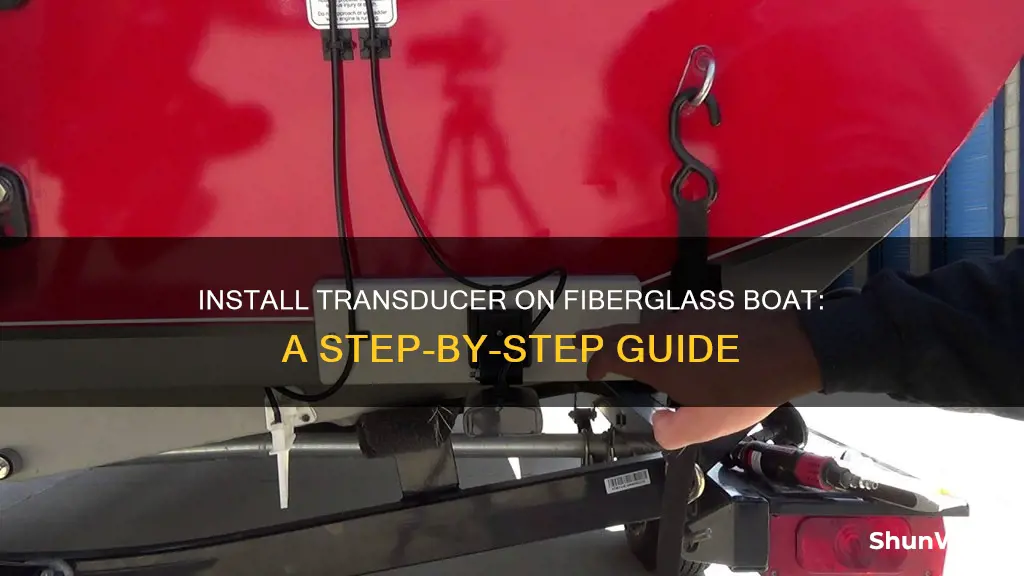

Installing a transducer on a fiberglass boat can be a straightforward process if you follow the right steps. This guide will provide a comprehensive overview of the process, ensuring you have the necessary tools and knowledge to complete the installation safely and effectively. From preparing the boat's surface to connecting the transducer, you'll learn how to make the most of your marine electronics setup.

What You'll Learn

- Preparation: Clean and inspect boat surface, ensuring it's dry and free of debris

- Material Selection: Choose appropriate adhesive and transducer mount for fiberglass

- Mounting Technique: Secure transducer with recommended fasteners, ensuring proper alignment

- Waterproofing: Apply sealant around mounting points to prevent water intrusion

- Testing: Verify transducer functionality and adjust positioning if necessary

Preparation: Clean and inspect boat surface, ensuring it's dry and free of debris

Before you begin the installation process of a transducer on your fiberglass boat, it's crucial to ensure that the surface is properly prepared. Start by thoroughly cleaning the area where the transducer will be mounted. Use a mild detergent or boat cleaner to remove any dirt, grime, or old paint that might be present. Rinse the surface with water to eliminate any remaining soap residue. Pay close attention to the edges and crevices, as these areas can accumulate dirt and may require extra cleaning.

Once the cleaning process is complete, it's essential to inspect the boat's surface for any damage or imperfections. Look for any signs of scratches, chips, or cracks, as these could affect the adhesion and performance of the transducer. If you notice any significant damage, it might be necessary to repair or fill the affected areas with a suitable fiberglass filler or putty. Smooth out the surface as much as possible to create a level and stable base for the transducer.

After cleaning and inspecting, ensure that the boat's surface is completely dry. Moisture can interfere with the installation process and may lead to issues with the transducer's functionality. If the weather is humid or rainy, consider using a dehumidifier or a hairdryer on a low setting to accelerate the drying process. Patience is key here; rushing the drying process might result in a less secure installation.

Additionally, check for any existing holes or mounts on the fiberglass surface that could be used for the transducer installation. Sometimes, manufacturers or previous owners might have pre-drilled holes for such purposes. Using these existing holes can simplify the process and provide a more secure mounting point. If no pre-drilled holes are available, you may need to carefully mark and drill new holes, ensuring they are aligned with the transducer's mounting points.

By taking the time to clean, inspect, and prepare the boat's surface, you'll create a solid foundation for a successful transducer installation. This step is often overlooked but is critical to ensuring the transducer functions optimally and remains securely in place over the long term.

Mastering Boat Control in Arcane Adventures

You may want to see also

Material Selection: Choose appropriate adhesive and transducer mount for fiberglass

When installing a transducer on a fiberglass boat, the choice of materials is crucial to ensure a secure and long-lasting setup. The primary challenge here is the smooth and non-porous surface of fiberglass, which requires a specific approach to bonding.

