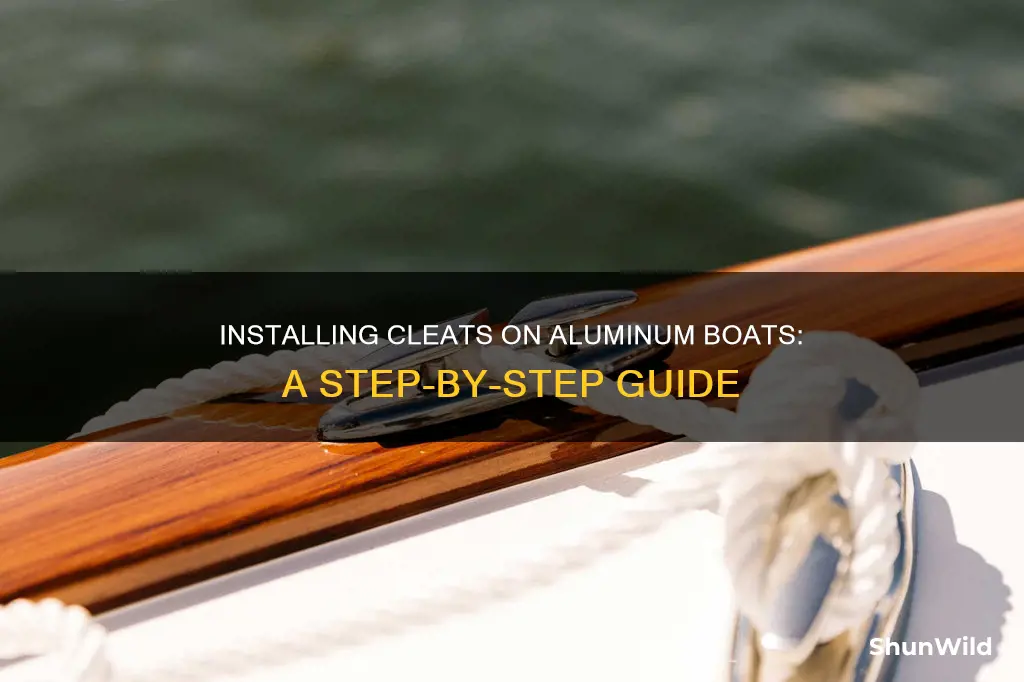

Installing cleats on an aluminium boat is a straightforward process, but it requires careful attention to ensure a proper fit. It is important to select the right type of cleat for your boat, taking into account factors such as size, usage, and material. Stainless steel and aluminium are popular choices due to their durability and corrosion resistance.

The placement of the cleats is also crucial. They are commonly placed at the bow, stern, and along the sides of the boat, ensuring efficient mooring and tying points without obstructing movement. Before installation, the mounting area should be cleaned and prepared, and the optimal locations for the cleats should be marked.

The actual installation process involves drilling holes, applying sealant or adhesive, and attaching the cleats with suitable fasteners like stainless steel screws or bolts. It is important to follow the manufacturer's instructions and recommendations to ensure a secure and watertight installation.

What You'll Learn

Choosing the right cleat material

When choosing the right cleat material for your aluminum boat, there are several factors to consider, including the type of boat, your sailing environment, durability, and aesthetics. Here are some common cleat materials to choose from:

Stainless Steel Cleats

Stainless steel cleats are known for their strength and corrosion resistance, making them ideal for saltwater environments and heavy-duty use. They are more expensive initially but will provide durability and a longer lifespan. Stainless steel is also a good choice if you want to combine functionality with aesthetics, as it looks great and can withstand harsh marine conditions.

Aluminum Cleats

Aluminum cleats are lightweight yet durable and offer resistance to corrosion. They are a popular choice for freshwater environments. Aluminum is also suitable for general mooring purposes and can be mounted vertically or horizontally, providing flexibility and a strong hold. Keep in mind that aluminum may not be the best choice for high-salt environments as it may not hold up as well.

