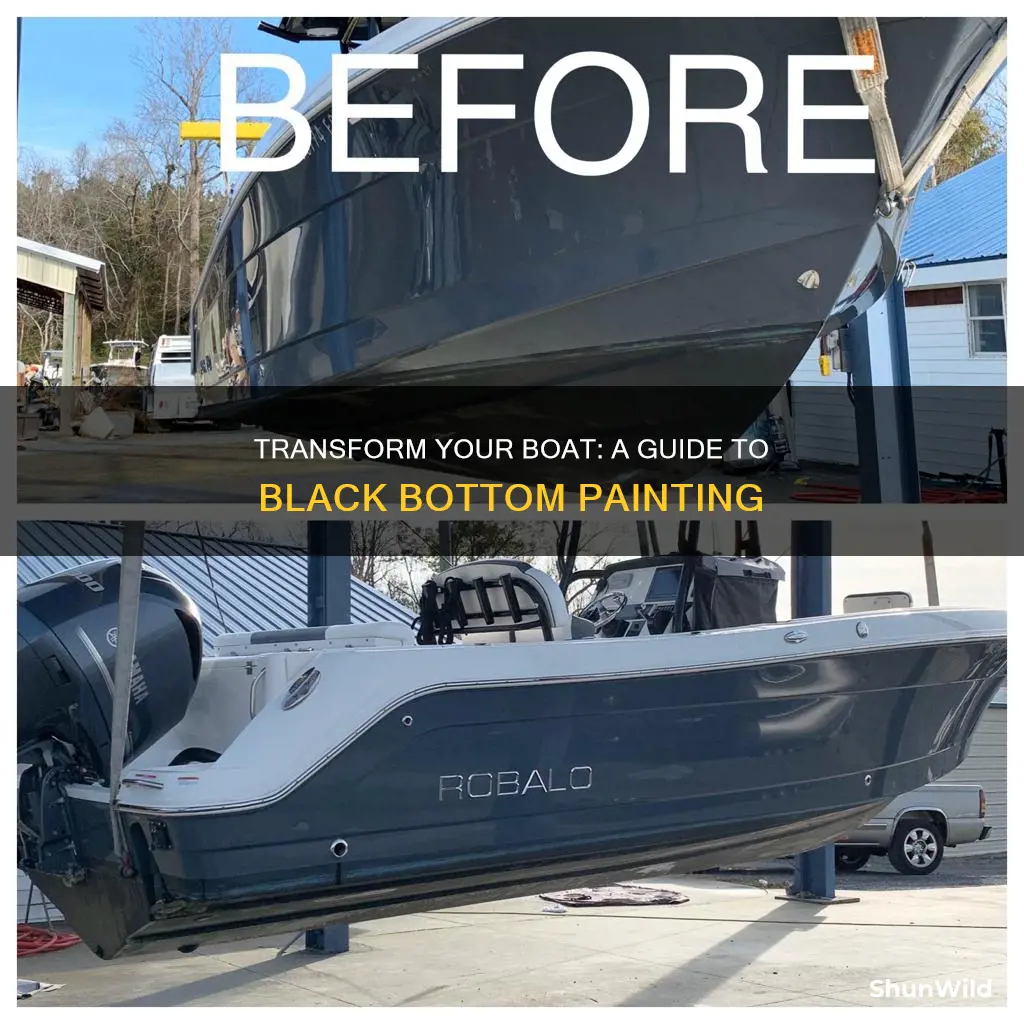

Painting the bottom of a fiberglass boat black can significantly enhance its appearance and protect the hull from UV damage and marine growth. This process requires careful preparation and the right materials to ensure a durable and long-lasting finish. Here’s a step-by-step guide to help you achieve a professional-looking black bottom on your fiberglass boat.

What You'll Learn

- Prepare the Surface: Clean, sand, and etch the fiberglass for optimal paint adhesion

- Choose the Right Paint: Select a marine-grade black paint with UV resistance

- Apply Primer: Use a suitable primer to ensure paint bonding and durability

- Apply Multiple Coats: Thin coats build coverage and avoid drips

- Seal and Protect: Finish with a marine sealant to prevent water infiltration

Prepare the Surface: Clean, sand, and etch the fiberglass for optimal paint adhesion

Preparing the surface of a fiberglass boat for painting is a crucial step to ensure a long-lasting and professional finish. Here's a detailed guide on how to achieve optimal paint adhesion through cleaning, sanding, and etching the fiberglass:

Cleaning the Fiberglass:

Start by thoroughly cleaning the boat's bottom to remove any dirt, grime, or old paint residues. Use a high-pressure washer or a strong hose to flush out any debris. If there are stubborn stains or old paint remnants, consider using a chemical cleaner specifically designed for fiberglass. These cleaners can help dissolve and lift off old coatings, ensuring a clean slate for the new paint. Rinse the boat thoroughly after cleaning to remove any chemical residue.

