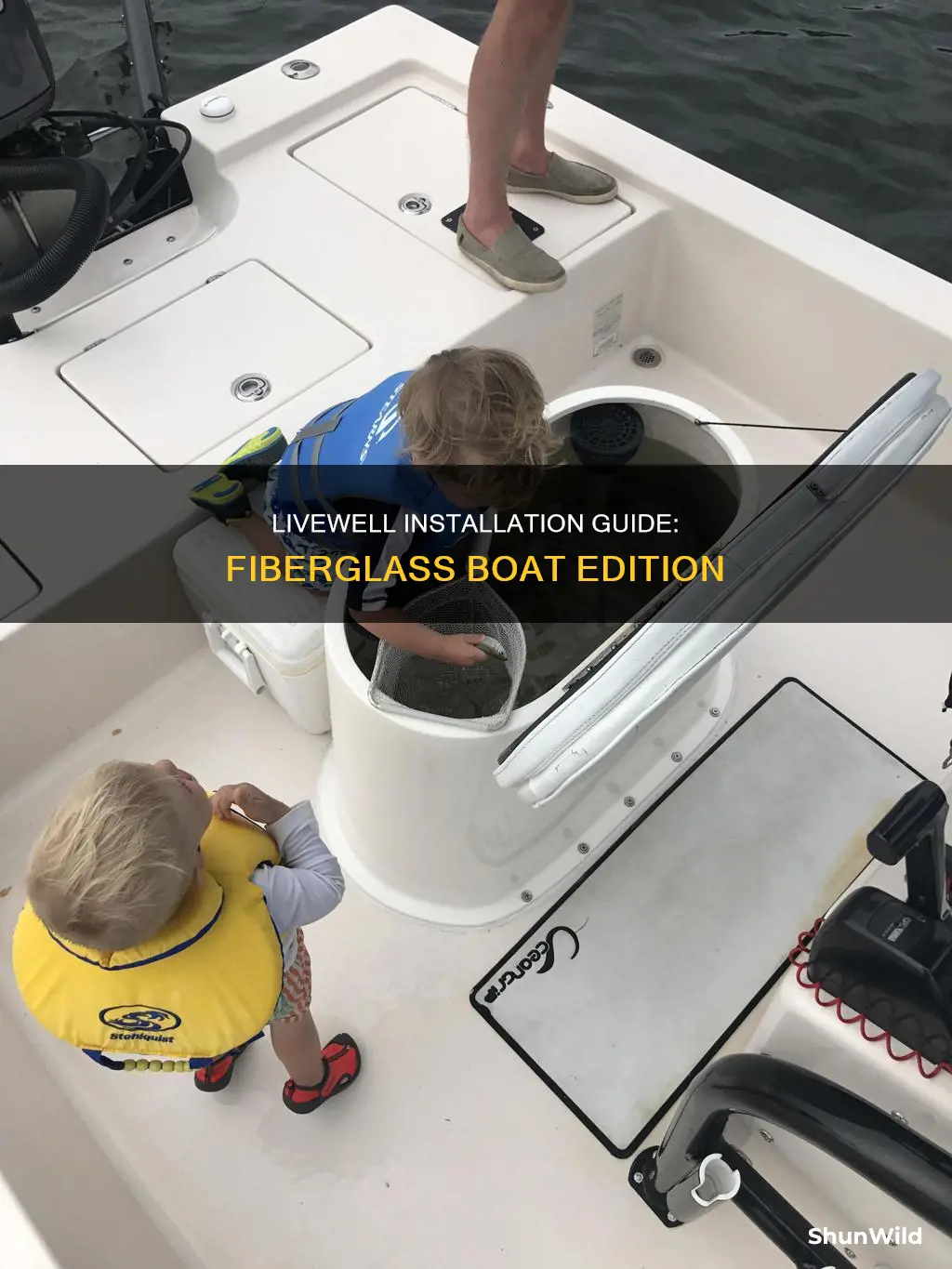

Installing a livewell system in a fiberglass boat can significantly enhance your fishing experience by keeping bait or catch alive and healthy. This process involves several steps, from choosing the right system to ensuring proper installation and maintenance. The first step is to select a livewell system that suits your boat's size and your specific needs. Next, you'll need to prepare the boat by identifying a suitable location for the system, which could be in the hull or on deck, and ensuring that the boat's structure can support the additional weight. Proper installation requires careful planning to avoid damage to the boat's interior and exterior. This includes cutting a hole in the hull or deck, securing the livewell unit, and connecting it to the boat's plumbing and electrical systems. Finally, regular maintenance is crucial to keep the system functioning optimally, ensuring that it remains a valuable asset during your boating adventures.

