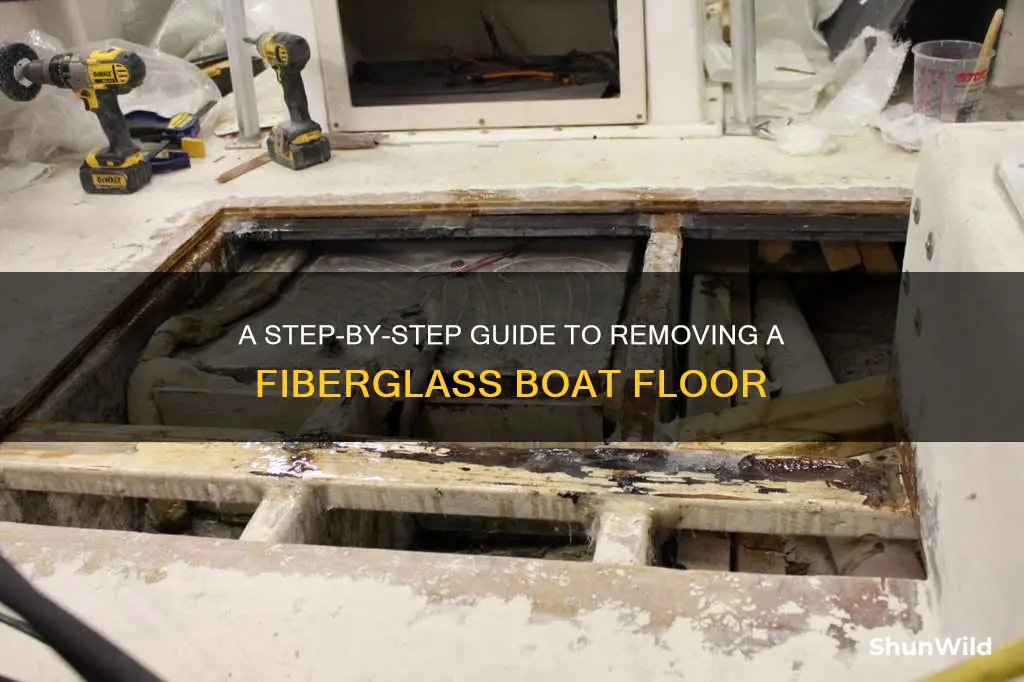

Removing the floor of a fiberglass boat can be a challenging but rewarding project for any boat owner. This process involves carefully dismantling the existing floor to access the underlying structure, which may include a wooden frame or a layer of insulation. It's crucial to understand the specific design of your boat to ensure a successful and safe removal. This guide will provide a step-by-step approach to help you navigate the process, including essential safety precautions and tips for handling the delicate fiberglass material.

What You'll Learn

Preparation: Gather tools, protect work area, and drain boat

Before you begin the process of removing the fiberglass boat floor, it's crucial to prepare the work area and gather the necessary tools to ensure a safe and efficient job. Start by identifying the tools you'll need, which may include a utility knife or a sharp blade for cutting, a screwdriver or a pry bar for prying, and a pair of gloves and safety goggles for protection. Additionally, you'll require a container or a bucket to catch any debris and a rag or cloth to wipe away any spills.

Protecting your work area is essential to prevent any accidents or damage to the boat's interior. Cover the floor and surrounding areas with a drop cloth or old newspapers to catch any falling fibers or debris. Ensure that the area is well-ventilated to avoid inhaling any harmful fumes. If possible, move the boat to a flat, stable surface to make the process easier.

Next, drain the boat to eliminate any potential hazards. This step is crucial for your safety and the safety of those around you. Locate the drain plugs and remove them to allow any remaining water to drain out. You can also use a bilge pump to assist in the drainage process, especially if there's a significant amount of water in the boat. Once the boat is drained, ensure that all electrical connections and systems are disconnected to prevent any accidents.

By following these preparation steps, you'll create a safe and organized environment for the upcoming task of removing the fiberglass boat floor. It's important to take these precautions to ensure a smooth and successful project.

Chaparral Boat Company: Who Owns This Boating Giant?

You may want to see also

Remove Fasteners: Loosen and remove screws, bolts, and clips

When preparing to remove the floor of a fiberglass boat, it's crucial to start by carefully loosening and removing the fasteners that secure the floor panels. These fasteners typically include screws, bolts, and clips, which are strategically placed to ensure a sturdy and secure installation. The first step is to identify the type and location of these fasteners. Most fiberglass boat floors use a combination of screws and clips, with screws often used for structural support and clips for a more secure grip.

