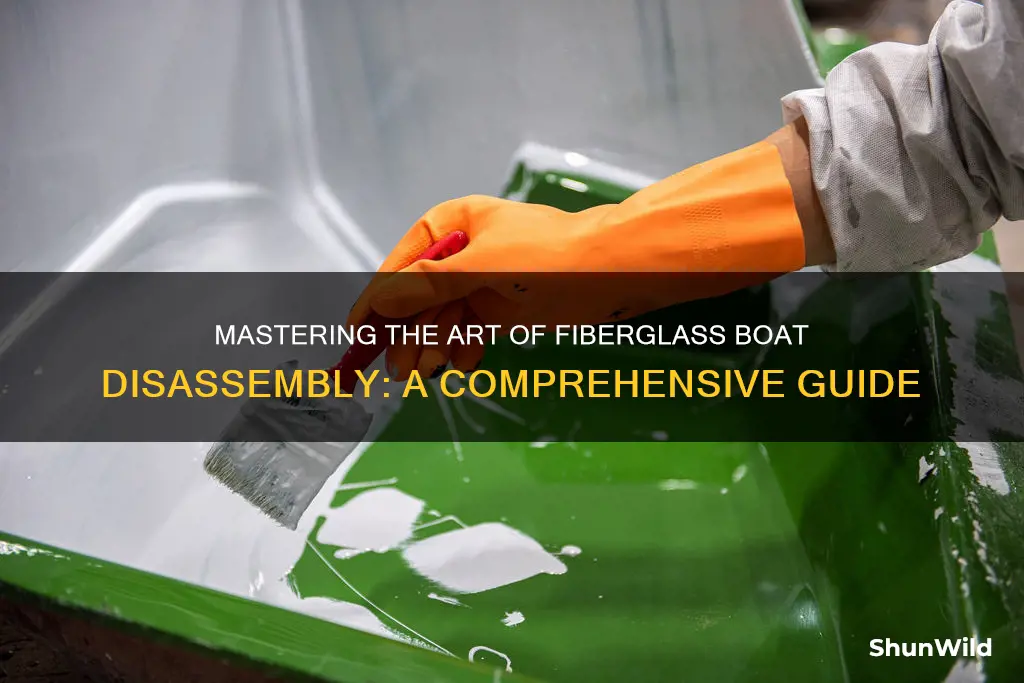

Separating a fiberglass boat requires careful planning and the right tools to ensure a successful and safe process. This guide will provide a step-by-step approach to help you effectively separate the various components of a fiberglass boat, whether you're performing maintenance, making repairs, or simply upgrading. By following these instructions, you can achieve a clean and precise separation, allowing for easier access to the boat's interior and exterior for further work.

What You'll Learn

- Safety Gear: Ensure you have protective gear like gloves, goggles, and a respirator

- Tools and Materials: Gather necessary tools: pry bars, screwdrivers, and fiberglass repair kit

- Disassembly Process: Carefully remove hardware and fasteners to separate hull and deck

- Fiberglass Repair: Use appropriate adhesives and resins for any damaged areas

- Final Steps: Sand and smooth surfaces, then reattach or replace components as needed

Safety Gear: Ensure you have protective gear like gloves, goggles, and a respirator

When embarking on the process of separating a fiberglass boat, prioritizing safety is paramount. This involves equipping yourself with the necessary protective gear to safeguard against potential hazards associated with fiberglass work. Here's a detailed guide on the essential safety gear you should have:

Gloves: Protecting your hands is crucial to avoid cuts, scrapes, and potential chemical exposure. Opt for heavy-duty gloves made from durable materials like leather or synthetic blends. Look for gloves with a snug fit to ensure dexterity while providing adequate protection. Consider gloves with reinforced fingertips for added durability when handling sharp tools or edges.

Goggles: Eye protection is vital to shield your eyes from potential fiberglass debris, dust, and splashes. Choose safety goggles that fit comfortably over your prescription glasses if you wear them. Ensure the goggles have a secure seal to prevent any particles from entering your eyes. Look for impact-resistant lenses to withstand the challenges of fiberglass work.

Respirator or Mask: Fiberglass work generates dust and fibers that can be inhaled, posing health risks. A respirator or dust mask is essential to filter out these hazardous particles. Select a respirator with a high-quality filter that can capture small particles effectively. Ensure it fits snugly over your nose and mouth, providing a secure seal to protect your respiratory system.

Additionally, consider wearing a full-body coverall or apron to protect your skin from chemical exposure and minor cuts. It's also advisable to work in a well-ventilated area or set up a fume hood to minimize the inhalation of harmful fibers. By investing in these safety gear items, you create a protective barrier, ensuring a safer and more controlled environment during the process of separating a fiberglass boat. Remember, safety should always be the top priority to prevent injuries and potential health issues.

