Fixing a hole in an aluminum boat can be done in a variety of ways, depending on the size of the hole and your budget. For small holes, many people recommend using a product called JB Weld, a two-part, marine-grade epoxy putty. This can be smoothed into the hole and onto the surrounding area, providing a strong and watertight seal. For larger holes, it is recommended to seek professional welding services, as this will provide a longer-lasting repair. Some people have suggested using fiberglass matting and resin to fix larger holes, but this method is not recommended for aluminum boats as it can separate and leak over time. Instead, a patch can be riveted over the hole, and sealed with a product such as 3M 5200 or Boatlife.

| Characteristics | Values |

|---|---|

| Durability | High resistance to impact and corrosion |

| Lightweight | Better fuel efficiency, easier to navigate and control |

| Maintenance | Require less upkeep, no need for regular painting or coating |

| Performance | Faster speeds and enhanced agility on the water |

| Design | Precise molding, sleek and aerodynamic hull shapes |

| Maintenance (Fiberglass) | Require periodic waxing or polishing |

What You'll Learn

Using fiberglass cloth and marine tex

To fix your aluminium jon boat with fibreglass, you can use fibreglass cloth and Marine Tex. Here is a step-by-step guide:

Step 1: Prepare the Area

Before beginning the repair, ensure the area is clean and dry. Sand or grind the area around the hole or crack and clean it with acetone or another solvent to remove any oil or grease. If the hole is a crack, drill a small hole at each end to prevent the crack from spreading.

Step 2: Apply Marine Tex

Mix the two-part Marine Tex epoxy putty until it is a uniform colour. Press and smooth the putty into the hole or crack, working it into the area with your fingers or a spatula. Ensure you apply it to both the inside and outside of the hole/crack if possible.

Step 3: Apply Fibreglass Cloth

Cut a piece of fibreglass cloth to size, ensuring it is large enough to cover the entire area of the repair. Lay the cloth over the Marine Tex and work it into the putty, ensuring it adheres well.

Step 4: Apply a Second Coat of Marine Tex

Cover the fibreglass cloth with a second coat of Marine Tex, smoothing it out to create an even finish. This will help to seal the repair and ensure the fibreglass cloth is properly bonded to the aluminium boat.

Step 5: Allow to Cure

Follow the manufacturer's instructions for curing time. Once cured, the repair will be strong and durable. You can sand the area if needed to smooth out any rough spots, but be aware that Marine Tex can be difficult to sand once fully cured.

This method is a good option for small to medium-sized holes or cracks in your aluminium jon boat. For larger repairs, you may need to consider a different method, such as welding or applying a patch with rivets. Always ensure you take the necessary safety precautions when working with boats and repair materials.

