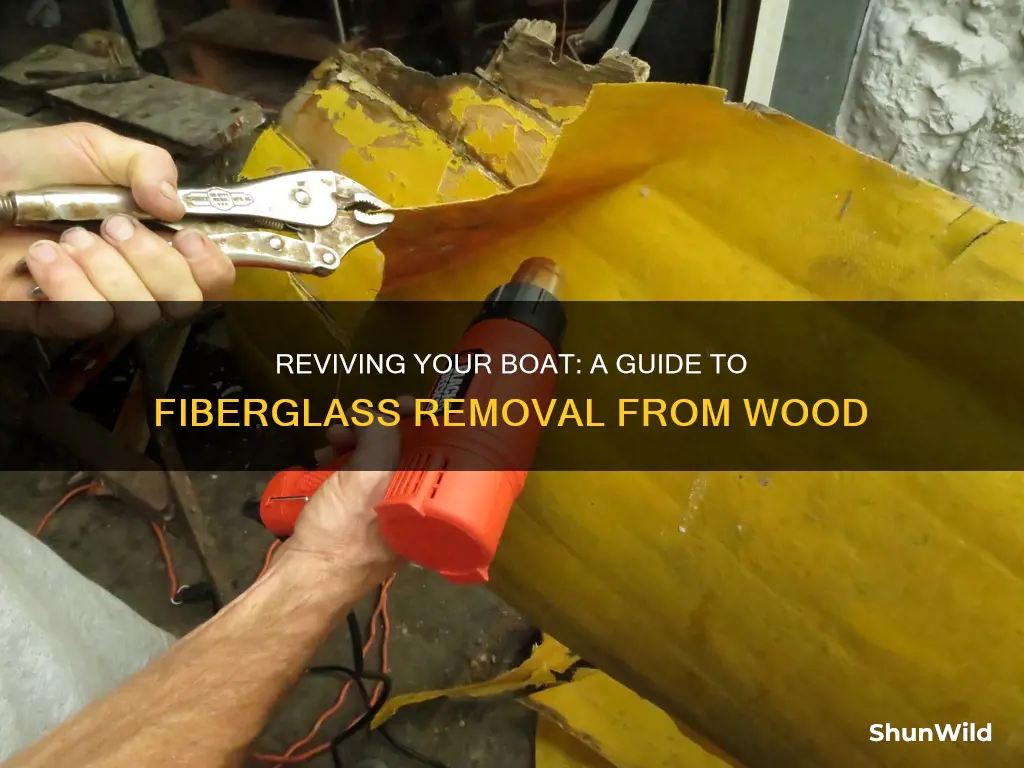

Removing fiberglass from a wooden boat is a delicate process that requires careful planning and the right tools. This guide will provide a step-by-step approach to safely and effectively remove the fiberglass, ensuring the preservation of the wooden structure. It's crucial to understand the potential risks and take necessary precautions to avoid damage to the boat and ensure a successful restoration.

What You'll Learn

- Safety Gear: Wear protective gear like gloves, goggles, and a respirator to avoid skin and lung irritation

- Chemical Agents: Use specific solvents like methyl ethyl ketone (MEK) or acetone to dissolve the fiberglass

- Scraping Technique: Employ a sharp blade or wire brush to carefully remove the fiberglass layer by layer

- Sandblasting: Consider using a sandblaster for faster removal, but ensure proper ventilation and safety precautions

- Wood Repair: After removal, inspect and repair any wood damage to ensure the boat's structural integrity

Safety Gear: Wear protective gear like gloves, goggles, and a respirator to avoid skin and lung irritation

When tackling the removal of fiberglass from a wooden boat, prioritizing safety is paramount. The process can be hazardous due to the potential release of harmful fibers and chemicals. To minimize risks, it's essential to wear appropriate protective gear.

Gloves are a crucial component of your safety arsenal. Opt for heavy-duty, latex, or nitrile gloves that provide a secure fit and offer protection against sharp edges and potential chemical exposure. These gloves will shield your hands from direct contact with the fiberglass, preventing skin irritation and potential cuts or punctures.

Eye protection is equally vital. Goggles or safety glasses will safeguard your eyes from airborne fiberglass particles and any splashes or spills. Look for impact-resistant goggles that provide a comfortable fit and ensure clear vision during the removal process.

Respiratory protection is often overlooked but is critical for your lung health. Fiberglass removal can release fine particles and volatile organic compounds (VOCs) into the air. Wearing a respirator mask with a suitable filter will trap these particles and prevent inhalation, reducing the risk of lung irritation and long-term health issues.

