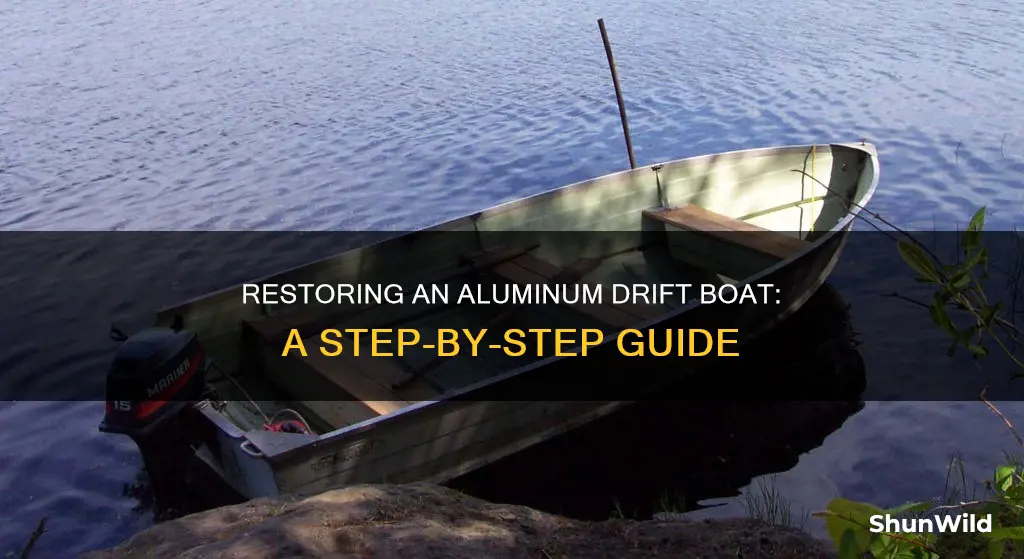

Aluminium boats are prone to oxidation, which can cause the metal to lose its shine. To restore an aluminium drift boat, you'll need to strip off any existing coatings, clean the aluminium, and apply a new protective coating. This process can be time-consuming and labour-intensive, but with the right tools and products, it is possible to achieve a professional finish.

What You'll Learn

Stripping and recoating the boat

Stripping and recoating an aluminium boat is a detailed process that requires a lot of elbow grease. Firstly, you need to decide on the method of stripping. Some people use a propane heater to heat up the boat's surface, and then use a scraper to get under the coating. This is a time-consuming method but can be effective. Alternatively, you could use an angle grinder with a wire brush to remove the coating. This method is good for removing stubborn areas and corrosion. It is important to wear protective gear, such as heavy gloves, and work in a well-ventilated area when using an angle grinder.

Once the majority of the coating has been removed, you can use a sander to smooth out the surface and remove any remaining residue. This will ensure that the new coating will adhere properly. It is important to use the correct grit sandpaper for the job; too fine, and it won't be effective, too coarse, and it may damage the aluminium. A medium grit, such as 36-grit, is a good starting point.

After sanding, the aluminium will need to be cleaned with a dedicated aluminium cleaner to remove any grease, dirt or oxidation. Ordinary soap and water will not effectively clean aluminium, so it is important to use the correct products. Once the boat is clean, it should be dried thoroughly and any remaining residue removed.

Now the boat is ready for the new coating. There are many products on the market, such as Coat-it, Glovit, Gluvit, Line-X, and UHMW. Each product has its own advantages and disadvantages, so it is important to research which one is best suited to your needs. Some products are smoother, some are thicker, and some are more resistant to UV light. The application method will also vary depending on the product, so be sure to read the instructions carefully. Some products require a roller for application, while others can be sprayed on.

Finally, it is important to allow the new coating to cure properly before using the boat. This may take several hours or even days, depending on the product and the temperature.

