Surveying a fiberglass boat is a crucial step in ensuring its structural integrity and safety. This process involves a thorough inspection of the boat's hull, deck, and other components to identify any potential issues or damage. It's essential to follow a systematic approach, checking for signs of corrosion, delamination, and structural weaknesses. By carefully examining the boat's construction and materials, you can assess its overall condition and make informed decisions about necessary repairs or maintenance. Understanding the unique properties of fiberglass and its potential vulnerabilities is key to a comprehensive survey, ensuring the boat's longevity and safe operation.

What You'll Learn

- Pre-Survey Inspection: Check for damage, corrosion, and structural integrity

- Hull Condition: Inspect for cracks, blisters, and gelcoat degradation

- Engine and Systems: Test engines, electrical, and plumbing for functionality

- Safety Equipment: Verify life jackets, flares, and communication devices

- Documentation and History: Review paperwork and previous maintenance records

Pre-Survey Inspection: Check for damage, corrosion, and structural integrity

Before diving into a comprehensive survey of a fiberglass boat, it's crucial to conduct a thorough pre-inspection to identify any potential issues. This initial assessment is a critical step to ensure the accuracy and safety of the survey process. Here's a detailed guide on how to approach this stage:

Exterior Examination: Start by inspecting the boat's exterior, as it provides an initial indication of its overall condition. Look for any visible signs of damage, such as scratches, dents, or cracks. Pay close attention to the hull, especially around the waterline, as this area is susceptible to impact damage and wear. Check the gelcoat or paint for any fading, chalking, or signs of deterioration, which could indicate exposure to harsh weather or chemicals. Inspect the boat's trim and accessories, ensuring they are secure and in good condition. Look for any signs of corrosion, particularly around metal components like cleats, anchors, and hardware.

Interior Inspection: Step inside the boat and assess the interior compartments. Check for any signs of water damage, mold, or mildew, especially in enclosed areas like the head and galley. Inspect the floor for any soft spots or delamination, which could indicate structural issues. Examine the walls and ceiling for cracks, warping, or discolored stains, as these may suggest previous water ingress or structural problems. Look for any loose or damaged hardware, such as cabin lights, ventilation fans, or storage compartments.

