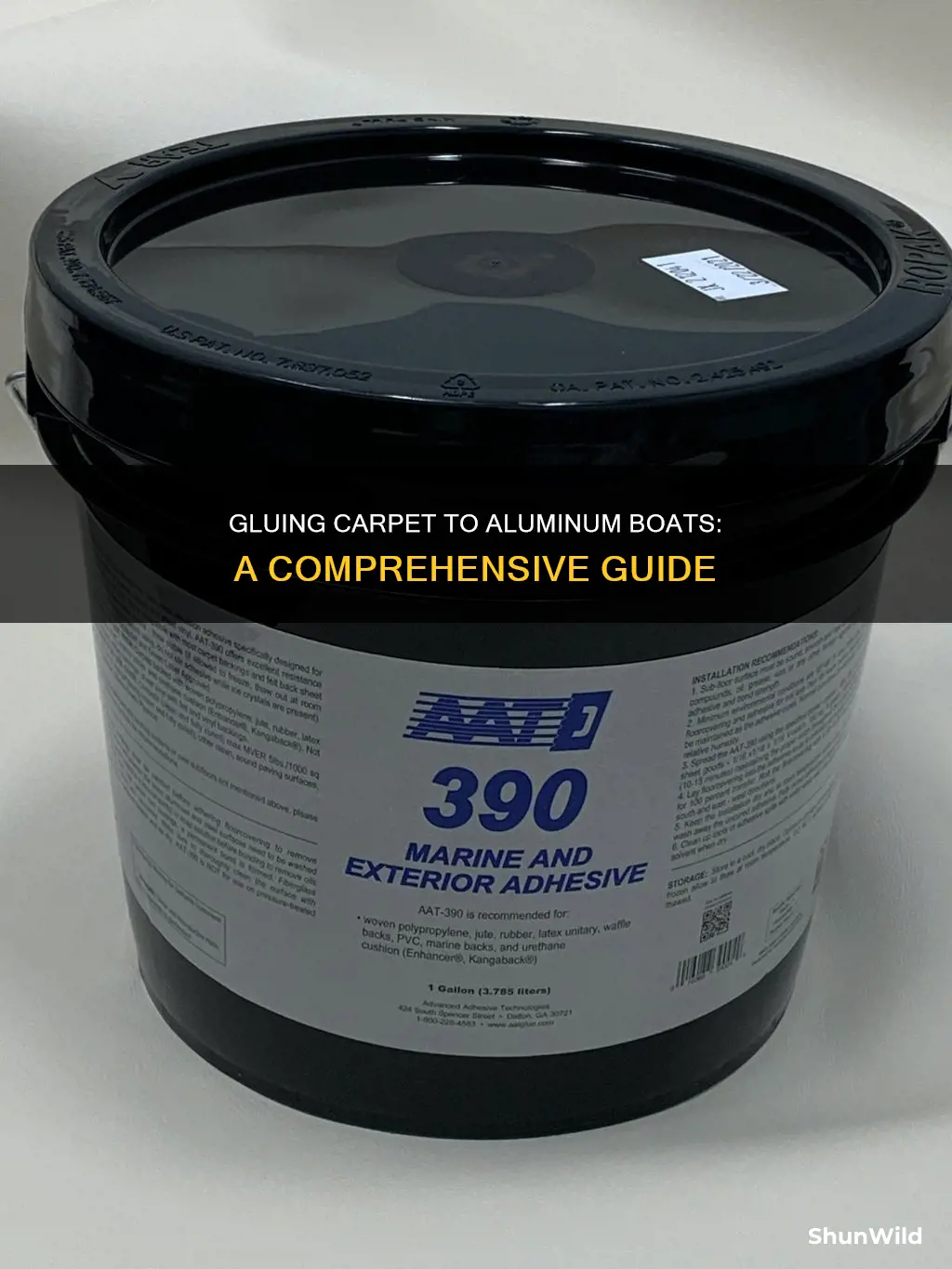

Gluing carpet to an aluminium boat is a common practice, but it can be tricky to get right. The first step is to ensure the aluminium surface is clean, and some sources suggest scuffing the surface with 80-grit for better adhesion. The next step is to choose the right glue. Some popular options include 3M 5200, 3M 77, 3M High-Strength 94 ET Spray Adhesive, and marine-grade carpet glue. When applying the glue, it's important to work in sections as the glue can dry quickly. Using a trowel or a brush can help spread the glue evenly, and a rolling pin or a piece of PVC pipe can be used to smooth out any bubbles. While gluing carpet to an aluminium boat can be a straightforward process, it's important to take your time and work in a well-ventilated area to avoid any health hazards from the glue.

| Characteristics | Values |

|---|---|

| Adhesive Type | Solvent-based, Water-based, Spray |

| Application | Spread with trowel, brush, or roller; use hands to smooth |

| Coverage | 1 gallon covers 50-140 sq ft, depending on surface and glue type |

| Curing Time | 24-48 hours |

| Surfaces | Wood, Marine Plywood, Aluminum, Fiberglass, Vinyl, Pressure-treated Plywood, Gelcoat |

| Backing | Polypropylene, Rubber, Urethane, Woven, Non-woven |

| Advantages | Carpets stay in place, improves appearance, increases safety |

| Disadvantages | Sticky and messy application, potential environmental and health hazards |

What You'll Learn

Choosing the right glue for your boat carpet

Type of Carpet and Flooring

The first step is to match the glue to the type of carpet and flooring you have. Boat carpets typically have rubber backings, so it's best to choose a water-based glue to avoid damaging the rubber. Solvent-based adhesives, while stronger, can be too harsh and cause deterioration. Consider the flooring material as well; aluminum, fiberglass, wood, and vinyl are common boat flooring materials, and you'll need a glue that adheres well to these surfaces.

Composition of the Adhesive

Adhesives are typically either water-based or solvent-based. Water-based adhesives are easier to apply, more affordable, and safer for your health and the environment due to their minimal VOC content. However, they may not be as effective in cold environments and can break down in high temperatures. Solvent-based adhesives, on the other hand, offer stronger bonds and higher temperature stability but contain harsh chemicals that can be harmful to your health and the environment.

