If you're looking to install a Humminbird transducer on an aluminium boat, there are a few different mounting options to consider. Most Humminbird units come with everything you need for installation and operation, except for products marked CHO (Control Head Only). If a transom-mount transducer won't work for you, alternatives include trolling motor mounting, portable mounting, in-hull mounting, and thru-hull mounting. It's important to note that bronze transducer mounting options are not recommended for aluminium or steel hull boats, while plastic transducer mounting is ideal for wooden boats.

What You'll Learn

Transom-mount transducers

Use a Mounting Plate

To minimise drilling into your transom, it is recommended to use a mounting plate. Commercially available options include screw-on Starboard plates and stick-on plates, or you can make your own out of Starboard or expanded PVC.

Drill Holes

When drilling holes in your transom, measure the length of your screws minus the thickness of your mounting bracket and mark the necessary depth on your drill bit with painter's tape. This will prevent you from drilling too deeply.

For aluminium boats, an alternative to drilling holes is to use a King Starboard (poly) block such as a Stern Saver, which accepts the retaining hardware. The block is glued to the hull with a special adhesive, and the hardware is screwed into the block.

No Electric Drivers!

Avoid using electric drills or drivers when tightening self-tapping screws into fiberglass, especially below the waterline. Instead, tighten the screws by hand to prevent stripping.

Chamfer and Seal Your Holes

Drilling below the waterline requires extra care to avoid gelcoat cracking. Run your drill in reverse until the bit reaches the fiberglass, then use a countersink to chamfer the edges around the hole carefully. Seal the installation by coating screws and filling pilot holes with a quality marine sealant approved for below waterline use.

Level Your Transducer with the Transom Waterline

It is important to get the bottom of your transducer parallel to the bottom of your hull. This can be done by holding a long straight edge against the bottom of your boat and adjusting the transducer to match the angle.

For side-imaging transducers, use a horizontal guideline on your transom (e.g. the bottom edge of a jackplate) and a framing square to ensure the transducer is level side-to-side.

Fine-Tuning

If you experience performance issues at high speeds, try lowering the transducer in 1/8" increments until it reads well. Additionally, you can try loosening the bracket bolts and lowering the tail end of the transducer a few degrees to improve the water flow across the bottom of the transducer.

