Non-skid surfaces are an essential component of boat design, providing safety and comfort for those on board. There are a variety of non-skid options available for boat floors, each with its own advantages and disadvantages. For example, boat carpet is soft and quiet but can trap moisture, leading to mould and rot. Grit non-skid offers good traction when dry but loses some grip when wet. Teak is a traditional option that offers good traction but tends to take longer to dry than other materials. Synthetic teak decking is a modern alternative that is durable, quiet, and stain-resistant. Other options include non-skid paint, adhesive sheets, interlocking floor tiles, and slip-resistant tapes. When choosing a non-skid solution, it's important to consider the type and size of the boat, the desired level of skid resistance, durability, ease of installation and maintenance, and UV resistance.

| Characteristics | Values |

|---|---|

| Non-skid material | Marine carpet, EVA foam, rubber, paint, tape, tread, gelcoat, diamond pattern, teak, faux teak, grit, fiberglass, PVC, TPO, contact cement, adhesive, sealant |

| Installation method | Peel and stick, glue, brush, roller, pour |

| Brand | 3M, KiwiGrip, Matson, Home Depot, SkidGuard, Sherwin Williams, Grady-White, SeaDek, Attwood, LifeGrip, TotalBoat, Dri-Dek, Treadmaster, Whitecap, Interlocking Tiles, Safety-Walk, Lewmar, Poli Grit, Poli Wash, Poli Ox, Poli Super Spray, Flexiteek, Sea Ray, PowerQuest, Sea Pro |

What You'll Learn

Non-skid paint

Step 1: Prepare the Surface

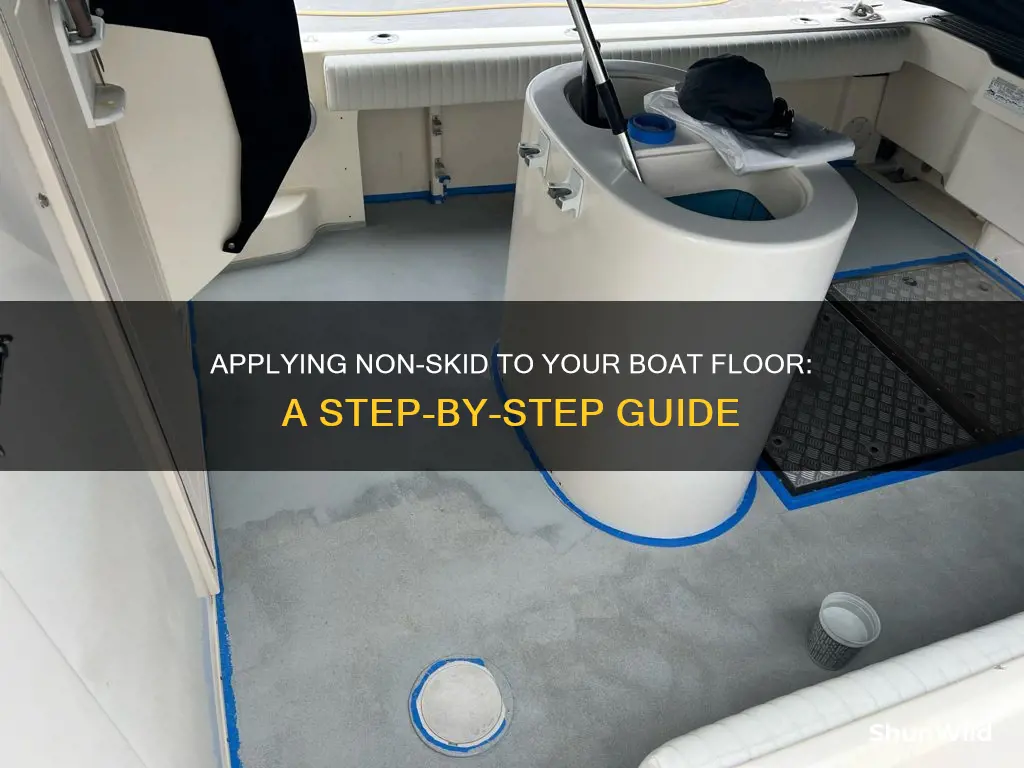

Before applying non-skid paint, it's important to ensure that the surface is clean and properly prepared. Start by removing any surface contaminants using a clean rag wetted with a dewaxer and surface prep solution. Then, lightly abrade the surface with a Scotch-Brite pad. Finally, wipe the surface with a suitable brushing thinner to ensure it is clean and ready for painting.