Additionally, consider wearing a full-body suit or coveralls to minimize skin contact and potential irritation. This protective clothing, combined with gloves and goggles, creates a comprehensive safety barrier, ensuring that you remain safe and healthy throughout the fiberglass removal process. Remember, taking these precautions will not only protect you but also ensure a more efficient and effective project completion.

Hull Numbers: Locating Your Boat's Identification Mark

You may want to see also

Chemical Agents: Use specific solvents like methyl ethyl ketone (MEK) or acetone to dissolve the fiberglass

When it comes to removing fiberglass from a wooden boat, chemical agents can be a powerful tool, but they should be used with caution and proper preparation. One effective method involves the use of specific solvents that can dissolve the fiberglass material.

Methyl ethyl ketone (MEK) and acetone are commonly recommended solvents for this task. These chemicals are known for their ability to break down the resin that holds the fiberglass together. MEK, also known as methyl ethyl ketone, is a clear, volatile organic compound that is highly effective in dissolving various resins. It is readily available in hardware and paint stores. Acetone, a clear, flammable liquid, is another excellent choice as it is a powerful solvent for many types of resins. Both solvents are relatively safe to use when handled properly, but it is crucial to follow safety guidelines and take necessary precautions.

To begin the process, ensure you have adequate ventilation in the work area. Wear protective gear, including gloves, goggles, and a respirator, to minimize direct contact and inhalation of the chemicals. Start by applying a generous amount of the chosen solvent to the fiberglass surface using a paintbrush or a spray bottle. Allow the solvent to penetrate the material for a few minutes, ensuring it seeps into the resin. The fiberglass should begin to soften and lose its structural integrity.

After the solvent has done its work, use a sharp tool, such as a utility knife or a specialized fiberglass removal tool, to carefully cut and lift the fiberglass away from the wooden boat's surface. Work in small sections to maintain control and avoid damaging the underlying wood. As you remove the fiberglass, wipe away any remaining solvent and debris to prevent further damage.

Remember, chemical agents should be used as a last resort, especially if the boat's wooden structure is valuable or delicate. Always test the solvents on a small, inconspicuous area first to ensure they don't cause any adverse reactions or discoloration. Proper research and understanding of the specific solvents' properties and compatibility with the boat's materials are essential before proceeding with the removal process.

Is the Pier Boat Open? Check for These Signs

You may want to see also

Scraping Technique: Employ a sharp blade or wire brush to carefully remove the fiberglass layer by layer

When it comes to removing fiberglass from a wooden boat, employing the right technique is crucial to ensure a thorough and safe process. One effective method is the scraping technique, which involves using a sharp blade or wire brush to carefully remove the fiberglass layer by layer. This technique requires precision and patience to avoid damaging the underlying wooden structure.

Start by assessing the extent of the fiberglass layer you need to remove. Carefully examine the boat's surface to identify the boundaries between the fiberglass and the wood. This initial inspection will help you plan the scraping process and ensure you don't accidentally remove too much of the wood.

Using a sharp blade, such as a utility knife or a specialized fiberglass removal tool, carefully cut along the edges of the fiberglass layer. Work slowly and steadily, making precise cuts to avoid cutting into the wood beneath. Take your time to ensure clean and controlled removal of the fiberglass. Once you've made the initial cuts, use the blade to carefully lift and peel off small sections of the fiberglass layer. This process might require some patience, but it ensures a controlled and safe removal.

Alternatively, a wire brush can be a powerful tool for this task. Wire brushes with stiff bristles can effectively scrape away the fiberglass layer. Apply firm pressure and move the brush in a steady, controlled motion. This method is particularly useful for larger areas, as it allows for quicker removal of the fiberglass. However, be cautious not to apply too much force, as it might damage the wooden boat.

Remember, the key to successful fiberglass removal is patience and precision. Take your time, work carefully, and inspect your progress regularly. This technique ensures that you can remove the fiberglass layer without causing harm to the wooden boat's structure. By employing the right tools and a steady hand, you can effectively transform your wooden boat by removing the unwanted fiberglass layer.

The Perfect Boat Tender Name: A Guide to Choosing Wisely

You may want to see also

Sandblasting: Consider using a sandblaster for faster removal, but ensure proper ventilation and safety precautions

Sandblasting can be an efficient method to remove fiberglass from a wooden boat, especially when dealing with larger surfaces or thicker layers of material. This process involves propelling a high-speed stream of abrasive particles, typically glass or aluminum oxide, onto the surface. Here's a step-by-step guide on how to approach this technique:

Preparation and Safety: Before starting, ensure you have the necessary safety gear, including a respirator mask, goggles, and protective clothing. Fiberglass dust can be harmful if inhaled, so proper ventilation is crucial. Set up your sandblaster in a well-ventilated area or consider using a portable industrial vacuum to capture the dust. It's essential to work in a controlled environment to minimize the risk of inhaling hazardous particles.

