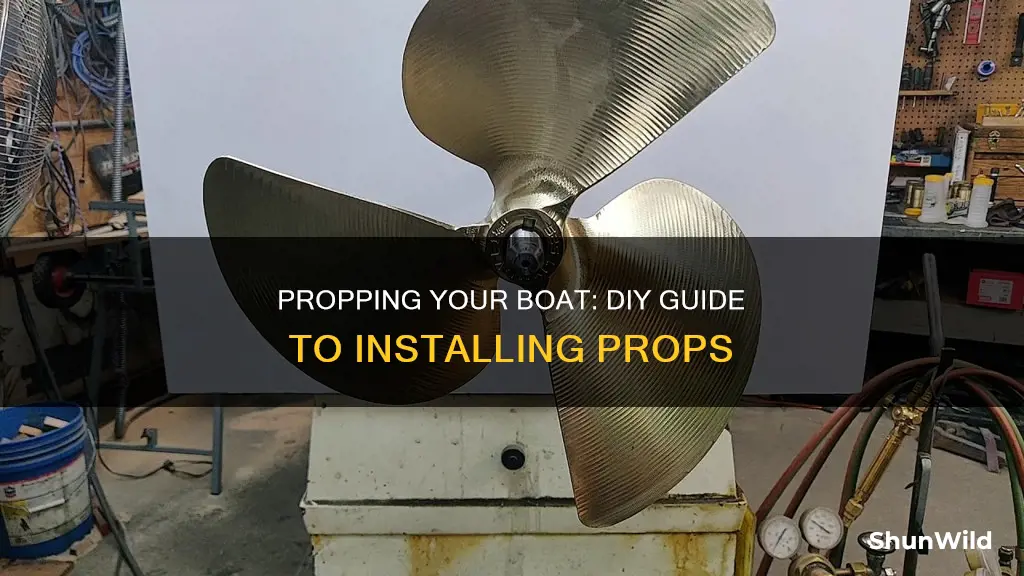

Putting a prop on a boat is a simple task that can be completed in under 30 minutes, even by a novice DIYer. A prop, or propeller, is a replaceable part of a boat that transfers the engine's power to the water, creating thrust. The first step in putting a prop on a boat is to choose the right replacement propeller, taking into account factors such as size, pitch, material, and the number of blades. The next step is to gather the necessary tools and replacement parts, such as a prop wrench, needle-nose pliers, a new prop, and grease. The process of installing the new prop involves removing the old prop, cleaning and inspecting the shaft, and then installing the new prop following the reverse of the removal procedure.

What You'll Learn

Choosing the right replacement propeller

Engine Specifications

Note down your engine's horsepower and RPM range, as these will affect the propeller pitch and diameter required. Choosing a propeller that aligns with your engine's specifications will ensure effective power transmission and maximise propeller performance.

Propeller Material

The most common propeller materials are aluminium and stainless steel. Aluminium is usually cheaper and more resilient to wear, making it a good option for novice boaters or those who boat in rough terrain. Stainless steel, on the other hand, offers increased strength, efficiency, and performance, especially in high-speed operations. It also has better initial acceleration and improved handling, making it suitable for sports or heavy-duty use.

Propeller Size

Propeller size refers to its diameter and pitch. The diameter is twice the distance from the centre of the hub to the tip of the blade. Generally, smaller diameter propellers are used with smaller engines and boats, while larger diameter propellers are used with larger boats. The pitch of the propeller is the forward movement of the propeller through one complete revolution, measured in inches. A higher pitch propeller will make a boat go faster, provided the engine has enough power to keep the RPMs in the optimum range.

Number of Blades

Three-blade propellers offer higher maximum speed, while four-blade propellers provide better turning and acceleration. For most purposes, 3- and 4-blade propellers can be used interchangeably on outboards and sterndrives without a significant change in performance.

Cupped Propellers

Cupped propellers have special curved trailing edges that enable the propeller to maintain performance at higher trim levels and in tight corners. They allow most boats to achieve a higher top-end speed or the same speed at a lower engine RPM, while also promoting more efficient fuel consumption.

Wide Open Throttle (WOT) RPM Range

The goal when selecting a propeller is to choose one that allows your engine to reach its optimal WOT RPM range. For outboards, this is generally between 5000 and 5500 RPM, while for sterndrives it is typically between 4400 and 4800 RPM, depending on the engine type. This information can usually be found in the owner's manual.

The Mystery of Scott Peterson's Boat: Blood Evidence?

You may want to see also

Preparing tools and replacement parts

Preparing the tools and replacement parts is a crucial step in the process of changing a boat propeller. Here are the key steps to follow:

Choose the Right Replacement Propeller:

The first step is to select an appropriate propeller for your boat, taking into account factors such as size, diameter, pitch, material, and the number of blades. The diameter refers to the distance between the midpoint of the propeller and the tip of each blade, with wider diameters generally indicating faster performance. Pitch refers to the average distance travelled by the propeller during a single revolution, dictating the average speed of the boat. You can choose between aluminium or stainless steel for the material, and decide between a three-blade propeller for top speed or a four-blade propeller for more power.

Gather the Necessary Tools:

Once you have selected the replacement propeller, it's time to gather the tools you will need for the job. At a minimum, you will require a prop wrench and a pair of needle-nose pliers. You may also want to have spare nuts, bolts, and washers on hand, as well as a block of wood to use during the removal process.

Prepare the Replacement Parts:

In addition to the tools, you will need to prepare the replacement parts. This includes the cotter pin, which is used to secure the propeller, and the new propeller itself. It is also recommended to have some waterproof grease on hand, as this will be applied during the installation process to reduce wear and improve the propeller's movement. Ensure the grease is recommended by the manufacturer and does not contain graphite, as this can lead to severe corrosion.