Flooding a Boat: Consequences and Safety Measures

You may want to see also

Removing algae, barnacles and zebra mussels

Removing algae, barnacles, and zebra mussels from your aluminium drift boat is a simple process with the right product. Aurora Marine's Algex is a no-fume formula that comes in a ready-to-use spray bottle. Spray it directly onto the algae, and it will penetrate and break the bond between the algae and the aluminium, making it easy to remove. For best results, scrub the affected areas with a brush and then rinse with a pressure washer or a garden hose. Alternatively, you can use a scraper to remove the softened barnacles and zebra mussels.

Algex is safe to use on aluminium and will not pit the metal or strip paint. It is also effective at removing rust and oxidation and can be used on aluminium boat bottoms, pontoons, outboards, sterndrives, and propellers.

If you are looking for a more heavy-duty solution, Aqua-Chem is another product that claims to remove zebra mussels, barnacles, and algae from all types of boat hulls and bottoms, including aluminium. Aqua-Chem contains inhibited and enhanced hydrochloric acid and is safe for the environment. However, it is important to follow the safety warnings and use goggles and rubber gloves when handling this product.

For a more natural approach, you can try using a propane heater to heat the affected areas and a scraper to remove the buildup. This method may require more elbow grease but can be effective in removing stubborn growths.

Remember to always follow the manufacturer's instructions and take the necessary safety precautions when using any cleaning products.

Fellowship's Journey: Why No Boat Adventure for Our Heroes

You may want to see also

Cleaning and brightening exposed metal surfaces

To restore an aluminium drift boat, it is important to clean and brighten exposed metal surfaces. This can be done using a dedicated aluminium boat cleaner, such as Aurora Alumabrite CBX, which is a concentrate that needs to be cut with water in a 1:12 ratio. It can be applied with a garden sprayer, but it is recommended to invert the boat to avoid getting overspray on the inside. Alternatively, you can use a product like Arcair - Protex, Alclean aluminium cleaner, which is available at welding shops. It is important to wear gloves and work outdoors or in a well-ventilated area when using these products, as the fumes can be dangerous. After cleaning, the surface can be polished with a product like Aurora Boat Scrub to achieve an even brighter finish.

Before applying any cleaner, it is important to remove any debris, dust, or grease that may have built up on the boat. This can be done by using a pressure washer to clean the boat inside and out, paying close attention to the seams to check for leaks. If there are any exposed fiberglass areas, they should be reinforced with epoxy and sanded before painting. It is also recommended to cover any painted areas of the boat to protect them from the cleaner, as it may damage the paint.

Once the cleaning and brightening process is complete, the topsides of the boat can be protected with a product like Premium Boat Shine, and the bottom can be coated with a product like VS721 Bottom Coat to maintain the shiny finish.

Retrieving a Boat Title: Navigating the Process in Pennsylvania

You may want to see also

Repairing the interior of the boat

Repairing the interior of an aluminium drift boat is no small task and requires a lot of elbow grease. Here is a step-by-step guide to help you through the process:

Step 1: Stripping

First, you need to strip the interior of the boat down to the original surface. This can be done using a propane heater to heat the existing coating and a scraper to remove it. An angle grinder with a wire brush can also be used to remove any stubborn areas and to clean the entire surface. It is important to wear heavy gloves and work in a well-ventilated area when undertaking this step.

Step 2: Cleaning

Once the interior is stripped, it is crucial to clean the aluminium surface to remove any remaining residue. A dedicated aluminium boat cleaner or a phosphoric acid-based product can be used for this step, ensuring that you follow the manufacturer's instructions. Be cautious when working with chemicals and wear appropriate protective gear.

Step 3: Prepping the Surface

Before applying any new coatings or paint, it is essential to prepare the surface properly to ensure a strong bond. This involves sanding the aluminium to create a rough surface for the new material to adhere to. Use sandpaper or a sanding disk with a suitable grit size, such as 60-grit or 36-grit, to thoroughly sand the interior. Vacuum and wipe down the surfaces to remove any dust or debris.

