A seized boat engine can be a nightmare for boat owners. There are several reasons why a boat engine might seize up, including rust from sitting too long, excessive heat from a lack of coolant or oil, or mechanical problems such as a foreign object in the cylinder or a crankshaft bearing failure. If your boat engine has seized, there are a few things you can try to get it running again. One method is to use penetrating oil or lubricants such as kerosene or Marvel Mystery Oil, which can help to free up rusted or stuck parts. Soaking the engine with oil and then trying to turn the crankshaft with a breaker bar or wrench is another common approach. If the engine still won't turn, it may be necessary to remove the cylinder head and crankshaft, and possibly even take the engine to a machine shop for further repairs.

| Characteristics | Values |

|---|---|

| Reasons for engine seizure | Rust, excessive heat, foreign object in cylinder, crankshaft bearing failure, low/no oil, overheating, broken timing belt |

| Confirmation of engine seizure | Remove spark plugs and try rotating the engine |

| First steps to repair | Use penetrating oil, try rotating crankshaft |

| Alternative lubricant | Kerosene |

| Alternative method | Use ATF and manually turn the engine |

| Engine seizure from sitting | Likely to be piston rings binding with cylinders |

| Engine seizure from overheating/no oil | Likely to be torn pistons, cylinders and bearings |

What You'll Learn

Remove spark plugs and try rotating the engine

If you suspect that your boat engine has seized, the first thing to do is remove the spark plugs and try rotating the engine. This will help you confirm whether the engine is indeed seized. If you can't rotate the engine by hand, it's probably seized.

To remove the spark plugs, use a socket to carefully disconnect each wire, numbering them to ensure that you reconnect each wire to its original cylinder when putting everything back together. This will keep the engine timing in sync. Removing the plugs will also release any pressure within the engine that could push against you as you work to free the pistons.

Once the spark plugs are removed, you can try rotating the engine by hand or, for larger engines, use a breaker bar to see if it will turn. If the engine is seized due to rusted cylinder walls, you may need to apply penetrating oil to the walls of each cylinder through the spark plug holes. This process may require several applications over several days.

If your boat is equipped with a manual transmission, you can put the boat in gear and rock it back and forth, using the momentum to help rotate the engine. If the engine still doesn't turn, the damage may be more extensive than simple cylinder rust, and you'll need to decide whether an overhaul is worth the effort to save the engine.

The Ultimate Guide to Boat Titling in Oregon

You may want to see also

Use penetrating oil

If your boat engine has seized, the first thing to do is to remove the spark plugs and try rotating the engine. If you can't rotate it, it's probably seized.

The next step is to try using a penetrating oil. This works well, especially with engines that have been stuck out in the rain, where water has rusted the piston rings to the cylinder.

There are many types of penetrating oil, but P'Blaster is a good option. Start by spraying oil down into the cylinder through the spark plug hole—the more, the better. Be sure to wear goggles to protect your eyes in case the oil sprays back.

For best results, spray the oil daily for about two weeks. Then, gently tap on the cylinder wall with a hammer handle. This creates vibrations that help the oil penetrate between the rings and the cylinder wall. After this process, try rotating the crankshaft. If the engine still won't turn, use more penetrating oil and ensure you're using enough. Half a can of oil per cylinder is usually sufficient.

If the engine still won't rotate after four weeks of daily treatment, it's time to consider more serious measures.