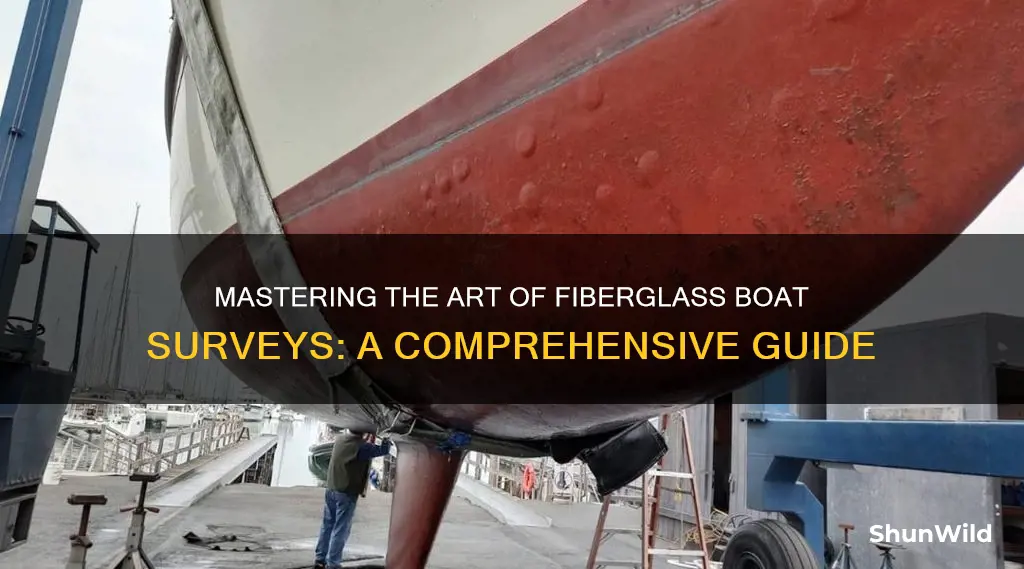

Structural Integrity Assessment: The structural integrity of a fiberglass boat is a critical aspect of the survey. Inspect the hull for any signs of delamination, which occurs when the fiberglass layers separate, often due to damage or poor bonding. Look for any visible separations or bubbles in the gelcoat, as these could indicate underlying structural issues. Check the boat's stringers, frames, and bulkheads for any signs of corrosion or damage, ensuring they are securely attached and in good condition. Assess the condition of the boat's core, as damage or degradation here can affect the overall structural integrity.

Corrosion and Maintenance: Fiberglass boats require regular maintenance to prevent corrosion. Inspect all metal components, including the engine mount, propeller shaft, and any metal fittings, for signs of rust or corrosion. Check the boat's electrical system for any signs of moisture or corrosion around terminals and connections. Ensure that all maintenance records are reviewed to understand the boat's maintenance history and identify any recurring issues.

During this pre-survey inspection, it's essential to document any defects or areas of concern. Take detailed notes and photographs to provide a comprehensive report, ensuring that potential buyers or owners are fully aware of the boat's condition. This initial assessment will also help in determining the scope and priority of repairs or maintenance required, making the subsequent survey process more efficient and effective.

Ratch's Boat: Unraveling the Mystery of Its Destination

You may want to see also

Hull Condition: Inspect for cracks, blisters, and gelcoat degradation

When inspecting the hull of a fiberglass boat, it's crucial to pay close attention to its condition, as this area is highly susceptible to various issues. Start by thoroughly examining the entire surface for any visible cracks. These can range from small, hairline fractures to larger, more extensive ones. Cracks may be surface-level or penetrate deep into the hull, and they can compromise the boat's structural integrity. Look for any signs of water seeping through these cracks, as this could indicate a more severe problem. Additionally, check for blisters, which are raised, bubble-like areas on the gelcoat surface. Blisters can be a result of water intrusion or poor resin systems and may lead to further degradation if left unattended.

The gelcoat, a protective layer applied to the fiberglass, is essential for maintaining the boat's appearance and structural stability. Inspect the gelcoat for any signs of degradation, such as chalking, fading, or a loss of its glossy finish. Over time, the gelcoat can become brittle and susceptible to damage, especially in areas exposed to sunlight and harsh weather conditions. Look for any discoloration or a change in texture, as these could indicate underlying issues.

To assess the severity of these issues, consider the following: small, isolated cracks or blisters might be repairable, but widespread damage or those affecting the boat's structural integrity should be addressed by a professional. Keep in mind that fiberglass is a composite material, and its strength relies on a uniform distribution of fibers and resins. Any deviations from this uniformity can lead to weaknesses in the hull.

During your inspection, take note of the boat's history and usage. Boats that have been exposed to harsh marine environments, frequent grounding, or collisions may have more significant hull issues. Additionally, consider the age of the boat; older fiberglass boats might require more frequent inspections and maintenance due to the natural aging process of the materials.

Remember, a thorough inspection of the hull is a critical step in the survey process, as it directly impacts the boat's safety, performance, and long-term value. If you notice any significant damage, it's advisable to consult a marine surveyor or a qualified professional for further assessment and guidance on necessary repairs.

Zinc Anodes: DIY Replacement for Moored Boats?

You may want to see also

Engine and Systems: Test engines, electrical, and plumbing for functionality

When inspecting the engine and systems of a fiberglass boat, it's crucial to ensure that all critical components are in good working order. Here's a step-by-step guide to testing the engines, electrical, and plumbing systems:

Engine Inspection:

- Start by examining the engine's overall condition. Check for any visible signs of damage, corrosion, or leaks around the engine compartment. Look for any signs of water intrusion, as this could lead to electrical issues or engine damage.