Adhesives: For fiberglass, the ideal adhesive is one that is specifically designed for marine environments and can withstand the unique challenges of bonding to this material. Epoxy-based adhesives are commonly used and highly recommended. These adhesives create a strong, durable bond and are resistant to the harsh conditions of saltwater. Look for epoxy systems that offer excellent adhesion to fiberglass, with a slow cure rate to allow for easy application and positioning. It's important to choose an epoxy that is compatible with the transducer's backing material to ensure a secure bond.

Transducer Mounts: Selecting the right mount is essential for a successful installation. Fiberglass boat surfaces can be relatively smooth, but the use of a mount provides additional stability and vibration damping. Consider using a mount made from a flexible, yet durable material like rubber or a specialized marine-grade foam. These materials can absorb vibrations, reducing the risk of damage to the transducer and the boat's structure. Mounts with a slightly raised surface can also help to create a small gap between the transducer and the boat, allowing for better heat dissipation and preventing potential corrosion.

The key to a successful installation is to ensure that the adhesive and mount are compatible with the fiberglass surface and the transducer's requirements. Testing the chosen materials in a controlled environment before final installation is a good practice to ensure everything works as expected. Additionally, always follow the manufacturer's guidelines for the specific transducer and adhesive being used to guarantee optimal performance and longevity.

The Perfect Guide to Installing Boat Numbers

You may want to see also

Mounting Technique: Secure transducer with recommended fasteners, ensuring proper alignment

When installing a transducer on a fiberglass boat, it's crucial to use the right fasteners to ensure a secure and reliable setup. The specific fasteners and their installation process will depend on the transducer model and the boat's structure. Here's a step-by-step guide to help you with the mounting technique:

Step 1: Prepare the Transducer and Fasteners

Before you begin, inspect the transducer and gather the appropriate fasteners recommended by the manufacturer. Typically, transducers come with specialized fasteners designed to secure them to fiberglass surfaces. These fasteners might include stainless steel screws, bolts, or even specialized transducer mounts. Ensure you have the correct size and type of fasteners to avoid any issues during installation.

Step 2: Locate the Ideal Mounting Position

Identify the best location on your fiberglass boat for the transducer. This area should provide optimal sound transmission and avoid interference with other boat components. Typically, transducers are mounted near the waterline, ensuring the transducer is submerged when the boat is in operation. Mark the position with a pencil or use a template to ensure accurate alignment.

Step 3: Apply the Recommended Adhesive (Optional)

Some transducers may require an adhesive or sealant for added security. If specified by the manufacturer, apply a small amount of marine-grade adhesive to the transducer's mounting surface. This step ensures a stronger bond and prevents any movement during operation. Make sure to follow the adhesive manufacturer's instructions for proper application and drying time.

Step 4: Secure the Transducer with Fasteners

Now, it's time to attach the transducer to the boat. Start by positioning the transducer at the marked location, ensuring it is level and aligned with the recommended angle for optimal performance. Use the appropriate fasteners provided with the transducer. Tighten the screws or bolts securely, but be careful not to overtighten, as this can damage the transducer or the boat's surface. The goal is to create a tight, vibration-resistant connection.

Step 5: Verify Alignment and Tightness

After securing the transducer, double-check the alignment to ensure it is level and facing the correct direction. Improper alignment can affect the transducer's performance and the clarity of the sonar readings. Also, inspect the fasteners to make sure they are tight and secure. Over time, fasteners may loosen due to vibrations, so it's essential to periodically check and retighten them.

Remember, proper alignment and secure fastening are critical to the transducer's functionality and the overall performance of your boat's sonar system. Always refer to the transducer's manual and the boat manufacturer's guidelines for specific instructions tailored to your vessel.

Adding Drain Plug to Aluminum Boat: A Step-by-Step Guide

You may want to see also

Waterproofing: Apply sealant around mounting points to prevent water intrusion

When installing a transducer on a fiberglass boat, ensuring proper waterproofing is crucial to prevent water damage and ensure the longevity of the electronic component. One critical step in this process is applying a high-quality sealant around the mounting points. Here's a detailed guide on how to do it effectively:

Step 1: Preparation

Before applying any sealant, it's essential to prepare the area. Start by cleaning the mounting points on the boat's hull. Use a mild detergent or a specialized boat cleaner to remove any dirt, grime, or old sealant residue. Ensure the surface is dry and free of any debris. This step is vital as it creates a clean and smooth base for the sealant, allowing it to adhere properly.

