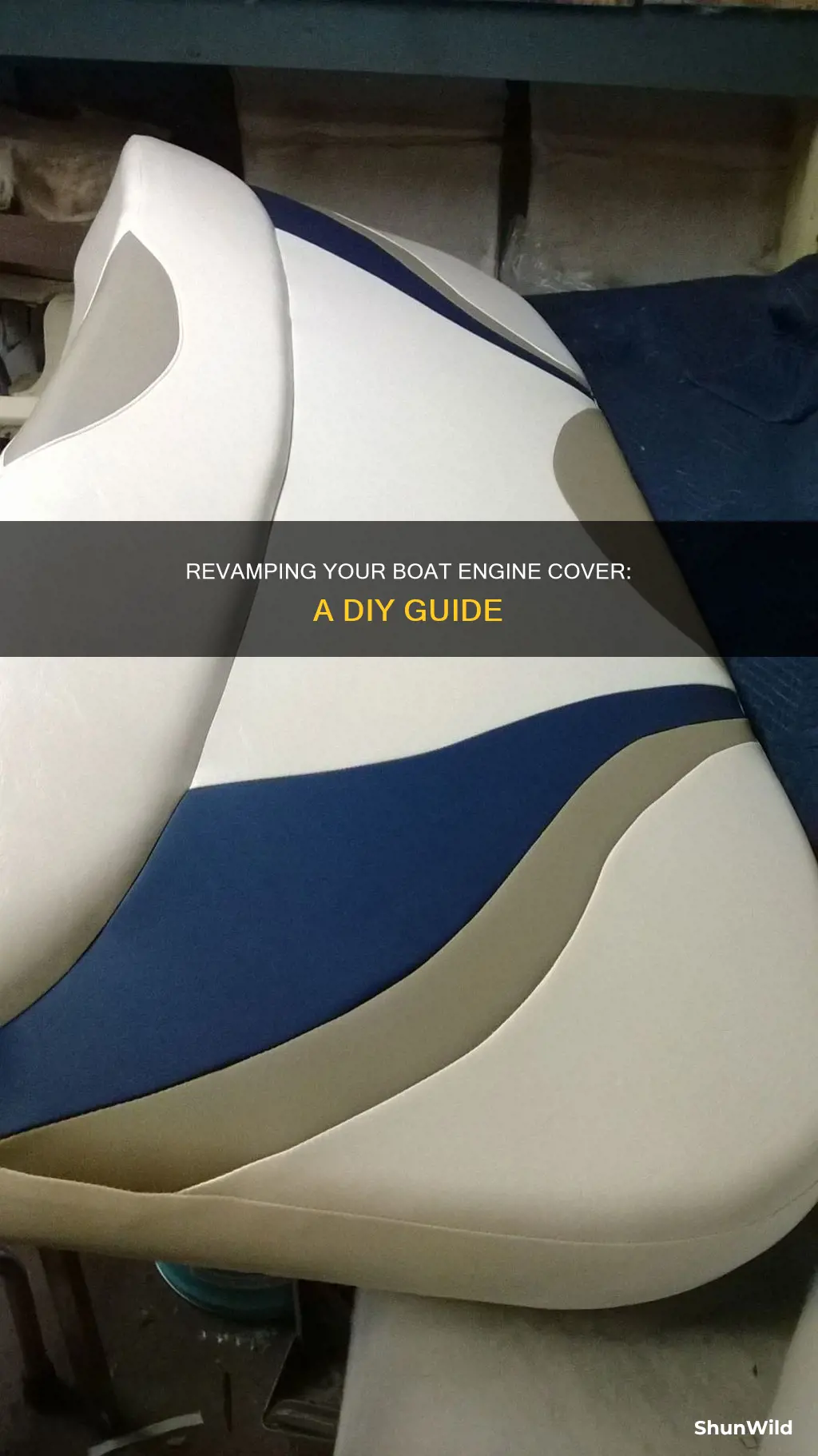

Reupholstering a boat engine cover is a time-consuming task that requires a certain level of patience and skill. It involves removing the existing fabric, inspecting the underlying materials, measuring and cutting the new fabric, and reassembling the cover. The process is similar to reupholstering boat seats, which are typically covered in vinyl for water resistance. Before beginning the reupholstering process, it is important to inspect the underlying foam and wood for any damage, as they can degrade or get mouldy over time. When choosing the new fabric, it is recommended to use marine-grade, UV-resistant vinyl to ensure durability and avoid premature wear and tear.

What You'll Learn

Inspect existing cover and foam

Before you begin the reupholstering process, it is important to inspect the existing cover and foam of your boat engine cover. This step will help you identify any issues or damage that need to be addressed. Here is a detailed guide to help you through the inspection process:

Begin by carefully removing the existing cover from the engine cover. Use a staple remover or a screwdriver to detach the cover gently, being mindful not to cut the skin, as this may leave staples behind and create more work for yourself. Take your time with this step to avoid damaging the underlying foam or other materials.

