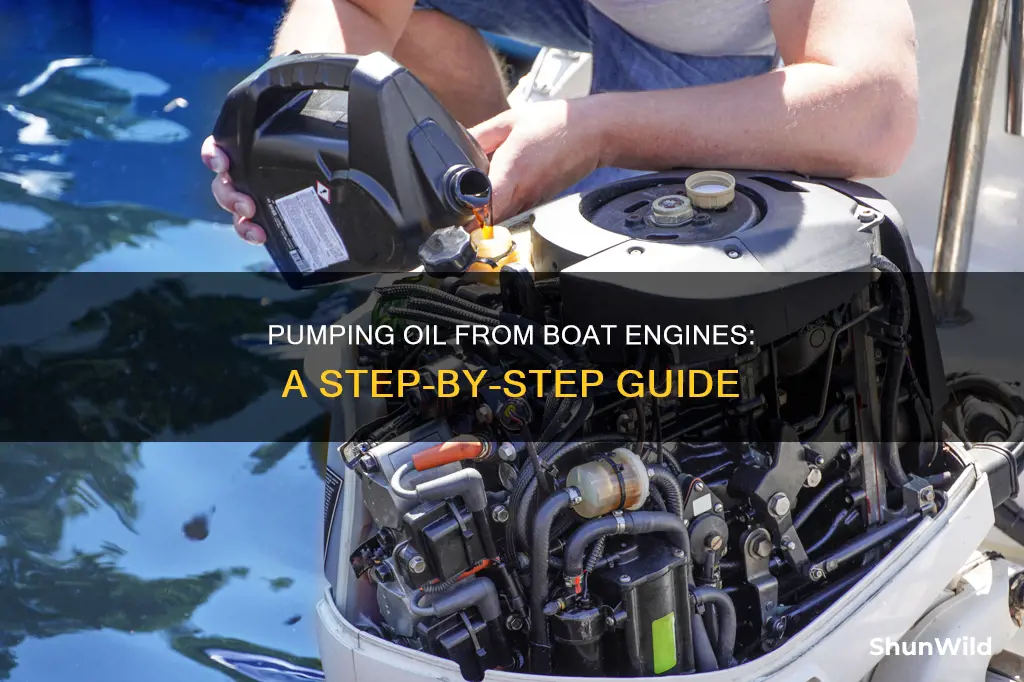

Pumping oil out of a boat engine can be a difficult and time-consuming process. Oil extractor pumps are a great solution to this problem, as they are designed to suction hot oil and drain it into a container. There are two types of oil extractor pumps: manual and electric. Manual pumps require continuous pumping by hand, while electric pumps are more convenient but require extra care as they cannot pump water or other non-lubricating liquids. When using an oil extractor pump, it is important to ensure that the oil is warm, as this makes it easier to drain and allows for the removal of more contaminants. Additionally, placing a catch pan and oil-absorbent pads under the engine and oil filter can help prevent accidental spills.

How to Pump Oil Out of a Boat Engine

| Characteristics | Values |

|---|---|

| Difficulty | Notoriously difficult due to the inaccessibility of the bottom of the engine |

| Tools | Oil extractor pump (manual or electric), catch pans, oil-absorbent pads, funnel, oil filter, oil |

| Engine Oil Changes | Recommended after every 100 hours of use or annually at a minimum |

| Engine Temperature | Warm engine before changing oil |

| Oil Temperature | Warm oil drains easier and holds more contaminants in suspension |

| Oil Analysis | Sending a sample to a lab can indicate unusual wear and the presence of water, antifreeze or diesel fuel |

| Oil Filter | Drip-free filter replacement is challenging; use oil pads, a catch pan or a zip-top bag to reduce spills |

| Waste Oil and Fluids | Contain and dispose of properly; marinas and auto-parts stores have disposal/recycling programs |

| Oil Absorbent Pads | Keep beneath engine to aid in spotting leaks |

| Bilge Pumps | Temporarily disable automatic bilge pumps to prevent oil from being pumped overboard in the event of a spill |

What You'll Learn

Manual vs electric pumps

There are two types of oil extractor pumps for boats: manual and electric. The right choice for you will depend on your needs, preferences, and the specifics of your boat. Here is a detailed comparison of the two types to help you decide.

Manual Pumps

Manual pumps are a great option when you don't have access to a power source. They require you to continuously pump the device to keep the oil flowing, which can be a good workout for the boat owner! They are typically more affordable than electric pumps and don't require a power source, making them a good choice for those on a budget or who want a simple, no-fuss option.