Stern Drive Boats: How They Work and Why Choose Them

You may want to see also

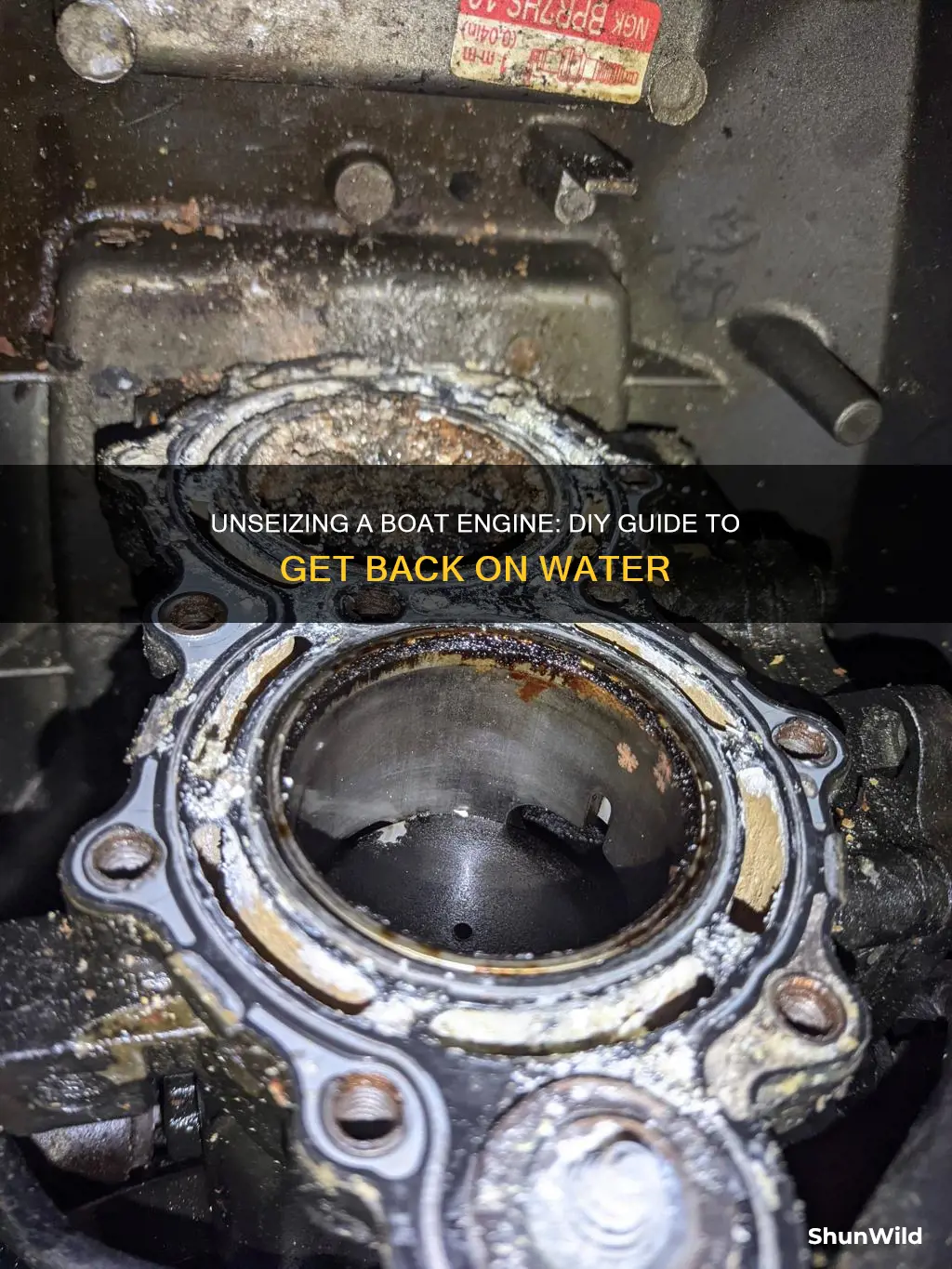

Pull the cylinder apart

If penetrating oil doesn't work, it's time to remove the cylinder head and, most likely, the crankshaft. On smaller stationary engines, this is pretty straightforward, but on larger tractor engines, you’ll be getting into quite a bit of work. On a multi-cylinder engine, it’s often possible to discern which cylinder is stuck, sometimes just by looking into each cylinder. If you’re lucky and you can figure it out, remove the end cap on the connecting rod of the offending cylinder and then rotate the crankshaft so the crankshaft throw for that cylinder is out of the way.

