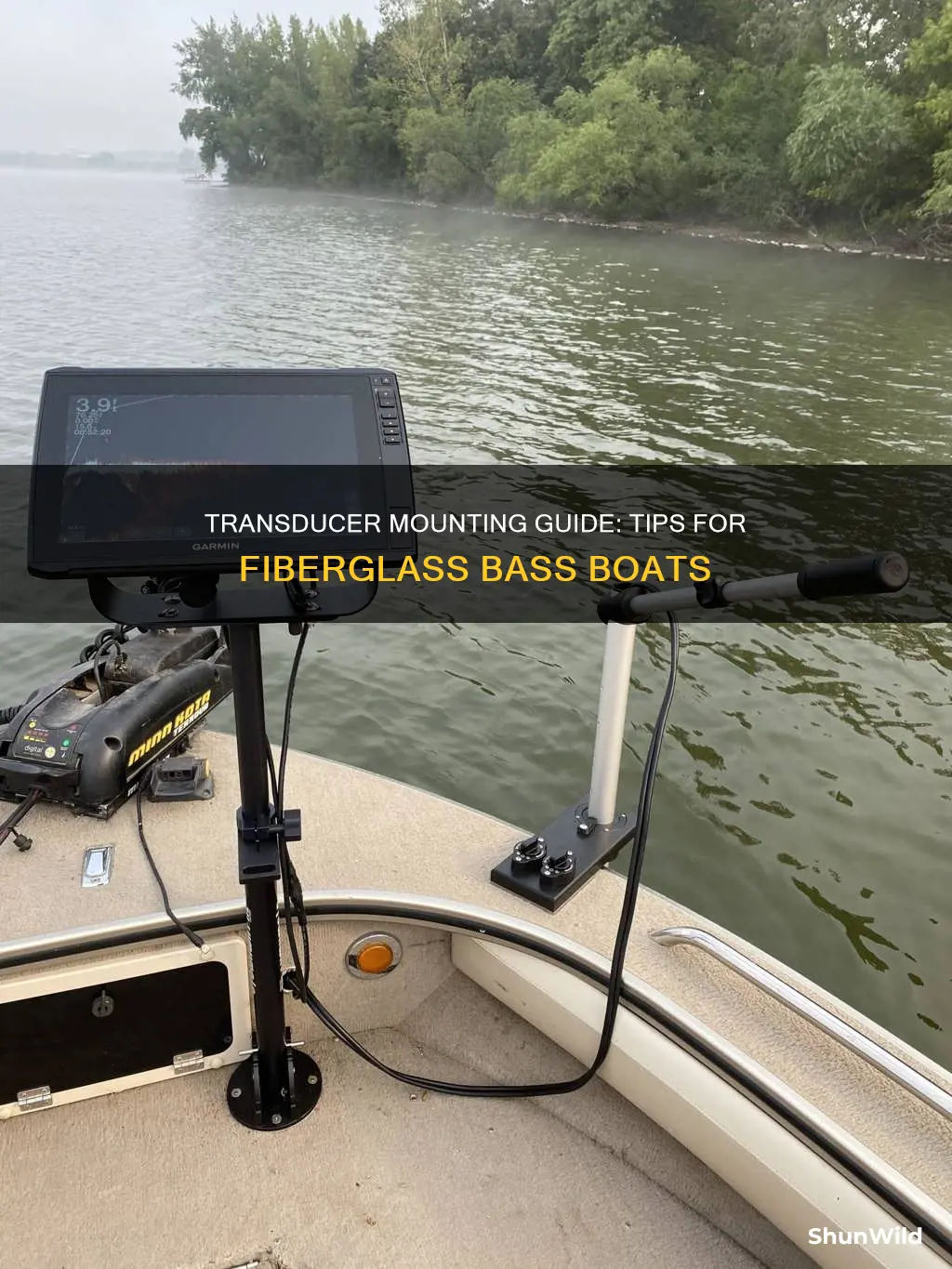

Mounting a transducer on the back of a fiberglass bass boat requires careful planning and execution to ensure optimal performance and safety. This guide will provide a step-by-step process for installing a transducer, covering essential considerations such as choosing the right mounting hardware, preparing the boat's surface, and ensuring proper wiring and water-tight connections. By following these instructions, anglers can effectively enhance their fishing experience with real-time sonar data while maintaining the integrity of their boat's structure.