Technique: Begin by testing the sandblaster on a small, inconspicuous area of the boat to determine the appropriate pressure and distance. Adjust the nozzle to control the force and direction of the abrasive stream. Hold the sandblaster at a slight angle to the surface, moving it in a steady, consistent pattern. The goal is to remove the fiberglass layer without damaging the underlying wood. Be cautious and patient, as the process requires precision.

Removing Fiberglass: When using a sandblaster, the abrasive particles will dislodge and remove the fiberglass. The speed and force of the stream should be adjusted based on the thickness of the fiberglass layer. For thinner layers, a lower pressure might be sufficient, while thicker sections may require more power. Remember to work in small sections and take breaks to assess your progress and ensure the wood is not being damaged.

Post-Blasting Care: After sandblasting, thoroughly clean the boat's surface to remove any remaining dust or debris. This step ensures that the wood is prepared for further treatment or restoration. Additionally, consider applying a suitable wood preservative to protect the underlying structure.

While sandblasting can be an effective method, it requires skill and caution. Always prioritize safety and consider seeking guidance from professionals or experienced boat restorers to ensure the best results.

Uninstalling Springfield's Boat Seats: A Step-by-Step Guide

You may want to see also

Wood Repair: After removal, inspect and repair any wood damage to ensure the boat's structural integrity

After the fiberglass has been carefully removed from the wooden boat, a thorough inspection of the wood is essential to ensure the vessel's structural integrity. This process involves a detailed assessment of the boat's frame, hull, and any other wooden components that may have been affected by the removal process. The goal is to identify and address any potential issues to maintain the boat's strength and safety.

Begin by carefully examining the wooden structure for any signs of damage, including cracks, splits, delaminations, or weakened areas. Pay close attention to the joints and seams, as these areas are critical to the boat's stability. Look for any signs of water damage, as this could have led to rot or decay, which must be addressed promptly. Use a sharp eye and a keen sense of touch to identify even the smallest issues.

Once the inspection is complete, it's time to repair the wood. Start by cleaning the affected areas to remove any debris or loose fibers. This can be done with a wire brush or a scraper, ensuring that all loose material is eliminated. After cleaning, fill any holes or cracks with a suitable wood filler, choosing a product that matches the boat's wood type for a seamless repair. Allow the filler to cure according to the manufacturer's instructions.

For more extensive damage, such as deep cracks or structural weaknesses, consider using a wood repair kit specifically designed for marine applications. These kits often include a bonding agent, putty, and a hardening compound, providing a comprehensive solution for repairing the wood. Follow the kit instructions carefully, ensuring proper mixing and application techniques.

Finally, once the repairs are complete, sand the area gently to create a smooth surface. This step is crucial to ensure a seamless blend between the repaired wood and the surrounding structure. Properly prepared wood will accept new finishes and coatings, restoring the boat's appearance and functionality. Regular maintenance and inspections will also help preserve the boat's longevity.

Repairing Your Paddle Boat: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Removing fiberglass from a wooden boat requires careful planning and the right materials. Start by wearing protective gear, including gloves, goggles, and a respirator, as fiberglass can be harmful if inhaled. Use a sharp utility knife or a fiberglass removal tool to carefully cut along the edges of the fiberglass, being mindful of the wooden structure beneath. Gradually work your way around the boat, avoiding any sharp or sudden movements that could damage the wood.

Essential tools include a utility knife or a specialized fiberglass removal tool with a sharp blade. You'll also need a pair of gloves to protect your hands, safety goggles to shield your eyes, and a respirator to avoid inhaling fiberglass dust. Additionally, consider using a respirator mask to filter out airborne fibers.

Yes, there are chemical agents specifically designed for fiberglass removal. These agents can help soften the fiberglass, making it easier to cut or scrape away. However, always follow the manufacturer's instructions and take necessary safety precautions when using chemicals. Ensure proper ventilation and wear protective gear to minimize any potential risks.

To minimize damage to the wooden boat, work carefully and avoid applying excessive force. Use a gentle, sweeping motion when cutting or scraping to remove the fiberglass. Take your time and be patient, as rushing the process may lead to unintended consequences. Regularly inspect the wooden structure to ensure it remains intact.

Dispose of the removed fiberglass debris properly. Fiberglass can be hazardous, so it's essential to handle it with care. Place the debris in sealed bags or containers to prevent fiber release into the environment. Check local regulations for proper disposal methods, as some areas may have specific guidelines for hazardous waste.