Replacing Gas Tanks in Older Proline Boats

You may want to see also

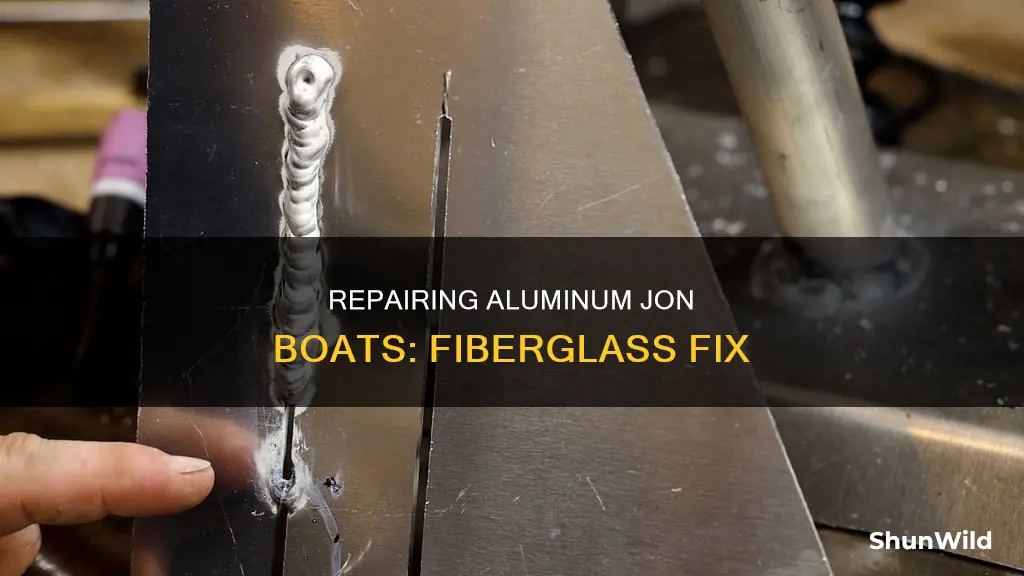

Repairing with fiberglass and epoxy resin

Repairing holes in an aluminium boat with fibreglass and epoxy resin is a challenging but rewarding task. Here is a step-by-step guide to achieving a successful repair:

Step 1: Surface Preparation

Firstly, protect the surrounding area of the boat by covering it with poly sheeting and masking tape. This will prevent any accidental damage to the boat's finish. Next, clean the surface of the repair area by wiping it with a clean cotton rag dampened with acetone. This will remove any contaminants and loose debris. Then, use 36-80 grit sandpaper and a grinder to remove any loose gel coat or fibreglass debris from the damaged area. For rounded edges, use an appropriate bit to ensure a thorough sanding. It is important to sand a little beyond the damaged area to ensure maximum adhesion for the repair. If the damage goes completely through the surface, grind out the area to a width that is 5:1 or greater than the depth of the repair. Finally, thoroughly clean the repair area by vacuuming away the sanding/grinding residue and wiping it with a clean rag dampened with acetone to remove any remaining residue.

Step 2: Prepare a Small Batch of Filler (Mixed, Thickened Epoxy)

To ensure maximum adhesion for your repair patch, you will need to mix and brush on a thin layer of thickened epoxy. Combine epoxy resin and a slow hardener in a 5:1 ratio by volume and mix thoroughly. Then, add a small amount of silica thickener and stir until the mixture reaches a ketchup-like consistency.

Step 3: Prepare a Small Batch of Mixed, Unthickened Epoxy

For this step, you will need to mix another batch of epoxy without any filler. Dispense 5 parts epoxy resin to 1 part slow hardener and stir thoroughly. This unthickened epoxy will be used to wet out small pieces of fibreglass cloth to create a patch for the repair area. If desired, pour the mixture into a small, clean, disposable cup to make it easier to dip your brush into.

Step 4: Cut Pieces of Fibreglass Cloth to Create a Layered Patch

To repair the damage, you will need to fill the area with multiple layers of fibreglass cloth, each saturated with the unthickened epoxy. Start by making a template and then cut successively smaller pieces of fibreglass cloth. The first piece should cover the entire repair area, with each subsequent piece being slightly smaller. You will need enough pieces to create a thick enough patch to complete the repair.

Step 5: Apply Mixed, Thickened Epoxy to the Repair Area

Use a small brush to apply a thin layer of the thickened epoxy mixture to the repair area. This layer will fill any cracks or voids and create a strong bond for the fibreglass patch. Be sure to only use a thin layer, as extra epoxy will not add strength and will create waste.

Step 6: Apply the First Fibreglass Patch Layer and Wet Out with Mixed, Unthickened Epoxy

There are two methods for creating your fibreglass patch. The first method involves building the patch directly on the repair area, layer by layer. Alternatively, you can build the entire patch on a separate work area, wetting out the fibreglass between each layer, and then transferring it to the repair area. For this example, we will build the patch directly on the repair area. Place the largest piece of fibreglass cloth onto the thickened epoxy and gently press it down. Use a small brush to wet out this first layer with the unthickened epoxy, applying just enough to saturate the cloth. Remember, extra resin will not add bulk or strength but will create brittleness. The strength of your repair comes from the fibreglass fabric.

