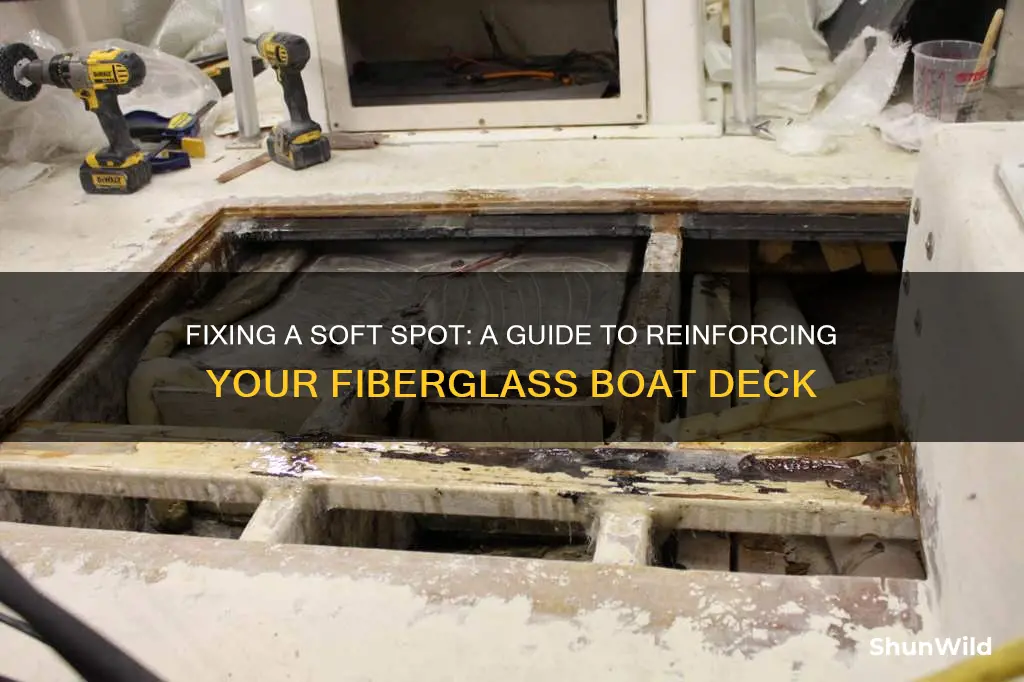

Repairing a soft spot on a fiberglass boat deck can seem daunting, but with the right tools and techniques, it's a manageable task. This guide will walk you through the process, from identifying the issue to choosing the appropriate materials and applying the repair. By following these steps, you can restore the structural integrity and appearance of your boat deck, ensuring a safe and enjoyable boating experience.

What You'll Learn

- Identify the Soft Spot: Inspect the deck for damage, noting the extent and location of the soft spot

- Clean and Prepare: Remove dirt and debris, ensuring a clean surface for repair

- Choose a Filler: Select a suitable fiberglass filler, matching the material's properties to the boat's structure

- Apply Filler: Follow manufacturer instructions, using a trowel or gun to fill the soft spot evenly

- Sand and Smooth: After curing, sand the area to match the surrounding surface, preparing for final finishing

Identify the Soft Spot: Inspect the deck for damage, noting the extent and location of the soft spot

When it comes to repairing a soft spot on a fiberglass boat deck, the first and most crucial step is to identify the issue accurately. This process involves a thorough inspection of the deck to understand the nature and extent of the damage. Here's a detailed guide on how to approach this:

Start by examining the deck surface carefully. Look for any visible signs of damage, such as soft or sunken areas, which are often the most apparent indicators of a soft spot. These areas might appear lower than the surrounding surface, almost like a dent or a dip. Pay close attention to the edges of the deck, as soft spots often start as small, localized issues and can expand over time. The location of the soft spot is crucial, as it will determine the approach to the repair.

Use a putty knife or a similar tool to gently probe the area. Feel for any give or flexibility in the deck surface. A soft spot will often feel softer or more pliable compared to the rest of the deck. The extent of the damage is also important; note if the soft spot is confined to a small area or if it has spread and affected a larger portion of the deck. Take measurements or sketch the area to document the size and shape of the soft spot, as this information will be valuable when deciding on the repair method.

In some cases, the soft spot might be less noticeable but still cause issues. Look for any signs of water damage, such as discolored or soft wood beneath the fiberglass. This could indicate a hidden soft spot that has progressed beyond the visible surface. Additionally, check for any loose or missing fiberglass pieces, as these can be a result of a soft spot that has caused the material to weaken and separate.

Identifying the soft spot accurately is the foundation of a successful repair. It allows you to assess the severity of the damage and choose the appropriate repair technique. Remember, a thorough inspection at this stage will save you time and effort later in the repair process.

