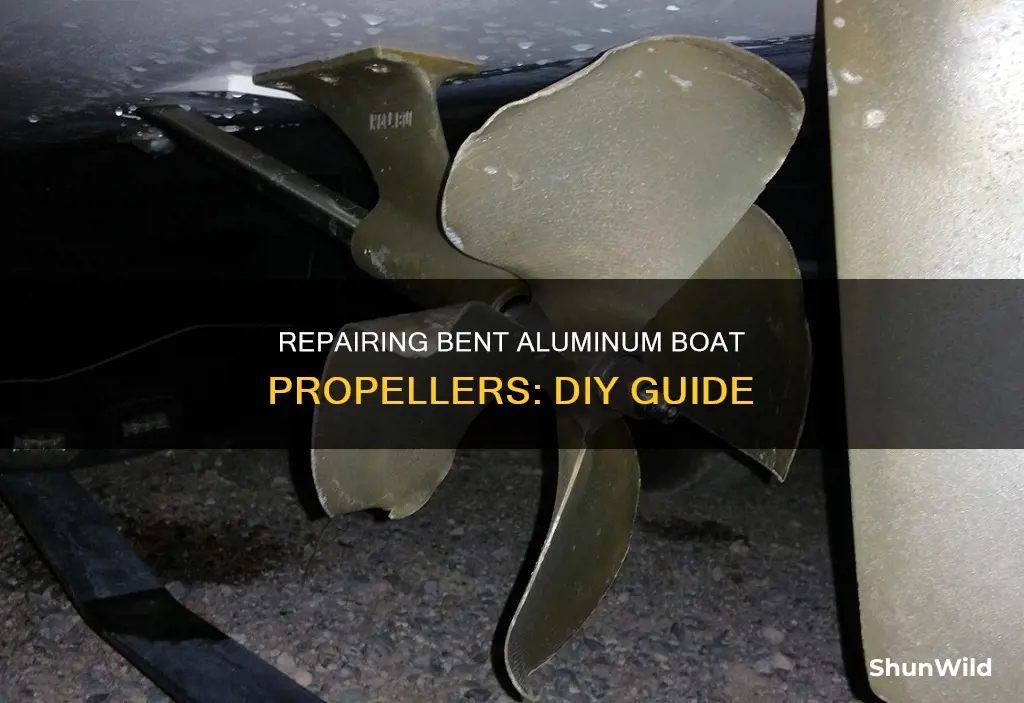

A bent boat propeller can cause a host of issues, including reduced performance, increased fuel consumption, and safety hazards. It is therefore important to know how to repair one. This article will outline the steps and precautions to repair a bent aluminum boat propeller. First, it is crucial to understand the causes of a bent propeller, which can include impact with objects in the water, running aground, misalignment, or age and wear. Before attempting any repairs, safety precautions such as turning off the engine, wearing protective gear, securing the boat, and disconnecting the battery should be taken. The repair process itself involves several steps, including inspecting the propeller, removing it, straightening minor bends, applying filler material, sanding, and finally testing the propeller.

How to Repair a Bent Aluminum Boat Propeller

| Characteristics | Values |

|---|---|

| Step 1 | Inspect the propeller |

| Step 2 | Remove the propeller |

| Step 3 | Straighten out minor bends |

| Step 4 | Apply filler material |

| Step 5 | Let the filler material dry |

| Step 6 | Sand the repaired area |

| Step 7 | Test the propeller |

| Safety Precautions | Turn off the engine, wear protective gear, secure the boat, disconnect the battery |

| Tools and Materials | Propeller repair kit, hammer, heat source, bench vise, grinder |

| Repair and Paint | Remove propeller, weld, grind, sand, apply primer, apply paint |

What You'll Learn

Remove the propeller

Removing the propeller

Before you start repairing a bent aluminium boat propeller, it is important to take safety precautions. Turn off the engine, wear protective gear, secure the boat, and disconnect the battery to prevent accidental electrical shock.

