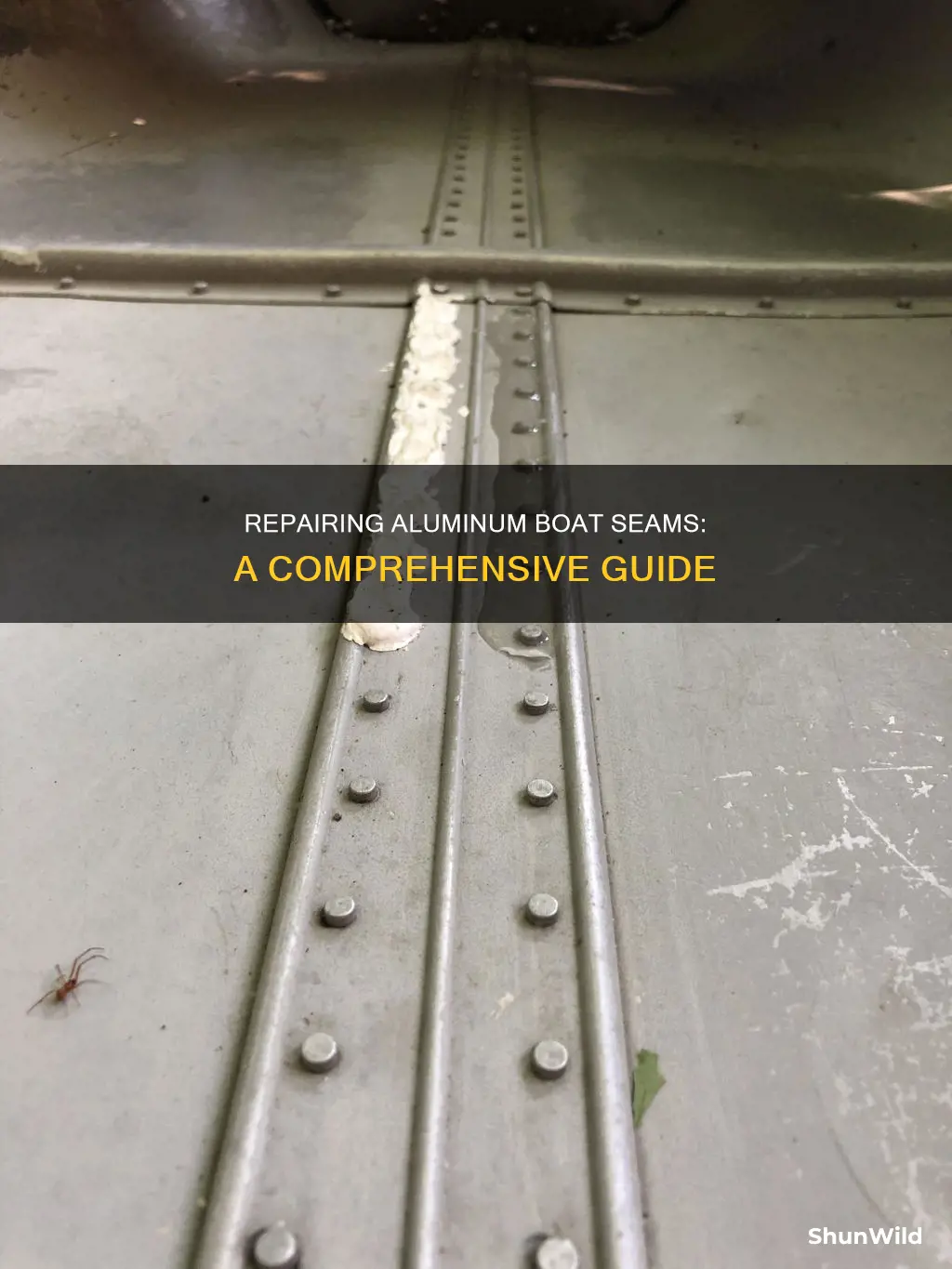

Aluminium boats are a popular choice due to their durability, sturdiness, and affordability. However, they require special maintenance as the material can corrode if not properly maintained. One of the challenges of owning an aluminium boat is repairing leaking seams. While epoxy is a common solution, it is only a temporary fix and not a long-term solution. For a permanent repair, a metal-to-metal bond is required. This can be achieved through welding using products like Super Alloy 5 and an oxyacetylene torch. Alternatively, one can use specialised epoxy products like G/flex or TotalBoat Aluminium Boat Leak Sealer, which are designed to repair leaking seams and rivets. Proper surface preparation and cleaning are crucial for successful repairs.