Step 7: Add and Wet Out Patch Layers Until You Build Sufficient Thickness

Continue applying each successive piece of fibreglass, wetting out each piece as you go with the unthickened epoxy. Be sure to only apply enough epoxy to saturate the cloth, as cured epoxy is difficult to sand.

Step 8: Apply Peel Ply and Let the Repair Cure

Cut a piece of peel ply, or 'release fabric', large enough to cover the repair area and lay it on top of the final coat of epoxy. Optionally, use a small dry brush to help the peel ply stick completely. Apply a thin coat of unthickened epoxy on top of the peel ply to prevent air bubbles, being careful not to use too much epoxy, as this will make it harder to remove.

Step 9: Sand the Repair Area Smooth

Once the repair is fully cured, slowly and carefully remove the peel ply. This will also remove any amine blush and excess epoxy. Sand and/or grind the repair to shape and smooth it out, then vacuum away the sanding dust. If desired, you can overcoat the repair with paint or primer. For a cosmetic finish, fair the repair before overcoating. You can do this by mixing epoxy resin, slow hardener, and microballoons to a peanut butter consistency, allowing it to cure, and then sanding, cleaning, and applying your desired finish. Alternatively, use a pre-thickened epoxy fairing compound and then prime and paint.

Adding Antifreeze to Your Boat: A Step-by-Step Guide

You may want to see also

Using a patch and rivets

Step 1: Prepare the Patch

First, you will need to cut an aluminum patch to size. The patch should be slightly larger than the hole you are trying to repair to ensure a strong bond. Make sure the patch is made from a thickness of aluminum that is as close to the original hull material as possible to help with the stresses of the repair.

Step 2: Drill and Debur

Before attaching the patch, it is important to drill and debur at the ends of the cracks in your boat. This will prevent the cracks from slowly continuing past the patch over time.

Step 3: Attach the Patch

Now it is time to attach the patch to your boat. You can use solid aluminum rivets or stainless steel screws to secure the patch in place. If using screws, be sure to coat each one with a sealant like 3M 5200 before screwing them in. This will help create a watertight seal.

Step 4: Seal the Patch

Once the patch is securely in place, you can apply a layer of sealant to the outside of the patch and the surrounding area. This will ensure that your repair is watertight and will help protect the aluminum from corrosion.

Step 5: Interior Repair

If needed, you can also apply a coat of Gluvit or a similar product to the inside of the repair for added protection. This will help ensure that your boat is sealed and protected from the inside as well.

By following these steps and using a patch with rivets, you can effectively repair holes in your aluminum Jon boat. This method is a durable and relatively inexpensive way to fix your boat and get it back on the water.

Southampton Boat Show Tickets: What You Need to Know

You may want to see also

Welding a patch

Step 1: Prepare the Area

Before welding, it is crucial to clean the area around the hole thoroughly. Use a surface sander with 80-grit discs to remove any paint, dirt, or debris. Ensure you wear a mask during this process to avoid inhaling contaminants. Once you have exposed the bare metal, use a die grinder to cut out and remove any remaining rusted metal. Treat the leftover rust inside the hole with a chemical rust converter. This step will vary depending on the products available to you, but it typically involves applying the converter and letting it dry before sanding again with 80-grit discs.

Step 2: Prepare the Patch

Cut out a patch from a piece of aluminium that is slightly larger than the hole in your boat. The patch should be made of aluminium with a thickness similar to your boat's hull to help distribute stress evenly. Clean the patch with a wax and grease remover to ensure no oil or grease is present, as this can interfere with the welding process.

Step 3: Weld the Patch

Now, it's time to weld! Place the patch over the hole, ensuring it overlaps the hole by at least an inch on all sides. Use a low heat setting on your welder (around 50-60 amps) to avoid warping the thin aluminium. Start welding from one side of the patch, working your way around the perimeter to secure it in place. Make sure you weld both the inside and outside of the hull for added strength.