Exploring the Seating Arrangements on Show Boat Belle

You may want to see also

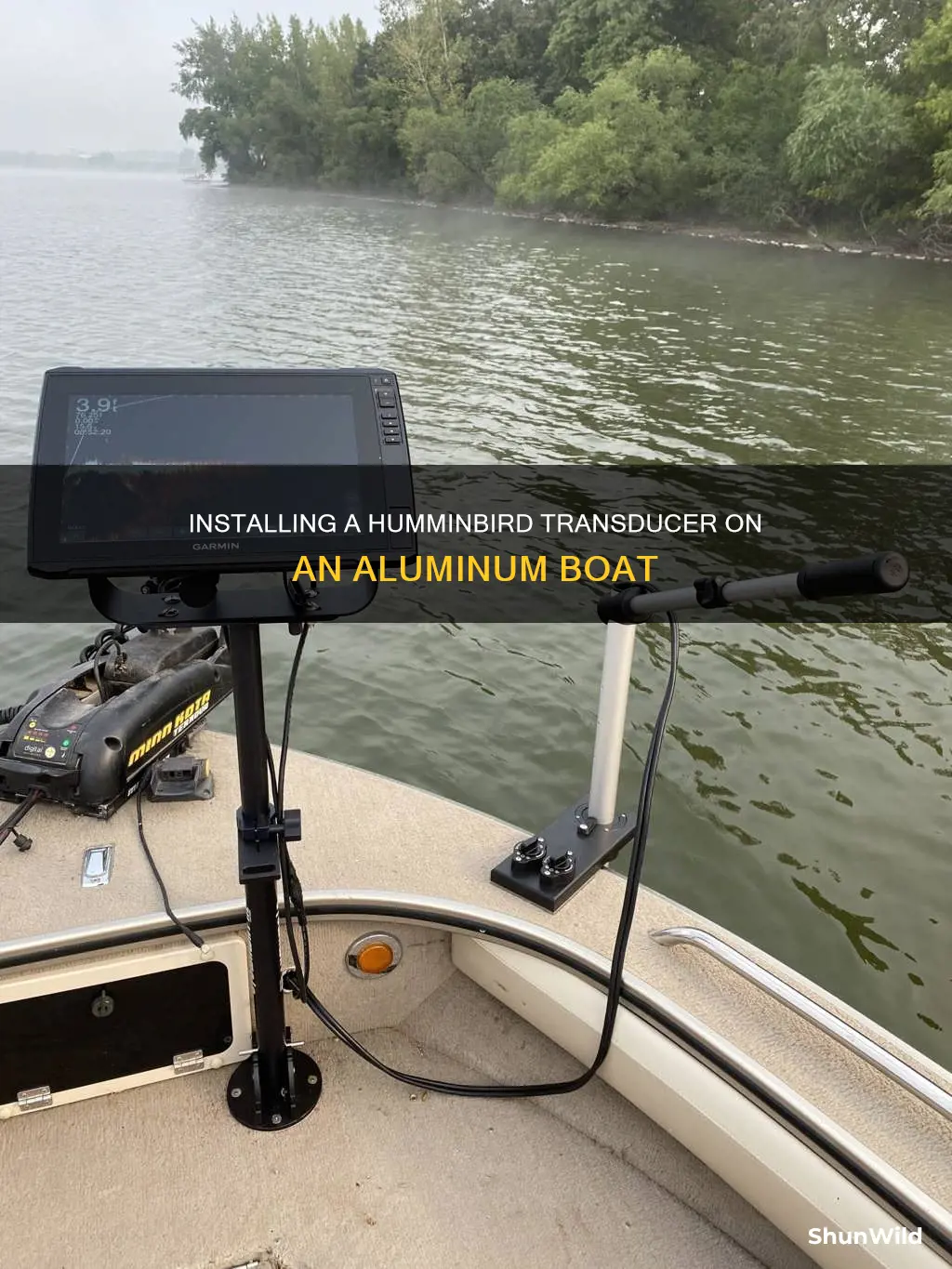

Trolling motor mount

Trolling motors can be mounted in one of three places: on the transom (stern), on the engine itself, or on the bow. Here is a step-by-step guide for each of these options.

Mounting a Trolling Motor on the Transom

- Open the mounting bracket clamps by turning them counter-clockwise (to the left).

- Slip the motor over the transom, placing it as close to the center of the stern as possible without interfering with the operation of the main motor. Ensure the top of the mounting bracket is flush with the top of the stern.

- Tighten the clamps by turning them clockwise (to the right) as far as they will go to secure the motor.

- Ensure the center of the motor section is at least 9 inches (22.5 cm) underwater while the motor is running to avoid breaking the water's surface, which can spook fish.

Mounting a Trolling Motor on the Engine

- Place the mounting bracket on top of the engine's anti-cavitation plate with the motor facing up. The anti-cavitation plate is a horizontal plate that prevents the propeller from breaking the water's surface.

- Ensure your anti-cavitation plate runs at a depth of at least 13 inches (32.5 cm) below the waterline so that the trolling motor will operate at least 6 inches (15 cm) below the waterline.

- Mark the holes to be drilled through the anti-cavitation plate using the mount as a template.

- Drill the holes for the mounting bolts using a drill bit suitable for drilling through the metal of the anti-cavitation plate.

- Place the mounting bracket back on top of the anti-cavitation plate and insert the mounting bolts to secure the trolling motor.

- Note that engine-mounted trolling motors are designed for V-hull or tri-hull boats that go "on plane" and are not suitable for pontoon boats or sailboats.

Mounting a Trolling Motor on the Bow

- Separate the trolling motor assembly from the mount base. Bow-mounted electric trolling motors are designed for boats with flat, raised forward decks, typically bass boats used for fishing in shallow water.

- Choose the place on the deck where the base should be attached, considering the motor's position when pulling the boat and when stowed on the deck while the main motor is in use. Ensure the base provides enough clearance for the motor to break away if using a breakaway mount and that the mounting screws can penetrate the deck but not the hull.

- Mark the holes to be drilled into the deck using the mount base as a template.

- Drill the holes for the mounting bolts using a sharp bit to a depth of 1/4 inch (6.5 mm). Clear out any debris after drilling, and if the boat is made of fibreglass, countersink the holes.

- Thread a bolt through each hole in the mount base.

- Slip a rubber washer onto each bolt, underneath the mount base, to hold it in position with your fingers as you move the mount base over the drilled holes. Alternatively, place the washers over the drilled holes if this is easier.

- Place the base over the drilled holes, slipping the bolts through each hole.

- Check that the base rests level against the deck surface. If it doesn't, add more rubber washers under the bolts where the base wobbles to level it. Ensure the base rests evenly so that the motor can be raised onto the deck and locked down for transport.

- Thread a steel washer and retaining nut onto each bolt and tighten the nuts to secure the base.

- Secure the motor assembly to the base.

- Ensure the bow-mounted trolling motor runs at least 5 inches (12.5 cm) below the water level to account for rough water. A depth of 12 inches (30 cm) is recommended if you fish from a standing position.

The standard Humminbird transducer can be adapted to mount on most trolling motors using an accessory kit. This kit includes a bracket and hose clamp that allow for mounting the transducer to the body of most trolling motors.

