There are various ways to seal an aluminium boat, including using bedliner products such as Rhino Liner or Line-X. However, opinions vary on the effectiveness of these products. Some people claim that they work great and add durability to the hull, while others argue that they can cause more friction between the hull and the water, slowing the boat down. Additionally, there may be issues with adhesion and water intrusion, which can lead to corrosion. Some alternative products suggested include Gluvit, Steelflex, Tuff Coat, Herculiner, and Durabak.

What You'll Learn

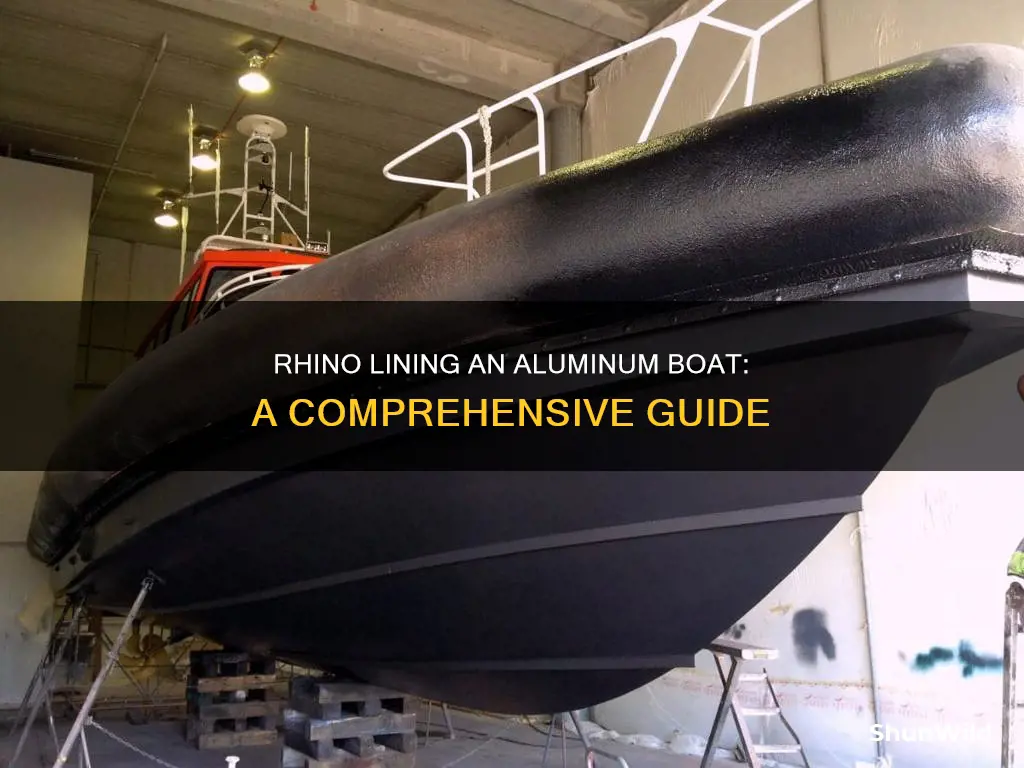

Pros and cons of using Rhino liner on the outside of an aluminium boat

Rhino liner can be a good option for sealing the exterior of an aluminium boat and adding durability to the hull. It can help seal leaks and protect the boat from water intrusion and corrosion. However, there are also some potential drawbacks to consider. Here are some pros and cons to help you decide whether or not to use Rhino liner on your aluminium boat.

Pros of Using Rhino Liner on an Aluminium Boat:

- Leak protection: Rhino liner can seal the exterior of an aluminium boat, preventing leaks and water intrusion.

- Durability: It adds a layer of protection to the hull, making it more durable and resistant to damage.

- Ease of application: Rhino liner can be applied directly to the exterior of the boat, without the need to remove everything from the inside.

Cons of Using Rhino Liner on an Aluminium Boat:

- Weight: Rhino liner is a heavy material, which can add significant weight to a small aluminium boat. This can affect the boat's performance and handling, especially in shallow waters or when navigating through brush to reach fishing spots.

- Drag: The application of Rhino liner to the bottom of a boat can increase drag, impacting the boat's speed and manoeuvrability.

- Adhesion issues: While Rhino liner can adhere well to itself, it may not always bond properly to the aluminium substrate. This can leave pockets between the liner and the boat, allowing for corrosion to start and making removal difficult.

