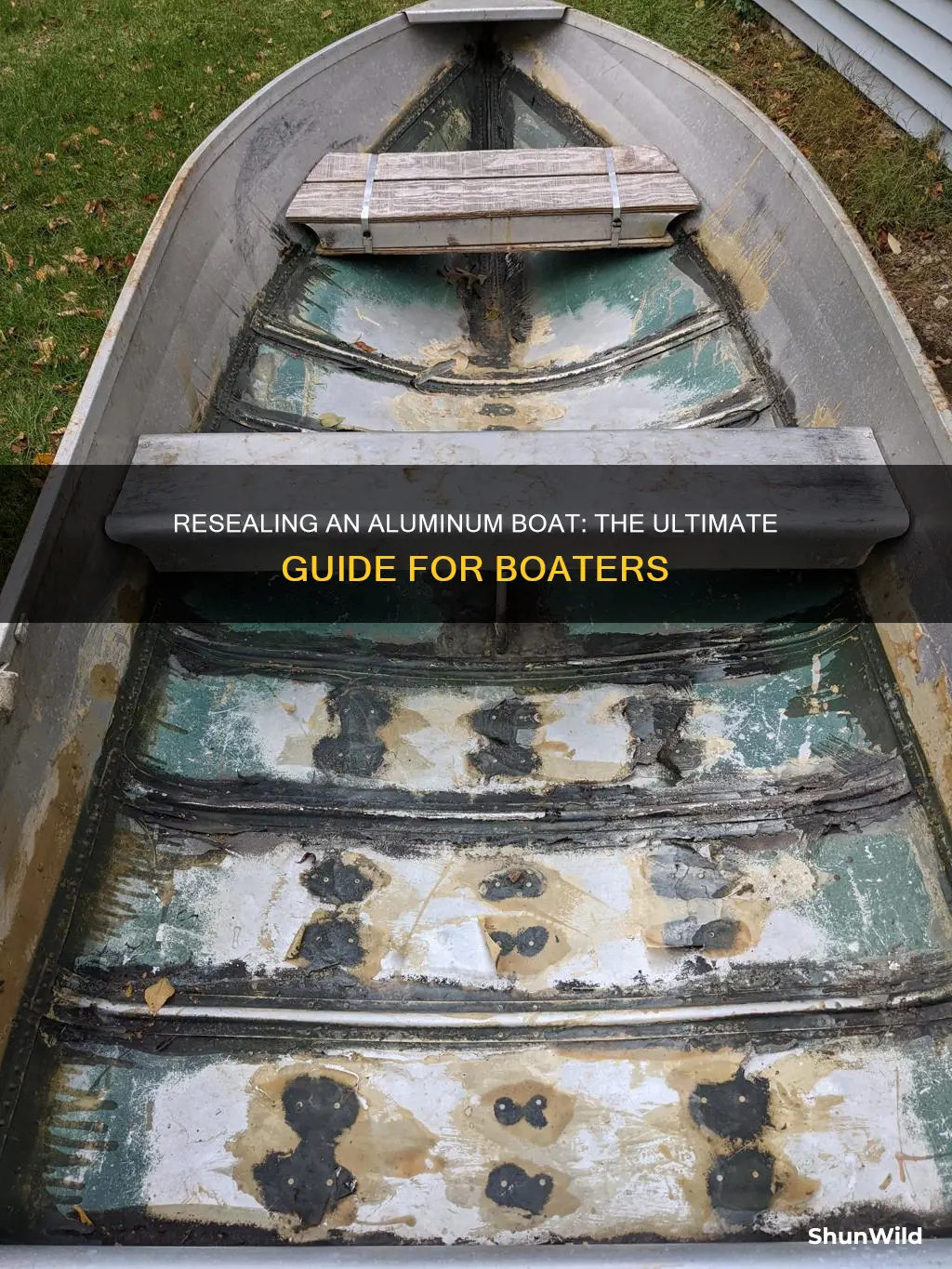

Owning a boat can be a lot of fun, but it also comes with maintenance responsibilities. If you're the proud owner of an aluminum boat, you may eventually need to reseal it to prevent leaks and ensure its longevity. This process involves identifying the source of any leaks, thoroughly cleaning the boat, choosing the right sealant, and properly applying it. One key consideration is whether to seal the boat from the inside or outside, as sealing from the outside can take advantage of water pressure to keep the seals in place. Additionally, it's crucial to follow the directions on your chosen sealant to ensure a proper cure.