Step 4: Finish and Seal

Once the welding is complete, you can finish the repair by sealing it. Use a product like 3M 5200 or Boatlife to seal the patch and create a smooth finish. Make sure to follow the instructions on the product you choose for the best results.

Remember, welding aluminium can be tricky, and if you're not confident in your skills, it's best to seek the help of a professional welder. Additionally, always put safety first and wear appropriate protective gear when working with power tools and chemicals.

Boat: A Company Worth Sailing With?

You may want to see also

Using marine adhesive and fiberglass cloth

To fix your aluminum Jon boat with fiberglass, you can use a combination of marine adhesive and fiberglass cloth. This method is ideal for small cracks or holes, especially in non-load-bearing areas above the water line. Here's a step-by-step guide on how to do it:

Step 1: Prepare the Area

Before applying any repairs, it's important to clean the area thoroughly. Use a solvent like acetone to remove any grease or oil from the surface. Make sure the area is completely dry before proceeding to the next step.

Step 2: Cut the Fiberglass Cloth

Measure the size of the crack or hole and cut a piece of fiberglass cloth that is slightly larger than the damaged area. You can use scissors or a utility knife to cut the cloth. It's important to have the cloth ready before mixing the adhesive, as you'll have a limited time to work with it once it's activated.

Step 3: Mix the Marine Adhesive

In a mixing bucket, combine the marine adhesive (also known as resin) with the hardener. Follow the manufacturer's instructions for the correct proportions and mixing techniques. You want to mix enough adhesive to cover the repair area, but not too much, as it will start to dry and harden within 15 to 20 minutes.

Step 4: Apply the Adhesive to the Boat

Using a paintbrush or roller, apply the mixed adhesive to the damaged area on your boat. Make sure to work quickly and evenly, ensuring the adhesive penetrates the fiberglass fabric and adheres to the surface. You can use a small brush for more precise application in tight spaces.

Step 5: Apply the Fiberglass Cloth

Place the cut fiberglass cloth over the repair area, ensuring it adheres to the adhesive. Smooth it out to remove any air bubbles and ensure a tight fit. The fiberglass cloth should conform to the contour of the boat, filling gaps and strengthening weak points.

Step 6: Apply Additional Adhesive Layers

Depending on the size and severity of the damage, you may need to apply multiple layers of adhesive and fiberglass cloth. Each layer should be allowed to cure before applying the next. Follow the manufacturer's instructions for curing times.

Step 7: Sand and Finish

Once the final layer has cured, you can sand the repaired area to smooth it out and create a seamless finish. Use a sanding block with the appropriate grit to get the desired smoothness. You can also apply a gel coat or paint over the repaired area to match the color of your boat.

Safety Precautions:

When working with fiberglass and marine adhesives, always prioritize your safety. Wear gloves, goggles, and a respirator to protect yourself from harmful chemicals and dust. Work in a well-ventilated area or outdoors if possible.

Lithium Boat Batteries: Why They're the Best Choice

You may want to see also

Frequently asked questions

First, clean the aluminum thoroughly. Then, apply a coat of marine-grade epoxy putty, such as Marine Tex, to the hole and a bit around it. Next, lay a piece of fiberglass cloth over the hole, pressing it into the epoxy putty. Finally, cover the cloth with additional epoxy putty and smooth it out.

The best way to fix a hole in an aluminum boat is to weld it shut. If welding is not an option, small holes can be fixed with epoxy putty or JB Weld.

While it is possible to use fiberglass cloth and epoxy resin to repair a tear in an aluminum boat, this method is not recommended. Fiberglass is not a good option for repairing aluminum boats as it can separate and leak over time.

To fix tears in an aluminum Jon boat, it is recommended to patch the tears with aluminum. Drill and debur at the ends of the cracks to prevent them from spreading, and then rivet an aluminum patch over the tear. Seal the patch with a product like 3M 5200 or Boatlife.