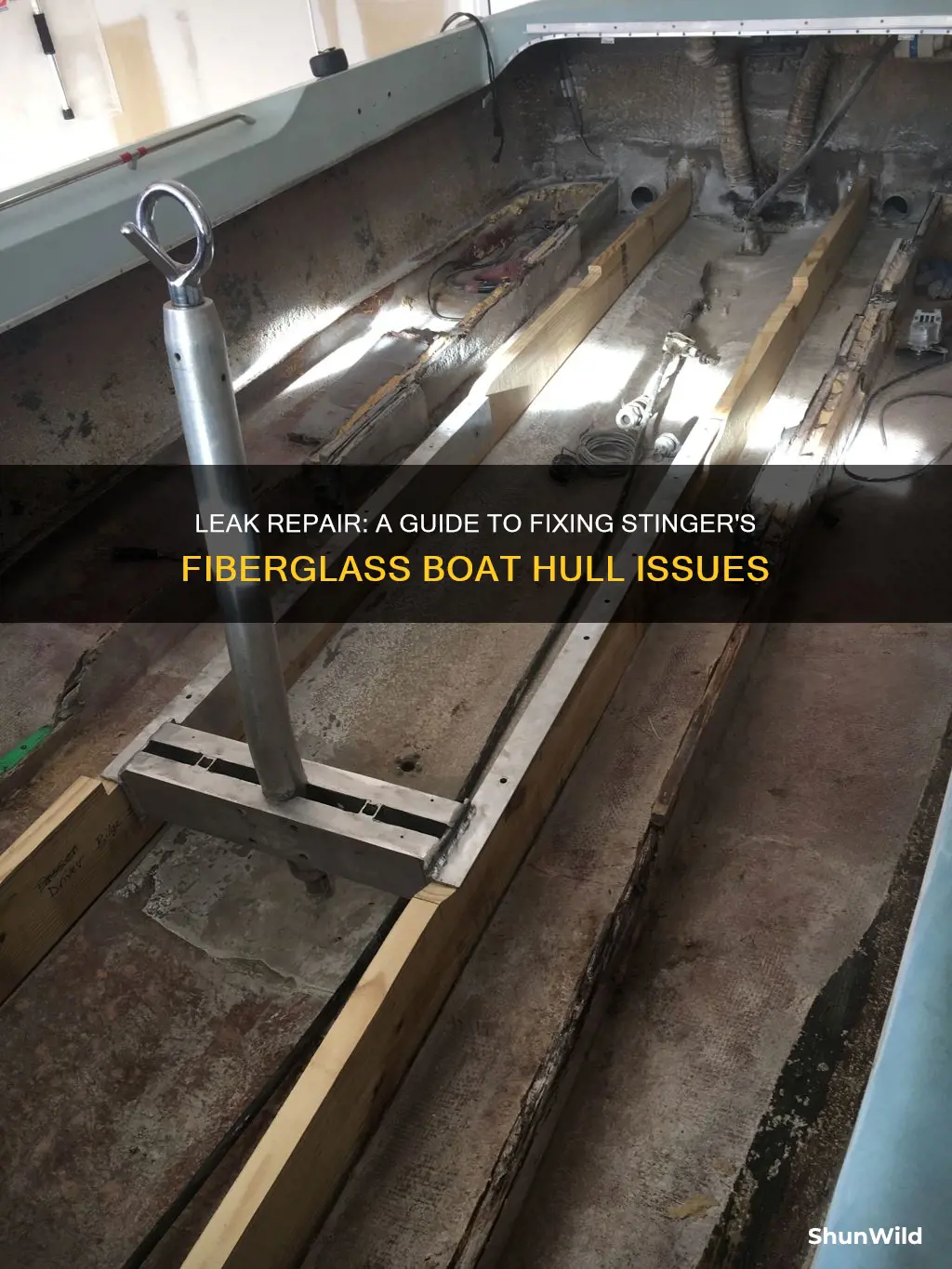

Fixing a leak near the stinger of a fiberglass boat hull can be a challenging task, but with the right approach, it's entirely manageable. The stinger, a crucial component connecting the engine to the propeller, often requires careful attention when addressing leaks. This guide will provide a step-by-step approach to identifying and repairing the issue, ensuring your boat remains safe and functional.