Ease of Application and Drying Time

Look for a glue that offers effortless application. A glue with a thin consistency will be easier to spread using a trowel. Also, consider the drying or curing time—some adhesives provide a longer working time, allowing you to make adjustments to the carpet's position before it sets completely.

Additional Protection

Some marine carpet adhesives offer additional features such as water resistance and antimicrobial protection. Water-resistant or waterproof glues are ideal for boat carpets since they are often exposed to water. Antimicrobial protection helps inhibit the growth of bacteria, mold, and mildew, keeping your carpet looking and smelling fresh.

Odor

Go for a glue with low or no odor. Strong-smelling adhesives usually indicate the presence of harsh chemicals, which can be irritating to your eyes and skin. Opt for a water-based glue or one that is specifically designed to have a low odor.

Brand Reputation

Consider purchasing from reputable brands such as Roberts, 3M, Permatex, Henry, and DAP. These brands have established themselves in the industry and are known for producing high-quality adhesives.

Coverage

Lastly, check the coverage of the glue to ensure you purchase enough for your project. A one-gallon container typically covers up to 100 square feet, but this can vary depending on the type of carpet and flooring. Aerosol cans have smaller coverage areas, so they may not be suitable for large boats.

Taking Apart a Boat Windshield: Step-by-Step Guide

You may want to see also

Preparing the surface of your aluminium boat

Clean the aluminium surface:

Start by thoroughly cleaning the aluminium surface of your boat. Use a putty knife to remove any old carpet residue or glue. You can also use a grinder with a brush attachment if there is stubborn glue residue. For a more eco-friendly option, consider using a rust remover or a dedicated marine cleaner to get rid of any dirt, oil, or wax. This step is important as it ensures that the glue will have a clean surface to adhere to.

