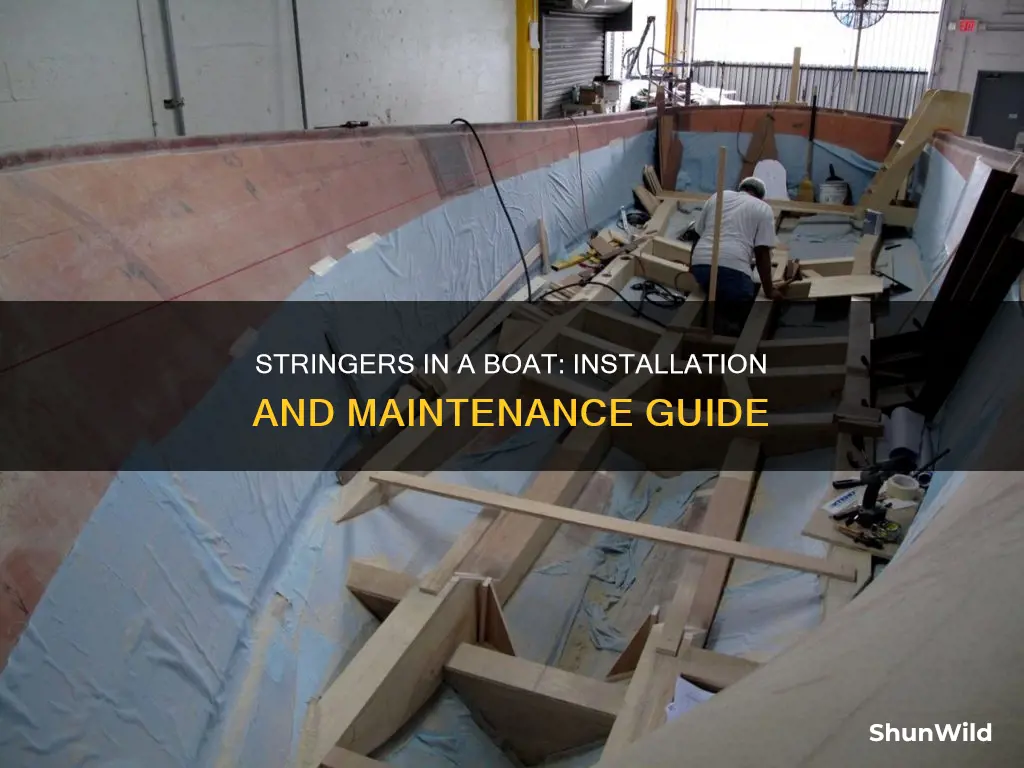

Boat stringers are an essential part of a boat's structure, providing support for the deck, hull, and other components. They are similar to the floor joists in a house, acting as the 'spine' of the boat. Stringers are usually made of wood, wood that has been fibreglassed, or entirely of fibreglass. Over time, wooden stringers can rot, and will need to be replaced. Replacing stringers is a complex and messy job, and it is important to mimic the boat's original construction as closely as possible when making repairs.

What You'll Learn

How to identify rotten stringers

Rotten stringers can cause serious issues for boats, compromising the integrity of the hull and leading to safety issues. As such, it's important to be able to identify rotten stringers. Here are some ways to do so:

Firstly, it's important to note that different types of stringers will show different signs of rot. For instance, bare wooden stringers will show rot and cracks more easily than those sealed in epoxy or fibreglass. For fibreglass-encased wooden stringers, look for impact damage, cracks or breaks in the encasement, and drill a small hole to inspect the wood for wetness or rot. Reseal any holes drilled to prevent water from penetrating the stringer.

One clear sign of a rotten stringer is brown spots, indicating that water is weeping from the inside out. Soft spots on the deck, delaminating fibreglass, age, poor-quality original stringers, and a bilge that stays filled with water can also indicate a rotten stringer. However, these issues could also indicate rotten deck material, so further inspection is necessary.

If your boat has inboard engines, a rotten stringer will likely require a full replacement. When replacing stringers, it's important to use the original wood type and dimensions, and to fit the new stringer in the exact location as the old one.

For fibreglass stringers, look for structural damage such as breaks in the encasement. You should also inspect the core, particularly if it is wooden, for signs of rot or impact damage.

The Integrity's Uncertain Fate: A Boat's Disappearance

You may want to see also

How to cut out old stringers

Before you cut out old stringers, you'll need to cut off the deck. This is one of the most stressful parts of the job because if you cut too deep, you risk piercing the hull. Set the saw blade to the correct height so you don't cut through the hull. Delicately drill a hole in the deck and measure its thickness with a probe. Then set the saw blade to cut through that depth and no more.

