impress.

Living on a Boat: Getting Started and Setting Sail

You may want to see also

Frequently asked questions

For fiberglass boats, a high-quality carnauba-based wax is recommended. These waxes provide excellent protection and a deep, glossy finish. Look for waxes specifically designed for marine environments, as they are more resistant to UV rays and saltwater.

Start by thoroughly cleaning the boat's surface to remove any dirt, grime, or old wax residue. Use a mild detergent and a soft brush or sponge to ensure the surface is clean and free of contaminants. Rinse the boat well and allow it to dry completely before applying the wax.

Begin by applying a small amount of wax to a clean, soft cloth. Work in small sections, applying the wax evenly across the boat's surface. Allow the wax to sit for a few minutes to soften, then use a buffer with a moderate setting to spread the wax and remove any excess. Buff in circular motions until the wax is melted and the surface is shiny.

Regular waxing is essential to maintain the boat's appearance and protect the fiberglass. Aim to wax your boat every 2-3 months, or more frequently if you use it regularly or in saltwater conditions. After each waxing session, inspect the boat for any damage or repairs needed, as wax can temporarily hide minor imperfections.