Wiring Your Inboard Boat Engine: A Step-by-Step Guide

You may want to see also

Tools and Materials: Gather necessary tools: pry bars, screwdrivers, and fiberglass repair kit

When preparing to separate a fiberglass boat, it's crucial to have the right tools and materials on hand to ensure a smooth and safe process. Here's a detailed guide on the essential items you'll need:

Pry Bars: These are indispensable tools for any fiberglass boat separation project. You'll require a set of pry bars with various sizes and lengths to access tight spaces and leverage the boat's components. Look for pry bars made from durable materials like steel, ensuring they have a comfortable grip for extended use.

Screwdrivers: Different types of screwdrivers are essential for this task. Flat-head and Phillips-head screwdrivers are common choices. Ensure you have a variety of sizes to accommodate various screw heads that may be used in the boat's construction. This tool will help you remove screws and fasteners that hold different parts of the boat together.

Fiberglass Repair Kit: A specialized repair kit is vital for addressing any fiberglass damage that may occur during the separation process. This kit should include materials like fiberglass cloth, resin, hardener, and a fiberglass repair tape. These components will enable you to fill any gaps, cracks, or holes that appear while working on the boat's structure. It's essential to follow the manufacturer's instructions for mixing and applying the repair materials.

Additionally, consider gathering other general tools like a hammer, utility knife, and safety gear such as gloves and eye protection. These items will contribute to a safer and more efficient working environment. Having the right tools and materials ready will empower you to tackle the challenges of separating a fiberglass boat effectively and minimize potential damage.

Derby Boat Race: When Do the Boats Set Sail?

You may want to see also

Disassembly Process: Carefully remove hardware and fasteners to separate hull and deck

The disassembly process of a fiberglass boat requires a systematic approach to ensure a safe and efficient separation of the hull and deck. This step is crucial when preparing the boat for maintenance, repairs, or even a complete rebuild. Here's a detailed guide on how to carefully remove the hardware and fasteners:

Identifying the Fasteners: Begin by thoroughly inspecting the boat to locate all the fasteners that secure the hull and deck. Fiberglass boats often use a variety of fasteners, including screws, bolts, and specialized marine hardware. Pay close attention to the areas where the hull and deck meet, as these joints are critical and may require specific techniques. Look for any visible damage or corrosion around the fasteners, as this could impact their removal.

Removing Hardware: Start the disassembly by carefully removing the fasteners one by one. Use the appropriate tools for each type of fastener. For screws, a screwdriver is essential, ensuring you use the correct size and type to avoid damage. Bolts may require a socket or wrench, and specialized marine fasteners might need specific tools. Always work systematically, documenting the order in which fasteners are removed to ensure an easier reassembly process later. When removing screws, be cautious not to strip the threads, and for bolts, ensure you have the necessary torque to avoid damage.

Deck Separation: When separating the deck, be mindful of the weight and potential shift of the boat. Carefully lift and support the deck at various points to prevent it from sagging or putting pressure on the hull. This step may require multiple people to ensure safety and control. Once the deck is supported, proceed with removing the fasteners along the joint, being cautious not to damage the fiberglass surface.

Hull and Deck Separation: After the fasteners are removed, gently but firmly separate the hull and deck. Fiberglass can be delicate, so use a soft-bristled brush or a plastic scraper to carefully pry the two components apart. Work along the joint, ensuring you don't apply excessive force that could lead to cracking or damage. Take your time and be patient, as this process may require multiple passes to ensure a clean separation.

Remember, the key to a successful disassembly is patience and attention to detail. Properly removing the hardware and fasteners will make the separation process smoother and reduce the risk of damage to the boat's structure.

The Transformation of Ranger Boat Company: A New Era

You may want to see also

Fiberglass Repair: Use appropriate adhesives and resins for any damaged areas

When it comes to repairing fiberglass boat damage, using the right adhesives and resins is crucial for a successful and long-lasting fix. Fiberglass is a composite material that relies on strong chemical bonds between its fibers and the resin matrix. Therefore, any repair should aim to recreate these bonds as closely as possible. Here's a guide on how to approach this task:

Assess the Damage: Before proceeding, thoroughly inspect the damaged area. Determine the extent of the damage, including any cracks, holes, or delaminations. Understanding the nature of the damage will help you choose the appropriate repair method and materials. For instance, a small crack might be suitable for a simple bonding repair, while a large hole might require a more complex process like patchwork.

Prepare the Surface: Proper surface preparation is essential for a strong bond. Clean the damaged area to remove any dirt, grime, or old adhesive residue. You can use a mild detergent or a specialized cleaner designed for fiberglass. Rinse the area thoroughly and allow it to dry completely. If the damage is extensive, you might need to sand the surface gently to create a rough texture that will provide better adhesion.

Choose the Right Adhesive: Adhesives play a critical role in fiberglass repair. There are various types available, each with its own strengths and applications. For structural repairs, a two-part epoxy adhesive is often recommended. These adhesives cure to form a strong, durable bond. Ensure you follow the manufacturer's instructions for mixing and application. For smaller, less critical repairs, a structural adhesive or a specialized fiberglass repair kit might be sufficient. These kits typically include a resin and a hardener that, when mixed, create a strong, flexible bond.