What You'll Learn

- Identify the source: Locate the specific area where the leak is occurring on the hull

- Inspect for damage: Carefully examine the hull for any signs of damage or wear

- Clean and prepare: Use a mild detergent to clean the area and ensure proper adhesion

- Apply a repair kit: Utilize a suitable kit for fiberglass repairs, following the manufacturer's instructions

- Reinforce with gelcoat: Add a layer of gelcoat to protect the repair and restore the hull's integrity

Identify the source: Locate the specific area where the leak is occurring on the hull

When dealing with a leak in a fiberglass boat hull, especially near the stinger, it's crucial to pinpoint the exact source of the issue. This step is fundamental to ensure an effective repair. Here's a detailed guide on how to identify and locate the leak:

Step 1: Visual Inspection

Start by thoroughly examining the hull. Look for any visible signs of damage, such as holes, tears, or cracks in the fiberglass. Pay close attention to the area near the stinger, as this is a common spot for leaks due to its structural complexity. Inspect the stinger itself for any signs of damage or wear, as it can be prone to deterioration over time.

Step 2: Check for Water Ingress

Look for any signs of water seeping into the hull. This could be in the form of wet spots, mold, or corrosion on the interior of the boat. Water ingress can occur through small openings or even through seemingly intact fiberglass. Carefully inspect all seams, especially those around the stinger, as these areas are more susceptible to leaks.

Step 3: Use a Strobe Light or Flashlight

In low-light conditions or at night, use a strobe light or a bright flashlight to illuminate the hull. Shine the light through the suspected areas, including the stinger, to detect any hidden water ingress. This technique can help reveal small leaks that might not be visible during a regular inspection.

Step 4: Apply a Waterproof Sticker or Tape

For a more targeted approach, apply waterproof stickers or tape over the suspected areas. Leave them in place for a few days and then check for any signs of water accumulation beneath the stickers. This method can help isolate the exact location of the leak.

Step 5: Use a Pressure Test

Consider using a pressure test to identify the leak. Fill the hull with water and use a pressure gauge to apply pressure. Inspect the hull for any areas where the pressure drops, indicating a potential leak. This method is particularly useful for locating leaks in hard-to-reach areas.

By following these steps, you can accurately identify the source of the leak near the stinger of your fiberglass boat hull. This knowledge is essential for proceeding with the appropriate repair methods and ensuring the longevity of your vessel.

How Much Is Too Much? Bass Boat Engine Hours Explained

You may want to see also

Inspect for damage: Carefully examine the hull for any signs of damage or wear

When dealing with a leak near the stinger of a fiberglass boat hull, a thorough inspection is crucial to understanding the extent of the damage and planning the appropriate repair. Here's a step-by-step guide to inspecting the hull for any signs of damage or wear:

Start by visually examining the hull in the area where the leak has occurred. Look for any visible cracks, chips, or delaminations in the fiberglass. These could be caused by the impact of the stinger or other structural elements. Pay close attention to the gelcoat, as it can provide clues about the type of damage. Check for any discoloration, soft spots, or a chalky appearance, which may indicate a compromised gelcoat layer.

Move on to the internal structure of the boat. Inspect the stringers, which are crucial components running along the length of the hull. These structural members provide strength and support, and any damage to them can compromise the boat's integrity. Look for signs of corrosion, especially if the boat has been exposed to saltwater. Corroded stringers may show signs of rust, pitting, or a deterioration of the material. Additionally, check for any signs of water intrusion, such as discolored or warped wood, which could indicate previous leaks or water damage.

The deck and its surrounding areas should also be inspected. Look for any signs of water accumulation or previous leaks, which might have caused damage to the deck structure or the hull-deck joint. Check for any loose or damaged fasteners, as these can lead to further issues and potential water ingress.

Don't forget to inspect the hull's access panels and compartments. These areas can sometimes be overlooked but are crucial in identifying the source of the leak. Remove any panels carefully and inspect the underlying structure for damage, corrosion, or signs of previous repairs.