Mastering Boat Driving for Wakeboarders: Tips and Tricks

You may want to see also

Clean and Prepare: Remove dirt and debris, ensuring a clean surface for repair

Before you begin the repair process, it's crucial to ensure that the fiberglass boat deck is clean and free of any contaminants. This step is often overlooked but is essential for a successful repair. Start by thoroughly cleaning the affected area. Use a stiff-bristled brush or a scrub brush to remove any loose dirt, grime, or debris. Pay close attention to the soft spot, as it may have accumulated more dirt over time. If the area is particularly dirty, consider using a pressure washer to give it a good rinse, but be cautious not to spray too close to the repair area to avoid any potential damage.

Once the initial cleaning is done, it's time to get more thorough. Mix a mild detergent or dish soap with warm water, ensuring it's not too harsh to avoid any chemical reactions with the fiberglass. Dip your brush or a soft sponge into the soapy water and gently scrub the soft spot and the surrounding area. Rinse thoroughly with clean water to remove any soap residue. You want to make sure that the surface is completely dry before proceeding, so give it ample time to air-dry or use a soft cloth to pat it dry.

For a more precise clean, consider using a vacuum cleaner with a soft brush attachment to remove any fine particles or dust that might be present. This step is especially important if the soft spot is in a hard-to-reach area or has a complex shape. Ensure that the vacuum is set to a low suction to avoid any potential damage to the fiberglass. After this thorough cleaning process, inspect the area to ensure it is completely free of dirt and debris, providing an ideal surface for the upcoming repair.

Remember, taking the time to clean and prepare the fiberglass boat deck properly will significantly contribute to the success and longevity of the repair. It ensures that the repair material adheres well to the surface and helps prevent any future issues.

Finding Boat Parts in Rave in the Redwoods

You may want to see also

Choose a Filler: Select a suitable fiberglass filler, matching the material's properties to the boat's structure

When repairing a soft spot on a fiberglass boat deck, choosing the right filler is crucial to ensure a strong and durable repair. The filler material should complement the boat's existing structure and withstand the marine environment. Here's a guide to selecting the appropriate filler:

Understanding the Boat's Structure: Before choosing a filler, it's essential to understand the composition of your boat's deck. Fiberglass is a composite material made of a resin and a fiber (often glass fibers). The resin can be either an epoxy or a polyester-based system. The type of resin used will influence the choice of filler. For example, if your boat's deck is made of a polyester resin, you should opt for a filler that is compatible with polyester systems.

Material Properties: Fillers for fiberglass repairs come in various forms, including putty, paste, and sprayable materials. Each has its advantages:

- Putty: Ideal for small, shallow voids, putty provides a smooth surface for bonding. It is easy to work with and can be sanded and shaped to match the surrounding area.

- Paste: Paste-like fillers are versatile and can be used for both shallow and deeper repairs. They offer excellent adhesion and can be applied in thin layers, making them suitable for filling small gaps or creating a smooth transition between old and new material.

- Sprayable Fillers: These are convenient for larger areas and can be sprayed or troweled onto the surface. They provide a quick and efficient way to cover larger soft spots, but they may not be as precise as putty or paste for detailed repairs.

Matching the Filler to the Resin: The key to a successful repair is to match the filler's properties to the boat's resin system. For epoxy-based fiberglass, you should use an epoxy-compatible filler. These fillers often have a higher viscosity, allowing for better control during application. Epoxy putties and pastes are commonly used for this purpose. For polyester-based fiberglass, look for fillers designed for polyester resins. These fillers tend to be more flexible and can accommodate minor structural movements.

Consideration of Environmental Factors: Marine environments can be harsh, so the chosen filler should be resistant to UV radiation, saltwater, and other corrosive elements. Some fillers are specifically formulated to withstand these conditions, ensuring the repair's longevity. Additionally, consider the temperature range your boat will operate in, as extreme temperatures can affect the filler's performance.

By carefully selecting a filler that matches the boat's structure and resin type, you can ensure a strong and long-lasting repair for your fiberglass boat deck's soft spot. This process requires attention to detail and a good understanding of the materials involved to achieve a seamless and durable finish.

Exploring Nautical Terms: Synonyms for Small Boats

You may want to see also

Apply Filler: Follow manufacturer instructions, using a trowel or gun to fill the soft spot evenly

Before you begin the repair process, it's crucial to gather the necessary materials and tools. You'll need a suitable filler material specifically designed for fiberglass, such as a two-part epoxy or a fiberglass repair kit. These products are formulated to bond well with the fiberglass and provide structural integrity. Additionally, ensure you have a trowel or a gun (also known as a caulking gun) to apply the filler evenly.