Step 2: Choose the Right Sealant

Selecting an appropriate sealant is key to a successful installation. For fiberglass boats, consider using a marine-grade silicone sealant. This type of sealant is designed to withstand the harsh marine environment, including UV rays, saltwater, and varying temperatures. It should be flexible to accommodate slight movement and provide an effective barrier against water intrusion. Ensure you choose a color that matches the boat's finish to maintain a seamless appearance.

Step 3: Application Technique

Now, you're ready to apply the sealant. Start by applying a thin, even layer around the mounting points. Use a small brush or a putty knife to ensure the sealant is applied neatly and without any gaps. Pay close attention to the corners and edges, as these areas are prone to water leakage. Apply enough sealant to create a continuous barrier, but be mindful not to overfill, as it may ooze and create mess.

Step 4: Allow for Curing

After applying the sealant, allow it to cure according to the manufacturer's instructions. This process typically involves waiting for a specified time before handling the installation. Avoid any pressure or impact on the sealant during this period to ensure its integrity. Once cured, the sealant will form a robust barrier, protecting the transducer and the boat's interior from potential water damage.

By following these steps, you can effectively waterproof the transducer's mounting points, ensuring a reliable and long-lasting installation. Remember, proper waterproofing is essential for the performance and durability of your boat's electronics.

Taking Apart a Boat Throttle: Step-by-Step Guide

You may want to see also

Testing: Verify transducer functionality and adjust positioning if necessary

Before finalizing the installation, it's crucial to thoroughly test the transducer to ensure it functions correctly and is positioned optimally for accurate readings. Here's a step-by-step guide to the testing process:

Initial Verification: Once the transducer is installed, power it up and check for any immediate issues. Ensure the display unit shows a stable reading, indicating the transducer is receiving and transmitting data. This initial check helps identify any potential hardware malfunctions right away.

Depth and Accuracy Testing: Submerge the transducer in a controlled environment, preferably a large container or a calm body of water. Test the transducer's depth detection capabilities by lowering and raising it while monitoring the display. Compare the readings with known depths to ensure accuracy. If discrepancies are found, adjust the transducer's position slightly and retest until the desired accuracy is achieved.

Calibration: Transducers often require calibration to ensure precise measurements. This process involves adjusting the transducer's settings based on its specific characteristics. Consult the manufacturer's guidelines for calibration instructions. This step is essential for obtaining reliable data, especially in professional applications.

Positioning Adjustments: The positioning of the transducer significantly impacts its performance. If the initial placement doesn't yield satisfactory results, consider the following:

- Angle: Adjust the angle of the transducer to find the optimal position for the desired depth and clarity.

- Depth: Ensure the transducer is at the correct depth. If it's too shallow or deep, the readings will be inaccurate.

- Obstructions: Check for any physical obstructions that might interfere with the transducer's signal. Remove or adjust these obstructions for better performance.

Environmental Factors: Consider environmental conditions that might affect the transducer's functionality. Factors like temperature changes, water salinity, and pressure can influence readings. If possible, test the transducer in varying conditions to ensure its reliability across different environments.

Documentation: Throughout the testing process, document any adjustments made and the corresponding results. This documentation will be valuable for future reference, allowing you to quickly identify and rectify any issues.

Remember, proper testing and adjustment are critical to ensuring the transducer provides accurate and reliable data for your fiberglass boat.

Bedding an Aluminum Boat Tank: The Ultimate Guide

You may want to see also

Frequently asked questions

Before beginning the installation, ensure the boat is clean and dry. Remove any dirt, grease, or old adhesive residue from the surface where the transducer will be mounted. This step is crucial for a successful bond and to prevent any interference with the transducer's performance.

Select a location that provides optimal sound transmission and avoids potential interference. Typically, the transducer is installed in the hull or on the transom, facing the water. Consider the depth and shape of the boat, as well as the desired scanning angle for the echo sounder. Avoid areas with sharp corners or protruding structures that might affect the sound wave propagation.

For fiberglass boats, it is recommended to use a high-strength marine-grade adhesive specifically designed for underwater applications. These adhesives are typically epoxy-based and provide excellent bonding strength. Alternatively, you can use specialized transducer mounts or brackets that are designed to adhere to the fiberglass surface. Ensure that the chosen adhesive or mount is compatible with the transducer's weight and size.

Yes, you will need a few essential tools. A power drill with a suitable bit for creating pilot holes is essential for secure mounting. Additionally, a marine-grade sealant or underwater tape can be used to provide an extra layer of protection against water intrusion. It is also advisable to have a helper assist with the installation, especially when handling the transducer and ensuring it is properly aligned and secured.