Apply the Resin: Resins are a key component in fiberglass repair, providing the matrix for the composite material. Choose a resin that is compatible with the type of fiberglass used in your boat. Epoxy resins are commonly used for their strength and versatility. When applying the resin, ensure you follow the manufacturer's guidelines for mixing ratios and application techniques. Use a brush or a specialized applicator to spread the resin evenly over the prepared surface. Allow it to set according to the resin's curing time.

Reinforce and Finish: To ensure the repair's strength, consider reinforcing it with additional fiberglass cloth or tape. This adds structural integrity to the repair area. After the resin has cured, carefully blend the repair into the surrounding fiberglass using a putty knife or a specialized tool. Sand the area smooth and ensure it matches the boat's surface texture. Finally, apply a suitable fiberglass paint or gelcoat to restore the original appearance and provide further protection.

Remember, fiberglass repair requires precision and attention to detail. Take your time, follow the manufacturer's instructions, and consider seeking guidance from experienced professionals if needed. Properly executed repairs will ensure the longevity and structural integrity of your fiberglass boat.

Animals on a Boat: A Guide to Safe Transport

You may want to see also

Final Steps: Sand and smooth surfaces, then reattach or replace components as needed

After you've carefully removed the bonding agents and prepared the surfaces, it's time to focus on the final steps to ensure a smooth and successful separation of your fiberglass boat. This phase requires precision and attention to detail to avoid any damage to the boat's structure.

Sand and Smooth Surfaces: Begin by sanding the surfaces that were previously bonded. Use a fine-grit sandpaper to ensure a smooth finish. Start with light strokes, gradually increasing the pressure to remove any remaining bonding agent residue. Pay close attention to the edges and corners, as these areas might require more effort to ensure a seamless separation. Remember, the goal is to create a clean, even surface that is free from any debris or rough textures.

As you sand, take regular breaks to inspect the progress. Look for any areas where the fiberglass has become thin or fragile, as these spots may require additional care. You can use a putty knife to gently lift and separate the bonded areas, ensuring that the surfaces are properly aligned. This process might take some time, especially for larger boat sections, but it is crucial for a successful repair or modification.

Prepare for Reattachment or Replacement: Once the surfaces are smooth and ready, it's time to consider the next steps. If you plan to reattach the separated components, ensure that all surfaces are clean and free from any debris. You might want to apply a small amount of bonding agent to the surfaces, following the manufacturer's instructions, to create a strong bond. Alternatively, if replacement is necessary, have the new components ready and ensure they fit perfectly before proceeding.

In some cases, you may need to fill any gaps or imperfections with a suitable fiberglass repair compound. This step is essential to create a seamless transition between the old and new surfaces. After filling, allow the compound to cure according to the product's guidelines, then sand it again to achieve a smooth finish. This meticulous process will ensure that your boat is restored to its original condition or prepared for new modifications.

Protecting Boat Seats: Best Products for Longevity

You may want to see also

Frequently asked questions

Separating a fiberglass boat requires careful planning and the right tools to avoid damage. Start by identifying the specific areas or components you need to access, such as the hull, deck, or engine. Gather the necessary tools, including a utility knife or a specialized fiberglass cutter, a heat gun or hairdryer for softening the resin, and protective gear like gloves and safety goggles. Begin by carefully cutting along the seams or areas where separation is needed, using a steady hand and a sharp blade. Apply heat to the resin to make it more pliable, but be cautious not to overheat or burn the fiberglass. Once the resin is softened, gently pry the separated sections apart, working your way along the cut lines. Take your time and be patient to avoid causing any damage.

To minimize the risk of damage, it's essential to work carefully and follow these tips. Always wear protective gear to safeguard your skin and eyes from potential hazards. Keep the cutting tools sharp to ensure clean cuts and avoid chipping the fiberglass. When applying heat, use a controlled source like a heat gun and maintain a safe distance to prevent overheating. Work in a well-ventilated area or outdoors to avoid inhaling any fumes. Take frequent breaks to assess your progress and ensure you're not causing unintended damage. If you encounter stubborn areas, consider using a specialized fiberglass separator or a gentle prying tool designed for this purpose.

Yes, there are techniques to minimize damage during the separation process. For delicate areas, such as around the cabin or console, use a thin, sharp blade and carefully cut along the edges, being mindful of the surrounding structures. When dealing with bonded surfaces, apply heat to the resin and use a gentle prying motion to separate the components. Avoid forcing tools into tight spaces to prevent damage to the boat's structure. Consider using a water jet or a specialized tool designed for fiberglass separation, as these can provide precise and controlled cuts without causing harm. Always test your tools and techniques on a small, hidden area first to ensure they are effective and safe for the specific boat model.