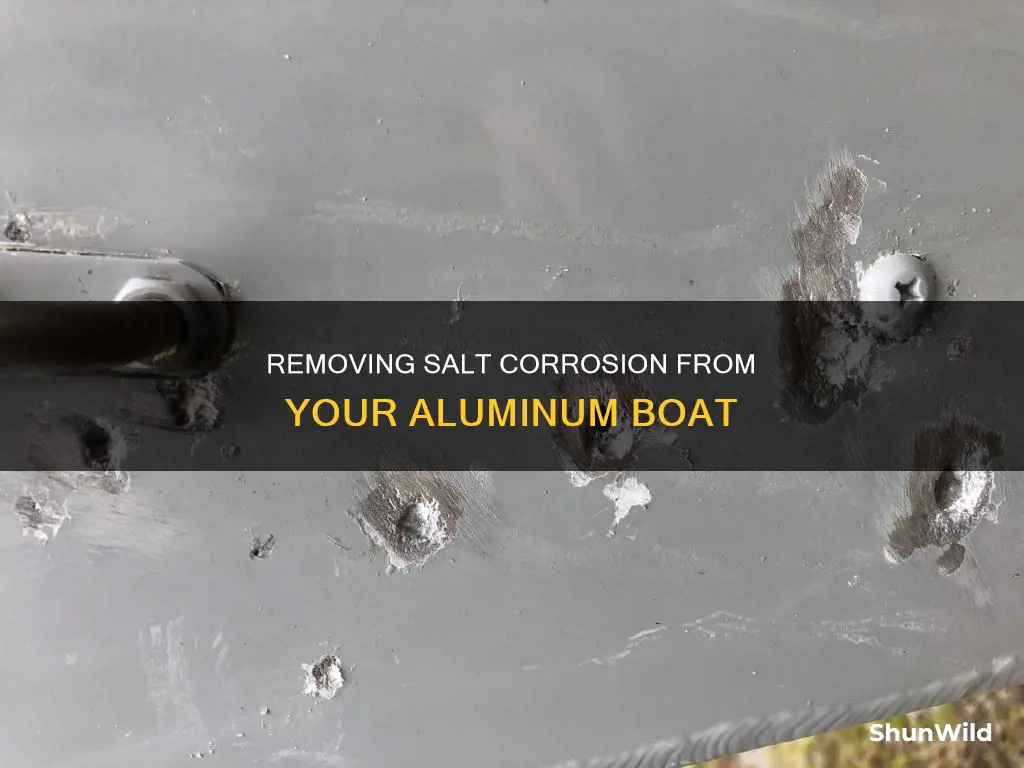

Aluminum boats are a popular choice for boat enthusiasts due to their affordability, lightweight, and durability. However, they are susceptible to corrosion when exposed to saltwater, which can cause significant damage if not addressed. This process, known as galvanic corrosion, is a result of aluminum's electrochemical properties, where it loses atoms when in contact with an electrically conductive solution like saltwater. To prevent and remove salt corrosion, proper maintenance is key. This includes regularly cleaning the boat with freshwater, using salt-removal products, and applying anti-fouling paint. Additionally, sacrificial anodes, which erode instead of the aluminum, can be attached to the boat for further protection. Taking these precautions can help extend the life of an aluminum boat and ensure safe and enjoyable boating experiences.

What You'll Learn

Rinse with freshwater

Rinsing your aluminium boat with freshwater after every use is one of the simplest and most effective ways to protect it from saltwater corrosion. This is because saltwater is a much more effective electrolyte than freshwater, and it is the presence of an electrolyte that enables galvanic corrosion to occur.

To ensure that you are effectively rinsing away the saltwater, you should pay particular attention to anywhere that water could pool, such as the bilge. It is also important to make sure that you are rinsing the whole boat, including the bottom and the hull. One way to do this is to flip the boat upside down, which will also allow you to clean the trailer bunks. If you are unable to flip the boat, you should at least ensure that the trailer bunks are covered in a solid material to separate the hull from the pressure-treated bunks.

If you are unable to rinse your boat with freshwater after every use, you should at least make sure that it is thoroughly dried. This will not prevent corrosion as effectively as rinsing, but it will help to slow the process.

It is also important to note that, while freshwater rinsing is an important step in protecting your aluminium boat from corrosion, it is not a substitute for other preventative measures, such as the use of protective coatings and sacrificial anodes.