- Heat absorption: Rhino liner can absorb and retain heat, making the boat's surface hot during the summer months. This can be uncomfortable for passengers and may affect certain equipment.

- Cost: The cost of applying Rhino liner can be high, especially for older boats, and there is no guarantee that it will work as intended.

- Warranty issues: Some boat manufacturers have reported warranty problems and separation issues with Rhino liner applied to decking surfaces.

- Alternative options: There are alternative sealing products available, such as Gluvit, which is designed for sealing seams and rivets in aluminium boats. It is also thinner and less expensive than Rhino liner.

Overall, while Rhino liner can provide some benefits for aluminium boats, it is important to carefully consider the potential drawbacks before making a decision. It is recommended to consult with boat maintenance experts or professionals who have experience with various sealing products to determine the best option for your specific boat and usage needs.

The Mystery of Destination's Ownership Unveiled

You may want to see also

How to prepare the aluminium surface for Rhino lining

To prepare the aluminium surface for Rhino lining, you must first clean the surface with a scotch-brite pad or scotch-brite surface conditioner. This will help to scuff and roughen the surface, creating a tooth for the Rhino lining to adhere to. You can also use a DA (disc sander) with medium grit sandpaper to achieve a similar effect. After scuffing, it is important to clean the surface with a degreaser or paint thinner to remove any remaining dirt, grease or oil. Some people recommend using acetone for this step.

Once the surface is clean and dry, you may want to apply a self-etching primer, such as Rust-Oleum, to further improve adhesion. This is especially important if you are Rhino lining an aluminium boat, as the surface will be in constant contact with water. Allow the primer to dry completely before proceeding.

Now, the aluminium surface is ready for the Rhino lining to be applied. You can either roll or spray on the Rhino lining, following the manufacturer's instructions. It is important to ensure that you have adequately masked off any areas that you do not want to be coated and that you are working in a well-ventilated area.

Boat Shoes and Blazers: Congress' Style Guide

You may want to see also

How to apply Rhino lining to an aluminium boat

Applying a spray-on coating like Rhino Liner to your aluminium boat can help seal it from leaks, add durability, and give it a fresh look. Here's a step-by-step guide on how to apply Rhino Liner to your aluminium boat:

Step 1: Surface Preparation

Before applying Rhino Liner, it's essential to prepare the surface of your aluminium boat thoroughly. Start by cleaning the surface with a suitable marine cleaner or degreaser to remove any dirt, grease, or contaminants. Ensure the surface is completely dry before proceeding to the next step.

Step 2: Sanding

Lightly sand the aluminium surface to create a rough profile that will enhance the adhesion of the Rhino Liner. Use a fine-grit sandpaper or sanding disc and sand in the direction of the metal grain. Wipe away any dust with a tack cloth or a damp cloth after sanding.

Step 3: Masking

Use masking tape and paper to cover any areas that you don't want to coat with Rhino Liner, such as windows, hardware, or other components. Make sure to mask off these areas carefully to avoid overspray.

Step 4: Priming (Optional)

Although not always necessary, applying a suitable primer can help improve adhesion and corrosion resistance. Choose a primer specifically designed for use with Rhino Liner and aluminium surfaces. Follow the manufacturer's instructions for application and drying time.

Step 5: Mixing and Application

Mix the Rhino Liner components according to the manufacturer's instructions. Typically, you'll need to mix a resin and a hardener together thoroughly. Once mixed, load the mixture into a suitable spray gun or roller applicator. Start applying the Rhino Liner to the boat, working in small sections and maintaining a consistent thickness.

Step 6: Texturizing (Optional)

If you desire a textured finish, you can texturize the Rhino Liner by lightly sprinkling a texturizing agent or sand onto the wet coating. This step is optional and depends on your preferred finish.

Step 7: Curing and Inspection

Allow the Rhino Liner to cure according to the manufacturer's instructions. This may take several hours or even a day, depending on the product and environmental conditions. Once cured, carefully inspect the coating for any imperfections, bubbles, or thin spots.

Step 8: Second Coat (If Needed)

If you notice any thin spots or areas that need improvement, apply a second coat of Rhino Liner following the same application process. Ensure proper curing between coats.

Step 9: Final Inspection and Touch-Ups

After the final coat has cured, inspect the Rhino Liner coating for any final touch-ups or imperfections. If necessary, use a small roller or brush to address any thin spots or imperfections.