Galvanized Steel Cleats

If you're looking for a cost-effective option that offers corrosion resistance, galvanized steel cleats are a great choice. They are suitable for both fresh and saltwater setups, providing versatility for different sailing environments.

Nylon Cleats

Nylon cleats are ideal for small to medium-sized boats. They are lightweight, durable, and highly resistant to corrosion. If you're looking for an economical option that doesn't compromise on quality, nylon cleats are a great choice.

Other Materials

Other materials such as bronze, brass, and plastic are also available for boat cleats. Bronze and brass offer a classic and elegant look, making them popular for traditional yachts or high-end boats. Plastic cleats, on the other hand, are best suited for smaller boats or temporary moorings, as they are more affordable and lightweight but may not have the same durability as metal cleats.

When choosing the right cleat material, it's important to consider the specific needs of your aluminum boat, the sailing environment, and your personal preferences for durability, aesthetics, and cost. Remember that the cleats play a crucial role in ensuring the safety and security of your boat, so investing in high-quality cleats is always a good decision.

How Cantonese Became the Language of Fresh Off the Boat

You may want to see also

Optimal cleat locations

When determining the optimal locations for cleat installation, it is important to consider both functionality and safety. Here are some key factors to keep in mind:

Bow, Stern, and Sides:

Cleats are commonly placed at the bow, stern, and along the sides of the boat. This provides efficient mooring and tying points. When installing cleats on the bow, consider placing them as close to the centreline as possible. This helps ensure that the boat can point directly into wind and wave action when anchored. For the sides, consider placing them amidships, also known as the "shoulder" area, for spring lines.

Ease of Access and Tripping Hazards:

Choose locations that allow for easy access to the cleats while avoiding potential tripping hazards. This is especially important if you plan to use the cleats frequently for mooring or docking.

Functionality and Purpose:

Consider the intended purpose and functionality of the cleats. For example, if you plan to use them for anchoring, you may want to install them in a location that is easily accessible when preparing to anchor the boat.

Boat Layout and Balance:

Take into account the layout and balance of your boat. Ensure that the cleats are positioned where they won't obstruct movement or interfere with other equipment on the boat.

Regular Intervals and Multiple Cleats:

It is recommended to place cleats at regular intervals along the port and starboard sides of your boat. At a minimum, consider installing three per side: one at the stern, one amidships, and one at the bow. However, remember that the more cleats you can reasonably install, the better, as it provides more options for securing your boat.

Strength and Weight Capacity:

Choose locations that are strong enough to support the weight of the cleats and the load they will bear. This is crucial for ensuring the safety and stability of your boat.

Avoid Frequent Contact Areas:

When selecting cleat locations, avoid areas that may come into frequent contact with objects or other boats, such as the prow or stern. This helps prevent damage to the cleats and ensures they remain secure.

Bass Boat Seating: Best Front Seat Options

You may want to see also

Preparing the mounting area

Firstly, it is important to choose the right location for your cleats. Consider the purpose and functionality of the cleats, as well as the layout and balance of your boat. Cleats are commonly placed at the bow, stern, and along the sides of the boat, providing efficient mooring and tying points without obstructing movement.

Once you have decided on the location, use a measuring tape to determine the exact position of the cleats. Mark the spots with a pencil or marker, ensuring that the markings are accurate and aligned with the boat's structure. It is important to make sure that the cleats will be centred on the boat and that the holes will be drilled in a straight line.

Before drilling, use a centre punch to make a small indentation at each marked spot. This will help prevent the drill bit from slipping when you start drilling. Also, make sure to wear appropriate safety gear, such as safety glasses, gloves, and a dust mask, during the installation process.

Now, you can begin drilling the pilot holes. Use an appropriate-sized drill bit that matches the diameter of the screws or bolts you will be using to secure the cleats. Drill slowly and carefully to ensure that the holes are straight and even. If your boat has multiple layers of aluminium, you may need to drill through both layers for a stronger hold.