Once the cover is removed, inspect the foam for any signs of deterioration. Boat foam can degrade over time due to exposure to moisture, and it can also get mouldy, creating health hazards and triggering allergies. Look for any discolouration, odours, or signs of rot. If the foam is flat, compressed, or feels uneven, it will likely need to be replaced.

If the foam is in good condition, proceed to inspect the underlying wooden structure. Ensure that the wood is not rotting or damaged. Moisture can cause wooden parts to deteriorate, so check for any signs of water damage or warping. Gently probe the wood to ensure it is still sturdy and intact.

After assessing the foam and wood, pay attention to the overall construction of the engine cover. Note the shape, size, and any unique features or contours. This information will be crucial when creating the new cover. Take detailed measurements of the engine cover, including its length, width, and height. Also, make note of any cut-outs or unusual shapes that need to be accommodated.

Finally, as you inspect the existing cover and foam, create a list of the materials you will need to purchase. This may include new foam, wood, vinyl fabric, and other supplies such as staples, screws, or adhesives. By creating a comprehensive list at this stage, you can ensure that you have all the necessary materials on hand before you begin the reupholstering process.

Remember, the inspection process is crucial to ensure a successful reupholstering project. Take your time, be thorough, and don't hesitate to seek advice or assistance if you encounter any issues or complexities that you are unsure how to address.

Transforming Boat Hull Drawings: CNC Conversion Process

You may want to see also

Measure and cut new vinyl

Measuring and cutting new vinyl for your boat engine cover is a crucial step in the reupholstering process. Here is a detailed guide to help you through it:

Preparation

Before measuring and cutting, gather the necessary tools and materials. You will need:

- Marine-grade, UV-resistant vinyl in a sufficient quantity (consider buying at least 10% more than you need, preferably 25% extra to account for errors and wastage).

- Your old vinyl cover, which will be used as a template.

- Marking pencils or grease marks to trace the pattern.

- Shears or scissors for cutting the vinyl.

- A flat surface to work on.

Measuring

Place your old vinyl cover on a flat surface. If it is attached to the seat with staples, remove these carefully without cutting the vinyl, as this can damage your new cover. Take close-up pictures of the old cover from multiple angles to reference later.

Lay the old cover flat and use it as a template to trace the pattern onto your new vinyl. You can place the new vinyl over the old cover and trace the outline with your marking pencil or grease marks. Make sure to mark all the necessary holes or cuts for fittings.

Cutting

Using your shears or scissors, carefully cut the new vinyl along the traced lines. Cut as close to the lines as possible to ensure a precise fit. Remember, it is better to cut slightly larger than needed and then trim down as necessary. You can always cut more, but you can't add back cut vinyl!

Final Checks

Before installing the new vinyl, double-check that it matches the size and shape of your old cover. Lay the new vinyl over the old cover to ensure it aligns correctly. Make any necessary adjustments by trimming the new vinyl.

Now you are ready to install your new vinyl cover onto your boat engine cover! Remember to follow the specific instructions for your engine cover model and seek help if needed.

Exploring Sicily: Palermo to Taormina by Boat

You may want to see also

Reinstall seats

Now that you've cut your vinyl and foam, it's time to reassemble your engine cover. This process will vary depending on the type of seat you have, but here are some general instructions for reinstalling boat seats:

First, determine the location of the driver's seat and place the backrest against the rear wall of the seating platform. The plastic bars connected to the seat backrest will help you set the seat cushion in place. These bars should be bolted to the inner frame of the backrest.

Next, you'll want to secure the backrest in place. The plastic bars and mounting blocks that support the backrests should have countersunk holes. You can use these to insert your stainless steel screws and drive them into the boat, securing the backrest. It is recommended to drill small pilot holes into your boat before installing the screws to prevent damage to the fiberglass.

Once the backrest is secure, you can determine the mounting location for each boat seat. Install the backrest first by driving the appropriate screws into the plastic mounting bars.

For bucket seats, line up the seat cushion with the installed backrest and adjust the spacing between the seat and the backrest using the hinge attached to the bottom of the cushion. There should be a matching vinyl piece that you can install with the hinge. Screw this vinyl piece to the platform to hide the aluminium hinge.

If you have a centre fold-down seat, determine its mounting location and install it with the attached hinge and vinyl piece.

For fishing seats and chairs, you may need to remove the attached stainless steel mounting bolts with a Phillips-head screwdriver. Attach the pedestal seat mount to the bottom of the fishing seat and screw the mounting bolts back into the plastic frame. Ensure that the metal t-nuts are inserted into the plastic frames and start the bolts by hand to prevent misthreading.