Step 10: Reassembly and Launch

Once you're satisfied with the Rhino Liner application, carefully remove the masking and reassemble any hardware or components you removed earlier. Follow the manufacturer's recommendations for the minimum curing time before launching your boat.

By following these steps and allowing adequate curing time, you can successfully apply Rhino Liner to your aluminium boat, enhancing its protection and giving it a refreshed appearance.

Exploring the 1000 Islands: Boat Trip Essentials

You may want to see also

Other products similar to Rhino lining

While Rhino Linings is a popular option for boat protection, there are several other products on the market that serve similar purposes. Here are some alternatives to Rhino Linings for aluminium boats:

Gluvit

A popular alternative to Rhino Linings is Gluvit, an epoxy coating designed to seal the exterior of aluminium boats. It can be applied to the interior and exterior of boats, helping to seal seams and rivets. While it does not have built-in UV protection, you can paint over Gluvit to protect it from sunlight exposure.

Marine Tex Putty

Another option for sealing boats is Marine Tex Putty. This product can be used in conjunction with Gluvit, providing a durable and watertight seal. However, caution should be exercised when using Marine Tex Putty, as it should not be applied in areas with a lot of flex.

Steelflex

Steelflex is a 2-part epoxy coating specifically designed to seal the exterior of aluminium boats. It is a similar product to Gluvit and can provide a strong and durable finish.

Vinyl

Vinyl is a good alternative for those looking for a non-slip and easy-to-clean option. It is durable, looks good, and is comfortable underfoot. Vinyl can be a great choice for boat floors, providing traction and a comfortable surface.

Epoxy Paint with Grit

For those looking for a DIY option, mixing epoxy paint with grit can create a non-slip and durable finish. However, this option may be more suitable for warmer temperatures, as epoxy paint typically requires a certain temperature range for proper application.

These are just a few of the many alternatives to Rhino Linings for boat protection. Each product has its own unique features and benefits, so it's important to choose the one that best suits your specific needs and preferences.

Replacing a Boat Starter: A Step-by-Step Guide for Beginners

You may want to see also

Pros and cons of using Rhino lining on the inside of an aluminium boat

Rhino lining is a popular option for aluminium boats, especially for sealing leaking boats. However, there are pros and cons to using it on the inside of an aluminium boat that should be considered before making a decision.

Pros of Using Rhino Lining on the Inside of an Aluminium Boat:

- Rhino lining can add a layer of protection to the inside of an aluminium boat, potentially sealing leaks and adding durability.

- It can be applied directly to the aluminium surface without the need to remove everything from the inside of the boat.

- It has skid-resistant properties, which can be beneficial for safety.

- It can be tinted to any colour, allowing for customisation.

- It can be applied by professionals or as a DIY project, depending on your preference and budget.

Cons of Using Rhino Lining on the Inside of an Aluminium Boat:

- One of the main concerns with rhino lining on aluminium boats is the potential for adhesion issues. It may not always adhere well to the aluminium substrate, leaving pockets between the compound and the aluminium, which can lead to corrosion.

- Removal of rhino lining can be challenging and time-consuming if you ever need to reverse the decision or make repairs.

- Rhino lining can be heavy, potentially affecting the performance and speed of the boat.

- It can be slippery when wet, which may be a safety concern.

- The lining can be hot during the summer and cold during the winter, impacting comfort.

- There is a risk of the lining cracking, which can lead to water intrusion between the lining and the boat.

- The cost of professional rhino lining can be high, and there may be no guarantee of long-term performance.

Overall, while rhino lining can provide some benefits for aluminium boats, it is important to carefully consider the potential drawbacks before making a decision. It may be wise to consult with boat restoration experts or professionals who have experience with rhino lining to ensure you make an informed choice.

Best Paint Options for Trailered Boats: A Comprehensive Guide

You may want to see also

Frequently asked questions

It is not recommended to use Rhino liner on the bottom of your boat. It can cause more friction between the hull and the water, resulting in slower speeds. Instead, consider using Steel Flex to protect the bottom of your boat.

Some alternatives to Rhino liner for the inside of your boat include Herculiner, Line-X, Safe Floor, Tuff Coat, and vinyl.

Rhino liner can seal up any leaky rivets in your boat and freshen up oxidized gel. It also comes in a variety of colours and can be custom-mixed.

Some potential issues with using Rhino liner on your boat include that it may not adhere well to aluminium, it can be very expensive, and it may peel off over time.