After drilling the holes, use a file or sandpaper to smooth out any rough edges. This step will help ensure a tight seal when the cleats are installed. You can also apply a marine-grade sealant or adhesive around the drilled holes to prevent water intrusion and corrosion. This will create a watertight seal and protect the integrity of your boat.

Finally, before attaching the cleats, make sure the mounting area is clean and free from any dirt, grease, or residue that could hinder the attachment. Use a solvent or cleaning agent to remove any impurities, and ensure the surface is dry before proceeding with the installation.

By following these steps, you will have a well-prepared mounting area that will provide a strong and secure foundation for your cleats.

The Luxury Yachts of Below Deck Mediterranean

You may want to see also

Drilling holes and applying sealant

Drilling Holes:

- Choose the Right Drill Bit: Select a drill bit that matches the diameter of the screws or bolts you will use to secure the cleats. Using the correct size is essential to ensure a snug fit.

- Mark the Drilling Spots: Use a centre punch or a pencil to mark the exact locations where you will drill the holes. This step ensures that the drill bit does not slip when you start drilling.

- Drill Pilot Holes: Create pilot holes at the marked spots using the appropriately sized drill bit. Drill slowly and carefully to ensure straight and even holes.

Applying Sealant:

- Sealant Selection: Choose a marine-grade sealant or silicone that is suitable for use in a marine environment. This type of sealant will prevent water intrusion and protect against corrosion.

- Sealant Application: Apply the sealant around the drilled holes, creating a watertight seal. Ensure that the sealant fills any gaps between the cleat and the boat's surface.

- Allow Drying Time: Before proceeding to the next step, make sure to allow the sealant to dry according to the manufacturer's instructions. This will ensure that the sealant is fully cured and effective.

By following these steps, you will ensure that your cleats are securely installed and protected from the elements. Remember to consult manufacturer guidelines and seek professional advice if you have any specific questions or concerns about the installation process.

Boat Ramp Car Sinking: Insurance Claims and Coverage

You may want to see also

Attaching the cleats

Now that you have selected the right location and marked the spots for the cleats, it is time to attach the cleats securely.

First, you will need to drill pilot holes at the marked spots. Ensure that you use an appropriately-sized drill bit that matches the diameter of the screws or bolts that will be used to secure the cleats. It is important to note that aluminium is a soft metal, so pre-drilling the holes is essential to prevent splitting the aluminium during the drilling process.

Once the pilot holes are drilled, position the cleat over the holes, aligning it with the markings. Check that the cleat is properly oriented and facing the correct direction.

To secure the cleats, insert screws or bolts through the cleats and into the pilot holes. Tighten them securely using a screwdriver or wrench, depending on the type of fasteners used. It is recommended to use stainless steel screws or bolts to prevent corrosion. Additionally, consider using washers and nuts to reinforce the connection and distribute the load.

After securing the cleats, apply a marine-grade sealant or silicone around the bolts to prevent water intrusion and potential corrosion. This will help create a watertight seal.

Finally, double-check the installation by giving the cleats a firm tug to test their strength and stability. Ensure they are firmly attached and do not wobble or shift. Repeat this process if you are installing multiple cleats, maintaining proper spacing and alignment.

The Ultimate Guide to Cargo Hulls on Boats

You may want to see also

Frequently asked questions

When drilling holes in an aluminium boat for cleat installation, it is important to use the correct drill bit size to match the screws or bolts provided with the cleat installation kit. Begin by marking the hole locations using masking tape and a pencil or marker. Use a steady hand and apply consistent pressure when drilling the holes.

To ensure a secure and watertight installation, it is important to use an appropriate cleat installation kit that includes screws, bolts, washers, and nuts designed for use with aluminium boats. Before installing the cleats, apply marine-grade silicone sealant around the holes to create a watertight seal and prevent water from seeping into the boat's structure. Tighten the screws or bolts firmly using a screwdriver or wrench, ensuring that the cleats are securely attached to the boat.

When installing cleats on an aluminium boat, it is recommended to use stainless steel bolts with washers and nuts. If you cannot access the underside of the boat, you can use rivets or rivnuts, which are aluminium threaded rivets.