Once you have your materials ready, carefully follow the manufacturer's instructions for the chosen filler. Typically, you'll start by cleaning the soft spot area to remove any dirt or debris. This step ensures proper adhesion. Then, apply a thin layer of primer to the prepared surface, allowing it to dry according to the product's guidelines. After the primer is set, you can begin applying the filler.

Using your trowel or gun, carefully spread the filler over the soft spot, ensuring an even and smooth surface. Work quickly but with precision to avoid any air bubbles. The filler should be applied in a thin, even layer, filling the void or damage completely. If needed, use a straight edge to guide your strokes and maintain a consistent thickness.

As you work, take the time to inspect your progress. Ensure the filler is level with the surrounding surface and smooth to the touch. If any imperfections or gaps appear, gently sand them down and reapply the filler until you achieve a seamless repair. Allow sufficient time for the filler to cure according to the manufacturer's instructions, typically several hours or overnight.

Once cured, carefully inspect the repair. Test the strength by gently tapping the area with a finger or a small tool. If the repair holds firm, you've successfully addressed the soft spot. However, if any issues persist or the repair seems weak, it's best to repeat the process or seek professional assistance to ensure a long-lasting solution.

Repairing Sticky Throttle Cables: A Boat Owner's Guide

You may want to see also

Sand and Smooth: After curing, sand the area to match the surrounding surface, preparing for final finishing

After the repair process is complete and the filler has cured, it's crucial to ensure a seamless finish to your fiberglass boat deck. The next step is sanding, which will help blend the repaired area with the original surface, creating a smooth and cohesive appearance. Here's a detailed guide on how to sand and smooth the repaired section:

Step 1: Choose the Right Sandpaper

Start by selecting the appropriate sandpaper for the job. For fiberglass, a fine-grit sandpaper is ideal, typically ranging from 400 to 600 grit. This grit range provides a smooth finish without being too aggressive, which could scratch the surface. You can find these grits in both wet/dry and dry varieties, with wet/dry sandpaper being more versatile for various applications.

Step 2: Lightly Sand the Repaired Area

Gently sand the cured filler and the surrounding area using the chosen sandpaper. Apply light, even pressure to avoid any uneven sanding or potential damage to the fiberglass. Work in small sections, ensuring you cover the entire repaired area and gradually move towards the edges. This process will help blend the repair seamlessly with the original deck surface.

Step 3: Check for Smoothness

As you sand, regularly check the surface to ensure it's becoming smooth and even. If you notice any rough patches or uneven areas, continue sanding until you achieve a consistent texture. It's important to be thorough during this stage to guarantee a professional-looking finish.

Step 4: Rinse and Inspect

Once you've finished sanding, rinse the area with water to remove any dust or debris. This step is essential to ensure a clean surface before the final finishing process. After rinsing, inspect the area closely to identify any remaining imperfections or uneven spots. These areas will need further attention to achieve a flawless result.

Step 5: Final Sanding and Preparation

If there are any remaining imperfections, use a finer grit sandpaper (e.g., 1200-1500 grit) to refine the surface further. This step ensures that the repaired area is completely smooth and ready for the final finishing process. Take your time during this stage to achieve the best results.

By following these steps, you'll effectively sand and smooth the repaired fiberglass boat deck, creating a seamless and professional-looking finish. Remember, patience and attention to detail are key during this process to ensure a successful repair.

Crick Boat Show: Know Before You Go

You may want to see also

Frequently asked questions

Repairing a soft spot on a fiberglass boat deck typically involves a process called "patching" or "re-glassing." Start by cleaning the affected area to remove any dirt or debris. Then, use a fiberglass repair kit that includes a filler or resin and a cloth or mesh. Apply the filler to the soft spot, ensuring it's level with the surrounding surface. Once it's cured, sand it down and repeat the process until you achieve a smooth finish. Finally, apply a clear coat or paint to protect the repair.

Soft spots on fiberglass boat decks can be caused by various factors, including water damage, UV exposure, chemical stains, or impact damage. Over time, the gelcoat layer can deteriorate, leading to a loss of structural integrity. It's important to identify the root cause to ensure effective repair.

For larger soft spots or holes, it's recommended to seek professional help or use a more extensive repair method. You can use a fiberglass repair kit as a temporary fix, but for a more permanent solution, consider re-glassing the entire area. This process involves removing the damaged section, laying new fiberglass cloth, and applying a new layer of resin and gelcoat.

Preventative maintenance is key to avoiding soft spots. Regularly inspect your boat deck for any signs of damage or wear. Keep the deck clean and dry, especially after exposure to water or harsh chemicals. Apply a protective coating or sealant to the gelcoat to enhance its durability. Additionally, ensure proper ventilation and avoid using abrasive cleaning tools that might scratch the surface.