Finally, consider the positioning of your seat base. You don't want it to be too far back or too close to the wheel or tiller. Remember to check the type and solidity of the decking under the seat and the structures, if any, under the deck. If possible, try to peek under the deck before installing your seat base to ensure you're screwing or bolting it into a supporting structure.

Once you're happy with the positioning, drill your holes and secure your seat base with screws or bolts.

Transferring Boat Ownership: Signing Over a Title in Florida

You may want to see also

Attach vinyl and foam

Attaching the vinyl and foam cuts to the seating cover is a crucial step in the reupholstering process. Here is a detailed guide to help you through this stage:

Firstly, place the vinyl flat on a surface, with the wrong side facing up. This will ensure that you don't accidentally damage the right side of the vinyl. Center the foam over the vinyl, taking care not to disturb its placement as you proceed to the next steps.

Now, pick up the front end of the vinyl and stretch it over the wooden structure of the seat. Ensure that the vinyl fits snugly against the foam, compressing it slightly. This step is important to achieve a smooth and wrinkle-free finish. Secure the vinyl in place with a staple gun. It is recommended to use four staples, one on each side, to hold the cover securely.

Next, continue stapling along the front, placing a new staple every one or two centimeters. For best results, it is advised to alternate sides, working your way outward from the center. This technique helps prevent bunching and wrinkling, ensuring a professional finish.

After completing the front, move on to the back, following a similar stapling pattern. Maintain a consistent distance between staples and continue to hold the vinyl taut as you work. Finally, staple both sides in the same manner as you stapled the front and back.

Once you have finished stapling, carefully inspect the cover for any signs of wrinkling or bunching. If you notice any imperfections, carefully remove the staples from the affected area and adjust the vinyl accordingly. This process may require some trial and error, but it is important to ensure a neat and secure finish.

As a final touch, consider applying a vinyl protectant to the reupholstered seat. This will help protect the vinyl from UV radiation, premature aging, and cracking. It will also add a long-lasting sheen to the surface, enhancing the overall appearance of your handiwork.

Crestliner Boats: Are They Worth the Hype?

You may want to see also

Apply vinyl protectant

Once you have reupholstered your boat engine cover, it is important to protect the vinyl from sun damage, wear and tear, and water damage. To do this, you can apply a vinyl protectant.

Step One: Clean Your Boat Engine Cover

Before applying the protectant, ensure your engine cover is clean. Dirt, mildew, and bird droppings can degrade the fabric over time, so it is important to wash the cover with water and avoid harsh detergents that can strip away protective coatings.

Step Two: Apply the Vinyl Protectant Spray

After cleaning, apply the vinyl protectant spray. Products like 303 Aerospace Protectant, STAR BRITE, and Scotchgard UV Protectant are specifically designed to shield vinyl from harmful UV rays.

Evenly spray the protectant over the entire surface of the cover, focusing on areas that receive the most sunlight exposure. The spray can be applied multiple times for added protection.

Step Three: Let It Dry

Allow the cover to dry completely before putting it back on your boat or storing it. For greater bonding and longevity, buff a few times with a dry cloth.

Step Four: Repeat the Process

To maximise UV protection, repeat the process of cleaning and applying the protectant every three to five weeks. It is also important to follow this protocol every time you use your boat and, when your boat is sitting unused, at least once a week.

By following these steps, you can help ensure that your boat engine cover's vinyl surfaces stay clean, protected, and looking new for years to come.

Exploring Bahamas: Boat Trip from Fort Lauderdale

You may want to see also

Frequently asked questions

If your boat engine cover is exposed to sun, wind, rain, and other weather elements, it will likely start to crack, tear, or fade over time. If you notice any of these signs, it may be time to consider reupholstering.

You will need a staple remover or a screwdriver to remove the old cover, as well as an upholstery stapler or carpet tacker, staples, marking pencils, and sewing shears. For the new cover, you will need marine-grade, UV-resistant vinyl, high-density foam rated for marine use (if replacing), and pressure-treated wood (if needed).

First, remove the old cover and inspect the underlying materials for any damage. Measure the old cover and the foam (if replacing) to determine the size and shape of the new material needed. Cut the new vinyl and foam to the required measurements. Reassemble the cover by laying the vinyl flat, placing the foam on top, and wrapping the vinyl around the sides. Stretch the vinyl over the wooden frame, ensuring it is pulled tight, and secure it with staples.

The cost of reupholstering a boat engine cover can vary depending on the materials used and the labour involved. If you plan to hire an upholstery shop, prices can differ based on location and the number of seats/cushions that need to be replaced. It may be more cost-effective to purchase new seats entirely in some cases.