- Test the engine's starting system. Ensure that the engine starts easily and responds promptly to the starter motor. Listen for any unusual noises during the starting process, as this might indicate a problem with the starter or battery.

- Check the engine's performance by running it at various speeds. Observe for any unusual vibrations, noises, or smoke. A well-maintained engine should run smoothly and consistently.

- Inspect the engine's cooling system. Verify that the coolant is at the correct level and check for any leaks in the cooling system. Overheating can cause significant engine damage, so this is a critical aspect of the survey.

Electrical System Testing:

- Begin by checking the battery. Ensure it is securely mounted and free of corrosion. Test the battery's voltage and capacity to ensure it can power the boat's electrical systems adequately.

- Inspect all electrical connections for corrosion or loose connections. Corroded terminals can lead to poor conductivity and potential electrical failures.

- Test the functionality of all electrical switches, gauges, and instruments. Ensure they respond accurately and consistently. This includes checking the navigation lights, anchor windlass, and any electronic systems on board.

- Examine the wiring for any signs of damage or wear. Look for frayed or exposed wires, as these can cause short circuits or electrical malfunctions.

Plumbing and Water Systems:

- Inspect the engine's raw water intake and ensure it is properly sealed to prevent seawater intrusion. Check for any signs of damage or wear in the intake system.

- Test the functionality of the freshwater system. Run the taps and check the water pressure. Ensure that all plumbing connections are tight and secure.

- Examine the holding tanks for any signs of damage or leaks. Verify that the pumps and valves associated with these tanks are working correctly.

- Check the boat's bilge system and ensure it is operational. A well-functioning bilge system is essential for keeping the boat dry and preventing flooding.

During this survey, it's important to document any issues or concerns found. Take detailed notes and photographs to provide a comprehensive report on the boat's condition. This will assist in making informed decisions regarding any necessary repairs or maintenance.

Unleash the Speed: Barefoot Water Skiing's Swift Boat Adventure

You may want to see also

Safety Equipment: Verify life jackets, flares, and communication devices

When conducting a survey of a fiberglass boat, ensuring that the safety equipment is in good working order is of utmost importance. This includes verifying the condition of life jackets, flares, and communication devices. Here's a step-by-step guide on how to approach this aspect of the survey:

Life Jackets: Start by checking the life jackets or personal flotation devices (PFDs) to ensure they are in compliance with maritime safety regulations. Inspect each jacket for any signs of wear and tear, including rips, punctures, or significant fading of colors. Ensure that the jackets are properly inflated and that the inflation valves are functioning correctly. Test the jackets by submerging them in water to confirm their buoyancy and effectiveness. It is crucial to verify that the life jackets are the appropriate size for the intended users, as ill-fitting jackets may not provide adequate protection. Additionally, check the expiration dates on the jackets, as some may have a limited lifespan and should be replaced periodically.

Flares: The next critical item is flares, which are essential for signaling in emergency situations. Examine the flares to ensure they are not past their expiration date. Check for any physical damage, such as cracks or leaks, that could render them ineffective. Test the flares by following the manufacturer's instructions, typically involving a small burst of air or a chemical reaction to ensure they produce a visible signal. It is recommended to have a variety of flare types on board, including day and night flares, to cater to different emergency scenarios.

Communication Devices: Effective communication is vital during emergencies, so verifying the functionality of communication devices is essential. Check the boat's radio equipment, ensuring it is properly licensed and operational. Test the radio by attempting to establish contact with nearby vessels or coastal stations. Additionally, inspect any satellite phones or emergency beacons to confirm their battery levels and signal strength. It is crucial to have a backup communication method, such as a handheld radio or a satellite phone, in case the primary system fails.

During the survey, it is essential to document the findings and any necessary repairs or replacements required. Creating a comprehensive report of the safety equipment's condition will assist in ensuring the boat's compliance with safety regulations and provide a reference for future maintenance. Regularly updating and replacing safety equipment is vital to maintaining a safe boating environment.

