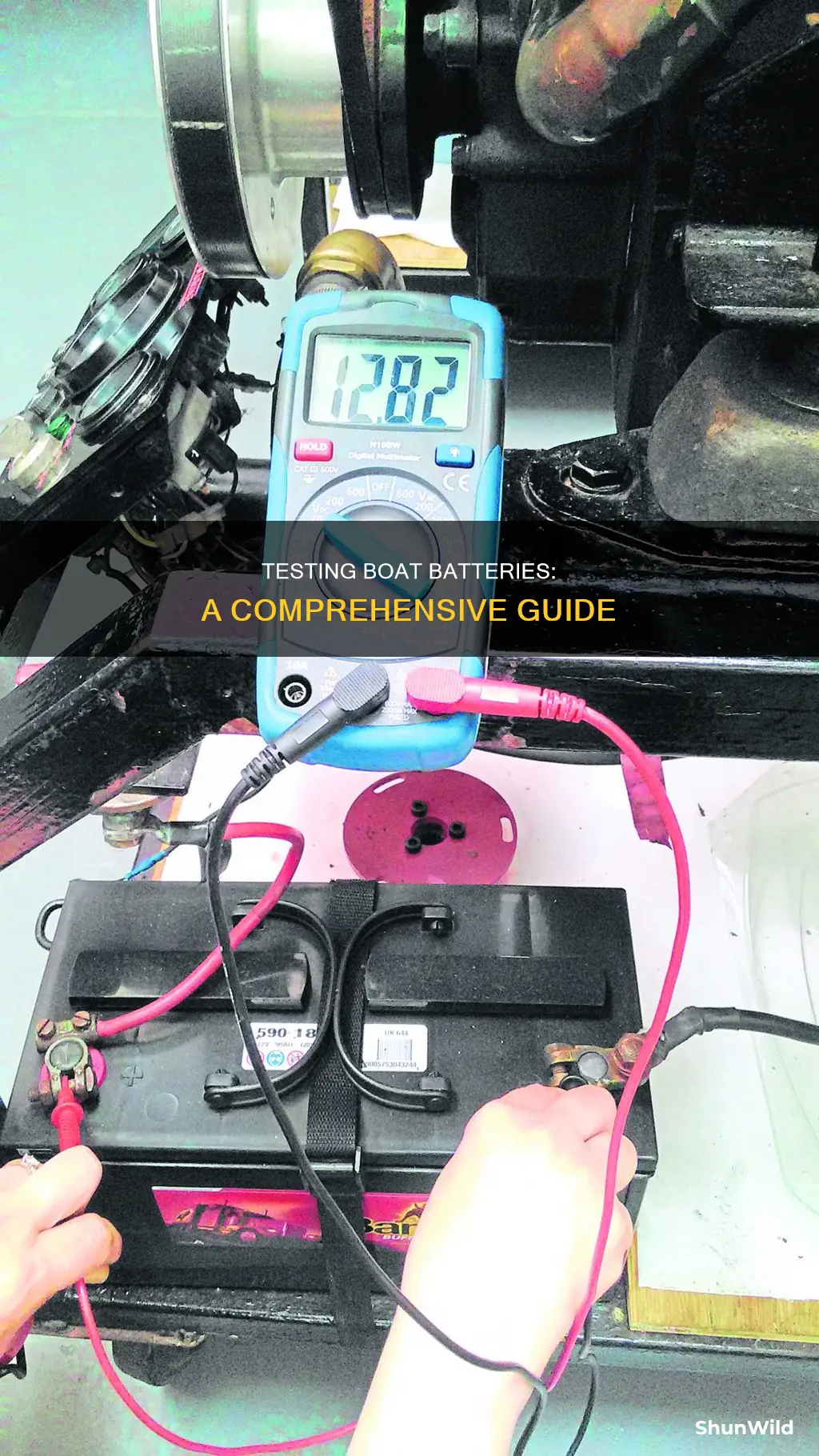

Testing a boat battery is important for boat owners to ensure their safety while on the water. It is possible to test a boat battery by taking it to a battery professional, such as a local marina or auto parts store, which will give you a general idea of the battery's health. Another way to test a boat battery is to use a hydrometer, but this requires fully charging the battery and then not using it for a specified amount of time. A third way to test a boat battery is to use a solar battery tester, which can be used with 12-volt conventional lead-acid (wet cell) batteries, AGMs, spiral-wound AGMs, and gel cells. Finally, a load test can be performed on a boat battery, which requires the battery to be at 100% voltage before applying the load.