Choose the right glue:

Not all glues are created equal, and using the wrong type can damage your boat or the carpet. Opt for a marine-grade glue designed for use on aluminium surfaces. Some recommended options include 3M adhesives, Sika high-strength contact cement, and Astroturf glue. If you're looking for an alternative to traditional glue, you can consider using snaps or staples to secure the carpet.

Prepare the glue and carpet:

Read and follow the instructions on your chosen glue carefully. Some glues may need to be applied with a brush, roller, or a trowel, while others might require a spray gun. Ensure you have the right tools on hand before beginning. Cut the carpet to size, allowing for some excess that you can trim later. If your boat has compartments, decide whether you want to cut the carpet around the edges or wrap it underneath.

Apply the glue:

Follow the instructions on your glue for the best results. Generally, you will apply the glue to both the aluminium surface and the back of the carpet, giving it time to become tacky before placing the carpet. Work in small sections to prevent the glue from drying too quickly. Use a trowel with a serrated edge to spread the glue evenly, ensuring a thin, consistent layer.

Attach the carpet:

Once the glue is tacky, carefully lay the carpet onto the aluminium surface, smoothing it out with your hands or a roller to remove any bubbles or wrinkles. Be cautious, as once the carpet makes contact with the glue, it will be difficult to reposition. If necessary, use a wooden rolling pin to even out any large globs of glue that may appear.

Finish and trim:

After attaching the carpet, apply pressure to the top using a carpet roller to enhance adhesion and remove any remaining bubbles. Allow the glue to cure for at least 24 hours, and up to 48 hours if possible, before stepping on the carpet or using the boat. Finally, trim any excess carpet with a sharp knife, taking care not to damage the aluminium surface.

Bass Boat Ranger: How Wide Can It Get?

You may want to see also

Applying the glue to your boat carpet

When applying glue to your boat carpet, there are a few important steps to follow to ensure a strong and long-lasting bond. Here is a detailed guide to help you through the process:

Preparation:

Before you begin, make sure you have all the necessary materials, including the glue, a trowel or notched putty knife, and a carpet roller. Clean the aluminium surface of your boat thoroughly, removing any dirt, wax, or oil that may weaken the bond. You can use a solvent or a product like trisodium phosphate to ensure the surface is ready for gluing. It is also important to ensure the surface is completely dry before moving on to the next step.

Gluing:

Follow the instructions on your chosen glue for application. Some glues need to be applied to both the carpet and the boat surface, while others may only need to be applied to one surface. If using a trowel or putty knife, use a notched edge to create ridges in the glue, which will help create a stronger bond. Allow the glue to become tacky according to the manufacturer's instructions—this usually takes a few minutes.

Attaching the Carpet:

Once the glue is ready, carefully lay the carpet onto the glued surface of your boat, ensuring proper alignment. Use your hands to smooth out the carpet and remove any bubbles or wrinkles. You can also use a rolling pin or a piece of PVC pipe to help with this process. Apply pressure to the top of the carpet once it is in place.

Curing:

Allow the adhesive to cure for up to 48 hours. During this time, minimise foot traffic on the carpeted area to ensure the glue sets properly. The curing time will depend on the type of glue you use and the temperature and humidity levels. Refer to the manufacturer's instructions for specific curing times.

Tips:

- Always do a small test area first to ensure the glue works well with your carpet and boat surface.

- Work in sections to avoid the glue drying before you can attach the carpet.

- Wear protective gear, including gloves and a mask, when working with strong adhesives.

- Ensure adequate ventilation during the gluing process.

- Avoid using solvent-based adhesives on rubber-backed carpets as they can damage the rubber.