What You'll Learn

Using an oxyacetylene torch and Super Alloy 5

To repair an aluminium boat seam using an oxyacetylene torch and Super Alloy 5, follow the steps below:

Firstly, it is important to note that aluminium is a non-ferrous metal with a melting point of 1215°F. It is lightweight, strong, and corrosion-resistant, making it ideal for boat construction. However, aluminium boats can frequently experience issues such as cracks, tears, split seams, and leaky rivets. Super Alloy 5 is an effective solution for repairing these issues, as it can fill and build up holes, dents, voids, and other damage.

Before beginning the repair, ensure that you have the necessary equipment: an oxyacetylene torch, Super Alloy 5 powder flux, and an aluminium brazing rod. Set the acetylene to 5 PSI and the oxygen to 15-20 PSI. Clean the aluminium surface to conserve flux. It is important to keep the flame moving during the repair process to avoid blowing a hole through the material.

Heat the area surrounding the seam to ensure that the cold metal does not leach heat from your work area. Once the area is thoroughly heated, use the torch to heat the tip of the brazing rod. Dip the heated rod into the jar of flux, and then melt the flux onto the weld area. Start depositing the rod and add more flux as needed. The flux will assist with the bonding process and help create a watertight seal.

If you encounter any issues during the repair process, such as the rod balling up, it indicates that the parent metal is not hot enough. Knock off the ball and start again. By following these steps and using Super Alloy 5, you can easily repair your aluminium boat seam and create a strong, permanent repair.

The Horseshoe Casino Boat: A New Destination Unveiled

You may want to see also

Epoxy repair

Epoxy is a strong and waterproof substance, making it ideal for repairing an aluminum boat. However, it is not a long-term solution and will eventually peel off. Nevertheless, if you are looking for a quick fix, here is a step-by-step guide on how to repair an aluminum boat seam using epoxy.

Step 1: Identify the Leaks

Firstly, identify and mark the areas where the leaks are coming from. It is recommended to work on the seams and rivets from the inside of the boat so that gravity can help draw the epoxy through the leaking area.

Step 2: Prepare the Surface

Before applying the epoxy, it is crucial to prepare the aluminum surface. It must be clean, dry, and free of any dirt, dust, grease, loose paint, oils, or other contaminants. Sand the aluminum with 60-80 grit sandpaper within a 1-inch radius of the repair area until the metal appears shiny. Make sure to remove any residue from sanding before proceeding.

Step 3: Mix the Epoxy

For this step, you will need to use an epoxy specifically designed for aluminum boat repairs, such as the West System G/Flex 650-K Aluminum Boat Repair Kit or the TotalBoat Aluminum Boat Leak Sealer. Mix equal parts of the resin and hardener provided in the kit.

Step 4: Warm the Seam and Rivets

Using a heat gun or a propane torch, warm the rivets and the seam for a 12-inch to 18-inch long section. This will help the epoxy move along the seam and penetrate deeper into the gaps. Be careful not to overheat the epoxy, as it may discolor or begin to smoke.

Step 5: Apply the Epoxy

Load the mixed epoxy into a syringe or a caulking gun, depending on the product you are using. Apply a continuous bead of epoxy along the seam and around the rivet heads. If needed, apply heat again to thin the epoxy and help it move along the seam.

Step 6: Wipe Away Excess Epoxy

Use paper towels to wipe away any uncured excess epoxy from both sides of the seam. If necessary, use a solvent like lacquer thinner or acetone sparingly to remove stubborn epoxy, being careful not to wipe it out of the gaps.

Step 7: Allow the Epoxy to Cure

Let the epoxy cure overnight at a temperature of 65°F or warmer before using the boat again. You can speed up the curing process by applying moderate heat.

Step 8: Paint (Optional)

If desired, apply a spray paint designed for aluminum, such as Rustoleum® All Finishes, to match the existing color.

By following these steps, you can repair your aluminum boat seam using epoxy. However, keep in mind that this is a temporary solution, and you may need to repeat the process in the future.

Elves' Mysterious Boat Journey: Unraveling the Unknown

You may want to see also

Gluvit epoxy sealer

To use Gluvit epoxy sealer, follow these steps:

- Remove all contaminants from the repair area using a solvent or a strong detergent cleaner.

- Sand the area with 80-100 grit sandpaper to provide a profile for adhesion, then wipe the area with a clean, dry rag.

- (Optional) Fill deep holes (more than 1/8" in depth) with Marine-Tex Epoxy Putty before applying Gluvit.