Now, you can begin the process of removing the propeller. First, mount the boat properly in a dry area that elevates the propeller to eye level. Ensure that you have easy access to the propeller and that the mounting is stable.

Next, cut off all power to the boat by removing the battery leads and disconnecting the wiring from the propeller. This step is crucial for your safety, as you risk serious injury if you work on a propeller that is still connected to a power source.

With the power off, you can start removing the propeller by taking off each small part that holds it to the boat. Remember that the blades are heavier than you might think, so have a safe place to rest them once removed.

After removing the propeller, you can proceed to inspect and repair or replace any damaged parts. Remember that even minor imperfections or dings can impact the performance and mechanical integrity of your boat.

Step-by-step guide to removing the propeller:

- Mount the boat properly: Place the boat in a dry area with the propeller at eye level. Ensure easy access and a stable mounting.

- Cut off all power: Disconnect the battery and wiring to prevent any accidental injuries.

- Remove the propeller entirely: Take off each small part holding the propeller to the boat. Be prepared for the weight of the blades.

- Check each part of the propeller: Inspect for broken, bent, or dented blades. Identify any problems that need to be addressed.

- Prepare for repairs or replacement: Once the propeller is off, you can decide on the next steps, whether it's straightening minor bends, applying filler material, or replacing blades.

St. Louis River Boat Tours: Open for Business?

You may want to see also

Check for cracks and other damage

When checking for cracks and other damage, it's important to remember that even small cracks can lead to serious consequences, including the total loss of the watercraft, loss of life, or delays. Therefore, propellers should be inspected for any signs of damage or wear.

Cracks can occur at various points on the propeller, but they typically start at points of highest stress, such as sharp edges, transitions from thick to thin metal, and areas that have been previously welded. The most common point of failure is where the blade joins the hub, but cracks can occur anywhere along the axis of the blade to the hub radius.

To check for cracks, you can use a variety of methods, including visual inspection, scanning with a probe, or using penetrating dye. Visual inspection may be challenging, as many cracks are hairline cracks that are difficult to spot. However, scanning with a probe or using penetrating dye can help identify these hard-to-see cracks.

If you do find a crack, it's important to have it repaired as soon as possible. A professional boat repair technician will be able to grind and weld the crack shut and ensure that there are no other cracks present. They may use eddy current testing, which can detect anomalies that are slightly subsurface, such as casting imperfections, and even estimate the depth of the anomalies in some cases.

In addition to checking for cracks, it's important to inspect the propeller for any other damage, such as dents, nicks, or bends. These types of damage can also impact the performance and safety of your boat, so they should not be ignored. If you notice any signs of damage, it's important to have the propeller repaired or replaced as soon as possible to avoid further issues.

Placing a Boat's Engine: Factors for Optimal Positioning

You may want to see also

Use a hammer to straighten out minor bends

To repair a bent aluminum boat propeller with a hammer, follow these steps:

First, it is important to inspect the propeller for any damage. Look for any bends, cracks, or nicks on the blades. If the damage is severe, it may be best to replace the propeller or seek professional repair services. Minor bends, however, can be straightened with a hammer.

Next, remove the propeller from the boat. Place it in a secure area where you have enough space to work on it. It is recommended to use a bench vise to hold the propeller in place while you work. This ensures stability and prevents further damage.

Now, it's time to straighten the minor bends with the hammer. Tap or hammer the bent areas of the propeller blades gently and soundly. Work the metal back to its original shape, using the unbent blades as a reference. It is crucial to be careful and avoid applying excessive force, as aluminum is a relatively soft metal and can crack or weaken if too much force is applied.

When straightening the bends, use another hammer or a body dolly to back up the bent blade. This provides support and helps you control the force of the blows. Work the metal slowly and patiently, checking the angle of the blade frequently to ensure you are achieving the correct shape.

Once you have straightened the minor bends, it is important to inspect the propeller again. Check all blades for equality in size, shape, and angle. Ensure that the propeller is balanced and there are no remaining imperfections that could affect its performance.

