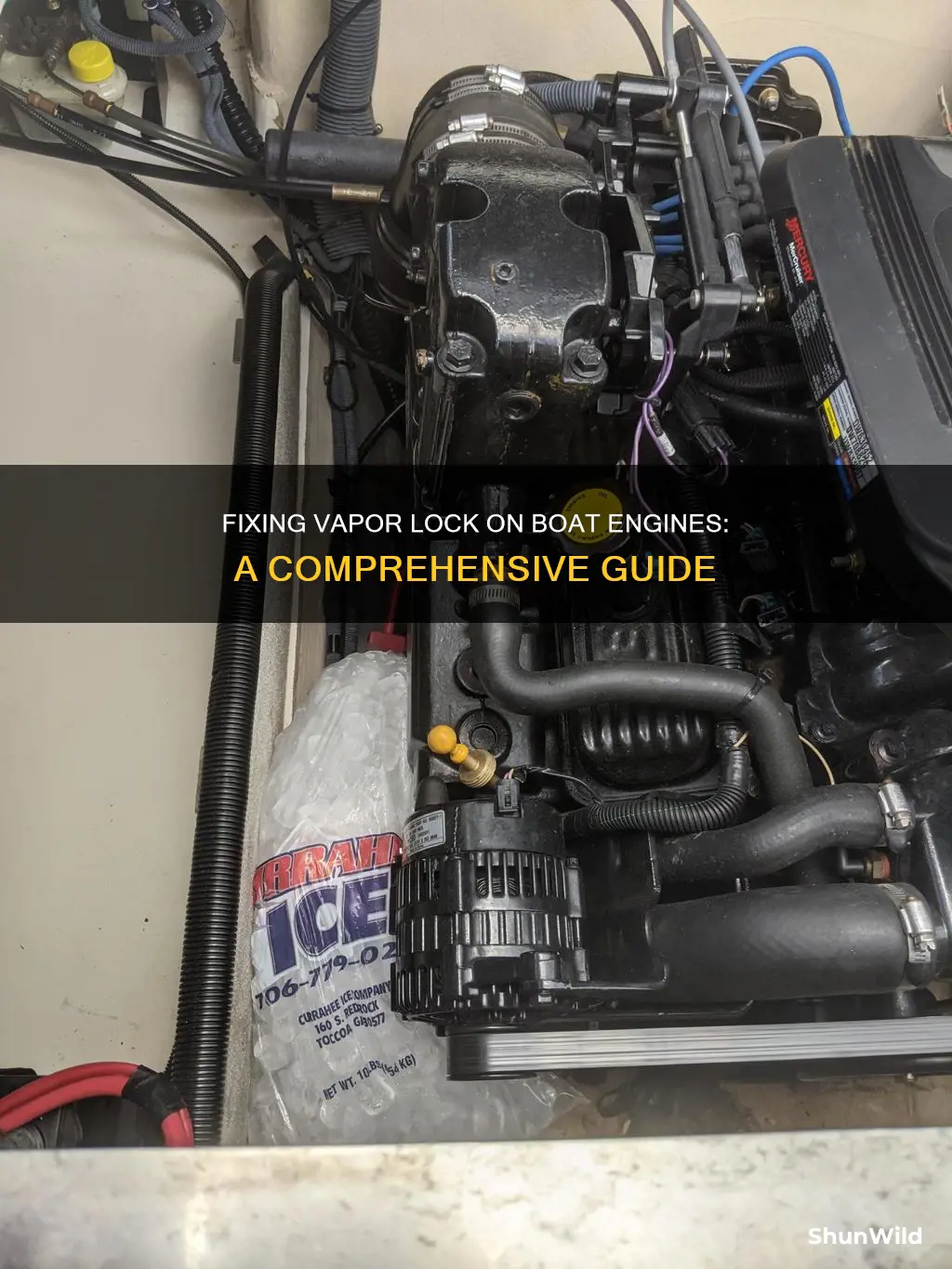

Vapor lock is a problem that can occur in boat engines, causing the engine to stall and not start. It is caused by heat, which boils the fuel and prevents it from being pumped into the carburetor or fuel injectors. This often happens when the boat is stationary for a long period in hot weather, or when there is minimal fuel in the gas tank. To fix vapor lock, one can try insulating the fuel lines, adding a fuel cooler, or using ethanol-free gas. Some people also suggest using additives such as Marvel Mystery Oil in the gas, or running a blower to cool the engine. In some cases, it may be necessary to upgrade the fuel pump or increase the size of the fuel feed line.