| Characteristics | Values |

|---|---|

| Preparation | Clean the surface of the boat's back with isopropyl alcohol to ensure a good bond. Use a marine-grade adhesive or epoxy to secure the transducer. |

| Location | Choose a spot with minimal obstructions for optimal signal reception. Avoid areas near the transducer's mounting holes. |

| Mounting Hardware | Use marine-grade screws and nuts to fasten the transducer securely. Ensure the hardware is corrosion-resistant. |

| Sealing | Apply marine-grade sealant around the mounting holes to prevent water intrusion. Use a waterproof tape or gasket for added protection. |

| Wiring | Route the transducer wiring through the boat's hull or use a dedicated wiring harness. Ensure proper grounding to minimize interference. |

| Transducer Angle | Adjust the transducer's angle for optimal performance. Aim for a 45-degree angle towards the water's surface. |

| Testing | After installation, test the transducer's functionality and adjust its position if necessary. |

| Maintenance | Regularly inspect and clean the transducer to remove dirt and debris. Check for any signs of corrosion and reapply sealant if needed. |

What You'll Learn

- Choose Transducer Mounting Location: Select a suitable spot on the boat's hull for optimal sound transmission

- Prepare Hull Surface: Clean and roughen the fiberglass surface for adhesive bonding

- Select Adhesive: Use a marine-grade adhesive suitable for fiberglass and water exposure

- Transducer Installation: Secure the transducer with the adhesive, ensuring proper alignment and tightness

- Testing and Calibration: Verify the transducer's functionality and calibrate for optimal performance

Choose Transducer Mounting Location: Select a suitable spot on the boat's hull for optimal sound transmission

When it comes to mounting a transducer on the back of a fiberglass bass boat, selecting the right location is crucial for optimal sound transmission and overall performance. The goal is to ensure that the sound waves generated by the transducer are effectively transferred through the hull and into the water, providing clear and accurate sonar readings. Here's a detailed guide on how to choose the best mounting spot:

Understanding Sound Transmission: Sound travels through different materials with varying efficiency. Water is a good conductor of sound, but the hull material and structure play a significant role in sound transmission. Fiberglass, being a lightweight and relatively rigid material, can transmit sound well when properly mounted. The key is to minimize any obstacles or air pockets that might absorb or reflect sound waves, causing distortion.

Consider the Hull Shape: The shape of the boat's hull is essential in determining the ideal mounting location. Bass boats often have a flat or slightly curved bottom, and the transducer should be positioned to take advantage of this shape. Aim for an area where the hull is relatively flat and smooth, as this provides a stable platform for sound transmission. Avoid mounting near sharp edges, ribs, or any protruding structures that could interfere with sound propagation.

Mounting Height and Angle: The height and angle of the transducer mounting are critical factors. Typically, the transducer should be mounted at a height that allows the sound waves to travel through the water without significant obstruction. A common practice is to position it just above the waterline, ensuring that it is not too low, which could result in water entering the transducer. Additionally, angling the transducer slightly downward can improve sound transmission, as it helps to avoid any air pockets that might form near the surface.

Avoiding Interference: Certain areas on the hull should be avoided due to potential interference with sound transmission. Mounting too close to the propeller or exhaust can cause vibrations and noise that might affect the transducer's performance. These areas can also generate their own sound waves, leading to interference and reduced clarity in sonar readings. It's best to maintain a safe distance from these components.

Experimentation and Fine-Tuning: Finding the perfect mounting spot might require some experimentation. Try different locations and angles to observe the sonar readings and overall performance. Adjusting the transducer's position can help optimize sound transmission. Remember, the goal is to create a clear and consistent signal, so take the time to fine-tune the setup for the best results.

Cooling Your Boat Engine: Tips for Summer Sailing

You may want to see also

Prepare Hull Surface: Clean and roughen the fiberglass surface for adhesive bonding

Preparing the hull surface is a crucial step in ensuring a successful and long-lasting transducer installation on your fiberglass bass boat. This process involves cleaning and roughening the surface to create an optimal bonding environment for the adhesive. Here's a detailed guide on how to achieve this:

Start by thoroughly cleaning the fiberglass surface where the transducer will be mounted. Use a mild detergent or boat cleaner specifically designed for fiberglass to remove any dirt, grime, or old adhesive residue. Rinse the area with clean water to ensure no soap or cleaning agent remains. It's essential to start with a clean slate to guarantee proper adhesion. Pay attention to any existing holes or imperfections in the fiberglass. These areas might require extra preparation. Use a small wire brush or a specialized fiberglass scraper to gently remove any loose fibers or debris. Be cautious not to scratch the surface too deeply, as this could compromise the structural integrity of the boat.