Sanding the Surface:

Sanding is an essential step to create a rough texture on the fiberglass, allowing the paint to grip better. Use a high-grit sandpaper (40-60 grit) to gently sand the entire bottom of the boat. Focus on the areas where paint adhesion is critical, such as the corners, seams, and areas with previous repairs. Work in small sections and follow the direction of the fiberglass weave. After sanding, wipe away the dust and any debris using a tack cloth or a damp cloth to ensure a smooth and clean surface.

Etching the Fiberglass:

Etching the fiberglass surface further enhances its roughness and provides an active surface for the paint to bond. You can use a variety of etching methods, such as mechanical etching or chemical etching. Mechanical etching involves using tools like a power drill with a small etching bit to create small, controlled grooves. Chemical etching, on the other hand, uses a specialized etching solution that reacts with the fiberglass, creating a textured surface. Follow the manufacturer's instructions for the chosen etching method, as different products may require specific application techniques.

After etching, inspect the surface to ensure it has a uniform texture. You can use a magnifying glass to verify the depth and consistency of the etch marks. If needed, re-etch problem areas to achieve the desired level of surface preparation.

By following these steps, you'll create a clean, textured surface on the fiberglass boat, providing an ideal foundation for the black paint to adhere and ensure a long-lasting finish. Remember, proper surface preparation is key to a successful painting project.

American Investors' Exit: Bavaria Boat Works' Uncertain Future

You may want to see also

Choose the Right Paint: Select a marine-grade black paint with UV resistance

When it comes to painting the bottom of your fiberglass boat black, choosing the right paint is crucial for a successful and long-lasting result. The harsh marine environment demands a paint that can withstand the test of time and the elements, so selecting a marine-grade black paint with UV resistance is essential. This type of paint is specifically formulated to endure the challenges of saltwater exposure, providing excellent protection against corrosion, fading, and the damaging effects of the sun's ultraviolet rays.

Marine-grade paints are designed to resist the corrosive nature of saltwater, which can quickly deteriorate regular paint. The bottom of a boat is particularly susceptible to wear and tear due to constant contact with the water and sediment. By opting for a marine-grade paint, you ensure that your boat's bottom will remain protected, even in the most demanding conditions. Look for paints that are specifically labeled for marine applications, as they will have the necessary additives to enhance durability and resistance.

UV resistance is another critical factor to consider. The intense sunlight on the water's surface can cause regular paints to fade and deteriorate over time. A UV-resistant paint will help maintain the black color of your boat's bottom, ensuring it looks sleek and professional for years. This is especially important if your boat spends a lot of time in direct sunlight or if you plan to keep it in the water for extended periods. The paint should be able to withstand the sun's rays without losing its color or becoming brittle.

When selecting a marine-grade black paint, consider the finish you desire. Paints can vary from high-gloss to matte, and each has its advantages. A high-gloss finish provides a sleek and shiny appearance, while a matte finish offers a more subtle and elegant look. Choose the finish that best suits your personal preference and the overall aesthetic you want to achieve. Additionally, ensure that the paint is compatible with fiberglass, as not all paints are suitable for this surface.

Applying the right paint to your fiberglass boat's bottom will not only enhance its appearance but also provide long-term protection. Take the time to prepare the surface properly by cleaning and smoothing it, ensuring a smooth and even paint application. With the right marine-grade black paint and careful preparation, you can transform the bottom of your boat, giving it a fresh and professional look while ensuring its longevity in the water.

Mastering the Art of Boat Seat Fiberglassing: A Comprehensive Guide

You may want to see also

Apply Primer: Use a suitable primer to ensure paint bonding and durability

When preparing to paint the bottom of a fiberglass boat black, one of the most crucial steps is applying a high-quality primer. This initial layer serves as the foundation for the paint, ensuring optimal bonding and longevity. The primer acts as a bridge between the fiberglass surface and the final paint coat, creating a strong and durable bond that can withstand the marine environment.

Selecting the right primer is essential. For fiberglass, an epoxy-based primer is often recommended due to its ability to penetrate the material and create a strong mechanical bond. These primers typically contain a hardener and a resin system that, when mixed, form a tough, durable layer. It's important to choose a primer specifically designed for marine applications to ensure it can withstand the harsh conditions of saltwater and UV exposure.

The application process is key to success. Start by thoroughly cleaning the fiberglass surface to remove any dirt, grease, or old paint. Use a mild detergent and water solution, ensuring the surface is completely dry before priming. Then, apply the primer using a brush or a spray gun, following the manufacturer's instructions for coverage and drying times. Multiple thin coats are often better than a single thick coat to ensure complete coverage and a smooth finish.

Let each coat dry thoroughly before applying the next. This may take several hours or even overnight, depending on the primer and environmental conditions. After the final coat of primer is dry, lightly sand the surface with fine-grit sandpaper to create a smooth, uniform texture. This step is crucial for the paint to adhere properly and ensures a professional finish.

By taking the time to apply a suitable primer, you're setting the foundation for a long-lasting and high-quality paint job. This step is often overlooked but is critical to the overall success of the project, ensuring the paint adheres well and the boat's bottom remains protected and aesthetically pleasing for years to come.

