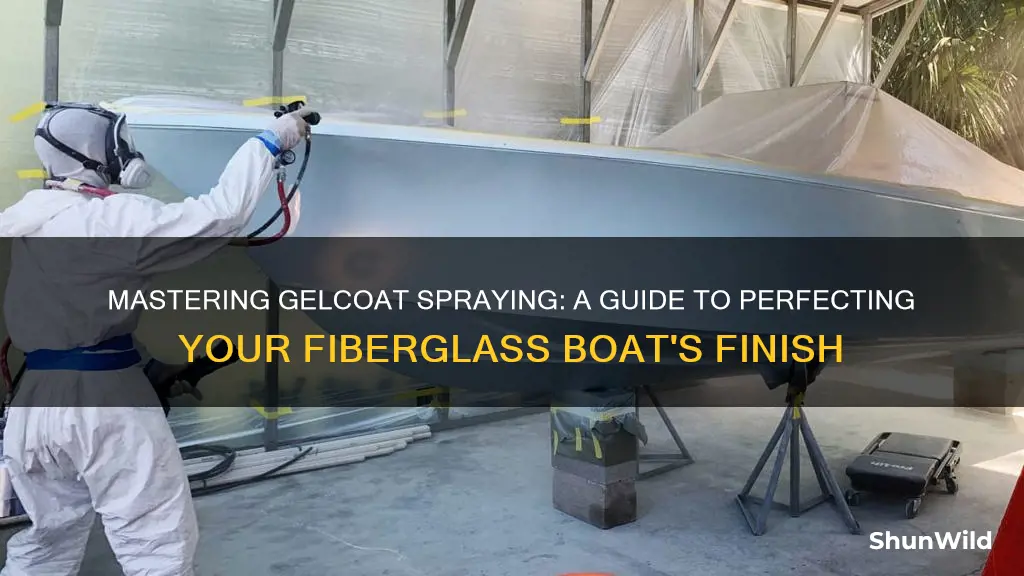

Spraying jelcoat onto a fiberglass boat is a crucial step in maintaining and restoring its appearance. This process involves applying a specialized paint or protective coating to the boat's surface, ensuring a smooth and durable finish. By following a few simple steps, you can achieve a professional-looking result, enhancing the boat's aesthetics and protecting it from the elements. This guide will provide a step-by-step approach to ensure a successful jelcoat application, covering preparation, equipment, and techniques for optimal results.

| Characteristics | Values |

|---|---|

| Preparation | Clean the boat's surface thoroughly, ensuring no dirt, grime, or old paint. Use a fiberglass cleaner and a scraper to remove any old gelcoat or paint. |

| Materials | Gelcoat: Choose a suitable jelcoat for your boat's color and finish. You can opt for a single-part or dual-part system, depending on the manufacturer's instructions. Primer: A fiberglass primer is essential to ensure proper adhesion. |

| Equipment | Spray gun: An airbrush or a high-pressure spray gun is ideal for an even finish. Masking tape and film: Use these to protect areas you don't want to paint. Stir sticks and mixing containers: For mixing the gelcoat and primer. |

| Application | Start by applying the primer, following the manufacturer's instructions for drying time. Once dry, lightly sand the surface to create a smooth base. Apply the gelcoat, using the spray gun to achieve an even coat. Work in small sections and overlap slightly for a seamless finish. |

| Drying and Finishing | Allow the gelcoat to dry according to the product's guidelines. You may need to apply multiple thin coats to achieve the desired thickness. After drying, sand the surface to remove any imperfections and create a smooth finish. |

| Safety and Ventilation | Wear protective gear, including gloves, goggles, and a respirator, as gelcoat can release fumes. Work in a well-ventilated area or outdoors. |

| Maintenance | Regularly clean and maintain the boat to preserve the jelcoat finish. Use marine-grade cleaners and avoid harsh chemicals that could damage the gelcoat. |

What You'll Learn

- Prepare the Surface: Clean and sand the boat's fiberglass for optimal adhesion

- Choose the Right Spray: Select a jelcoat spray that matches the boat's color

- Application Technique: Use a steady hand and a smooth, even spray pattern

- Thin the Coat: Mix the jelcoat with a thinner to achieve the desired consistency

- Multiple Coats: Apply multiple thin coats, allowing each to dry before adding the next

Prepare the Surface: Clean and sand the boat's fiberglass for optimal adhesion

Preparing the surface of a fiberglass boat for jelcoat application is a crucial step to ensure a successful and long-lasting finish. The process begins with thorough cleaning to remove any dirt, grime, or old paint that could interfere with adhesion. Start by washing the entire boat with a high-pressure washer or a powerful hose to eliminate loose debris and surface contaminants. Pay close attention to the nooks and crannies, as these areas can trap dirt and create a barrier for the new coating. For a more thorough clean, consider using a specialized fiberglass cleaner or a mild detergent mixed with water. This will help to break down any stubborn stains or old finishes.