Additional Considerations:

Before beginning the process of changing the propeller, it is important to tilt the engine to a comfortable working height. This will provide easier access and improve your ability to manipulate the various components. Additionally, it is worth noting that the process of changing a boat propeller is relatively straightforward and can be accomplished by even a novice DIYer with basic tools in less than half an hour.

Best Grease for Boat Trailer Wheel Bearings

You may want to see also

Removing the cotter pin

First, tilt the engine up to a convenient working height. This will give you easy access to the cotter pin. Once you have located the cotter pin, use a pair of pliers to straighten out the legs of the pin. This will allow you to pull it out. It is important to note that the cotter pin will not be reused, so it can be discarded after removal.

When removing the cotter pin, be gentle and take your time. It is important to ensure that you don't bend or damage the pin, as this can make it difficult to remove. If the cotter pin is bent or damaged, you may need to use a pair of needle-nose pliers or wire cutters to straighten it out or cut it off.

Once the cotter pin is removed, you can proceed to the next step of changing the propeller. This typically involves unscrewing the propeller nut with a suitable socket and removing the washer and propeller. It is a good idea to have a block of wood handy to wedge between the prop blades and the cavitation plate to prevent the prop from turning as you loosen the nut.

By following these steps, you can easily remove the cotter pin and proceed with changing your boat propeller. Remember to wear disposable gloves to keep your hands clean and free from grease and dirt during the process.

Who is Holly on Fresh Off the Boat?

You may want to see also

Loosening the propeller nut

To loosen the propeller nut, you'll need to follow a few careful steps. Firstly, ensure the engine is tilted up to a convenient working height. This will give you the access and space needed to work on the propeller. Next, remove the cotter pin, which prevents the propeller nut from becoming undone. Use a pair of pliers to straighten and pull out the cotter pin, which will not be reused.

Now, you need to prevent the propeller from turning while you loosen the nut. Wedge a block of wood between the propeller blades and the cavitation plate. This will keep the propeller steady as you work. With the propeller secured, you can now unscrew the propeller nut with a suitable socket. It's important to apply force evenly and firmly to avoid any slippage, which could be dangerous.

If the nut is particularly tight, you may need to try some additional techniques. One method is to use a smoke wrench, also known as a torch, applied to the hub. This can help to loosen a stubborn nut. Alternatively, try using an impact gun or impact wrench, which can deliver a sudden impact torque that may break the bond. If you have access to a powered impact wrench, this could be a good option.

For severely stuck nuts, you may need to try some additional techniques. One suggestion is to heat the nut with a small propane/butane torch, and then use a wrench and a hammer to give it a couple of sharp whacks. This combination of heat and shock therapy can often break the bond of corrosion or thread goop. You could also try a harmonic puller, or prop knocker, which uses vibration to help loosen the nut.

With the propeller nut loosened, you can now move on to the next steps of removing the propeller and making any necessary repairs or replacements. Remember to work slowly and carefully, as this is a delicate task that requires patience and controlled force.

Replacing a Wench Strap: A Step-by-Step Boat Guide

You may want to see also

Detaching the washer and nut

- Engine Tilt and Cotter Pin Removal: Begin by tilting the engine to a comfortable working height. The first component to address is the cotter pin, a thin, metal pin that prevents the propeller nut from loosening. Using a pair of pliers, straighten out the legs of the cotter pin and then pull it out. Cotter pins are designed for single-use, so you will need a new one when reassembling the propeller.

- Propeller Nut and Washer Removal: With the cotter pin removed, you can now focus on the propeller nut and washer. Use a suitable socket to unscrew the propeller nut. To prevent the propeller from turning while you loosen the nut, it is crucial to wedge a block of wood between the propeller blades and the cavitation plate. Once the nut is loose, remove both it and the washer.

- Propeller Removal: At this stage, the propeller itself can be removed. It should slide off the splined shaft easily. However, if it has been in place for an extended period, you may need to gently tap the forward face of the propeller with a wooden block to dislodge it.

- Inspection and Cleaning: Once the propeller is removed, set it aside and inspect the splined shaft. Use a clean rag to wipe down the shaft, checking for any signs of wear and tear. This is also an opportune moment to inspect for any monofilament fishing line that may be wrapped around the shaft, as this can cause damage to seals and bearings. If any fishing line is present, carefully cut it away with a sharp razor knife.

By following these steps, you will have successfully detached the washer and nut, as well as removed the propeller for further inspection and maintenance. Remember to wear disposable gloves to keep your hands clean and free from grease and dirt.

Removing Boat Foam: Easy and Effective Tricks

You may want to see also

Frequently asked questions

A prop, or propeller, is the part of the boat that transfers the engine's power to the water, creating thrust.

The correct propeller size for your boat is based on the wide-open throttle (WOT) operating range for your engine. The goal is to determine the style and size that will maximise your boat's performance while allowing your engine to operate in the recommended rpm range.

The diameter is the distance between the midpoint of the propeller and the tip of each blade. Generally, wider diameters are equivalent to faster performance.

Pitch is the average distance made by the propeller after a single revolution. It dictates the average speed of a boat.

First, choose the right replacement propeller. Then, prepare the tools and replacement parts. Next, start with the cotter pin by tilting the engine to a comfortable position and using a pair of pliers to uncurl and remove the pin. After that, loosen the propeller nut by placing a block of wood between the cavitation plate and the blades to prevent the propeller from turning. Then, detach the washer and nut by pulling the propeller off the shaft.