Determining if a fiberglass boat has suffered from rot or damage can be a complex task, but it's crucial for ensuring safety and longevity. This guide will provide an in-depth look at the signs and methods to identify if a fiberglass boat is rotten, helping boat owners and enthusiasts make informed decisions about maintenance and repairs. By understanding the unique characteristics of fiberglass and the potential causes of rot, you can take proactive steps to preserve your boat's integrity and performance.

What You'll Learn

- Visual Inspection: Look for soft, discolored, or crumbling areas

- Moisture Detection: Use a moisture meter to identify wet spots

- Structural Weakness: Check for warped or damaged hull components

- Gelcoat Damage: Inspect for fading, chalking, or cracking gelcoat

- Core Integrity: Examine the core for signs of water absorption and decay

Visual Inspection: Look for soft, discolored, or crumbling areas

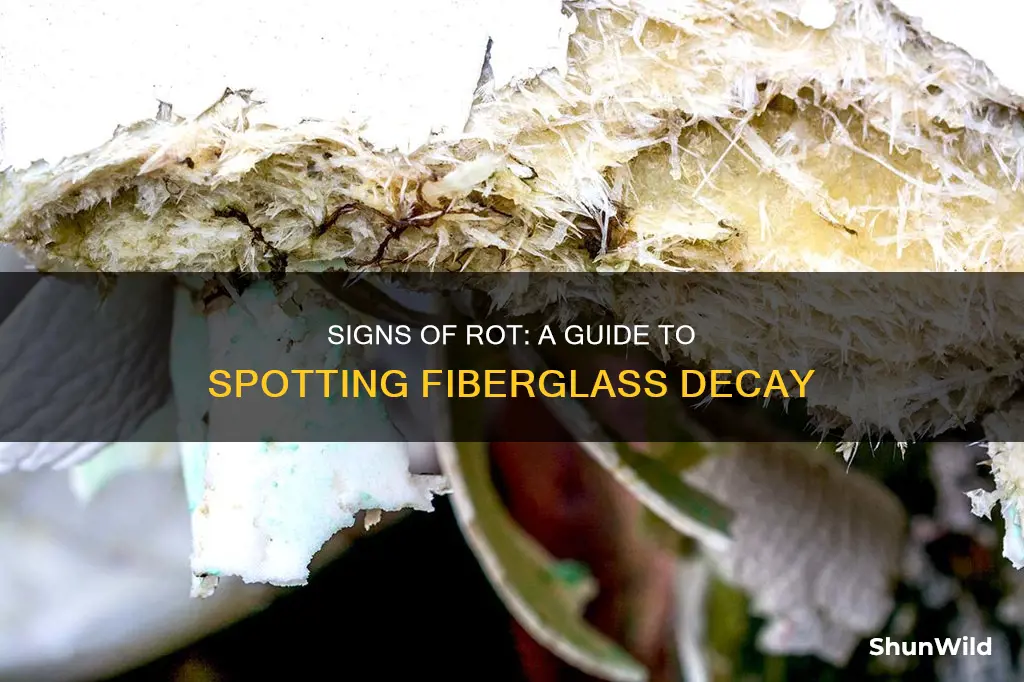

When inspecting a fiberglass boat for signs of rot, a thorough visual examination is crucial. Start by carefully scanning the entire structure for any areas that appear soft, discolored, or crumbly. These visual cues are often the first indicators of potential damage. Soft spots may feel squishy or spongy when pressed, and they can be a result of water absorption, leading to deterioration of the fiberglass. Discoloration, such as yellowing or darkening, is another warning sign, as it suggests that the fiberglass has been exposed to moisture for an extended period. Look for areas where the surface appears to be losing its glossy finish or has a dull, faded appearance.

Pay close attention to areas that are typically more susceptible to water intrusion, such as the hull bottom, stringers, and compartments. These areas are more prone to moisture accumulation and can be more susceptible to rot. Inspect the interior of the boat as well, including the cabin and any storage compartments. Check for any signs of water damage, such as peeling paint, warped surfaces, or a musty odor, which could indicate prolonged exposure to moisture.

Look for any visible mold or mildew growth, as this is a clear indication of moisture-related issues. Mold often appears as dark spots or a fuzzy texture on the surface. It is essential to identify and address these signs early on, as mold can spread rapidly and cause further damage. Additionally, check for any signs of corrosion, such as rust or oxidation, especially around metal fasteners or hardware.

Remember, the goal of this visual inspection is to identify any areas that might be hiding hidden damage. Soft, discolored, or crumbling spots are often the result of prolonged exposure to water and should be treated as potential indicators of rot. If you notice any of these signs, it is advisable to seek professional advice to assess the extent of the damage and determine the necessary repairs.