Once the boat is clean, it's time to focus on the surface preparation. Sanding is an essential step to create a rough texture that will provide better grip for the jelcoat. Use a fine-grit sandpaper, starting with a lower grit (e.g., 120-150) to remove any remaining imperfections and smooth out the surface. Work in small sections, applying gentle pressure to avoid damaging the fiberglass. After sanding, wipe away the dust and any remaining debris with a clean cloth to ensure a smooth transition to the next step.

For an even more thorough preparation, consider using a power sander or a random orbit sander, especially for larger surfaces. This will help to create a consistent texture and ensure an even application of the jelcoat. Remember to work in a well-ventilated area and wear appropriate protective gear, including goggles and a dust mask, to avoid inhaling any dust or debris.

After sanding, inspect the surface to ensure it is free from any dust or residue. If necessary, use a tack cloth or a damp cloth to wipe down the area, removing any remaining particles. This step is vital to guarantee a smooth and clean surface for the jelcoat, allowing for optimal adhesion and a professional finish.

By following these steps, you'll create a solid foundation for the jelcoat, ensuring it adheres properly and provides a long-lasting, beautiful finish to your fiberglass boat. Proper surface preparation is key to the success of any painting or coating project.

How Coke Affects Boat Engine Performance and Lifespan

You may want to see also

Choose the Right Spray: Select a jelcoat spray that matches the boat's color

When it comes to restoring or repainting a fiberglass boat, choosing the right jelcoat spray is crucial for a successful and professional-looking finish. The color of the jelcoat, or the final layer of paint, is essential to ensure it matches the boat's existing color scheme. Here's a guide to help you select the appropriate jelcoat spray:

Identify the Boat's Color: Start by carefully examining the boat's current color. Look for any existing paint chips, small sections of the boat's surface, or even the manufacturer's color code. This is the most accurate way to determine the exact shade. If the boat has a faded or worn-out finish, you might need to consider a slightly darker or lighter shade to account for the natural aging process.

Research and Compare: Once you have the color information, search for jelcoat sprays that offer similar shades. Many manufacturers provide detailed color charts and guides on their websites. Compare the available colors to the boat's existing hue. It's important to choose a color that is as close as possible to the original to ensure a seamless and professional appearance.

Consider the Finish: Jelcoat sprays come in various finishes, such as flat, satin, or high-gloss. The finish you select should complement the boat's overall design and your personal preference. For a classic, traditional look, a flat or satin finish might be ideal. If you want a more modern and sleek appearance, a high-gloss finish can provide a shiny, reflective surface.

Test Before Applying: Before committing to a specific jelcoat spray, it's highly recommended to perform a small-scale test. Apply a few samples on a hidden area of the boat or a test panel to see how the color and finish look in real-world conditions. This will help you make an informed decision and ensure that the chosen spray matches the boat's color perfectly.

Remember, taking the time to select the right jelcoat spray will result in a high-quality finish that enhances the boat's appearance. It's an essential step in the process of restoring or repainting a fiberglass boat, ensuring a professional and long-lasting result.

The Unpopular Opinion: Boat Shoes Are Unappealing

You may want to see also

Application Technique: Use a steady hand and a smooth, even spray pattern

When applying jelcoat to a fiberglass boat, maintaining a steady hand and a consistent spray pattern is crucial for achieving a professional and smooth finish. This technique ensures that the paint is applied evenly, covering the entire surface without any visible brush strokes or uneven patches. Here's a detailed guide on how to master this application technique:

Start by ensuring you have the right equipment. A high-quality airbrush or a spray gun with a fine nozzle is ideal for jelcoat application. Practice with the equipment beforehand to get a feel for the spray pattern and control. Adjust the air pressure and nozzle size to achieve a fine mist, which will allow for better control and precision. A steady hand is essential, so consider using a support system like a spray gun rest or a tripod to stabilize your equipment.

Hold the spray gun or airbrush at a consistent distance from the surface of the boat. Too close, and you might create drips or uneven coverage; too far, and you'll lose control over the spray pattern. Aim for a distance that allows you to move the gun or airbrush smoothly across the surface, maintaining an even distance. Practice this technique on a test area to get a feel for the optimal distance and spray angle.

As you begin spraying, focus on creating a smooth, continuous motion. Start from one end of the surface and work your way to the other, maintaining an even speed. Avoid any sudden stops or starts, as this can create visible lines or uneven coverage. Keep the spray pattern consistent, moving the gun or airbrush in a gentle, sweeping motion. This technique ensures that the paint is applied in a uniform layer, resulting in a seamless finish.

To further enhance the application, consider using a technique called 'overlapping strokes'. This involves slightly overlapping the previous stroke with the next one, creating a seamless blend. Start by spraying a small section, then move the gun or airbrush slightly to the left, overlapping the previous stroke. Continue this process, ensuring that each stroke is slightly offset, resulting in a smooth, continuous coverage.

Remember, practice makes perfect. Take your time and be patient. Applying jelcoat to a fiberglass boat requires precision and a steady hand. With practice, you'll develop a sense of control and be able to create a beautiful, professional finish. Always work in a well-ventilated area and follow the manufacturer's instructions for the specific jelcoat product you are using.