Step 4: Repairing Structural Damage

If there is any structural damage, such as holes or cracks, these need to be addressed before proceeding. Use a suitable filler or epoxy to repair the damage and ensure it is sanded smooth once cured. For metal brackets or other hardware that need to be reattached, use bi-axial tape saturated with epoxy and apply it with a squeegee and a brush.

Step 5: Painting or Coating

Finally, you can apply a new coating or paint to the interior of the boat. Choose a product specifically designed for aluminium drift boats, such as an epoxy coating or a bed liner. Follow the manufacturer's instructions for mixing and application, ensuring that you work in a well-ventilated area and use the appropriate safety gear. Allow the coating to cure completely before using the boat.

It is important to note that this is a general guide, and the specific steps may vary depending on the condition of your boat and the products you choose to use. Always refer to the instructions provided by the manufacturers of the products you are using and take the necessary safety precautions throughout the process.

Pontoon Paddling: Do You Need an Oar?

You may want to see also

Painting the boat

Preparation

Before painting, it is essential to prepare the boat's surface. Start by stripping off any old paint, coatings, or debris. This can be done using a propane heater to soften the old coating, followed by a scraper to remove large pieces. An angle grinder with a wire brush can also be used to clean the boat's bottom and remove any stubborn areas of corrosion. Sanding the surface with a medium grit sandpaper, such as 36-grit or 60-grit, is then recommended to create a rough texture that will help the new paint adhere better. It is important to work in a well-ventilated area and wear protective gear, including heavy gloves and eye protection, during this process.

Cleaning

Once the surface is prepared, it needs to be cleaned thoroughly. Use a dedicated aluminium boat cleaner or a phosphoric acid-based product to remove any remaining grease, dirt, or oxidation. Follow the manufacturer's instructions for application and safety. A Scotch-Brite pad can be used to clean problem areas. Rinse the boat with plenty of water to remove any residue.

Priming

Before painting, it is essential to prime the aluminium surface. Choose a primer designed specifically for aluminium, such as a metal primer, and apply it according to the manufacturer's instructions. This will help the paint adhere better and provide a more durable finish.

Painting

When selecting a paint for your aluminium drift boat, choose a product designed for this purpose, such as a bed liner or an epoxy coating. Bed liners, such as "Raptor" or "Durabak 18", provide a non-slip surface and can be applied with a roller or sprayed on. Epoxy coatings, such as "Glovit" or "Coatit", provide a slick finish and can be applied with a foam roller or brush. Follow the manufacturer's instructions for mixing and application, ensuring that you work quickly as epoxy starts to heat up and cure within 20 minutes. Apply at least two coats of paint, allowing the recommended curing time between coats.

Finishing

Once the final coat of paint has cured, you can finish the restoration by reassembling any removed hardware and sealing any exposed screws or fasteners with a product like Flex Seal. Remember to polish or wax the painted surface regularly to maintain its shine and protect it from the elements.

Storing Kayaks: Using Your Boat Dock Space Efficiently

You may want to see also

Frequently asked questions

The first step is to deconstruct the boat and check for any damage.

It is important to clear off any debris, dust, or grease that might have built up on your aluminum boat before you apply a cleaner. Use a dedicated aluminum boat cleaner to brighten, protect, and restore shine.

You can use products like Aurora Algex, Aurora Alumabrite CBX, Aurora Boat Scrub, Premium Boat Shine, VS721 Bottom Coat, Flex Seal, JB Weld, Krylon Plastic Primer, and truck bed liner.

Common mistakes to avoid include not properly prepping the surface before applying fiberglass or paint, using the wrong type of cleaner or paint, and not sealing the boat properly.

When recoating an aluminum drift boat, make sure to strip off any old coating completely. Use a propane heater to heat and remove old coating, and use a scraper to get under it. Clean the surface thoroughly and follow the instructions for your chosen coating product carefully.