How to Reseal an Aluminum Boat

| Characteristics | Values |

|---|---|

| Step 1 | Identify the source of the leak, paying special attention to seams and rivets. |

| Step 2 | Get the boat dry and check for leaks again, marking any areas that leak. |

| Step 3 | Choose the right sealant for your boat. Select a sealant that adheres to metal. |

| Step 4 | Prepare the area by cleaning it with an aluminum boat cleaner. Allow the area to dry. |

| Step 5 | Apply the sealant generously. It is better to over-seal than under-seal. |

| Step 6 | Follow the directions on your sealant and allow the boat to cure overnight. |

| Step 7 | Inspect the seal and test if it is waterproof. |

| Products | Gluvit, Coat-It, 3M Yellow Weatherstripping Adhesive, Life-Calk, Silicone Rubber Sealant, Flex Seal, JB Weld, Marine Putty, Life Caulk |

What You'll Learn

Identify the source of the leak

Identifying the source of a leak in an aluminium boat can be a challenging task. Here is a step-by-step guide to help you locate the leak and prepare for the repair process:

Step 1: Inspect the Boat on Land

Take your boat out of the water and place it on land, preferably on a trailer. This will allow you to thoroughly inspect the hull and identify any visible signs of leakage. If the leak is large, it should be noticeable right away.

Step 2: Fill the Boat with Water

If you don't spot any obvious leaks, the next step is to fill the boat with water. Make sure not to fill it too high, as this could put excessive weight on the trailer. Inspect the hull for any signs of leakage. If you are having trouble spotting the leak, consider adding food colouring to the water, which will make it more visible.

Step 3: Check Common Leakage Spots

If you still can't identify the source of the leak, it's time to check some common leakage spots. Start with the drain plug seal and livewell pumps, especially on the transom, as these can be hard to spot. The most common leakage spots are often around transducer screw holes and rivets.

Step 4: Inspect Seams and Rivets

Aluminium boats are constructed with seams and rivets, which can be prone to leaking if they get loose. Dry the boat thoroughly and carefully inspect these areas, as they are prime suspects for leaks. However, keep in mind that leaks can also start from other sources, so give the entire boat a thorough look-over.

Step 5: Prepare the Area

Once you've identified a leak, it's time to prepare the area for repair. Use an aluminium boat cleaner to ensure a high-quality clean while protecting the metal. Allow the area to dry completely so that you have a smooth, clean surface to work with.

Step 6: Consider Minor Sources

If you still can't find the source of the leak, consider some minor sources that could be the culprit. For example, small cracks or holes could be causing the issue. Sand these areas by hand to clear any dirt that might prevent proper sealing. Ensure the surfaces are fully dry before applying any sealant or repair solutions.

By following these steps, you should be able to identify the source of the leak in your aluminium boat and prepare for the necessary repairs. Remember to take your time and inspect the boat thoroughly to increase your chances of finding the leak.

Troubleshooting a Boat Engine Seizure: What to Do?

You may want to see also

Prepare the area by cleaning and drying

Before you begin sealing your aluminium boat, it's important to prepare the area by thoroughly cleaning and drying the surface. This will ensure that the sealant adheres properly and that you're able to identify any leaks. Start by giving the boat a comprehensive clean, using a dedicated aluminium boat cleaner to protect the metal. Pay special attention to the seams and rivets, as these are common sources of leaks. A pressure washer can be useful for this task, as it will allow you to spray hard at the seams to check for leaks. Even if you don't find any leaks, consider sealing all the seams and rivets for added protection.

Once you've cleaned the boat, it's important to let it dry completely. Make sure to give the aluminium enough time to dry so that you can work with a smooth, clean surface. This will ensure that you're not interrupted by any lingering water during the sealing process. It's also a good idea to perform a leak test by filling the bottom of the boat with a few inches of water and watching for any leaks, especially around the seams and rivets. Mark any leaks that you find so that you can address them during the sealing process.

In addition to cleaning and drying, you may need to address any issues with the transom, which is the stern of the boat that the outboard motor is clamped onto. Check for any signs of rot or damage, as water may be entering the boat through the holes where the motor mount bolts are located. If the transom is rotten, you may need to replace it entirely, ensuring that the new transom is bolted securely in place.

Finally, inspect the rivets on the hull seams and replace any that are missing or damaged. Use new aluminium rivets that are the same size as the originals, clamping and straightening the hull as needed to ensure a tight fit. By taking the time to thoroughly clean, dry, and inspect your aluminium boat, you'll be well-prepared to move on to the sealing process, ensuring a successful and long-lasting result.

Repairing Your Bait Boat: A Step-by-Step Guide

You may want to see also

Choose the right sealant

When it comes to choosing a sealant for your aluminium boat, there are several options available, each with its own advantages and use cases. Here are some detailed considerations to help you make the right choice:

Firstly, it is essential to understand that aluminium boats are constructed with seams and rivets, which can be prone to leaking if they become loose. Therefore, when choosing a sealant, opt for one that is specifically designed to adhere to metals and fill in gaps around rivets. For instance, Life-Calk, an acid-free formula, is suitable for sealing to metals. Similarly, Silicone Rubber Sealant is another option that won't corrode metal and will protect your boat.