Finally, take note of any unusual noises or vibrations while the boat is in operation. These could be indicators of structural issues or damage, especially if they are related to the area where the leak has occurred.

A thorough inspection will help you understand the extent of the damage and guide you in deciding the most appropriate repair methods for the leak near the stinger of your fiberglass boat hull.

Boating in Minnesota: Do You Need a Coastguard Certification?

You may want to see also

Clean and prepare: Use a mild detergent to clean the area and ensure proper adhesion

When dealing with a leak near the stinger of a fiberglass boat hull, a crucial step in the repair process is ensuring a clean and prepared surface for the new material. This initial preparation will significantly impact the success of the repair, promoting strong adhesion and a seamless finish.

Begin by thoroughly cleaning the affected area. Fiberglass is a porous material, and any dirt, grime, or old sealant must be removed to allow the new repair material to bond effectively. Use a mild detergent mixed with water, ensuring it is gentle enough to avoid damaging the fiberglass. Apply this solution to the leak area and surrounding surfaces, scrubbing gently to lift away any contaminants. Rinse thoroughly with clean water to remove all traces of detergent, ensuring no residue remains.

After cleaning, the surface should be smooth and free from any debris. If there are any remaining imperfections or rough spots, carefully sand them down using fine-grit sandpaper. This step is essential to create a uniform and even surface, ensuring the repair material adheres properly. Take your time with this process, as a smooth finish will contribute to a professional-looking repair.

Once the area is clean and smooth, it's crucial to ensure proper adhesion. This can be achieved by applying a suitable primer designed for fiberglass. Choose a primer that is compatible with the repair material you will be using. Follow the manufacturer's instructions for application, ensuring an even and thin layer. Allow the primer to dry completely according to the product's guidelines, as this will further enhance the bond between the old and new materials.

By taking the time to thoroughly clean and prepare the leak area, you create an optimal environment for the repair. This process ensures that the new material will adhere strongly, providing a robust and long-lasting solution to the leak near the stinger of your fiberglass boat hull. Proper preparation is key to a successful and durable repair.

Jackdaw's Intriguing Identity: Unveiling the Boat's True Nature

You may want to see also

Apply a repair kit: Utilize a suitable kit for fiberglass repairs, following the manufacturer's instructions

When dealing with a leak near the stinger of a fiberglass boat hull, a repair kit specifically designed for fiberglass repairs is an excellent solution. These kits provide a comprehensive approach to fixing the issue, ensuring a strong and durable repair. Here's a step-by-step guide on how to effectively use such a kit:

Step 1: Preparation

Before beginning the repair, ensure the boat is in a secure location and the water is drained from the affected area. Clean the surface thoroughly to remove any dirt, debris, or old paint. This step is crucial as it ensures proper adhesion of the repair material. Use a mild detergent and water solution to clean the area, and then rinse it thoroughly. Allow the surface to dry completely before proceeding.

Step 2: Inspect and Prepare the Damage

Carefully examine the leak to understand the extent of the damage. If the leak is a small hole or crack, you can proceed with the repair kit. For larger damage, you might need additional materials or a more complex repair process. Use a putty knife or a similar tool to gently remove any loose fibers or debris around the damage. This step helps create a clean and smooth surface for the repair material.

Step 3: Follow the Kit Instructions

Each repair kit will have specific instructions, so it's essential to read and understand them before starting. Typically, the process involves applying a bonding agent or primer to the prepared surface, allowing it to dry, and then applying the repair material. This material is usually a two-part epoxy or a similar composite resin. Follow the kit's guidelines for mixing and applying the materials, ensuring you cover the entire damaged area.

Step 4: Application and Curing

Apply the repair material in a thin, even layer, ensuring it overlaps the edges of the damage. Use a putty knife or a similar tool to smooth out any air bubbles and create a seamless finish. Once applied, allow the material to cure according to the kit's instructions. This process may take several hours or even overnight, depending on the product.