Step 2: Prime the Surface (if necessary)

Priming is not always necessary, but if you are painting over a metal surface or a previously painted surface, it is recommended to apply a suitable primer. For metal surfaces, you can use an epoxy primer, a barrier coat, or a specialized metal primer, depending on the type of metal. For previously painted surfaces, use a topside primer and lightly sand the cured primer before proceeding.

Step 3: Mix the Non-Skid Paint

Step 4: Apply the First Coat of Paint

Apply the non-skid paint to the prepared surface using a brush or roller. You can also thin the paint with a suitable thinner (5-10%) if needed. This first coat will provide a good base for the non-skid surface. Allow the first coat to dry completely (8-16 hours, depending on temperature) before proceeding.

Step 5: Sand the First Coat (optional)

Lightly sand the dried first coat of paint with 220-grit sandpaper. This step is optional but will help create a stronger bond between coats and improve the overall durability of the non-skid surface. Be careful not to sand completely smooth, as you still want some texture to be present.

Step 6: Apply the Second Coat of Paint

Wipe the surface with a suitable thinner to remove any dust or residue from sanding. Then, apply the second coat of non-skid paint in the same manner as the first coat. This second coat will provide increased traction and durability. For even more texture and grip, you can apply a third coat if desired.

Step 7: Allow the Paint to Cure

Once you have applied the desired number of coats, allow the non-skid paint to cure for at least 48 hours before use. This curing time will ensure maximum anti-wear characteristics and provide a long-lasting, slip-resistant surface for your boat floor.

Some popular non-skid paint products include TotalBoat TotalTread, Interlux Interdeck, Pettit EZ-Decks, and KiwiGrip. These products are designed specifically for boat decks and offer a range of colors to match your boat's topsides. Remember to always follow the manufacturer's instructions and safety guidelines when working with these products.

The Etymology of "Boat Race": Unraveling the Term's Nautical Origins

You may want to see also

Adhesive sheets

Materials

Installation

Maintenance

Customisation

Durability

Sizing

Haunted Queen Mary: A Ghostly Boat or Just Tales?

You may want to see also

Interlocking floor tiles

One of the most popular options for boat flooring is the Dri-Dek interlocking tile system. These tiles are made in the USA and are designed to keep your gear dry while protecting your boat. The tiles are flexible and durable, and they snap together easily, making installation a breeze. They can also be trimmed to fit any shape and allow for airflow, which helps keep your belongings dry. The patented self-draining surface makes them perfect for compartments, anchor dry lockers, and deck flooring. With over 500 positive reviews, Dri-Dek tiles are a trusted choice for boat owners.

Another option for interlocking floor tiles is the Patio Outdoor Tile. These tiles offer a safe, slip-resistant texture and are made from waterproof and flexible PVC plastic. They are easy to install, with connectors on all four edges, and can be placed directly over compacted surfaces or concrete. The perforated design allows for water drainage, making them ideal for wet areas near pools, locker rooms, greenhouses, boat decks, and outdoor sport courts. The tiles come in four attractive color options and can be mixed and matched to create a unique layout.

When choosing interlocking floor tiles for your boat, consider the size of your vessel, the level of skid resistance needed, durability, and ease of installation and maintenance. These tiles provide a comfortable and safe surface for your boat while also adding a touch of style and functionality to your space.

Finding Your Boat's VIN: Where to Look

You may want to see also

Slip-resistant tapes

When choosing an anti-slip tape, consider the colour, length, and material to ensure it meets your specific needs. For example, the FindTape Marine Anti-Slip Tape is available in black, grey, or blue and comes in 10-foot or 60-foot lengths. It is constructed with a non-grit material that provides skid resistance while being comfortable to walk on with bare feet. This tape is also salt-resistant and suitable for various water environments.

Another option is the Shoreline Marine Self-Adhesive Non-Skid Tape, which comes in black or white and is 2 inches wide by 10 feet long. It is easy to apply and can be cut to the desired length. This tape is great for use on boats, trailers, ladders, and docks.