Secondly, if you're looking for a sealant that can handle the unique challenges of an aluminium boat, consider Gluvit or Coat-It. These epoxy-based products are highly regarded in the boating community for sealing boats from the inside. While they require protection from UV rays, they offer an effective solution for preventing future leaks.

Additionally, for a flexible and durable solution, consider using 3M Yellow Weatherstripping Adhesive. This product can be applied around leaking rivets after cleaning the area with a wire brush. It stays on for a couple of years and can be re-applied if needed.

Another option is to use a product like Flex Seal, which is designed to seal watercraft from the outside. By applying it to the seams and rivets, you utilise the water pressure to help keep the seals in place. While paint may not adhere well to Flex Seal, it can provide additional camouflage for your boat if needed.

Lastly, for a quick and easy fix, Life Caulk is a good option. It adheres to raw aluminium and can be rolled onto the seams and cracks to prevent leaks.

Remember, when choosing a sealant, opt for one that is specifically designed for metal and aluminium boats, and always follow the manufacturer's instructions for application and curing.

Fresh Off the Boat: A Journey Through the '90s

You may want to see also

Apply the sealant generously

When it comes to resealing an aluminium boat, applying the sealant generously is crucial. It is always better to over-seal than under-seal, as you can easily remove any excess sealant later. However, under-sealing can lead to starting the entire process over again. Therefore, don't hold back when applying the sealant.

To ensure a proper seal, it is recommended to use a sealant specifically designed for metal adhesion. Look for products that clearly state their suitability for metal surfaces on their labels. For instance, Life-Calk is a cartridge sealant that adheres well to metals, and Silicone Rubber Sealant is an acid-free formula that won't corrode metal.

When applying the sealant, make sure the aluminium surface is thoroughly cleaned and dried. This will ensure a smooth and clean surface for the sealant to adhere to. Take your time and be generous with the amount of sealant you apply. It is also important to follow the directions on the sealant packaging for proper curing. Typically, this involves keeping the boat undisturbed overnight to allow the sealant to cure completely.

After the curing process, carefully inspect the seal and test it to ensure it is waterproof. This step is crucial to confirm that the resealing process was successful and that your boat is ready for the water again.

By following these instructions and applying the sealant generously, you can effectively reseal your aluminium boat and prevent future leaks. Remember, it is always better to have too much sealant than too little, as you can always scrape off any excess later.

Leather or Vinyl Boat Seats: Which Material Floats Your Boat?

You may want to see also

Cure the sealant overnight

Once you've applied the sealant, it's time to let it cure. Curing is the process of drying and hardening, and it's essential for creating a strong, waterproof seal. The curing process for sealants can vary, so it's important to follow the directions on your specific product.

Most sealants require a stable environment to cure properly. This means finding a place where your boat won't be disturbed and leaving it overnight. After this period, you can inspect the seal and test if the curing has been successful by checking if it's waterproof.

Some sealants, like Capt. Tolley's Penetrating Sealant, cure overnight and are ideal for hairline cracks in boats. This thin, penetrating sealant is perfect for tiny cracks that let water in, such as those in teak decks or around port holes. It's a quick fix that can be done in less than five minutes, and it doesn't require any preparation or disassembly. Simply apply a few drops with a dropper bottle, and the sealant will pull itself into the cracks and cure overnight.

Other sealants, like the 3M Marine Adhesive Sealant 5200, have a longer curing process. This product is a fast-curing version of the standard 3M Marine Adhesive Sealant 5200, curing in 48 hours instead of the usual 5-7 days. It's a flexible polyurethane sealant ideal for permanent bonding and sealing on various surfaces, including wood, gel coat, fiberglass, and metal.

When curing your sealant, it's important to follow the instructions on your chosen product. Some may require more time to cure fully, and others may have specific environmental requirements. Always read the label to understand the curing process and ensure a proper seal.

Angelina's Identity in Romancing the Stone: Unveiling the Mystery

You may want to see also

Frequently asked questions

Dry the boat and watch for any leaks, paying special attention to the areas of seams and rivets.

Use a sealant that is specifically designed to adhere to metal. Apply the sealant generously and follow the product's instructions for curing.

You can use products such as Life-Calk, Silicone Rubber Sealant, Gluvit, Coat-It, 3M Yellow Weatherstripping Adhesive, Flex Seal, or JB Weld.

You can replace the rivets or apply a sealant such as Gluvit or Coat-It to the inside of the hull.