What You'll Learn

- Preparation: Gather tools, safety gear, and a plan for the installation

- Drilling: Mark and drill holes for wiring and plumbing connections

- Sealing: Use appropriate sealant to ensure a watertight fit

- Wiring & Plumbing: Connect electrical and water lines to the livewell system

- Testing: Fill and test the livewell to ensure proper function

Preparation: Gather tools, safety gear, and a plan for the installation

Before you begin the installation process, it's crucial to prepare thoroughly to ensure a smooth and safe project. Here's a step-by-step guide to gathering the necessary tools, safety equipment, and creating a detailed plan:

Tools and Equipment:

- Start by making a comprehensive list of all the tools you'll need. For installing a livewell system in a fiberglass boat, you'll likely require various sizes of drills and drill bits, a power drill or impact driver, a saw (preferably a reciprocating saw or a utility knife for precision), a file, sandpaper, a utility knife or box cutter, and a set of screwdrivers. Additionally, you might need a tape measure, a level, and a pencil for marking.

- Consider the specific requirements of your boat model. Some boats may have unique fittings or compartments that need specialized tools for access.

- Gather any additional equipment you might need, such as a vacuum pump or a water-resistant sealant, depending on your chosen method for the livewell installation.

Safety Gear:

- Personal protective equipment (PPE) is essential to ensure your safety during the installation process. Safety goggles are a must to protect your eyes from any potential debris or splinters.

- Wear gloves to safeguard your hands from sharp edges and to provide a better grip on tools. Choose gloves that offer dexterity and are suitable for the materials you'll be working with.

- Ear protection is also important, especially if you'll be using power tools that can generate loud noises.

- Depending on the work area, a dust mask or respirator might be necessary to avoid inhaling any harmful particles.

Planning the Installation:

- Create a detailed plan and diagram of the livewell system you intend to install. This will help you visualize the process and ensure you have all the necessary components.

- Measure the designated area in your boat where the livewell will be installed. Note the dimensions and any specific features or obstacles.

- Research the type of livewell system you want to install, whether it's a simple bucket-style system or a more complex, pressurized unit. Each design may have unique installation requirements.

- Familiarize yourself with the manufacturer's guidelines and instructions for your chosen livewell system. This will provide valuable insights into the specific tools and techniques required.

- Consider the boat's electrical system if your livewell requires a pump or lighting. You might need to consult an electrician to ensure the wiring is done safely and correctly.

- Create a timeline for the installation process, allowing for potential delays and unexpected challenges. This will help you stay organized and ensure the project stays on track.

Skipping Boat Docks: A Guide to Mastering the Art

You may want to see also

Drilling: Mark and drill holes for wiring and plumbing connections

Drilling is a critical step in installing a livewell system in your fiberglass boat, as it requires precision and careful planning to ensure a successful and safe installation. Here's a detailed guide on how to mark and drill holes for wiring and plumbing connections:

Step 1: Planning and Marking

Before you start drilling, it's essential to plan the layout of your livewell system. Refer to the instructions provided by the livewell manufacturer or the resources you gathered online. Identify the locations for the livewell pump, intake, and outlet ports, as well as the wiring and plumbing connections. Use a pencil or a permanent marker to lightly mark these spots on the boat's fiberglass surface. Ensure that the markings are clear and visible, as this will guide your drilling process.

Step 2: Measuring and Drilling

Take your drill bit and carefully measure the distance from the marked spots to the desired depth. For wiring holes, you typically want to drill a small pilot hole first to guide the wire. Use a drill bit slightly smaller than the wire's diameter to avoid damaging the fiberglass. Then, drill the main hole, ensuring it's deep enough to accommodate the wiring or plumbing component. For plumbing connections, you might need to consider the type of fittings and pipes you're using. Measure and mark the spots accordingly, allowing for the appropriate size of the fittings.