| Characteristics | Values |

|---|---|

| Causes of vapor lock | Heat, high altitude, fuel modifications, engine modifications, clogged fuel lines, fuel type, weather |

| Symptoms of vapor lock | Rough-running, stumbling, stalling, engine not starting |

| Solutions to vapor lock | Running the blower, using non-ethanol gas, adding another fuel pump, using fuel additives, insulating fuel lines, increasing fuel line diameter, using fuel coolers, drilling a hole in the gas cap, using higher octane fuel |

What You'll Learn

Insulating fuel lines from heat sources

Vapor lock is a common issue in the marine world, and it can be caused by a variety of factors such as the use of ethanol fuel, the proximity of fuel lines to heat sources, and the design of the engine compartment. To remedy vapor lock, it is crucial to insulate the fuel lines from heat sources. Here are some detailed instructions on how to do this:

Identify Heat Sources

Before insulating the fuel lines, it is important to identify the sources of heat in the engine compartment. Common heat sources include the engine block, exhaust manifolds, and catalytic converters. The fuel lines should not come into direct contact with these components.

Choose the Right Insulation Material

There are several materials available for fuel line insulation, each with its own advantages:

- Heat-resistant sleeving: Made from materials like fiberglass, silicone, or Nomex, these sleeves provide a snug fit around the fuel line, creating an effective barrier against heat.

- Heat-resistant tape: Typically made from aluminum or fiberglass, this tape can be wrapped around the fuel line multiple times to create a protective layer.

- Heat-resistant foam: Insulating foams, such as polyethylene or neoprene, are ideal for filling gaps and providing a barrier against heat transfer when fuel lines run close to heat sources.

Install the Insulation

The process of installing fuel line insulation will depend on the type of material chosen:

- Heat-resistant sleeving: Cut the sleeving to the desired length and slide it onto the fuel line, ensuring a snug fit. Secure it in place using zip ties or heat-resistant tape.

- Heat-resistant tape: Start wrapping the tape from one end of the fuel line, slightly overlapping each layer. Continue wrapping until the entire line is covered, then secure the tape with zip ties or more tape.

- Heat-resistant foam: Cut the foam to fit snugly around the fuel line and place it between the line and any heat sources. Use zip ties or heat-resistant tape to secure the foam in place.

Consider Additional Factors

When insulating fuel lines, there are several other factors to keep in mind:

- Line diameter: The diameter of the fuel line will determine the type and amount of insulation required. Choose sleeving or tape that is slightly larger than the line for a snug fit.

- Heat source proximity: If the fuel line is located close to a heat source, use thicker insulation or multiple layers for better protection.

- Environmental conditions: Consider the conditions in which the boat will be operated. Choose insulation materials that are resistant to moisture, chemicals, and UV radiation for long-lasting protection.

- Safety: Always wear gloves and safety glasses when handling insulation materials. Keep insulation away from open flames or sparks, as it can be flammable.

By following these steps and choosing the appropriate insulation materials, you can effectively insulate your boat's fuel lines from heat sources, reducing the risk of vapor lock and improving the safety and performance of your vessel.

Repairing a Leaky Boat Fender Valve: Quick Fix Guide

You may want to see also

Using non-ethanol fuel

One way to prevent vapor lock is to use non-ethanol fuel, which has a higher boiling point. This can be purchased on land at a high turnover location. However, finding non-ethanol fuel may become more difficult over time, as many gas stations are now offering E10 fuel, which contains 10% ethanol.

It is important to note that E10 fuel is still suitable for most marine engines and has been used for over a decade. Additionally, all types of fuel should be treated if they won't be used within a few weeks. However, if you are experiencing vapor lock issues and have access to non-ethanol fuel, using it may be a simple solution.

If you choose to use non-ethanol fuel, it is important to take some precautions during the transition period. When switching from non-ethanol to E10 fuel, ethanol can dissolve and loosen deposits in the tank and fuel system, leading to phase separation. To minimize problems during this transition:

- Check for water in the fuel tank and water-separating fuel filter.

- Pump the tank dry or siphon it dry if water is found.

- Examine the fuel in a clear container; if it is not clear or has a sour odor, the tank should be cleaned.

- Add a quality cleaner to help remove deposits in the engine.

- Completely fill the tank with E10 fuel to maximize the amount of ethanol and absorb any water.

- Monitor filters and carry extra fuel filters, as they may become clogged.

By following these steps, you can help prevent issues when transitioning to E10 fuel and reduce the likelihood of vapor lock in your boat engine.

California to China: How Long by Boat?

You may want to see also

Running a blower to cool the engine

- Install a blower: If your boat doesn't already have one, you'll need to install a blower to help circulate air and cool the engine. It's best to consult a professional or a mechanic to ensure proper installation.