Once the cleaning and initial preparation are complete, it's time to roughen the surface. This step is vital as it provides a mechanical bond for the adhesive, ensuring a stronger hold. You can use a fine-grit sandpaper (around 120-150 grit) to gently sand the cleaned area. Apply light pressure and work the sandpaper over the surface in a circular motion. The goal is to create a slightly textured surface without removing too much of the fiberglass. After sanding, wipe away any dust or debris with a clean cloth. This roughened surface will now be ready to accept the adhesive, providing a secure base for your transducer.

Remember, the key to a successful installation is taking the time to properly prepare the hull surface. This process might seem tedious, but it will significantly contribute to the longevity and effectiveness of your transducer mounting. Always follow the manufacturer's instructions for the adhesive you choose, as different products may have specific requirements for surface preparation.

Mastering the Art of Twin Engine Boat Sideways Maneuvering

You may want to see also

Select Adhesive: Use a marine-grade adhesive suitable for fiberglass and water exposure

When it comes to mounting a transducer on the back of a fiberglass bass boat, selecting the right adhesive is crucial for a successful and long-lasting installation. The harsh marine environment demands a special type of adhesive that can withstand the test of time and the elements. Marine-grade adhesives are specifically formulated to resist the corrosive effects of saltwater, UV radiation, and temperature fluctuations, ensuring your transducer remains securely attached.

Fiberglass, being a composite material, requires an adhesive that can bond effectively to its surface without causing damage. Look for adhesives designed for use with fiberglass, as these products often have a flexible and durable composition that can accommodate the material's natural expansion and contraction. This flexibility is essential to prevent cracking or peeling over time.

Water exposure is another critical factor. The adhesive must create a waterproof seal to protect the transducer and the boat's interior from potential water intrusion. Marine-grade adhesives are typically made with a water-resistant formula, ensuring that the bond remains intact even when submerged or exposed to splashes and waves.

Consider the type of transducer you have and the specific requirements of your boat. Some transducers may have unique mounting needs, so it's essential to choose an adhesive that can accommodate these specific demands. For example, if your transducer has a heavy-duty design, you might need an adhesive with exceptional strength to handle the additional weight.

In summary, for a fiberglass bass boat, opt for a marine-grade adhesive that is specifically tailored to bond with fiberglass and withstand the marine environment. This will ensure a secure and long-lasting installation, providing peace of mind that your transducer is safely and effectively mounted. Always follow the manufacturer's instructions for the chosen adhesive to ensure optimal results.

Harley's Boat: Lost at Sea?

You may want to see also

Transducer Installation: Secure the transducer with the adhesive, ensuring proper alignment and tightness

When installing a transducer on the back of a fiberglass bass boat, one of the most effective methods is to use an adhesive mount. This technique provides a strong and durable bond, ensuring the transducer remains securely in place even during turbulent waters. Here's a step-by-step guide to help you through the process:

Step 1: Prepare the Transducer and Mounting Surface

Start by cleaning the transducer and the designated area on the boat's hull. Ensure the surface is free from dirt, grease, or any debris that might interfere with the adhesive's performance. You can use a mild detergent and a soft cloth for this task. Once cleaned, allow the area to dry completely.

Step 2: Apply the Adhesive

Choose a high-quality marine-grade adhesive suitable for fiberglass surfaces. Follow the manufacturer's instructions for application. Typically, you'll need to apply a thin layer of adhesive to both the transducer's backing and the boat's hull. Ensure you cover the entire mounting area, including any screws or fasteners that will be used to secure the transducer.

Step 3: Position and Align

Gently place the transducer onto the adhesive-covered area, ensuring it is aligned correctly. Check that the transducer is level and positioned as per the manufacturer's guidelines for optimal performance. You might need to use a spirit level to verify the alignment.

Step 4: Secure with Adhesive and Fasteners

For added security, you can use marine-grade screws or fasteners specifically designed for fiberglass. Apply a small amount of adhesive to the threads of the screws and insert them into the pre-drilled holes on the transducer. Tighten the screws firmly, being careful not to overtighten, as this could damage the transducer or the boat's surface.