Repairing Ripped Boat Seats: A Step-by-Step Guide

You may want to see also

Moisture Detection: Use a moisture meter to identify wet spots

Moisture detection is a critical step in identifying potential rot in a fiberglass boat. Over time, water can seep into the boat's structure, leading to structural damage and compromising its integrity. One effective method to detect hidden moisture is by using a moisture meter, a tool specifically designed for this purpose.

A moisture meter works by measuring the electrical conductivity of materials. Water, being a good conductor of electricity, will register a higher reading on the meter compared to dry materials. When you scan the boat's surface with the meter, any areas with moisture content above a certain threshold will be indicated, suggesting potential water intrusion. This is particularly useful for fiberglass, as it can be challenging to visually inspect every inch of the boat's interior and exterior for signs of rot.

To use a moisture meter, follow these steps: Start by ensuring the boat is clean and dry. Remove any visible water or condensation from the surface. Then, gently press the moisture meter's probe against the fiberglass surface, applying light pressure. The meter will display a reading, with higher values indicating higher moisture content. Pay close attention to areas that are more susceptible to water damage, such as the hull, deck, and compartments.

Focus on areas where water could potentially accumulate, such as bilge areas, below deck compartments, and any areas with poor ventilation. These spots are prime candidates for moisture buildup and potential rot. If the meter registers high moisture levels in these areas, further investigation is warranted. You may need to remove panels or access points to inspect the underlying structure for signs of damage.

Remember, early detection of moisture is key to preventing extensive rot in your fiberglass boat. By utilizing a moisture meter, you can identify problem areas before they become major issues, ensuring the longevity and safety of your vessel. Regularly checking for moisture, especially after exposure to water or in areas prone to condensation, will help maintain the boat's structural integrity.

Kickstarting Your 2-Stroke: A Beginner's Guide to Boat Engines

You may want to see also

Structural Weakness: Check for warped or damaged hull components

When inspecting a fiberglass boat for signs of rot or structural damage, one of the most critical areas to examine is the hull. The hull is the primary structure that provides buoyancy and protection for the boat's interior. Over time, exposure to the elements, especially saltwater and UV radiation, can lead to various issues that may not be immediately visible.

To assess the hull for structural weaknesses, start by visually inspecting the surface for any visible signs of damage. Look for areas where the gelcoat (the outer layer of the fiberglass) may be cracked, chalky, or discolored. These signs often indicate that the underlying fiberglass has been compromised and may be rotten. Check for any soft spots or areas where the fiberglass feels spongy or gives way when pressed. These could be early indicators of rot.

Next, carefully examine the hull for any warping or distortion. Warped hulls can be a result of improper construction, age, or previous damage. Walk along the length of the boat, feeling for any uneven surfaces or areas where the hull curves abnormally. Warped hulls can affect the boat's stability and performance, and they may also lead to issues with the boat's trim and stability.

Pay close attention to the seams and joints where different hull components meet. These areas are susceptible to damage and rot due to the difficulty in accessing and maintaining them. Look for any signs of seepage or moisture accumulation around these joints. Moisture can lead to mold and rot, especially if the boat has been in contact with saltwater.

Additionally, inspect the hull for any signs of previous repairs. Over time, repairs can weaken the structural integrity of the hull, making it more prone to further damage. Look for visible signs of repair, such as patches or areas where the fiberglass appears thicker or uneven. These repairs may not be immediately noticeable, but they can significantly impact the boat's overall strength and longevity.

Remember, when checking for warped or damaged hull components, it's essential to be thorough and methodical. Take your time to inspect every inch of the hull, and don't rely solely on visual cues. Feel the surface, look for subtle changes, and trust your instincts. If you notice any suspicious areas, it's best to consult a marine specialist or a professional boat inspector to ensure a comprehensive assessment.

Finding Your Boat's MPG: A Comprehensive Guide

You may want to see also

Gelcoat Damage: Inspect for fading, chalking, or cracking gelcoat

When inspecting a fiberglass boat for signs of damage, one of the most critical areas to examine is the gelcoat. Gelcoat is a protective layer applied to the fiberglass during the manufacturing process, providing a smooth, durable surface that protects the underlying fiberglass from UV rays, chemicals, and other environmental factors. Over time, however, gelcoat can deteriorate, leading to various issues that may indicate the boat is in poor condition. Here's a detailed guide on how to inspect for gelcoat damage, specifically focusing on fading, chalking, and cracking.

Fading:

The first sign of gelcoat damage is often fading. Gelcoat can lose its color intensity over time due to prolonged exposure to sunlight. This fading is more noticeable in areas that receive direct sunlight, such as the deck, sides, and upper parts of the hull. To check for fading, look for areas where the color has become lighter or has a dull appearance compared to the rest of the boat. Faded gelcoat not only affects the aesthetics but can also indicate that the underlying fiberglass is more susceptible to damage from UV radiation.