Now you're ready to cut out the old stringers. The wood that used to be inside them has likely turned into a gelatinous mess of rot, so you'll mostly be dealing with the fibreglass shell that used to surround them. Depending on how well the boat was laminated and how it has withstood the test of time, it may be possible to simply rip out the remainder or bang them out. Otherwise, you'll have to shave them down along the hull and then grind away the remnants.

Once the old stringers have been removed, it's time for grinding and sanding. Grind and sand the inside of the hull to get a good secondary bond between the new stringers and the hull. You'll need to create a clean surface, so grind away all the glass from the old stringers and then sand until you're working with a "new" surface free of contamination and obstructions. Be careful with the grinder, as too much pressure in one spot for too long could cause you to grind through the hull.

Mark and re-mark the stringer locations as necessary. The easiest way to do this is to make your marks well outside the area being prepped so you don't sand away your markings.

Hansen Trawler: A Good Boat Option?

You may want to see also

How to prepare the boat's hull for new stringers

Preparing the hull of your boat to install new stringers is a complex process that requires a basic knowledge of working with wood and fibreglass. It is a messy and challenging job, but it is not impossible. Here is a step-by-step guide on how to prepare your boat's hull for new stringers:

Step 1: Remove the Deck

The first step is to cut off the deck of your boat. This can be a stressful task as you need to be careful not to cut too deep, especially near the sides and bow, to avoid piercing the hull. It is recommended to drill a small hole in the deck first and measure its thickness with a probe. Set your saw blade to cut through that depth and no more. If your boat has a fuel tank built-in, be extremely cautious to avoid cutting the tank or its lines.

Step 2: Measure and Cut the Core for New Stringers

You want to duplicate the old stringers as closely as possible. Make a rough cut of the new stringer core, put it next to the old stringer, and then modify it as needed. Don't forget that the fibreglass skin will increase the size of the stringer. Cut away a sample of the old fibreglass stringer skin to determine the thickness and number of layers. Also, duplicate any limber holes at the bottom of the stringers and coat the inside with resin to prevent water soaking.

Step 3: Remove the Old Stringers

The old stringers are likely to be a gelatinous mess of rot, so you will mostly be dealing with the fibreglass shell. Depending on how well the boat was laminated, you may be able to rip or bang out the remnants. Otherwise, you will need to shave them down along the hull and then grind away the remaining pieces.

Step 4: Grind and Sand the Hull

To get a good secondary bond between the new stringers and the hull, you must create a clean surface. Grind away all the glass from the old stringers and then sand the hull thoroughly. Be careful not to apply too much pressure in one spot for too long, as you may grind through the hull. Mark and re-mark the stringer locations to ensure you don't sand away your markings.

Step 5: Prepare the Surface for Bonding

Choose solvents and preparation methods following the fibreglass resin manufacturer's instructions. Prepare a jig to support the stringers as the bedding dries and set it aside. Use putty or epoxy to create fillets at all 90-degree angles so that the fibreglass has a radius to lie against.

Now that you have completed these steps, you are ready to install the new stringers! Remember to always wear protective equipment and follow safety guidelines when working with these materials.

Best Chiswick Spots to Watch the Boat Race

You may want to see also

How to install new stringers

Stringers are an essential part of a boat's structure, providing support for the deck, hull, and other components. They are often referred to as the "spine" of the boat. Over time, wooden stringers may rot and need to be replaced. Here is a step-by-step guide on how to install new stringers:

Step 1: Cut Off the Deck

This is a delicate process as you need to be careful not to cut too deep and pierce the hull. First, determine the thickness of the deck by drilling a small hole and probing it. Set your saw blade to cut through that depth. Be mindful of any fuel tanks, wiring, or cable runs that may be located underneath the deck. In most cases, you will need to remove the deck completely and replace it along with the stringers.

Step 2: Measure and Cut the New Stringers

Duplicate the measurements of the old stringers as closely as possible. Use marine plywood or fiberglass sheets to cut the core for the new stringers. Don't forget to account for the thickness of the fiberglass skin that will be applied later. Cut away a sample of the old fiberglass stringer to determine the thickness and number of layers. Also, remember to duplicate any limber holes at the bottom of the stringers. Coat the inside of these holes with resin to prevent water seepage.

Step 3: Remove the Old Stringers

This step can vary in difficulty depending on how well the boat was laminated. You may need to rip or bang out the old stringers, shave them down along the hull, or grind away the remnants. This will be a messy process.