Step 5: Finishing and Testing

After the repair material has cured, sand the surface to create a smooth finish. This step ensures that the repair blends seamlessly with the surrounding hull. You can then apply a suitable fiberglass cloth or tape to reinforce the repair, if desired. Finally, test the boat's integrity by taking it out on the water. Ensure the leak has been successfully sealed and that the boat's performance is unaffected.

Remember, fiberglass repair kits are designed to provide a strong and long-lasting solution. By following the manufacturer's instructions carefully, you can effectively repair the leak near the stinger of your fiberglass boat hull.

Secure Your RAM Mount: A Guide to Attaching to Fiberglass Boats

You may want to see also

Reinforce with gelcoat: Add a layer of gelcoat to protect the repair and restore the hull's integrity

When dealing with a leak near the stinger of a fiberglass boat hull, one effective method to reinforce and protect the repair is by applying a layer of gelcoat. Gelcoat is a crucial component in the world of boat restoration and repair, offering both structural and aesthetic benefits. Here's a step-by-step guide on how to achieve this:

Preparation: Before applying the gelcoat, ensure the repair area is thoroughly cleaned and free from any debris or contaminants. Use a sharp blade or a specialized tool to carefully remove any loose fibers or damaged material around the leak. This step is essential to ensure the gelcoat adheres properly and provides a seamless finish.

Mixing the Gelcoat: Follow the manufacturer's instructions to mix the gelcoat properly. Typically, you'll need to combine the resin and hardener in the correct proportions. Stir the mixture thoroughly to ensure a consistent and smooth consistency. Gelcoats come in various colors, so choose one that closely matches the original hull color for a discreet repair.

Application: Apply the mixed gelcoat to the repair area using a brush or a specialized tool. Start from the center of the leak and work outward, ensuring complete coverage. Pay attention to the edges and any intricate details around the stinger, as these areas require precise application. Gelcoat is typically applied in thin layers, allowing it to build up gradually to achieve the desired thickness.

Curing and Sanding: After the gelcoat is applied, allow it to cure according to the manufacturer's guidelines. This process may take several hours or even days, depending on the type of gelcoat used. Once cured, inspect the repair and gently sand the surface with fine-grit sandpaper to create a smooth finish. This step is crucial to ensure the gelcoat blends seamlessly with the surrounding hull.

Final Touches: After sanding, wipe away any dust and ensure the surface is clean. You can now apply additional coats of gelcoat if needed to further enhance the repair's strength and appearance. This process helps to reinforce the hull's integrity, providing a protective barrier against future leaks and damage. Remember, gelcoat not only repairs the leak but also adds an extra layer of protection, ensuring the longevity of your fiberglass boat hull.

Boat Launches in New York: Open or Closed?

You may want to see also

Frequently asked questions

Locating the leak can be challenging, but there are a few methods to help pinpoint the issue. Start by inspecting the boat's exterior for any visible damage or cracks, especially around the stringers, which are structural components running along the hull. Use a flashlight to examine tight spaces and look for any signs of water intrusion. If the leak is near the stringers, it might be a result of a compromised bond between the stringer and the hull, or a damaged stringer itself.

If you identify a potential issue, it's crucial to act promptly. Clean the affected area and ensure it is dry. Then, apply a marine-grade epoxy or a suitable repair compound specifically designed for fiberglass. Follow the manufacturer's instructions carefully, and consider seeking professional assistance for complex repairs. For minor leaks, temporary solutions like sealing tape or marine-grade putty can provide short-term relief while a more permanent fix is planned.

Regular maintenance is key to preventing leaks. Keep the boat's surface clean and free from debris, especially in areas prone to damage. After each use, ensure the boat is thoroughly cleaned and dried, paying extra attention to the stringers and any other structural components. Regularly inspect the hull for any signs of wear and tear, and address any issues promptly. Additionally, consider using a protective coating or gelcoat to enhance the hull's durability and resistance to water intrusion.

Yes, there are specialized products available for such repairs. Marine-grade epoxy systems are commonly used and can provide strong, durable bonds. These epoys are designed to withstand the harsh marine environment. When using any repair product, ensure proper ventilation and follow safety guidelines. It's recommended to consult with marine repair professionals or seek guidance from the product manufacturer to ensure the best results and long-term effectiveness of the repair.