Chalking:

Chalking is another common issue with gelcoat. It occurs when the gelcoat begins to break down, releasing small particles of calcium carbonate, which are then washed away by rain or splashed by waves. As a result, the gelcoat surface becomes rough and powdery, often leaving a white, chalky residue. This type of damage is particularly prevalent in areas where the boat is frequently exposed to saltwater, as the salt can accelerate the breakdown process. Inspect the gelcoat for any powdery or rough patches, especially around the waterline and in areas where the boat's structure is most exposed to the elements.

Cracking:

Cracks in the gelcoat are a serious concern and can indicate significant damage to the boat's structure. Gelcoat cracks can occur due to various factors, including age, poor installation, or impact damage. These cracks may be visible as fine lines or larger, more extensive breaks. Inspect the entire surface of the gelcoat, paying close attention to areas where stress is concentrated, such as near the waterline, along the gunwales, and at the corners of the boat. Cracks can allow water to penetrate the underlying fiberglass, leading to corrosion and further structural issues.

In addition to these visual inspections, it's essential to feel the gelcoat surface for any roughness or texture changes. Use your fingers to run along the gelcoat, as this can help you detect subtle changes that might not be immediately apparent to the naked eye. If you notice any of these issues, it's crucial to address them promptly. Fading and chalking can be treated with gelcoat repair kits, while more severe damage, such as cracking, may require professional repair to ensure the boat's structural integrity. Regular maintenance and inspections can help extend the life of your fiberglass boat and ensure it remains in optimal condition.

Bolting Boat Seats: The Aluminum Edition

You may want to see also

Core Integrity: Examine the core for signs of water absorption and decay

When assessing the core integrity of a fiberglass boat, it's crucial to inspect the core for any signs of water absorption and decay. The core is the central structure of the boat, often made of foam or balsa wood, and its condition directly impacts the boat's overall strength and longevity. Here's a detailed guide on how to examine the core for these issues:

Visual Inspection: Start by carefully examining the core structure. Look for any visible signs of disintegration, such as soft or spongy areas, which could indicate water absorption. Check for any discolored or stained areas, as these might suggest that the core has been compromised by water exposure. Pay close attention to the edges and seams of the core, as these areas are more susceptible to water intrusion.

Touch and Feel: Run your fingers or a tool across the core surface. If it feels soft, spongy, or gives way under pressure, it's a strong indicator of water damage. Healthy core material should be firm and resilient. Also, check for any unusual textures or rough patches, which might suggest the presence of mold or decay.

Moisture Detection: Use a moisture meter or a damp cloth to test for wetness. If the core feels damp or moist, it's a clear sign of water absorption. This is especially important in areas where the core is exposed to the elements, such as the hull's bottom or sides. Moisture in the core can lead to structural weakness and potential rot.

Structural Integrity Check: Assess the overall structural integrity of the boat. Does it feel stable and sturdy when you walk on it? Any noticeable sagging or bending in the core could indicate significant water damage and potential decay. This is a critical step in determining the boat's overall health and safety.

Professional Assessment: For a thorough evaluation, consider consulting a marine specialist or a boat inspector. They can provide expert advice and use specialized tools to detect hidden water damage. A professional inspection is invaluable, especially if you're considering a significant investment or an older boat with a complex history.

By carefully examining the core for water absorption and decay, you can make an informed decision about the boat's condition and its suitability for use. This process is essential in ensuring the safety and longevity of your fiberglass boat.

Bartlett Iowa Boat Ramp: Open for Business?

You may want to see also

Frequently asked questions

Inspect the boat's hull, deck, and any composite parts thoroughly. Look for visible signs of deterioration, such as soft or discolored areas, cracks, or delamination. Feel the surface for any areas that are spongy or give way under pressure. Keep an eye out for mold or mildew growth, as this can indicate underlying rot.

Yes, you can use a moisture meter to detect hidden moisture or dampness within the fiberglass structure. Insert the meter into the suspected areas, and if it reads above a certain threshold, it may indicate the presence of water damage or rot. Another method is to use a black light to reveal any hidden mold or discolored areas that might not be visible during the day.

In some cases, minor rot or damage can be repaired. Start by removing the affected area and replacing it with new fiberglass. Use a suitable epoxy resin and gelcoat to bond the repair. However, for extensive damage or if the rot has compromised the boat's structural integrity, replacement of the affected sections or even a complete rebuild might be necessary.

Proper maintenance and regular inspections are key. Keep the boat clean and dry, especially after exposure to water. Ensure that all hardware and fasteners are tight to prevent water intrusion. Regularly check for any signs of damage or wear, especially in areas prone to moisture, such as bilge areas and below deck compartments. Address any issues promptly to prevent further deterioration.