Electric Pumps

Electric pumps are more convenient and can make the job of pumping oil much easier, especially for larger engines. They are often faster and more efficient than manual pumps. However, they require a bit more care as you cannot pump water or other non-lubricating liquids through them. The pump components require lubrication from the medium being pumped, so if there is no oil to act as a lubricant, the pump could be damaged.

Key Considerations

When choosing between a manual and electric pump, consider the following:

- Engine capacity: Ensure the pump can handle the total oil capacity of your engine.

- Effort: Decide how much effort you are willing to put into the oil change process. Manual pumps require more physical labour, while electric pumps are generally easier to use.

- Power source: Consider whether you have access to a power source for an electric pump, or if you would prefer the simplicity of a manual pump.

- Storage and portability: Manual pumps tend to be smaller and more portable, while electric pumps may require more storage space.

- Hose size: Choose a pump with a hose that fits your engine's oil extraction port.

- Maintenance and cost: Electric pumps may require more maintenance and can be more expensive to purchase and run, while manual pumps are generally lower maintenance and more affordable.

Both manual and electric pumps have their advantages and disadvantages, so consider your specific needs and preferences when making your decision. By choosing the right pump for your boat, you can make oil changes quicker, cleaner, and more efficient.

Bass Master Boat: Who Makes These Watercraft?

You may want to see also

Warm the engine before pumping

Warming up your boat engine before pumping the oil out is a crucial step in the oil-changing process. Here are some reasons why you should always warm up your boat engine before changing the oil:

Easier Drainage

Warm oil is less viscous and flows more easily, making it simpler to drain from the engine. This is especially beneficial if you're changing the oil in cold weather conditions. By warming up the engine, you ensure that the oil is less thick and can be pumped out more efficiently.

Suspending Contaminants

The primary reason for heating the oil is to bring it to its normal operating temperature, which helps put contaminants into suspension. This includes things like water vapour, gaseous fuel by-products, and other impurities. When the oil is hot, these contaminants are more likely to detach from internal engine parts and be removed along with the oil. As a result, your engine will be cleaner, and the new oil will be more effective.

Engine Lubrication

Warming up the engine before an oil change ensures that the engine is well-lubricated for the dry restart. This is important because, during an oil change, the filter is often put on an empty engine. Warming up the engine helps to get oil onto crucial parts before the restart.

Improved Pump Performance

Using an oil extractor pump to remove oil from a boat engine is a common method. Warming up the engine first improves the performance of these pumps, as they can more easily suction hot oil through a small opening. This makes the oil change process faster and more efficient.

Safety

Working with hot oil may seem counterintuitive from a safety perspective, but it can actually be safer. Warm oil is less likely to splatter and cause burns when handled carefully. Additionally, it is easier to work with when using an oil extractor pump, reducing the risk of spills and messes.

In summary, warming up your boat engine before pumping out the oil is essential for a successful oil change. It improves the drainage of oil, suspends contaminants, lubricates the engine, enhances pump performance, and can even increase safety. By following this step, you'll ensure that your oil change is more effective and efficient, keeping your boat engine in optimal condition.

Exploring the 1000 Islands: Boat Trip Essentials

You may want to see also

Place the pump higher than the drain bucket

To pump oil out of a boat engine, it is recommended to place the pump higher than the drain bucket. This is because it reduces the possibility of spillage when you are done.

To do this, you will need to set up the pump above the level of the bucket or container that will catch the oil. This may require some creativity and planning, especially if you are working in a tight space. Here are some steps and tips to help you:

- Find a stable surface or structure above the bucket that can support the weight of the pump. This could be a shelf, a workbench, or even a sturdy box. Make sure whatever you choose can bear the weight without wobbling or tipping over.

- Prepare the pump by attaching the necessary hoses and ensuring it is securely fastened to the stable surface. You don't want it to fall into the bucket during the process.

- Ensure the pump's hose can reach the oil fill port on the engine. You may need to use an extension hose or a wand to reach the port, depending on the height of the pump's placement.

- Test the setup before starting the extraction process. Make sure the pump is secure, the hoses are connected properly, and there are no leaks.

- During the oil extraction process, monitor the bucket to ensure it does not overflow. Keep an eye on the oil level and be prepared to stop the pump or pause the process to change the bucket if needed.

- Consider using a larger bucket or container to reduce the risk of overflow. This will give you more time to focus on the extraction process without constantly worrying about the bucket filling up.