Finally, if you are satisfied with the repairs, reinstall the propeller and test it to ensure it is functioning correctly. It is important to note that this is a temporary solution, and you should consider taking the propeller to a professional prop shop for a more permanent repair or replacement.

The Intriguing Smirk: Boat Hull Design Secrets

You may want to see also

Sand the propeller

Sanding the propeller is an important step in the repair process, as it helps to smooth out any repaired areas and remove any excess filler material. Here is a detailed guide on how to sand an aluminium boat propeller:

Before beginning the sanding process, ensure you have the necessary safety gear, including protective gloves and eye gear. It is also important to work in a well-ventilated area to avoid inhaling any dust particles. Once you have protected yourself and your work area, you can begin sanding.

Start by using a coarse grit sandpaper, such as 120-grit, to remove any excess filler material and create a uniform surface. Sand the propeller until the entire surface becomes dull. This process may take some time, depending on the extent of the repairs and the amount of filler material used. Be sure to sand in the direction of the blades, as this will help create a smoother finish.

Once you have finished sanding with the coarse grit sandpaper, wipe down the propeller with a tack cloth to remove any dust particles or fingerprints. This step is important, as it will help create a clean surface for the next steps.

After sanding and wiping down the propeller, you will need to apply a primer. Spray three coats of aluminium oxide primer on the propeller, waiting 30 minutes between each coat for it to dry. Allow the primer to dry completely, which typically takes around three hours.

Once the primer is dry, you can move on to the next step, which is painting the propeller. Apply three to five coats of paint, waiting at least 15 minutes between each coat. It is important to follow the instructions on your chosen paint and allow the propeller to dry thoroughly before handling it.

By following these steps, you will be able to effectively sand and refinish your aluminium boat propeller, restoring it to a smooth and functional state. Remember to take your time, work in a safe and well-ventilated area, and always follow the instructions on any products you are using.

Understanding LAO: Boat Dock Acronym Explained

You may want to see also

Test the propeller

Once you have completed the repairs on your aluminium boat propeller, it is important to test it to ensure that it is functioning correctly and that your boat is safe to use. Here is a step-by-step guide on how to test your propeller:

Reinstall the propeller:

Carefully attach the propeller back onto the boat, ensuring that all the small parts are securely connected. The propeller must be completely installed before you can test it.

Disconnect power:

Before testing, make absolutely sure that all power is disconnected from the boat. Remove the battery leads and disconnect the wiring from the propeller to protect yourself from any risk of injury.

Test the propeller:

Now you can test the propeller to see if your repairs have been successful. This simple test will reveal if the propeller is functioning as it should.

Continue repairs if necessary:

If the test is unsuccessful, you may need to remove the propeller again and continue the repair job. This process may take a few attempts, so be patient and don't waste time replacing the propeller every time. Use your experience and judgement to determine when the repairs are complete.

Buy a replacement:

If, after several attempts, the propeller is still not functioning, it may be time to accept that it is beyond repair. You will then need to purchase a replacement propeller that matches your boat perfectly.

Safety precautions:

Always keep safety in mind when testing a boat propeller. Do not take any risks and follow all the necessary precautions, including disconnecting the power and wearing protective gear if necessary.

By following these steps, you can ensure that your repaired aluminium boat propeller is safe and ready to use.

Choosing the Right Anchor Chain for Your 29-Foot Sailboat

You may want to see also

Frequently asked questions

If you feel new or unusual vibrations in your boat, the propeller is one of the first things to check for damage. Other signs include reduced performance, increased fuel consumption, and strange noises.

It is recommended to go slow and return to the dock as soon as possible. Do not attempt to get the boat on plane, and if you feel abnormal vibrations, shut down the engine and call for a tow. Once you're back at the dock, remove the propeller and take it to a prop shop for professional repair.

Minor repairs can be done yourself with the right tools and safety precautions. However, for severe damage, it is best to seek professional help as specialized tools and machinery are required.