Mystery of the Sunken Gold-Digging Boat, Christine Rose

You may want to see also

Documentation and History: Review paperwork and previous maintenance records

When conducting a survey of a fiberglass boat, one of the most crucial aspects is delving into the documentation and maintenance history. This process provides valuable insights into the boat's condition, its previous care, and any potential issues that may have been addressed. Here's a step-by-step guide on how to approach this task:

- Gather Maintenance Records: Start by collecting all available paperwork related to the boat's maintenance. This includes service manuals, owner's manuals, repair invoices, and any correspondence with previous owners or mechanics. Look for records of regular maintenance tasks such as engine tune-ups, oil changes, and system flushes. These records can provide a baseline for understanding the boat's overall maintenance history.

- Identify Major Repairs and Overhauls: Scrutinize the maintenance records for any significant repairs or overhauls. Pay close attention to the reasons behind these repairs, as they may indicate recurring issues or areas of weakness in the boat's design or construction. For example, frequent engine overhauls could suggest potential engine reliability problems, while multiple repairs to the electrical system might indicate wiring issues.

- Review Previous Surveys: If the boat has been surveyed before, obtain a copy of those survey reports. These reports often contain detailed observations and recommendations from previous surveyors. They can provide valuable context and help identify any recurring problems or areas of concern that have been addressed or ignored over time.

- Check for Compliance with Regulations: Ensure that the boat complies with all relevant safety and environmental regulations. This includes verifying the proper disposal of old or hazardous materials, such as batteries, paint, or fuel. Also, check for any modifications or alterations that may require additional documentation or permits.

- Document Current Condition: As you review the paperwork, take notes on the current condition of the boat. Make observations about the overall appearance, functionality, and performance of various systems. This documentation will serve as a reference for your survey findings and can help you identify areas that require further inspection or attention.

- Cross-Reference with Visual Inspections: While reviewing the paperwork, conduct a visual inspection of the boat to cross-reference the written information. Look for any signs of damage, corrosion, or wear and tear that may not be immediately apparent from the records. This combined approach will provide a comprehensive understanding of the boat's current state.

By thoroughly examining the documentation and maintenance history, you can gain a deeper understanding of the fiberglass boat's past, present, and potential future issues. This knowledge is invaluable for making informed decisions during the survey process and ensuring the boat's long-term reliability and safety.

Understanding the Mechanics: 3-Position Boat Switches Explained

You may want to see also

Frequently asked questions

Surveying a fiberglass boat is an essential process to assess its overall condition, structural integrity, and value. It involves a comprehensive inspection to identify any potential issues, damage, or wear and tear, ensuring the boat's safety and providing an accurate valuation.

The frequency of surveys depends on various factors, including the boat's age, usage, maintenance history, and the owner's preferences. As a general guideline, a boat should be surveyed annually or every few years to ensure it remains in good condition and to identify any emerging issues. Regular surveys are crucial for older boats or those with a history of problems.

During a survey, inspectors focus on several critical areas: structural integrity (including hull and deck), gelcoat and paint condition, interior fittings and upholstery, electrical systems, engine and propulsion, safety equipment, and navigation systems. Each component is examined for damage, corrosion, wear, and proper functionality.

While some basic inspections can be done by boat owners, a thorough survey is best handled by a qualified marine surveyor. These professionals have the expertise, knowledge, and tools to identify hidden issues and provide an accurate report. They are trained to recognize structural problems, corrosion, and other potential hazards that may not be apparent to an untrained eye.

A marine survey report will typically include a detailed description of the boat's condition, highlighting any defects, repairs needed, and potential risks. It will cover all inspected areas and provide recommendations for necessary maintenance or repairs. The report may also include a valuation of the boat's current market value, which can be useful for insurance purposes or when selling the vessel.