A Battle on Water: Boat Fight Recap

You may want to see also

Use salt-removal products

Saltwater can and will corrode aluminum boats, so it's important to take steps to protect your vessel. One way to do this is by using specially made salt-removal products. These products are designed to not only remove salt deposits but also to form a protective layer that helps prevent further corrosion.

To find the right salt-removal product for your boat, start by researching trusted brands that specialize in marine maintenance. Look for products that are specifically formulated for aluminum boats and read reviews to get a sense of their effectiveness. It's important to select a product that is compatible with the other materials on your boat, such as the paint or any protective coatings you may have applied.

When using a salt-removal product, always follow the instructions provided by the manufacturer. This typically involves applying the product to the affected areas of your boat, allowing it to sit for a specified amount of time, and then rinsing or wiping it off. Some products may require multiple applications or specific techniques for optimal results.

In addition to salt-removal products, there are other measures you can take to protect your aluminum boat from saltwater corrosion. For example, regular cleaning with freshwater after each use can help prevent salt buildup and slow down the corrosion process. Proper maintenance, such as repairing any chips or scratches in the paint, will also help maintain the integrity of your boat's protective coatings.

By using a combination of salt-removal products and following maintenance best practices, you can effectively protect your aluminum boat from the damaging effects of saltwater corrosion and ensure its longevity for years to come.

The Best Seating Options for a Moving Boat

You may want to see also

Apply anti-fouling paint

Applying anti-fouling paint to your aluminium boat is a crucial step in preventing corrosion. Here are some detailed instructions to guide you through the process:

Preparation:

Firstly, you'll need to prepare the surface of your boat. This involves thoroughly cleaning and drying the aluminium hull. It is imperative that the hull is free of any salt residue, grime, or contaminants before applying any paint. If your boat has an existing coating, it is recommended to sandblast or sand down the surface to create a smooth base for the new paint.

Priming:

Once the hull is prepared, you'll need to apply a primer. The primer serves as a protective layer between the aluminium and the anti-fouling paint, helping to prevent galvanic corrosion. Choose a primer specifically designed for aluminium surfaces, and follow the manufacturer's instructions for application. It is common to apply multiple layers of primer, such as 4-6 coats, to ensure a thorough base.

Choosing the Right Anti-Fouling Paint:

When selecting your anti-fouling paint, it is crucial to choose a product specifically designed for aluminium boats. Some paints contain copper, which can cause corrosion on aluminium if not expertly applied. Look for copper-free options or seek advice from marine paint experts. Trilux 33 with Biolux, Seahawk Colorkote, and Interlux Micron CSC CA are some examples of anti-fouling paints suitable for aluminium boats.

Application:

Read and follow the manufacturer's instructions for your chosen anti-fouling paint. The paint application process may vary depending on the product. Generally, multiple thin coats are preferable to one thick layer. Ensure you have the right tools for application, such as brushes, rollers, or spray guns. Proper mixing and application techniques are essential to achieving the desired result.

Maintenance:

Remember that anti-fouling paint is not a permanent solution. Depending on your usage and environment, you may need to reapply the paint every few years. Regularly inspect your hull for any signs of corrosion or damage, and be mindful of any soft growth or barnacles that may accumulate over time.

By following these steps and choosing the right products, you can effectively apply anti-fouling paint to your aluminium boat, helping to prevent salt corrosion and maintain the integrity of your vessel.

Branson Duck Boat Tragedy: What Happened?

You may want to see also

Use sacrificial anodes

Sacrificial anodes are an effective way to protect your boat from corrosion. They are metal rods or electrodes that attract corrosion to themselves, thus protecting the boat's metal parts. The anode is made from a metal that is more easily corroded than the boat, and when connected to the boat, it draws corrosion away, sacrificing itself in the process. This process is called galvanic corrosion and occurs when two metals with different electrical activity levels are immersed in a conductive liquid, such as seawater.

Sacrificial anodes are available in zinc, aluminum, and magnesium. Aluminum is a popular choice for boat owners as it is lightweight, eco-friendly, and works in both saltwater and brackish waters. It also lasts longer than zinc, which is the traditional anode material. Aluminum anodes are now commonly used for all hull materials, thanks to new alloys developed by the US Navy. These alloys are more electrically active and offer better protection than zinc. They also use a less toxic activator, making them a more environmentally friendly option.