- Mix the resin and hardener in a 5:1 ratio (by volume). If using the entire kit at once, add the entire contents of the hardener to the resin and mix thoroughly for 3-4 minutes.

- Apply Gluvit with a brush or roller to a thickness of 6-8 mils.

- (Optional) Lightly drag a foam brush in long, even strokes over the freshly applied coating to smooth the surface.

- Allow the coating to cure. Gluvit will harden overnight, but for maximum strength, allow 48 hours at 72°F.

Note that Gluvit must be painted after a full cure to provide maximum ultraviolet protection. Any marine paint or coating compatible with epoxies can be used.

Insuring Your Rowing Boat: Theft Protection Measures

You may want to see also

Brazing with HTS-2000

To use the HTS-2000 brazing rod, you will need a heat source such as propane or MAPP gas, a turbo tip, or oxy-acetylene. The melting point of the rod is 500 degrees lower than the surface of an aluminum boat, making it ideal for quick and easy repairs. Even holes can be filled due to the rod's anti-drip properties.

The HTS-2000 brazing rod is suitable for repairs on all types of aluminum boats and can also be used on other boat-related components like the engine, fuel tanks, and trailer. It is a no-flux brazing rod, which means there is no need for special brushes or mixes during the repair process.

The HTS-2000 is a high-strength brazing rod that provides stronger repairs than those achieved with a TIG welding machine. It is also more affordable than welding machines or buying new or used parts. With its easy one-page instruction sheet, anyone can perform aluminum repairs, regardless of experience level.

The HTS-2000 brazing rod is not just limited to aluminum repairs. It can also be used on cast aluminum, pot metal, copper, magnesium, and all white or porous metals. It can even repair corroded or oil-impregnated areas that are typically challenging to fix with conventional welding methods.

Horsepower on the Water: Calculating Boat Engine Strength

You may want to see also

Sealing with gutter sealant

Step 1: Clean the Seam

Before applying any sealant, it's important to prepare the area. Remove any debris, such as leaves or dirt, and ensure the seam is dry. This is crucial for the sealant to adhere properly.

Step 2: Choose a Suitable Gutter Sealant

Not all gutter sealants are created equal. When selecting a gutter sealant, consider the following:

- Waterproof capabilities: Ensure the sealant is designed to be waterproof, as it will be in constant contact with water.

- Ability to dry on wet surfaces: Look for a sealant that can cure in damp environments, as you don't want to risk the sealant failing due to moisture.

- Drying time: Faster drying times are generally preferable, but also consider the time needed to apply the sealant thoroughly.

- Removability: Choose a sealant that can be removed if needed for future repairs or adjustments.

Step 3: Apply the Sealant

Once you've selected the appropriate gutter sealant, carefully apply it along the seam. Ensure you cover the entire length of the seam, and don't be afraid to use a generous amount to create a strong seal. Use masking tape to create a neat bead along the seam, then use a small spreader to push the bead down and ensure it fills any gaps or crevices.

Step 4: Allow the Sealant to Cure

After applying the gutter sealant, give it enough time to cure and harden. Refer to the manufacturer's instructions for the recommended curing time, as it can vary depending on the product and environmental conditions.

Step 5: Inspect and Test

Once the sealant has cured, inspect the seam to ensure it is properly sealed. Look for any gaps or cracks in the sealant, and if necessary, apply an additional layer to ensure a watertight seal. Finally, test the boat in the water to ensure the seam is no longer leaking.

Remember, repairing an aluminium boat seam with gutter sealant is a relatively simple process, but it's important to take your time and follow the steps carefully to ensure a durable and effective repair.

Tartan's Resin Boat Journey: An Early Start

You may want to see also

Frequently asked questions

The best way to repair an aluminium boat seam is to use a metal-to-metal bond. You can use a product like Super Alloy 5, which is a permanent solution with a bonding strength of 30,000 psi. You will also need an oxyacetylene torch, Super Alloy 5 powder flux, and an aluminium brazing rod.

Epoxy is a rubbery substance that works for minor, temporary repairs. When it comes to aluminium boats, it is unreliable and will eventually fail. However, if you are looking for a quick fix, you can use an epoxy such as TotalBoat Aluminium Boat Leak Sealer, which can repair leaking rivets, cracks, and seams.

To identify the exact location of the leaks, fill your boat with water up to the waterline. If possible, fill one end of your boat and then the other to reduce the risk of causing damage or distorting the shape. Once you have identified the leaks, mark them with a waterproof marker.