Begin by inspecting the floor panels and locating the fasteners. Use a screwdriver or a tool designed for this purpose to carefully loosen the screws. It's important to apply the right amount of force to avoid stripping the screw heads. For bolts, you might need a socket wrench or a specialized tool to turn them counterclockwise. Loosen them gradually, ensuring they are not overtightened, as this can damage the surrounding structure. Once loosened, you can start to remove the fasteners one by one.

For screws, you may need to apply a small amount of force to pull them out, especially if they have been tightened over time. Be cautious not to force them out, as this could damage the fiberglass. For clips, you might need to use a flathead screwdriver or a tool with a thin, flat edge to pry them off gently. Some clips might be difficult to remove, so you may need to apply a bit of pressure while carefully prying. It's essential to be gentle to avoid damaging the fiberglass surface.

As you remove each fastener, set it aside safely. Keep track of the order in which you remove them to ensure you can re-install them in the same positions later. This organized approach will make the re-installation process much easier. Remember to work systematically, panel by panel, to ensure you don't miss any fasteners and to maintain a consistent approach throughout the process.

Once all the fasteners are loosened and removed, you'll have access to the interior of the boat, allowing you to proceed with the next steps of your project, such as inspecting the floor for damage or preparing for any repairs or replacements.

Bass Boat Hull Separation: A Step-by-Step Guide

You may want to see also

Lift Floor: Carefully lift and pry floor panels free

When it comes to removing the floor of a fiberglass boat, one of the most crucial steps is carefully lifting and prying the floor panels free. This process requires patience, precision, and a systematic approach to ensure you don't damage the boat's structure or any of its components. Here's a detailed guide on how to execute this step effectively:

Step 1: Prepare Your Tools and Materials

Before you begin, gather the necessary tools and materials. You'll need a flat-head screwdriver, a pry bar, and a set of rubber gloves for protection. Additionally, have a helper or a second person assist you during this process, as lifting the floor panels alone can be challenging.

Step 2: Identify the Fasteners

Locate the fasteners that hold the floor panels in place. Fiberglass boat floors often use a combination of screws, bolts, and clips. Carefully inspect the floor panels and identify the specific fasteners used in your boat model. This knowledge will guide your prying technique.

Step 3: Start at the Edges

Begin the lifting process at the edges of the floor panels. Carefully insert the flat-head screwdriver or pry bar between the floor panel and the boat's structure, starting from a corner or an edge. Gently pry upwards to create a small gap. Be cautious not to apply excessive force, as this could lead to damage.

Step 4: Work Your Way In

Once you've created a small opening, work your way along the panel, prying and lifting gently. Use your pry bar to carefully lift the panel, ensuring you don't catch any cables, wires, or other components. Take your time and be methodical to avoid any mishaps.

Step 5: Secure the Panel

As you lift each panel, secure it in a safe place. You can use a rope or a strap to hold it temporarily. This prevents the panels from falling and potentially causing injury or damage.

Step 6: Repeat the Process

Continue this process for each floor panel, working systematically across the boat. Remember to be gentle and patient, as rushing could lead to mistakes. If you encounter any stubborn fasteners, use the appropriate tool to carefully remove them without causing damage.

By following these steps, you'll be able to carefully lift and pry the floor panels free, setting the stage for the next phase of your boat floor removal project. Remember, this process requires a gentle touch and a systematic approach to ensure a successful outcome.

Unraveling the Mechanics: How Boat Watches Keep Time Afloat

You may want to see also

Inspect Damage: Check for damage, rot, or water intrusion

When preparing to remove the floor of a fiberglass boat, a crucial step is to thoroughly inspect the structure for any signs of damage, rot, or water intrusion. This process is essential to ensure the safety and longevity of the boat, as well as to prevent further issues during the removal process. Here's a detailed guide on how to inspect for these potential problems:

Visual Inspection: Begin by carefully examining the entire boat's interior. Look for any visible signs of water damage, such as discolored or warped surfaces, especially in areas where water might have accumulated, like the bilge or beneath the seats. Check for soft or spongy spots on the floor, as these could indicate rot or water damage. Pay close attention to the seams and joints where the floor meets the sides and transom, as these areas are prone to leaks and water intrusion. Use a flashlight to illuminate dark corners and crevices, as water damage might be hidden.

Test for Moisture: Moisture meters are invaluable tools for this inspection. These devices can detect the presence of moisture in the fiberglass, even if it's not visible to the naked eye. Scan the floor with a moisture meter, ensuring you cover all relevant areas. Moisture readings indicate potential water intrusion or hidden rot, which could compromise the structural integrity of the boat.