Becoming a Duck Boat Captain: Requirements and Training

You may want to see also

Thin the Coat: Mix the jelcoat with a thinner to achieve the desired consistency

When preparing to apply jelcoat to a fiberglass boat, achieving the right consistency is crucial for a smooth and professional finish. The jelcoat, a specialized marine paint, needs to be thinned to ensure it flows and adheres properly to the surface. This process is particularly important when using a spray gun, as it requires a specific viscosity to ensure an even and flawless application.

Thinning the jelcoat is a simple yet essential step in the preparation process. It involves mixing a small amount of a suitable thinner with the jelcoat to adjust its consistency. The goal is to create a smooth, pourable liquid that can be easily sprayed onto the boat's surface. This step is often overlooked, but it significantly impacts the final result.

To begin, gather the necessary materials: the jelcoat, a high-quality thinner specifically designed for marine applications, and a mixing container. Ensure you have the correct ratio of jelcoat to thinner; this ratio can vary depending on the brand and the specific requirements of your project. A common starting point is a 1:1 ratio, but you may need to adjust this based on the consistency you aim to achieve.

Carefully measure the jelcoat and pour it into the mixing container. Then, add the thinner in a measured amount, following the recommended ratio. Stir the mixture thoroughly to ensure complete blending. The consistency should be similar to heavy paint or a thick syrup. If the mixture is too thick, add more thinner; if it's too runny, add more jelcoat. This process requires patience and precision to get the desired result.

Once the jelcoat is properly thinned, it's time to move on to the spraying process. Prepare your spray gun and ensure it is functioning correctly. Test the spray pattern and adjust the pressure to achieve a fine, even mist. Now, you're ready to apply the jelcoat to your fiberglass boat, ensuring a beautiful and durable finish. Remember, practice makes perfect, and you may need to make adjustments to the thinning process for different areas or textures on the boat's surface.

Getting Your Regal Boat Started: A Beginner's Guide

You may want to see also

Multiple Coats: Apply multiple thin coats, allowing each to dry before adding the next

When it comes to applying jelcoat to a fiberglass boat, a technique that often yields excellent results is the use of multiple thin coats. This method allows for a more even and professional finish, ensuring that the boat's surface is protected and aesthetically pleasing. Here's a step-by-step guide on how to achieve this:

Start by preparing your workspace. Ensure the boat's surface is clean and free of any debris. You might want to lightly sand the surface to create a slightly rough texture, which will provide better adhesion for the jelcoat. After preparation, it's time to begin the application process. Spray the jelcoat using a high-quality spray gun, ensuring an even and thin layer. The key here is to apply a very thin coat, allowing the solvent to evaporate quickly. This initial coat will serve as a base and will also help to prevent drips and runs.

Once the first coat is applied and has started to dry, typically within a few hours, it's time for the next step. Before adding the second coat, inspect the boat's surface. If there are any visible imperfections or areas that require additional coverage, touch them up with a small brush or a fine-tipped applicator. This ensures that the final finish is smooth and flawless.

When applying the subsequent coats, maintain a thin and even application. Thinner coats allow for better control and reduce the risk of drips and runs. Allow each coat to dry thoroughly before applying the next. This process might take a bit longer, but it's crucial for achieving a high-quality, professional-looking jelcoat finish. The multiple coats build up the protection and color, creating a robust barrier against the elements.

Remember, the goal is to create a smooth, seamless finish. Multiple thin coats help to avoid the issues that can arise from thicker applications, such as bubbling or peeling. By taking the time to apply each coat carefully and allowing for proper drying, you'll be well on your way to a beautiful and durable jelcoat finish on your fiberglass boat.

Luxury Boat Chase in Hitman's Bodyguard: A Cinematic Escape

You may want to see also

Frequently asked questions

The ideal time to apply jelcoat is during the early morning or late afternoon when the temperature is cooler, as this can help prevent the paint from drying too quickly, allowing for better control and a smoother finish.

Preparation is key to a successful paint job. Start by thoroughly cleaning the fiberglass surface to remove any dirt, grime, or old paint. Use a mild detergent and a soft brush to scrub the area, then rinse and allow it to dry completely. After that, lightly sand the surface with fine-grit sandpaper to create a smooth, even base for the jelcoat.

When spraying jelcoat, it's important to use a high-quality spray gun and a fine-mist setting. Start by applying a thin, even coat in one direction, using smooth, overlapping strokes. Maintain a consistent distance from the surface to ensure an even coverage. Allow each coat to dry according to the manufacturer's instructions before applying additional layers.

To minimize overspray, ensure your spray gun is in good working condition and adjust the pressure to a level that provides a controlled mist. Practice on a test area before starting the boat to get a feel for the spray pattern. Keep the gun at a consistent distance, and use masking tape or painter's tape to cover any areas you don't want to paint, such as trim or hardware.

If you encounter any imperfections, such as runs or drips, immediately wipe them away with a clean cloth before the jelcoat dries. For larger areas, you can carefully sand the affected area with fine-grit sandpaper and re-spray. Always work quickly and efficiently to ensure a professional-looking finish.