If you're looking for an extra-wide tape, Better Boat offers a 4-inch by 40-foot roll of premium anti-slip safety tape that can quickly add traction to large areas. It adheres to most surfaces, including wood, concrete, metal, and plastic, making it a versatile option. This tape is also waterproof and weatherproof, ensuring it stands up to heavy foot traffic and rough weather conditions.

When applying slip-resistant tapes, ensure the surface is clean and dry. You can also use a surface primer or edge fix sealer to supplement the adhesion and longevity of the tape, although these are not always required.

Bass Pro's Boat Brands: Unveiling the Top Names

You may want to see also

Non-skid deck restoration

Step 1: Understand the Importance of Deck Maintenance

Before embarking on the restoration process, it's crucial to recognize why deck maintenance is essential. Boat decks are constantly exposed to various elements, including mud, grime, seaweed, fish debris, and water residue. Regular cleaning and upkeep prevent the buildup of these substances, reducing the risk of accidents and extending the lifespan of your deck. Additionally, non-skid surfaces can become smooth and slippery over time, creating a fall hazard that can be easily avoided with proper care.

Step 2: Gather the Necessary Tools and Products

To clean and restore your non-skid deck, you'll need a few essential items. These include a high-quality boat soap like Poli Wash™, a soft brush or cloth, a hose or bucket, and a mild detergent. For more extensive restoration, you may also require a non-skid deck sealer kit, such as Poli Grit™, which includes a texture enhancer, a deck sealant, and roller covers.

Step 3: Clear and Inspect Your Deck

Before beginning the cleaning process, remove any loose items, secure ropes or sails, and close cabin doors. Sweep the deck with a broom to remove large debris and inspect for any signs of damage, such as chips or cracks. Staying on top of minor repairs will save you time and effort in the long run.

Step 4: Wash Your Deck

Use a hose to rinse away loose dirt and debris from the deck. Fill a bucket with warm water and a mild detergent, and use a soft brush to scrub away the remaining grime. This initial wash will remove the bulk of the dirt, and you can then rinse the deck again with the hose.

Step 5: Deep Clean with a Specialized Boat Soap

For a more thorough clean, use a specialized boat soap like Poli Wash™. Pour a small amount into a bucket, create suds using water pressure, and apply it to the deck with a mop or brush. Let the product sit for a few minutes, scrub any stubborn spots, and then rinse thoroughly. You can either buff the deck dry with a microfiber towel or let it air dry.

Step 6: Restore Texture, Grip, and Shine

If your non-skid deck feels slick and slippery, it's crucial to restore traction and protection. Use a non-skid deck sealer kit to add texture and grip to the surface. Follow the instructions provided with the kit, which may include using a prep product to remove stains and create a uniform surface before applying the texture enhancer and deck sealant.

Step 7: Maintain Your Deck

To keep your deck in pristine condition, incorporate a few simple habits into your routine. Sweep, hose down, and dry your deck at the end of each boating day. Regular cleaning will prevent the buildup of dirt and debris, reducing the need for intensive cleaning sessions. Additionally, opt for covered storage or a boat cover to shield your deck from constant sun exposure, which can cause damage over time.

By following these steps, you can effectively restore your non-skid deck, ensuring a safe and aesthetically pleasing surface for years to come. Remember to choose products specifically designed for boat decks and always test a small area first to ensure satisfactory results.

Launching a Rescue Boat: A Step-by-Step Guide

You may want to see also

Frequently asked questions

There are several non-skid options available for boat floors, including non-skid paint, adhesive sheets, interlocking floor tiles, and slip-resistant tapes. You can also use non-skid pads, mats, or deck and floor coverings made from materials like EVA foam, rubber, or carpet.

When choosing a non-skid product, consider the type and size of your boat, the level of skid resistance needed, durability, weather resistance, and ease of installation and maintenance.

Regular cleaning and maintenance are important to keep your non-skid boat floor in good condition. Sweep, hose down, and dry your deck after each use. Use mild detergents and soft brushes for cleaning, and avoid harsh chemicals or abrasive tools that can damage the surface.

It is recommended to clean and maintain your boat deck regularly, ideally at the end of each boating day. In addition, an annual touch-up and deep cleaning at the end of the summer boating season can help extend the life of your non-skid boat floor.