Step 3: Safety and Support

When drilling into fiberglass, it's crucial to use a drill press or a steady hand to ensure accuracy and prevent the boat from shifting or moving. Consider using a drill guide or a template to maintain a straight and consistent hole. Always wear appropriate safety gear, including eye protection, and work in a well-ventilated area to minimize the inhalation of fiberglass dust.

Step 4: Reinforcement (Optional)

For added strength and to prevent any potential damage to the boat's structure, you might consider reinforcing the drilled holes. This can be done by inserting a small piece of fiberglass or a suitable filler material into the hole and allowing it to cure according to the manufacturer's instructions.

Remember, precision is key during this process. Take your time, double-check your measurements, and ensure that all connections are secure before finalizing the installation. Properly marked and drilled holes will make the wiring and plumbing installation process smoother and more efficient.

Replacing Lost Boat Titles: Oregon's Process Simplified

You may want to see also

Sealing: Use appropriate sealant to ensure a watertight fit

When installing a livewell system in a fiberglass boat, proper sealing is crucial to ensure the system remains watertight and prevents any leaks. The process involves several steps to guarantee a secure and effective seal. Firstly, it's essential to clean the surface of the boat's hull where the livewell will be installed. Remove any dirt, grime, or old sealant to create a clean, smooth base for the new seal. This step is often overlooked but is vital for the long-term success of the installation.

Next, you'll need to choose the right sealant. There are various types available, such as epoxy, silicone, or polyurethane sealants, each with its own advantages. For fiberglass boats, a flexible sealant is often preferred as it can accommodate the natural movement and expansion of the boat's materials. This type of sealant also provides a strong bond, ensuring the livewell remains sealed even in the face of potential vibrations and impacts.

Apply the sealant generously to the livewell's base and the corresponding area on the boat's hull. Ensure an even layer, paying attention to all edges and corners, as these areas are prone to leaks. The key is to create a continuous, smooth surface without any gaps or voids. You can use a small brush or a putty knife to spread the sealant evenly, ensuring complete coverage.

After applying the sealant, allow it to cure according to the manufacturer's instructions. This process may take several hours or even days, depending on the type of sealant used. During this time, avoid any heavy use of the boat or placing additional weight on the livewell to ensure the sealant sets properly.

Finally, once the sealant is fully cured, test the livewell system for any leaks. Fill the livewell with water and observe if there are any signs of leakage around the sealed areas. If everything is dry, your livewell installation is now ready for use, providing a reliable and durable water source for your boating activities. Proper sealing is a critical step that ensures the longevity and functionality of your livewell system.

Unfreezing Your Inboard Boat Engine: Quick and Easy Methods

You may want to see also

Wiring & Plumbing: Connect electrical and water lines to the livewell system

When installing a livewell system in a fiberglass boat, proper wiring and plumbing are crucial to ensure the system functions efficiently and safely. Here's a step-by-step guide to connecting the electrical and water lines:

Electrical Connections:

- Identify the power source: Determine the power source for your livewell system. It could be the boat's main battery, a dedicated battery, or an alternator. Ensure you have the appropriate gauge wiring to handle the expected current draw.

- Wire the pump: Connect the livewell pump's electrical terminals to the power source. Use marine-grade wiring to withstand the aquatic environment. Typically, you'll need to run a positive and negative wire from the power source to the pump.

- Switch and Control Panel: Install a switch to control the livewell pump's operation. This could be a simple on/off switch or a more advanced system with adjustable flow rates. Connect the switch to the pump wiring and ensure it is properly labeled for easy identification. Consider adding a control panel to monitor and manage the livewell system, especially if you have multiple livewells or additional features.

- Grounding: Proper grounding is essential for safety. Connect a ground wire from the pump's electrical terminal to a suitable grounding point on the boat's frame or hull. This helps prevent electrical hazards and ensures a stable electrical connection.

Water Lines:

- Choose the Right Hoses: Select marine-grade flexible hoses for connecting the livewell pump to the water source and the livewell itself. These hoses should be durable and resistant to corrosion. Ensure the hose sizes are appropriate for the desired water flow rate.

- Water Supply Connection: If your boat has a freshwater tank, connect one end of the water hose to the tank's outlet. Use a suitable fitting to ensure a tight seal. If you're using a freshwater source directly from the boat's plumbing, connect the hose accordingly.