Boat Battery Basics: Consumer Guide to Marine Power

You may want to see also

Attaching the carpet to the aluminium boat

Before you start gluing your carpet to your aluminium boat, it is important to prepare the surface. Clean the aluminium thoroughly to ensure that the glue will stick. You can use a putty knife to remove any old glue, and a grinder with a brush to remove any residue. For best results, you can also use a solvent to clean the aluminium, such as tri-sodium phosphate or aircraft stripper. Once the surface is clean and dry, you may want to scuff the aluminium with some fine-grit sandpaper (80-grit was recommended by one source).

When it comes to choosing an adhesive, there are a few options. Some boat owners have recommended using staples to attach the carpet, which can be easier to remove than glue. If you do opt for glue, there are a variety of options available, including water-based and solvent-based adhesives. Water-based adhesives are safer and easier to apply, but may not be as strong as solvent-based adhesives. Solvent-based adhesives are stronger but can be more dangerous and difficult to work with due to the toxic fumes they emit.

Some specific glue products that were recommended by boat owners include:

- 3M 5200 (although some users warned that this glue is very difficult to remove)

- 3M High-Strength 94 ET Spray Adhesive

- 3M 77 Adhesive Spray

- Marine-grade carpet adhesive (sold by BoatCarpet.com)

- Contact cement (sold by Lowes)

- Weldwood contact cement

- 3M adhesive glue spray

When applying the glue, be sure to follow the manufacturer's instructions. Many glues will need to be applied to both the carpet and the boat, and then allowed to dry for a short time before attaching the carpet. Use a trowel or a brush to apply the glue, and be sure to work in small sections so that the glue doesn't dry before you can attach the carpet. Once the carpet is in place, use a roller or a wooden rolling pin to smooth out any bubbles or creases.

Allow the glue to dry for at least 24 hours, and up to 48 hours if possible, before using the boat. This will ensure that the glue has fully cured and will provide the strongest bond.

Painting Boat Interiors: A Step-by-Step Guide

You may want to see also

Drying and curing the glue

Allow Sufficient Curing Time:

Give the adhesive enough time to cure completely. The curing time can vary depending on the type of glue used and environmental conditions. Some glues may take up to 48 hours or more to cure fully. Refer to the manufacturer's instructions for the recommended curing time and ensure that the glued area remains undisturbed during this period.

Ensure Proper Ventilation:

During the curing process, maintain adequate ventilation in the workspace. This is especially important if you are using solvent-based adhesives, which tend to release volatile organic compounds (VOCs) and other hazardous gases. Proper ventilation helps to minimise potential health risks associated with inhaling these fumes.

Avoid Heavy Foot Traffic:

Keep people away from the glued area during the curing process. Heavy foot traffic can put stress on the adhesive bond before it has fully cured, potentially weakening it or causing the carpet to shift or wrinkle.

Maintain Optimal Temperature:

Aim to maintain a room temperature of around 65°F to 70°F (21°C) during the curing process. This temperature range helps strengthen the bond and prevents the glue from freezing or evaporating too quickly.

Use Carpet Seam Tape:

Consider using carpet seam tape in areas where two pieces of carpet meet. This tape provides a strong hold and creates a seamless appearance, enhancing the overall durability and aesthetic appeal of the installation.

Address Bubbles or Wrinkles:

If you notice any bubbles or wrinkles during the curing process, use a carpet roller or your hands to smooth them out. This ensures proper contact between the adhesive and the carpet, maximising adhesion and preventing premature wear.

Understand the Impact of Environmental Conditions:

Be mindful of environmental factors such as humidity and temperature, as they can affect the curing process. For example, excessive moisture can weaken the adhesive bond, so controlling humidity levels is crucial. Aim to maintain a relative humidity between 30% and 50% for optimal carpet performance and longevity.

Follow Manufacturer's Instructions:

Always refer to the manufacturer's instructions for specific guidelines on curing their adhesive product. Different adhesives may have varying requirements, so adhering to these instructions is essential for achieving the best results and ensuring the longevity of your carpet installation.

Sailing Offshore: Donna's Adventure and Exploration

You may want to see also