Tiger Woods' Mom: Fresh Off the Boat Guest Star

You may want to see also

Thru-hull transducers

When installing a thru-hull transducer, it is important to select the correct type of transducer for your boat's hull material. For aluminium boats, stainless steel transducers are recommended. It is also important to isolate the transducer from the hull to prevent galvanic corrosion.

- Select the correct transducer: Ensure that the transducer is compatible with your fishfinder and includes the specific capabilities you require. It should also be compatible with your boat's hull material.

- Choose the mounting location: Avoid mounting the transducer near the engine water intake, discharge openings, or obstructions such as the boat's keel. Ensure that the water flowing under the hull is smooth, especially at high speeds, and that the transducer will be continuously immersed in water.

- Prepare the hull: Drill a pilot hole perpendicular to the waterline from inside the hull. Use the appropriate size hole saw drill bit to cut a hole from outside the hull, ensuring that the drill is held perpendicular to the water's surface. Sand and clean the area around the hole to ensure that the marine sealant will adhere properly.

- Tape off the hull: Use blue masking tape to cover the hull around the hole. Dry-fit the transducer and trace the outline of the head on the tape. Cut out the hole in the tape to make sealant cleanup easier later.

- Bed the transducer: Remove the hull nut. Thread the transducer cable through the fairing, if used. Apply a layer of marine sealant to the surface of the transducer that will contact the hull/fairing and up the stem. For stainless steel transducers, slide the isolation sleeve over the bedded transducer stem and apply sealant to the outside of the sleeve.

- Apply sealant to the fairing: Apply marine sealant to the fairing, backing block, and hull nut. Seat the transducer firmly against the fairing with a pushing and twisting motion.

- Install the transducer: From outside the hull, thread the cable through the mounting hole and push the transducer stem through, using a twisting motion to squeeze out excess sealant. Ensure that the transducer is aligned with the blunt end facing forward toward the bow and the long side parallel to the centerline of the boat.

- Secure the transducer: From inside the hull, slide the backing block and hull nut onto the cable. Seat the backing block against the hull, then screw and tighten the hull nut in place.

- Clean up excess sealant: Remove any excess marine sealant on the outside of the hull and fairing to ensure smooth water flow under the transducer.

- Route the cable: Route the cable to the fishfinder, being careful not to tear the cable jacket when passing it through bulkheads and other parts of the boat. Use grommets and cable clamps or wire ties to support the cable and prevent chafing.

- Connect the transducer: Refer to the fishfinder owner's manual to connect the transducer to the instrument.

- Check for leaks: When the boat is placed in the water, immediately check around the transducer for leaks. Small leaks may not be immediately obvious, so do not leave the boat in the water for more than three hours before checking again.

A Boat's Dark Secrets Unveiled

You may want to see also

Portable mounting

If you want to install a Humminbird transducer on an aluminium boat using portable mounting, you can adapt the standard transducer for portable installations with a portable mounting kit available from Humminbird. This kit lets you adapt your transducer to a suction cup mount for temporary installation on the boat hull or other surfaces.

Most Humminbird units come with everything necessary for installation and operation on most boats. However, products marked "CHO" (Control Head Only) are an exception to this.

If a transom-mount transducer will not work for your aluminium boat, there are several other options that may be more suitable. These include trolling motor mounting, in-hull mounting, and thru-hull mounting.

Trolling motor mounting uses an accessory kit with a bracket and hose clamp that allows mounting the transducer to the body of most trolling motors. In-hull mounting is recommended for single-layer fibreglass hulls and comes with an installation kit containing a two-part slow-cure epoxy. Thru-hull transducers install through a hole drilled in the hull of the boat and are recommended for larger boats or boats with inboard motors that create turbulence, making transom mounting ineffective.

Exploring Vice City: Mastering Boat Driving

You may want to see also

In-hull mounting

To install an in-hull transducer, first, locate the best position for the transducer inside the hull. This position will depend on the type and size of your boat. Mark the position of the transducer on the hull. Drill holes in the hull according to the installation instructions. Fix the transducer in place using the provided epoxy, following the manufacturer's instructions for the correct mix ratio and cure time. Ensure that the transducer is securely attached to the hull and that all connections are sealed and waterproof.

It is important to follow the specific instructions provided with your transducer for in-hull mounting, as the process may vary slightly depending on the model and your boat's unique characteristics.

Sportfishing Boat Features: What Makes a Good Catch?

You may want to see also

Frequently asked questions

Most Humminbird units come with everything necessary for installation and operation on most boats. However, if a transom-mount transducer will not work for your boat, there are several other options, including trolling motor mounting, portable mounting, in-hull mounting, and thru-hull mounting.

For an aluminium boat, a transom-mount transducer is recommended.

Transom-mount transducers are also used on fiberglass boats, pontoon boats, inflatable boats, and search and rescue boats.