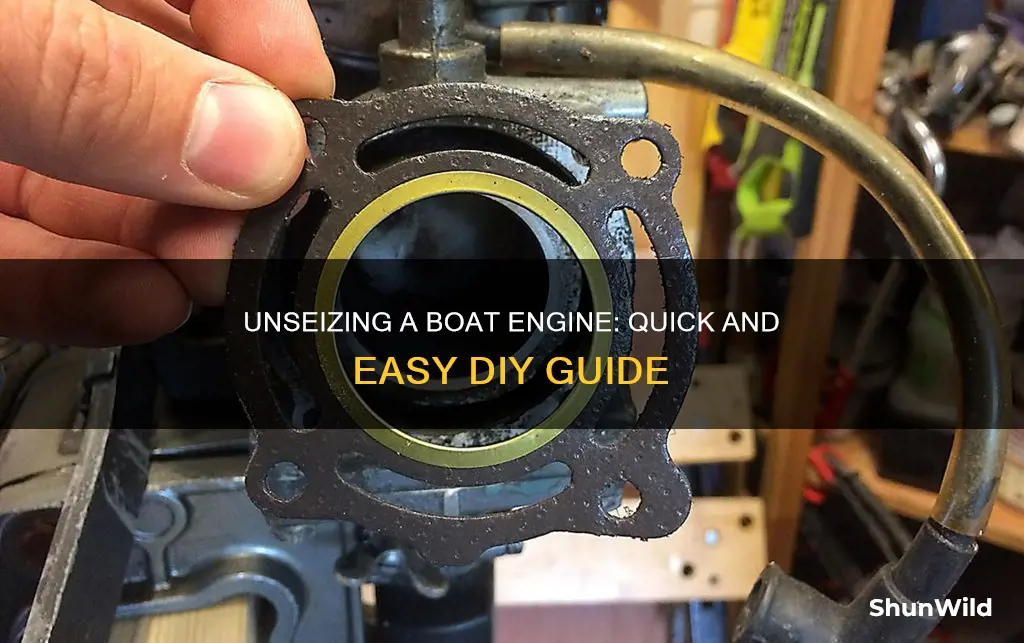

If your boat engine has seized, there are a few things you can try before giving up and paying for a costly repair. First, you need to confirm that the engine is actually seized. Remove the spark plugs and try rotating the engine. If it's definitely seized, the next step is to try using penetrating oil. This works well for engines that have seized up due to rust, usually from sitting out in the rain. Spray oil down into the cylinder through the spark plug hole and leave it to soak for a few hours or even a few days. You can also try using a hammer to tap the cylinder wall, which will create vibrations to help the oil penetrate. If this doesn't work, you may need to remove the cylinder head and crankshaft, and if the piston is still stuck, you'll need to head to a machine shop to have it pressed out or bored out.

| Characteristics | Values |

|---|---|

| Reasons for engine seizure | Rust, excessive heat, foreign object in cylinder, crankshaft bearing failure, insufficient lubrication, or long periods of storage |

| Confirmation of engine seizure | Remove spark plugs and try rotating the engine |

| First course of action | Use penetrating oil, spraying daily for about two weeks, followed by gentle tapping on the cylinder wall with a hammer handle |

| Alternative solution | Use a breaker bar to rotate the engine |

| Further steps | Pull the cylinder apart, remove the cylinder head and crankshaft, and try to pound the piston out with a mallet and wooden block |

| Additional considerations | Check for damage to piston and cylinder, assess wrist pin and connecting rod bearings for looseness or wear |

| Prevention | Winterize the boat engine, including running antifreeze, spraying carb intakes with oil, and filling spark plug holes with oil |

What You'll Learn

Remove the spark plugs and try rotating the engine

Removing the spark plugs and trying to rotate the engine is one of several methods to free a seized boat engine. This method is worth trying before you begin to dismantle the engine.

First, place the boat in an upright position on a dolly truck, ensuring the propeller faces outward. Then, remove the spark plug wires from the spark plugs. You can do this by hand or with a wrench.

Now, try to rotate the engine. If it still won't turn, you can try injecting penetrating oil into the spark plug holes and letting it soak for a few hours or even days. You can also try tapping the pistons lightly with a wrench. If the engine still won't rotate, you may need to try a more invasive method, such as dismantling the engine to reach the lower unit, which may be the source of the problem.

Replacing Skeeter FX Boat Seats: A Step-by-Step Guide

You may want to see also

Use penetrating oil

If your boat engine has seized, the first thing to do is remove the spark plugs and try rotating the engine. If you can't rotate it, it's probably seized.

The next step is to use a penetrating oil. This works well, especially for engines stuck from years of sitting out in the rain, where water has rusted the piston rings to the cylinder.

Wear goggles to protect your eyes in case the penetrating oil sprays back at you. Spray the oil generously down into the cylinder through the spark plug hole. If you have the patience, spray some in every day for about two weeks, followed by gently tapping on the cylinder wall with a hammer handle. This creates vibrations that help the oil penetrate between the rings and the cylinder wall.

After soaking the engine for a while, try rotating the crankshaft. If the engine still won't budge, use more penetrating oil and make sure you're using enough. Keep repeating this process for about four weeks.

If the penetrating oil doesn't work, it's time to try more serious measures, such as removing the cylinder head and crankshaft.

Conor McGregor's Luxurious Boat: A Lavish Yacht Tour

You may want to see also

Pull the cylinder apart

Pulling the cylinder apart is a crucial step when it comes to repairing or replacing any part of a boat engine. Here is a step-by-step guide on how to do this safely and efficiently:

Step 1: Safety First

Before beginning the process of taking apart the cylinder, ensure you are wearing safety glasses and other protective equipment, such as gloves. It is also important to work in a well-ventilated area to avoid inhaling any fumes.