- Run the blower continuously: To prevent vapor lock, it's recommended to run the blower constantly while the boat is in operation. This will help pull heat out of the engine compartment, as heat is the primary culprit of vapor lock.

- Positioning the blower: Ensure the blower is positioned to pull in cool air and direct it towards the engine. You may need to adjust the blower's positioning or add additional blowers to maximize airflow and cooling.

- Ventilation: Adequate ventilation is crucial to preventing vapor lock. Ensure there are enough vents and openings in the engine compartment to allow for proper airflow. If necessary, consider adding additional vents, especially on the transom, to create a natural airflow path.

- Blower switch and fuse: Each blower should have its own dedicated switch and fuse. This way, if one blower fails, the other can still operate without overloading the wiring.

- Blower size and capacity: Ensure the blower you install is powerful enough to cool your engine effectively. You may need a larger or more powerful blower, especially if you have a larger engine or insufficient ventilation.

- Additional measures: Combining the use of a blower with other vapor lock prevention methods can be beneficial. This includes things like insulating fuel lines, using fuel additives, or installing a fuel cooler, if possible.

Remember to always consult a qualified marine mechanic if you're unsure about any aspects of your boat's engine or ventilation system. They can provide personalized advice and ensure any modifications or installations are done correctly and safely.

Exploring Block Island: Boat Trip from Montauk

You may want to see also

Upgrading the fuel pump

There are several options for upgrading your fuel pump to mitigate vapor lock. One approach is to install an additional electric fuel pump in the fuel line. This increases the pressure and helps keep the fuel in a liquid state. It is important to ensure that the electric pump is compatible with your engine and does not exceed the pressure that your carburetor can handle. Consult a mechanic or a marine specialist to determine the appropriate specifications for your boat.

Another option is to relocate the fuel pump to a cooler area of the boat. Vapor lock is often caused by the fuel line being too close to a heat source, such as the engine or exhaust pipes. By moving the fuel pump away from these heat sources, you can reduce the temperature of the fuel and lower the risk of vaporization. This may involve rerouting fuel lines or making other modifications to the fuel system.

Additionally, consider upgrading to a higher-quality fuel pump with better heat dissipation properties. Some fuel pumps are designed to handle higher temperatures and can prevent vapor lock by effectively dissipating heat away from the fuel. This can be a more expensive option, but it may be worth considering if you frequently experience vapor lock issues.

When upgrading your fuel pump, it is important to address any other contributing factors to vapor lock. Ensure that your fuel lines are intact and well-maintained, as leaks or cracks can lead to vapor lock. Also, consider using fuel additives that are known to raise the temperature at which gas vaporizes, such as Marvel Mystery Oil (MMO). These additives can provide an extra layer of protection against vapor lock.

Finally, regular maintenance and monitoring of your boat's fuel system are crucial. Keep your fuel lines and engine compartment well-insulated and consider running a blower to reduce heat buildup. By combining an upgraded fuel pump with good maintenance practices, you can effectively minimize the chances of vapor lock and ensure the reliable operation of your boat engine.

Local Theaters Present 'The Boys in the Boat

You may want to see also

Adding a second fuel pump

Some boat owners have suggested that adding a second fuel pump can help alleviate vapor lock issues, especially if the problem is caused by hot fuel lines. However, others have expressed skepticism, noting that the problem is likely due to the lines from the engine to the fuel pump getting hot, and a second pump may not solve this issue.

If you decide to add a second fuel pump, you can purchase a kit from your dealer or an inline pump from an automotive store. The installation process may vary depending on your boat's configuration, and it is recommended to seek the advice of a mechanic or a professional.

It is important to note that there are other methods to address vapor lock issues, such as keeping the fuel lines cool by isolating them from engine heat, using a different fuel grade, or installing an electric fuel pump or a plastic carb spacer.

The Andrea Gail: A Fishing Vessel's Tale

You may want to see also

Frequently asked questions

If your boat engine has vapor lock, you will experience rough-running, stumbling, and stalling with the application of throttle.

Vapor lock is caused by heat, which boils the fuel, preventing it from being pumped into the carburetor or fuel injectors. It can also be caused by engine modifications that push a car's fuel system beyond its design limits, such as adding freer-breathing induction, headers, or exhaust components.

There are several ways to fix vapor lock:

- Replace the fuel filter.

- Increase the size of the fuel feed line.

- Upgrade the mechanical fuel pump.

- Add an electric pusher pump at the tank.

- Isolate fuel lines from sources of heat, such as long-tube headers.

- Add a fuel cooler.

- Use ethanol-free gas.

To prevent vapor lock, try to avoid running your boat in hot weather, at high altitudes, or in heavy traffic. Keep your fuel tank full, especially in hot weather, to avoid heat buildup.