- If possible, choose a pump with a hose size that fits your engine's oil extraction port. This will ensure a proper seal and reduce the chance of leaks or spills.

- Always have rags or oil-absorbent pads nearby in case of any spills or drips. This will make cleanup easier and help you adhere to proper waste disposal procedures.

By following these steps and tips, you can effectively place the pump higher than the drain bucket when pumping oil out of a boat engine, minimising the risk of spills and making the process cleaner and more efficient.

Get Your Larson Boat Started: A Beginner's Guide

You may want to see also

Types of extractor pumps

There are two main types of oil extractor pumps: manual and electric.

Manual Pumps

Manual pumps require you to continuously pump the device to keep the oil flow moving. They are a great option when you don't have access to a power source. Manual pumps are typically designed to be hand-held and portable, making them easy to use and store.

Electric Pumps

Electric pumps are more convenient and often have a higher flow rate than manual pumps. However, they require a power source and extra care during use. You cannot pump water or other non-lubricating liquids through them, as the pump components require lubrication from the medium being pumped.

Specific Models

Extractor pumps come in a variety of models, each with unique features and specifications. Here are some specific models of extractor pumps that are commonly used for boat engines:

- Jabsco Porta-Quick Oil Changer

- Overton's Oil Changer/Fluid Evacuator Kit - 4 Liter Capacity

- TRAC Fluid/Oil Extractor, 7L/7.40 Qt.

- EWK 6L Vacuum Oil Extractor Pump

- Mercury Precision Crankcase Oil Pump 802889A 1

- Jabsco 34060-0130 Marine Engine Oil Drain Hand Pump

Replacing Steering Cables on Center Console Boats: A Step-by-Step Guide

You may want to see also

How to inspect the old oil

Inspecting the old oil in your boat's engine is a crucial step in engine maintenance. Here are some detailed instructions on how to do it:

Before inspecting the old oil, it is essential to prepare the boat for an oil change. This includes disconnecting the battery, removing any debris around the engine, and placing a drip pan or oil pan underneath the engine to catch the drained oil. It is also recommended to have oil-absorbent pads and rags on hand to prevent and clean up any accidental spills.

Once the boat is prepared, the old oil can be drained from the engine by removing the oil drain plug. After draining, you will have access to the old oil for inspection. Here are some key things to look for:

- Milky appearance: Oil that appears milky or cloudy may indicate the presence of water, antifreeze, or fuel. This could be a sign of a blown gasket or a cracked block, which requires further investigation.

- Abrasiveness or burnt odour: Rub a small amount of the old oil between your fingers. If it feels gritty or abrasive, it may suggest bearing wear. If it has a burnt odour, it could indicate that the oil has been exposed to high temperatures or has not been changed in a long time.

- Contamination: Check the oil for any signs of contamination, such as water or fuel. Water-contaminated oil will have a milky colour, while fuel-contaminated oil will have a strong fuel smell. Contamination could be due to various issues, so it is important to have the engine checked by a dealer or a professional.

- Particulates: Warm oil will have circulated throughout the engine, suspending any particulates. Observe the oil for any suspended particles, such as dirt or metal shavings, which could indicate engine wear or the need for a new oil filter.

After inspecting the old oil, it is important to dispose of it properly. Used oil should be contained and disposed of at a designated recycling facility or as per your local regulations. Do not pour used oil down the drain or into the environment, as it can cause pollution.

By regularly inspecting the old oil in your boat's engine, you can gain valuable insights into the engine's health and address any potential issues early on. This proactive approach can help extend the life of your boat's engine and ensure its smooth and efficient operation for years to come.

Finding the Manufacturer Date on an Old Mirrocraft Boat

You may want to see also

Frequently asked questions

An oil extractor pump is a device used to suction oil through a small opening and drain it into a container. There are two types: manual and electric. Manual pumps require continuous pumping by hand, while electric pumps are more convenient but require extra care as they cannot pump water or other non-lubricating liquids.

First, ensure the oil is warm by running the engine. Then, insert the suction tube through the oil fill port, adjusting the depth until oil begins to flow. Remove the oil filter to extract more oil. Place the pump higher than the drain bucket to prevent spillage.

Engine manufacturers recommend changing engine oil after every 100 hours of use or annually. Before changing the oil, place catch pans and oil-absorbent pads beneath the engine to prevent spills. Always dispose of waste oil and fluids properly, and recycle used oil and filters.