When choosing an anode, it is important to consider the type of water your boat will be exposed to. Zinc anodes are best suited for saltwater, while aluminum is a good choice for brackish water. If your boat is used in freshwater, magnesium is the best anode to use as it offers superior protection in low-conductivity liquids.

To ensure optimal protection, it is important to place the anodes strategically. They should be attached to all metal parts underneath the boat and remain submerged. They can be welded, bolted, or tied with brackets to keep them in place. It is also crucial to keep the anodes free from paint and other solvents, as this will hinder their conductivity.

Regular maintenance is key to preserving your boat. Sacrificial anodes should be replaced when they are approximately 50% corroded. This will ensure that your boat's metal parts remain protected. Additionally, it is a good idea to inspect your boat regularly, especially if it is docked in an area with many other boats, as this can cause anodes to corrode faster.

Tige Boats: Performance and Luxury Reviewed

You may want to see also

Avoid mixing metals

When it comes to maintaining an aluminum boat, it's crucial to understand the concept of galvanic corrosion, which is the arch-enemy of aluminum. Galvanic corrosion occurs when two dissimilar metals come into contact with each other in the presence of an electrolyte, such as saltwater. In this process, one metal acts as the anode and sacrifices its electrons to the other metal, the cathode, resulting in the breakdown and corrosion of the anode.

To avoid mixing metals and prevent galvanic corrosion on your aluminum boat, here are some essential guidelines:

- Avoid Direct Contact with Other Metals: Do not place other metals, such as copper or bronze, in direct contact with the aluminum hull. This includes metal hardware, fittings, and components. Use nylon isolators or similar methods to separate and isolate dissimilar metals.

- Choose Compatible Metals: When using metals in close proximity to aluminum, opt for zinc or magnesium. These metals are less active than aluminum and are less likely to cause a galvanic reaction.

- Use Sacrificial Anodes: Install sacrificial anodes made of zinc or aluminum alloy. These anodes will corrode instead of your aluminum hull, providing protection in both saltwater and freshwater environments.

- Avoid Treated Wood: Never allow aluminum to come into contact with pressure-treated wood. The copper in the treated wood can react with aluminum, causing oxidation and corrosion.

- Select Appropriate Hardware: When using hardware, such as screws or bolts, choose high-grade marine stainless steel, specifically 316 stainless steel. This grade has a lower voltage potential difference with aluminum, reducing the risk of galvanic corrosion.

- Proper Maintenance: Regularly inspect your boat for any cracks or scratches that expose bare aluminum. Repair these areas to prevent corrosion. Additionally, always rinse your boat with freshwater after saltwater use and ensure it is dried thoroughly.

- Avoid Mixing Metals in Bilge: Be cautious about what ends up in the bilge. A copper penny, bronze hook, or any other metal object can cause significant corrosion if it comes into contact with aluminum and saltwater.

- Use Compatible Paint and Coatings: Only use paint and coatings specifically designed for aluminum boats. Incompatible coatings can hinder the protective oxide layer that forms on aluminum.

- Avoid Exceeding Voltage Limits: When using impressed voltage to protect aluminum, do not exceed 1,300 millivolts. Higher voltages can increase the risk of galvanic corrosion.

- Use Proper Anode Placement: Ensure anodes are installed in the correct locations and are not painted or coated. Anodes need to be exposed to the electrolyte to function effectively.

By following these guidelines and being mindful of the metals that come into contact with your aluminum boat, you can effectively prevent galvanic corrosion and maintain the integrity of your vessel.

Ideal RPM for Timing a Boat Engine

You may want to see also

Frequently asked questions

To remove salt corrosion from your aluminum boat, you should clean it with fresh water after every use. You can also use specially made salt-removal products, which will remove salt residue and form a protective layer to prevent further corrosion.

Saltwater causes galvanic corrosion on aluminum boats, which may appear as pitting, especially when docked next to a boat made of a different metal.

To prevent salt corrosion, you can use anti-fouling paint, sacrificial anodes, and volatile corrosion inhibitors (VCI) during storage.

Salt corrosion can cause severe damage to your boat over time. It can affect the metal mast and rigging, wires, valves, and steering systems. It can also corrode the green wire (or grounding wire), fuel shut-off valve, shift and throttle cables, and navigation light sensor, which are critical for your safety.