Step 5: Final Checks

After allowing the adhesive to cure according to the manufacturer's instructions, perform final checks to ensure the transducer is secure and functioning correctly. Test the transducer's range and clarity, making any necessary adjustments to its position. Verify that all connections are tight and that there is no interference with other boat components.

By following these steps, you can effectively secure the transducer to the back of your fiberglass bass boat, ensuring a reliable and long-lasting installation. Remember, proper alignment and the use of high-quality adhesives are key to a successful transducer mounting process.

Securing Gas Tanks in Aluminum Boats: A Guide

You may want to see also

Testing and Calibration: Verify the transducer's functionality and calibrate for optimal performance

Testing and Calibration: A Crucial Step for Optimal Transducer Performance

After mounting the transducer on your fiberglass bass boat, the next critical step is to ensure its functionality and calibrate it for optimal performance. This process involves a series of checks and adjustments to guarantee accurate readings and reliable operation. Here's a detailed guide on how to verify and calibrate your transducer:

Initial Testing:

Start by testing the transducer's functionality immediately after installation. Turn on the boat's power and engage the transducer's power supply. Listen for any audible feedback from the transducer, ensuring it emits a clear signal. Use a multimeter or an oscilloscope to measure the electrical output of the transducer. Compare the readings with the manufacturer's specifications to confirm it is operating within the expected range. This initial test will help identify any immediate issues and ensure the transducer is functioning as intended.

Water Immersion and Calibration:

Submerging the transducer in water is essential for calibration. Fill the boat's tank or a large container with water and place the transducer in the desired position. Ensure the water level is sufficient to cover the transducer's face and any exposed parts. Turn on the transducer and adjust the gain settings on your fish finder or sonar device to its maximum value. This step is crucial as it allows you to fine-tune the transducer's sensitivity. Gradually reduce the gain until you achieve a clear and stable image on the display. The goal is to find the sweet spot where the image is crisp and free of distortion.

Fine-Tuning and Adjustment:

During the calibration process, pay close attention to the transducer's performance. Adjust the transducer's angle and position slightly to observe how it affects the image. You might need to experiment with different angles to optimize the signal reception and image clarity. Additionally, check for any interference or noise in the readings. If you notice any unwanted signals or distortions, consider adjusting the transducer's depth or using a different frequency setting to minimize these issues.

Professional Calibration (Optional):

For highly accurate and precise calibration, consider seeking professional assistance. Specialized technicians can use advanced equipment to fine-tune the transducer's performance. They may employ techniques like signal processing and frequency analysis to optimize the transducer's output. Professional calibration is especially beneficial if you plan to use the transducer for scientific research or professional fishing competitions, where precision is critical.

Remember, proper testing and calibration ensure that your transducer provides reliable and accurate data, enhancing your overall boating experience and fishing success. It is an essential step that should not be overlooked when mounting transducers on fiberglass bass boats.

Bass Tracker Boats: Are They Worthy Watercraft?

You may want to see also

Frequently asked questions

Mounting a transducer on a fiberglass boat requires careful consideration to ensure it is secure and performs optimally. Start by choosing a suitable mounting location, typically on the transom or the back of the boat, ensuring it is level and free from obstructions. Use a transducer mount or a custom-made bracket to secure the transducer, ensuring it is firmly attached to the boat's surface. Consider using marine-grade adhesive or screws for a strong bond.

Proper positioning is crucial for accurate sonar readings. Align the transducer's beam direction with the desired scanning area. For a bass boat, you might want to aim it downward to detect fish in the water column. Adjust the tilt and angle of the transducer to cover the desired depth and area. Regularly test the sonar readings to ensure the transducer is positioned correctly.

Yes, you'll need a few essential tools and materials. Gather marine-grade adhesive or epoxy, suitable for bonding to fiberglass. Use screws or bolts with marine-grade corrosion-resistant coatings. A transducer mount or bracket designed for fiberglass boats will provide a secure base. Ensure you have the necessary hardware and tools for a precise and secure installation.

While double-sided tape might be an option for a temporary fix, it is not recommended for a permanent or long-term solution. Marine-grade adhesive or epoxy provides a stronger bond and better durability. For a more permanent installation, consider using screws or a custom-made bracket to ensure the transducer remains secure and stable over time, especially in varying water conditions.