Check for Structural Damage: While inspecting, also assess the overall structure of the boat. Look for any signs of corrosion or damage to the hull, especially around the floor attachment points. Check the condition of the stringers and ribs, as they provide structural support to the floor. If you notice any significant damage or deterioration, it might require additional repairs before the floor removal process can begin.

Document the Condition: As you inspect, take detailed notes and photographs of any damage or areas of concern. This documentation will be crucial for planning the repair and removal process. It also helps in identifying the extent of the issue, ensuring that no hidden damage is overlooked.

Safety Precautions: When inspecting, always wear protective gear, including gloves and eye protection, to avoid any potential hazards. Work in a well-ventilated area, and ensure proper ventilation during the inspection, especially if using any chemicals or cleaning agents.

By following these steps, you can ensure that the fiberglass boat floor removal process is approached with a comprehensive understanding of the boat's condition, allowing for a more efficient and effective repair process.

Replacing a Lost Boat Title: A Comprehensive Guide

You may want to see also

Replace or Repair: Decide on replacement or repair, then proceed

When it comes to maintaining or repairing your fiberglass boat, one common task you might encounter is removing the floor. Whether you're planning to replace it entirely or just need to fix a damaged section, understanding the process is crucial. Here's a step-by-step guide to help you decide between replacement and repair:

Assess the Damage: Before you begin, inspect the fiberglass floor thoroughly. Look for any signs of damage, such as cracks, holes, delamination (where the fiberglass layers separate), or significant wear and tear. Take note of the extent and location of the damage. If it's limited to a small area, repair might be a viable option. However, if the damage is widespread or the floor is severely compromised, replacement could be necessary.

Consider the Boat's Condition: Evaluate the overall condition of your boat. If the damage to the floor is accompanied by other structural issues or if the boat is old and has accumulated significant wear, it might be more cost-effective to replace the floor as part of a larger restoration project. On the other hand, if the boat is relatively new and well-maintained, repairing the floor might be sufficient.

Decide on Replacement: If the damage is extensive or the floor is beyond repair, replacement is the logical next step. Start by carefully removing any existing hardware and fasteners that secure the floor. This process may vary depending on the boat model and design. Once the old floor is completely removed, ensure the underlying structure is clean and free of debris. Then, measure and cut new fiberglass flooring to fit the boat's dimensions accurately. Use a suitable adhesive to bond the new floor in place, following the manufacturer's instructions.

Repairing the Floor: For minor damage, such as small cracks or holes, repair is the appropriate approach. Clean the affected area to remove any dirt or debris. Then, use a suitable fiberglass repair kit, which typically includes a filler compound and a hardening agent. Follow the kit instructions to fill the damage, ensuring it's level with the surrounding surface. Once the filler is dry, sand it smooth and prepare the area for re-finishing or painting.

Remember, the decision to replace or repair should be based on the severity of the damage and the overall condition of your boat. If you're unsure, consulting with a professional marine technician or a fiberglass specialist can provide valuable guidance tailored to your specific situation.

Boat Battery Maintenance: Essential Care Tips for Boaters

You may want to see also

Frequently asked questions

Removing the floor of a fiberglass boat requires careful preparation and the right tools. Start by ensuring the boat is dry and you have the necessary safety gear, such as gloves and eye protection. Use a utility knife or a specialized fiberglass cutter to carefully cut along the seams and edges of the floor panels. Work in small sections to avoid damaging the surrounding structure. Once the cuts are made, gently pry the panels loose using a flathead screwdriver or a plastic tool to avoid scratching the fiberglass. Take your time and be patient to ensure a clean removal process.

If the floor is glued to the boat's structure, you'll need to use a different approach. Begin by identifying the type of adhesive used. For most epoxy-based glues, you can use a heat gun or hairdryer to soften the adhesive, making it easier to lift the floor panels. Alternatively, you can carefully scrape off the excess glue with a putty knife, being cautious not to damage the fiberglass. Always test the adhesive removal process in an inconspicuous area first to ensure it doesn't affect the boat's finish.

Yes, having the right tools can make the process smoother. A fiberglass cutter or a sharp utility knife with a disposable blade is ideal for cutting through the seams. A flathead screwdriver or a plastic pry bar can be used for prying the panels loose. Additionally, consider using a respirator mask and safety goggles to protect yourself from any potential fiberglass dust during the removal process.

To minimize damage, it's crucial to work carefully and methodically. Take your time when cutting and prying to avoid applying excessive force. If you encounter any stubborn areas, consider using a thin-walled putty knife or a specialized fiberglass removal tool to gently lift the panels. Regularly inspect the boat's interior to ensure no damage has occurred, and consider applying a protective layer of fiberglass repair compound to any affected areas before reinstalling the floor.