Bass Boat Fronts: Which Design Cuts Through the Waves?

You may want to see also

Apply Multiple Coats: Thin coats build coverage and avoid drips

When painting the bottom of a fiberglass boat black, applying multiple thin coats is a crucial technique to ensure a smooth and professional finish. This methodical approach allows for better coverage and helps to avoid any unwanted drips or runs, which can be unsightly and compromise the overall appearance.

The key to success with multiple coats is to keep the application process thin and controlled. Each coat should be applied with a light hand, using a brush or roller that is suitable for the chosen paint. A thin coat means using a minimal amount of paint, ensuring that it is spread evenly across the surface. This technique allows the paint to flow and level out, creating a smooth finish.

Here's a step-by-step guide to achieving this: Start by cleaning the boat's bottom thoroughly to remove any dirt, grime, or old paint. Ensure the surface is dry and free of any contaminants. Then, apply the first thin coat, working in small sections to avoid overloading the brush or roller. Allow the first coat to dry completely, following the manufacturer's instructions for drying time. Once dry, inspect the surface for any missed spots or imperfections.

For the subsequent coats, continue the process, ensuring each coat is very thin and carefully applied. The goal is to build up the color and coverage gradually, allowing each coat to dry before applying the next. This methodical approach ensures that the paint adheres properly and creates a seamless finish. Remember, thin coats are more forgiving and allow for easier touch-ups if needed.

By applying multiple thin coats, you can achieve a high-quality, professional-looking black finish on your fiberglass boat. This technique requires patience and attention to detail but will result in a durable and aesthetically pleasing outcome. It's a common practice in marine painting and is often recommended by professionals for optimal results.

Paddle Boat Registration: North Carolina's Requirements

You may want to see also

Seal and Protect: Finish with a marine sealant to prevent water infiltration

After you've prepared the surface and applied the primer, it's crucial to seal and protect your fiberglass boat's bottom to ensure a long-lasting finish. This step is essential to prevent water infiltration, which can lead to corrosion and damage over time. Here's a detailed guide on how to achieve a professional-looking black finish:

Step 1: Choose the Right Marine Sealant

Select a marine-grade sealant specifically designed for use on boats. These sealants are formulated to withstand the harsh marine environment, including UV rays, saltwater, and varying temperatures. Look for a sealant that is flexible, durable, and resistant to abrasion. Silicone-based sealants are a popular choice due to their versatility and ease of application. Ensure you read the product instructions and choose a color that complements your desired black finish.

Step 2: Prepare the Surface

Before applying the sealant, ensure the surface is clean and free of any debris or contaminants. Use a mild detergent or boat cleaner to wash the bottom of the boat. Rinse thoroughly with freshwater to remove any residue. Allow the surface to dry completely; ensure there is no moisture present, as this can affect the sealant's adhesion.

Step 3: Application Technique

Follow the manufacturer's instructions for the best application method. Typically, you'll want to apply the sealant in a thin, even layer. Use a brush or a roller to ensure complete coverage. Start from one corner and work your way across, maintaining a consistent thickness. Take care not to apply too much pressure, as this can cause the sealant to ooze or create an uneven finish. Allow the first coat to dry according to the product's guidelines.

Step 4: Multiple Coats for Durability

For optimal protection, apply multiple thin coats of sealant. This technique ensures a smooth and even surface while providing enhanced durability. Allow each coat to dry before applying the next. The number of coats required may vary depending on the product and the desired thickness, so refer to the manufacturer's recommendations.

Step 5: Final Touches and Maintenance

Once the sealant is fully cured, inspect the boat's bottom for any imperfections or areas that may require touch-ups. You can use a fine-grit sandpaper to smooth out any rough spots and create a seamless finish. After the final coat is dry, your boat's bottom will be protected and ready for the black paint. Regular maintenance, including cleaning and reapplying sealant as needed, will help preserve the finish and ensure the boat's longevity.

Fortnite's Boat Races: A Guide to Victory

You may want to see also

Frequently asked questions

For painting the bottom of a fiberglass boat, it is recommended to use a specialized marine paint designed for underwater applications. Epoxy-based paints are a popular choice as they provide excellent adhesion and durability. Look for paints specifically formulated for fiberglass surfaces, ensuring they are UV-resistant and can withstand the harsh marine environment.

Proper preparation is crucial for a successful paint job. Start by thoroughly cleaning the fiberglass surface to remove any dirt, grime, or old paint. Use a mild detergent and a soft brush or sponge to scrub the area. Rinse and dry the surface completely. Then, use a fine-grit sandpaper (around 400-600 grit) to smooth out any rough spots and create a uniform surface for the paint to adhere to. Ensure you wear protective gear during this process.

Yes, using a spray gun can provide a smooth and even finish. However, it requires some practice and skill. Ensure you have a suitable spray gun setup, including a compressor and a suitable nozzle for the paint you are using. Practice on a test surface to achieve the desired coverage and texture. Spray guns can be efficient, but they may require more care and attention to detail compared to traditional brushing methods.