- Livewell Installation: Attach the other end of the water hose to the livewell system. This may involve using a union fitting or a dedicated livewell fitting with a quick-connect coupling. Ensure the connection is secure and leak-free.

- Test for Leaks: After connecting the water lines, thoroughly test for any leaks. Start the pump and check for any water escaping at the connections. Tighten or adjust fittings as needed to ensure a proper seal.

Remember, when working with electricity and water systems, it's essential to follow local regulations and safety guidelines. Consider consulting a marine electrician or plumber if you're unsure about any step, ensuring a professional and safe installation.

Understanding Metered Boat Docks: What You Need to Know

You may want to see also

Testing: Fill and test the livewell to ensure proper function

Once you've installed the livewell system, it's crucial to thoroughly test its functionality to ensure it works as intended. Here's a step-by-step guide on how to fill and test your livewell:

Step 1: Prepare the Livewell: Before filling, make sure the livewell is clean and free of any debris. Rinse the system with fresh water to remove any dust or contaminants that may have accumulated during the installation process. This step is essential to prevent any unwanted substances from affecting the water quality.

Step 2: Fill the Livewell: Locate the filling port, typically found on the side or bottom of the livewell. Use a suitable water source, preferably filtered or dechlorinated water, to fill the livewell. Start with a partial fill to allow for adjustments and testing. As you fill, observe the water level and ensure it reaches the appropriate height, as indicated by the water level gauge or indicator.

Step 3: Check for Leaks: After filling, inspect the livewell for any signs of leaks. Pay close attention to the connections and seams where the livewell components were installed. You can use a mild detergent solution and a bubble indicator to detect any small leaks. If you notice any leaks, tighten the connections or consider using additional sealant to ensure a watertight seal.

Step 4: Test Pump Functionality: With the livewell filled, it's time to test the pump. Turn on the pump and monitor the water flow. Check if the pump is delivering water at the desired rate and pressure. Listen for any unusual noises, and ensure the pump's operation doesn't cause any vibrations or movement that could affect the boat's stability. If everything functions correctly, you can proceed to the next step.

Step 5: Monitor Water Quality: As the pump runs, regularly check the water quality. Use a hydrometer or pH test kit to measure the specific gravity and pH levels of the water. The ideal range for livewell water is typically around 1.000 for specific gravity and a neutral pH of 7.0. If the readings deviate significantly, you may need to adjust the water chemistry or consider adding a water treatment solution to maintain optimal conditions for fish or aquatic life.

Step 6: Long-Term Testing: Finally, conduct long-term testing to ensure the livewell system's reliability. Fill the livewell again and run the pump for an extended period, simulating real-world usage. Regularly check the water level and quality during this test to identify any potential issues. This comprehensive testing phase will help you fine-tune the system and address any problems before relying on it for actual use.

The River Styx: Acheron's Boatman Unveiled

You may want to see also

Frequently asked questions

The initial step is to carefully inspect the boat's structure and choose a suitable location for the livewell tank. It's crucial to consider factors like weight distribution, access for maintenance, and the boat's overall design to ensure a secure and functional installation.

Before installing, clean the boat's surface thoroughly. Remove any dirt, grime, or old paint. Ensure the surface is smooth and free from debris. You might need to sand the area slightly to create a rougher texture for better adhesion, especially if the fiberglass surface is smooth.

Yes, you'll need a few essential tools and materials. These include a drill with various bits, a screwdriver, a tape measure, a level, and a suitable adhesive or sealant. Additionally, you'll require the livewell tank, plumbing components (hoses, fittings), and any necessary mounting hardware.

While it is possible to install a livewell system yourself, especially if you have some experience with boat maintenance, it is generally recommended to seek professional assistance. Livewell systems involve plumbing and electrical connections, and a professional can ensure a safe and proper installation, adhering to industry standards.

Regular maintenance is key to keeping the livewell system in optimal condition. This includes cleaning the tank and plumbing regularly to prevent algae growth and debris buildup. Check for any leaks or damage to the system and ensure the water circulation is functioning correctly. It's also advisable to monitor water quality and consider using a livewell system cleaner to maintain the system's longevity.