Step 4: Grind and Sand the Inside of the Hull

Create a clean surface by grinding away all the glass from the old stringers. Sand the area thoroughly to ensure a good secondary bond between the new stringers and the hull. Be careful not to apply too much pressure with the grinder in one spot for too long, as you may accidentally grind through the hull.

Step 5: Prepare the Surface for Bonding

Follow the manufacturer's instructions for solvents and preparation methods. Pre-prep a jig to support the stringers as the bedding dries. Use putty or epoxy to create fillets at all 90-degree angles, providing a radius for the fiberglass to lie against.

Step 6: Install the New Stringers

Bed the core of the new stringers in thickened epoxy or fiberglass putty. Put the stringers in place and add the jig pieces to support them. Form a "fillet" or radius along the bottom edges of the stringers to provide a curved surface for the fiberglass to adhere to. Add more epoxy or putty as needed.

Step 7: Apply the Fiberglass Stringer Skin

Cut fiberglass cloth to wrap the stringers and extend on either side ("tabbing"). Apply multiple layers, making each consecutive layer slightly smaller than the previous one for a stepped effect. Wet out the stringer cores with fiberglass resin and center the cloth layers, following the manufacturer's instructions.

Step 8: Finishing Touches

Once the fiberglass has cured, sand or grind any jagged edges or fiberglass hairs to ensure a smooth finish. Replace the deck and perform any necessary finish work.

Additional Tips:

- Always try to mimic the boat's original construction when replacing stringers. Deviating significantly from the original design can lead to hull damage or structural failure.

- It is generally recommended to replace the entire stringer rather than just a portion of it. Stringers are under a lot of stress, and a partial replacement may not be strong enough.

- If you are working with wooden stringers, use a marine-grade bonding agent and screws or epoxy glue to hold the components together.

- For fiberglass stringers, cut new sheets to match the original dimensions and thickness, coat them with epoxy, and fasten them in the exact location as the old stringers.

Exploring Barcelona: Sagrada Familia to the Cruise Port

You may want to see also

How to seal gaps between stringers

Sealing the gaps between the stringers of a boat is an important step in boat maintenance. Stringers are an essential part of a boat's structure, providing support to the deck, hull, and other components. They are often made of wood, wood with a fibreglass coating, or entirely of fibreglass.

- Prepare the Boat: Before sealing any gaps, it is important to ensure that the boat is clean and dry. Remove any old or damaged stringers, and sand the hull to create a smooth surface for the new stringers to adhere to.

- Measure the Gaps: Take accurate measurements of the gaps between the stringers. This will help you determine the amount of sealing material needed and ensure a precise fit.

- Choose a Suitable Sealant: Select a sealant that is specifically designed for boat repairs and compatible with the materials of your boat's stringers. Epoxy resin or fibreglass putty are commonly used for sealing gaps between stringers.

- Apply the Sealant: Follow the instructions provided with your chosen sealant for mixing and application. Carefully fill the gaps between the stringers with the sealant, ensuring that it adheres to both surfaces.

- Smooth and Level the Sealant: Use appropriate tools, such as putty knives or rollers, to smooth out the applied sealant. Ensure that it is level with the stringers and fills the gap completely.

- Allow the Sealant to Cure: Refer to the manufacturer's instructions for the recommended curing time. Do not disturb the sealed areas during this period to ensure proper adhesion and hardening.

- Sand and Finish (if needed): Once the sealant has cured, you may need to sand the area for a smoother finish. This step may be necessary if you plan to paint or coat the stringers and the surrounding area.

- Test and Inspect: After sealing the gaps, test the boat on the water to ensure that the repairs are successful. Inspect the sealed areas for any signs of leakage or damage.

By following these steps, you can effectively seal the gaps between the stringers of your boat, ensuring its structural integrity and preventing water damage. Remember to choose materials compatible with your boat's construction and always work in a well-ventilated area when using sealants and adhesives.

Navigate Your Boat: Creek to Open Water

You may want to see also

Frequently asked questions

Boat stringers are frame components that extend along the hull's length. They are similar to floor joists and provide support for the deck, hull, and other boat components.

Look out for brown spots, soft spots on the deck, or impact damage. For wooden stringers, check for structural damage like rot and cracks. For fibreglass stringers, look for breaks in the encasement.

For wooden stringers, cut marine-grade plywood to the size your boat requires. Apply a marine-grade bonding agent and use screws or epoxy glue to hold the components together. For fibreglass stringers, cut new sheets to match the original stringers' dimensions and thickness, coat them with epoxy, and fasten them in the exact location as the old stringers.

While it is technically possible to replace only part of a boat stringer, it is generally recommended to replace the entire thing. Stringers are under a lot of stress, and replacing only part of them may not be strong enough to handle the boat's weight and the impact of waves.