| Characteristics | Values |

|---|---|

| Battery Type | Deep-cycle battery |

| Tools Required | Hydrometer, DC voltage meter, load tester |

| Battery Preparation | Fully charge the battery or let it sit for one hour after use |

| Safety Precautions | Wear PPE, remove metallic objects, work in a well-ventilated area |

| Battery Inspection | Check for broken or loose terminals, leaks, dirt and grime |

| Hydrometer Reading | All cells should be at least 1.225, with less than a 50-point difference between high and low readings |

| Battery Voltage | A fully charged and healthy battery will read 12.6V or higher (12-volt battery) or 6.4V or higher (6-volt battery) |

| Load Testing | Apply a 15-second load equivalent to 50% of the battery's CCA rating |

| Load Tester Minimum Passing Voltage | Refer to the load tester's specifications |

| Battery Replacement | If the test voltage is below the minimum passing voltage, replace the battery |

What You'll Learn

Using a hydrometer to test a boat battery

Step 1: Prepare the Battery

First, ensure the battery is fully charged. If it's not, the readings from the hydrometer may not be accurate. Connect the battery to a charger and let it charge until it reaches full capacity. It's also important to note that you shouldn't perform a hydrometer test on a battery that has just been watered. The battery must go through at least one charge-discharge cycle to allow the water to mix adequately with the electrolyte.

Step 2: Gather the Necessary Materials and Safety Gear

You will need a container to hold the electrolyte, safety goggles, and gloves. It is important to wear protective gear when handling batteries and electrolytes to avoid contact with sulfuric acid.

Step 3: Insert the Hydrometer into the Battery

Insert the hydrometer into the battery cell, making sure the tip is fully submerged in the electrolyte. Squeeze the rubber bulb on the hydrometer to draw a sample of the electrolyte into the device.

Step 4: Take the Reading

Read the specific gravity of the electrolyte from the hydrometer and record the reading for each cell. The specific gravity is a measure of the density or weight of the electrolyte solution. As the battery discharges, the sulfuric acid reacts with the lead plates, reducing the specific gravity. A fully charged battery will have a specific gravity of around 1.265, while a discharged battery will be closer to 1.120.

Step 5: Interpret the Results

Compare the readings from each cell to determine the state of charge of the battery. If the specific gravity of a cell is significantly lower than the others, it may indicate a failing or undercharged cell. A brown or grey colour of the electrolyte also indicates a problem with the battery.

Additional Tips:

- Correct the hydrometer reading to a temperature of 80° F (27° C). The electrolyte temperature is often significantly different from the ambient temperature, so this correction is important for accurate results.

- Test each cell and note the readings. A variation of fifty points between any two cell readings indicates a problem with the lower reading.

- Avoid common mistakes such as not cleaning the hydrometer, not testing all cells, not letting the battery rest after charging or discharging, and not following safety precautions.

Repairing Your Zodiac Inflatable: A Step-by-Step Guide

You may want to see also

Load testing a sealed battery

Load testing a sealed lead-acid battery can be done by following these general steps:

Preparation:

First, ensure your safety by wearing gloves, goggles, and protective clothing. Then, charge the battery to its full capacity and maintain its recommended temperature.

Connect Equipment:

Following the manufacturer's instructions, connect the load tester, multimeter, and any other required equipment to the battery. Ensure that the equipment is properly calibrated for accurate measurements.

Set Load Parameters:

Configure the load tester to apply a controlled load to the battery based on specific test requirements or industry standards. The load should reflect expected real-world usage to obtain accurate results.

Perform Load Test:

Apply the load to the battery for a predetermined duration, typically outlined in the battery's specifications or industry standards. Monitor the battery's voltage, current, and other parameters during the test, recording data using a data logger if available.

Monitor and Analyze:

Observe the battery's performance during the load test, noting any abnormalities or voltage fluctuations. Analyze the data after the test to accurately interpret the results.

Interpret Results:

Compare the test results with the battery's specifications or industry standards. Look for signs of degradation, voltage drops, or other indications of battery health. Based on the findings, determine if the battery needs replacement or maintenance.

It is important to note that load testing a sealed battery should be done carefully and only a few times during its lifetime, as the test can put a strain on the battery.

Baking Bread Aboard Old Sailboats: What's the Story?

You may want to see also

What to do before load testing

Before load testing a boat battery, there are several important steps to follow to ensure accurate results and maintain safety.

Firstly, it is crucial to have a basic understanding of how batteries work and the potential risks associated with handling them. This includes wearing personal protective equipment, such as goggles and gloves, removing metallic objects like jewellery, and working in a well-ventilated area to avoid any potential hazards.