Step 2: Disconnect the Fuel Line

The first step is to unsnap the quick-release fuel line hose from the outboard motor, which is usually located near the carburetor. This will prevent any fuel from flowing into the engine during the disassembly process.

Step 3: Remove the Motor

Next, remove the motor from the transom of the boat. You may need an assistant to help with the lifting. Place the motor in an upright position on a dolly truck, ensuring that the propeller faces outward. If the cylinders are horizontal, lay the dolly truck down on its frame with the spark plug holes facing up.

Step 4: Unsnap the Top Motor Cowl Case

Pull the plug wires off the spark plugs and use a socket wrench to remove the spark plugs. This will allow you to access the cylinder head.

Step 5: Remove the Cylinder Head

The cylinder head is the component that sits on top of the cylinder and houses the valves and spark plugs. Carefully unscrew the bolts holding the cylinder head in place and remove it from the cylinder.

Step 6: Remove the Piston

The piston is located inside the cylinder and is connected to the crankshaft. To remove the piston, turn the cylinder upside down and carefully tap it out with a hammer. The piston may be stuck due to corrosion or carbon buildup, so you may need to use a penetrating oil to help loosen it.

Step 7: Clean the Cylinder

Once the piston has been removed, use a cloth and a suitable cleaning agent to clean the inside of the cylinder. This will remove any debris or residue that could interfere with the proper functioning of the engine.

By following these steps, you can safely and effectively pull apart the cylinder of a boat engine, allowing you to inspect, repair, or replace any internal components as needed.

Forrest Gump's Boat: A Name and Its Significance

You may want to see also

Assess cylinder and piston damage

To assess cylinder and piston damage, you will need to remove the engine and separate the top and bottom halves. This will allow you to determine if the problem is in the top or bottom of the engine.

Once the engine is removed, check the flywheel for any movement. If the crankshaft can be moved, this indicates piston issues, whereas if it is frozen, it suggests rusted bearings.

Next, examine the pistons themselves. Look for any signs of damage, such as gouges, pits, or missing parts. Pay attention to the piston rings, as carbon buildup or stuck rings can cause compression issues. If the piston rings are not sealing properly, the piston can become stuck in the cylinder due to increased heat.

Additionally, check the cylinder walls for scoring or damage. If the walls are smooth and undamaged, it suggests that the piston may have released the broken part through the exhaust.

If the pistons appear to be in good condition, the issue may lie elsewhere in the engine, such as with the bearings or crankshaft. In this case, further disassembly and inspection may be required to identify the root cause of the seizure.

Exploring Fawn Lake: Boat Launching Options

You may want to see also

Check pin and rod bearings

Checking the pin and rod bearings is an important step in engine maintenance, especially before storing the boat for winter. It is a good way to identify potential issues before they cause serious problems. Here is a step-by-step guide to checking the pin and rod bearings:

Tools and Supplies:

- Engine stand

- Torque wrench

- Replacement oil pan gaskets

- Replacement timing chain gaskets

- Silicone sealer/gasket maker

- Box/open-end, sockets as needed

- Magnetic base and 1" dial indicator in thousandths of an inch

- Soft brass hammer

- Solvent (lacquer thinner, brake clean, etc.)

- Torque specs for your engine

Procedure:

- Drain the oil and remove the oil filter. Inspect the filter paper to identify any debris, such as silicone, cork, paper, or metal fragments.

- Remove the oil pan and oil pump, if necessary, to access the main bearings.

- Remove the front cover and clean any old gasket material from the mating surfaces. Use a solvent to scrub and clean the area.

- Remove the main bearing caps one at a time, noting the location of the tangs on the bearing shells.

- Clean the bearing shells with solvent and wipe them dry with a lint-free cloth. Inspect the bearing shells for any signs of damage, such as scars, copper exposure, or deep grooves. Small scratches are normal.

- If the bearing shells appear undamaged, wipe and dry the back of the shell and the cap. Lubricate the shell surface and the crank journal.

- Place the cap back on and insert the bolts, nuts, and washers. Tighten the nuts/bolts to the recommended torque specifications for your engine.

- Before loosening the thrust main bearing, measure the end-play in the crankshaft. It should be between .005" and .010".

- Repeat the process for all main bearing shells and crankshaft bearings. Torque all the main nuts/bolts to the recommended specifications.

- Check the rod bearings by trying to slide the rod caps back and forth on the rod journal. They should move easily with an audible 'click'.

- Re-install the oil pump and any other accessories, such as the front cover, fuel pump, or oil pan.

By following these steps, you can ensure that your pin and rod bearings are in good condition and properly lubricated, reducing the risk of engine seizure.

Sea-Doo Challenger Boat: Worth the Investment?

You may want to see also

Frequently asked questions

If you can't rotate the engine by hand, it's probably seized. Try removing the spark plugs and then rotating the engine.

Try using a penetrating oil like P'Blaster. Spray it into the cylinder through the spark plug hole and leave it to soak for a few hours or days. You can also try using a breaker bar to rotate the engine.

There are several possible reasons for a boat engine to seize. These include rust from sitting too long, excessive heat from running the engine without coolant or oil, a foreign object in the cylinder, or a crankshaft bearing failure.

You may need to remove the cylinder head and crankshaft. This can be a straightforward process for smaller engines, but it's more challenging for larger tractor engines. If you can identify which cylinder is stuck, you can try removing the end cap on the connecting rod and rotating the crankshaft to move the piston.

Always wear eye protection when working with penetrating oil to avoid sprayback. If you need to use a hammer, place a block of wood on top of the piston to avoid damage.