Next, fully charge the battery or, if charging is not possible, allow it to sit for at least an hour after use before testing. This step is essential to obtain an accurate reading of the battery's condition. During this time, you can also perform a visual inspection of the battery. Check for any broken or loose terminals, as these can result in dangerous short circuits. Also, look for leaks or damage to the battery case, especially in flooded batteries, as operating a damaged battery can be unsafe. Additionally, ensure that the top of the battery and terminals are free from dirt and grime, as this corrosive buildup can cause the battery to self-discharge.

After inspecting and preparing the battery, gather the necessary tools for load testing. You will need a hydrometer to measure the specific gravity of the acid within the battery fluid and a DC voltage meter to measure voltage. These tools are typically available at local auto parts or battery retail stores.

Before conducting the load test, it is crucial to ensure that the battery terminals are free of corrosion and that the battery is at 100% voltage. At this stage, you should also refer to the manufacturer's instructions for any specific requirements or precautions related to your particular battery.

By following these steps, you will be well-prepared to safely and effectively load test your boat battery.

Ohio's Paddle Boat Odyssey: The Ultimate Adventure

You may want to see also

How to load test step-by-step

Before you begin, it's important to note that load testing puts a strain on your boat battery, so you should only perform this test a few times within a battery's lifetime.

Now, to load test a boat battery, follow these steps:

- Ensure your battery is at 100% voltage before applying a load test.

- Remove all battery cables from their terminals.

- Using a load tester, apply a load equivalent to 50% of the battery's CCA (Cold Cranking Amps) rating for 15 seconds.

- Refer to the load tester's minimum passing voltage to determine the battery's condition. If the test voltage is below the minimum, replace the battery.

- If your battery still performs poorly, you can refer to a seasonal battery brochure for troubleshooting ideas.

Alternatively, you can calculate the total C/20 battery amp-hour capacity and then create a load of amps that will provide this capacity rating. For example, if you have three 8D batteries, you would have a total of 720 AHrs. You would then divide 720 AHrs by 20 hours, resulting in 36 amps. You would then create a load of 36 amps on your battery and measure the voltage and amp hours drawn every hour for the next 20 hours. Stop the draw once the battery reaches 10.5 volts.

If you don't want to perform the load test yourself, you can take your boat battery to a local marina or auto parts store, where professionals can perform a load test for you, usually at no charge.

Essentials for a Boat Trip: What to Pack

You may want to see also

What to do if your battery performs poorly

If your boat battery is performing poorly, there are several steps you can take to address the issue.

Firstly, it's important to determine whether the battery is simply dying or if there is another underlying issue. Check for any visible signs of damage, such as cracking, warping, or bulging, as this would indicate the need for a replacement. Additionally, ensure that the battery voltage is within the acceptable range. A fully charged marine battery should have a reading of around 12.6 to 12.8 volts when not in use, and anything below 12.4 volts is a cause for concern.

If you suspect that the battery is dying, refrain from attempting to jump-start it, especially with a car battery. This could damage both the boat battery and the boat itself. Instead, consult a battery professional who can perform a load test to assess the battery's health and determine if a replacement is necessary.

In some cases, poor battery performance may be due to factors other than aging or damage. For example, corrosion on the battery terminals can cause sulfation, which hinders the battery's ability to deliver a quick burst of energy. Therefore, it is important to regularly clean the terminals and inspect for any signs of corrosion. Additionally, parasitic draw, caused by leaving electronics on, can drain the battery.

Finally, consider the age of your battery. Marine batteries typically last around 3 to 5 years, and proactive replacement can prevent unexpected failures. By regularly maintaining your battery and being mindful of its age, you can help ensure reliable performance and avoid getting stranded on the water.

Launching a Profitable Paddle Boat Rental Business in Florida

You may want to see also

Frequently asked questions

You can take your boat battery to a battery professional, like your local marina or auto parts store. They should have a load tester, which will give you a general idea of the health of your battery. You can also buy a load tester and perform the test yourself.

First, make sure your battery is at 100% voltage. Then, remove all battery cables from their terminals. Apply a load equivalent to 50% of the battery's CCA rating for 15 seconds. Refer to the load tester's minimum passing voltage to determine the battery's condition. If the test voltage is below the minimum, replace the battery.

There are a few signs that your battery is damaged. Broken or loose terminals, a leaking or damaged battery case, and dirt and grime can all indicate that your battery is damaged. If you notice any of these issues, be sure to address them as soon as possible to prevent further damage or safety hazards.