With the cylinder head off, take a mallet and try to pound the piston out, placing a block of wood on top of the piston so you don’t damage it. Make sure the wooden block is clean – you don’t want to mar the top of the piston with sand or small rocks. Make sure the piston can slide out the bottom of the cylinder without smashing the crankshaft—you don’t want to make things worse than they already are. Most of the time, this is the extent of removing a stuck piston, but if it’s still stuck, it’s time to bite the bullet and head to a machine shop to have the piston pressed or, even worse, bored out.

Fresh Off the Boat: Chinese Language Authenticity

You may want to see also

Assess cylinder and piston damage

Assessing cylinder and piston damage is a critical step in repairing a seized boat engine. The extent of the damage will determine the necessary remedial actions and the overall cost of the repair. Here is a detailed guide to help you through the process:

Firstly, if you had to forcefully remove the piston using a mallet, there is a high probability that the piston rings have been damaged. Piston rings are delicate and tend to shatter when subjected to excessive force. Inspect the rings for any signs of breakage and ensure they rotate freely in the piston grooves. If the rings are stuck, penetrating oil can be used to free them. However, if they are broken, replacement is necessary.

When replacing piston rings, it is crucial to note the position of the ring end gaps and the type of rings used in each groove. Clean the piston ring grooves thoroughly with a piece of an old piston ring, ensuring that all dirt and varnish are removed. This step is essential to prevent the new rings from sticking.

Next, carefully examine the piston itself. Clean it thoroughly and inspect it under a light. Look for any scoring, tears, cracks, or breaks. Measure the piston at multiple points and compare these measurements to the specifications provided in a manual or similar engines if a manual is unavailable.

After assessing the piston, turn your attention to the cylinder wall. Clean the wall and shine a bright light down the cylinder to check for any visible damage. Minor scratches on the cylinder wall can be removed with a cylinder hone, but deeper scores will require the expertise of a machine shop. Depending on the extent of the damage, you may need to install an oversized piston or resleeve the cylinder.

To determine if the cylinder is out of round, it is recommended to take measurements at various locations within the cylinder, such as the top, middle, and bottom, and at different angles. These measurements will help you make an informed decision about the necessary repairs.

In conclusion, assessing cylinder and piston damage is a crucial step in repairing a seized boat engine. By following the steps outlined above, you can identify the extent of the damage, plan the necessary repairs, and make informed decisions about piston and cylinder replacements or modifications.

Bonnie Prince Charlie's Dramatic Escape to Skye

You may want to see also

Check pin and rod bearings

Checking the pin and rod bearings is an essential step in engine maintenance, especially for boat engines that may be exposed to corrosive saltwater environments. Here is a detailed guide on how to check the pin and rod bearings of your boat engine:

Gather the necessary tools and supplies:

- Engine stand

- Torque wrench

- Replacement oil pan gaskets

- Replacement timing chain gaskets

- Silicone sealer/gasket maker

- Box/open-end sockets as needed

- Magnetic base and 1" dial indicator in thousandths of an inch

- Soft brass hammer

- Solvent (lacquer thinner, brake clean, etc.)

- Torque specs for your specific engine

Drain the oil and inspect the oil filter:

Cut open the oil filter and carefully examine the filter paper. Identify any small bits and try to determine their material. Common materials include silicone, cork, paper, iron, or rubber. Keep track of your findings, as they can provide valuable clues about the condition of your engine.

Remove the oil pan and oil pump:

To gain access to the main bearings, carefully remove the oil pan and oil pump. It is important to inspect the main bearings for any signs of damage or abnormal wear.

Remove the front cover and clean the mating surfaces:

Use a solvent and scrotchbrite to scrub away any old gasket material from the mating surfaces. Ensure that the surfaces are thoroughly cleaned and dried before proceeding.

Inspect the main bearing caps and shells:

Remove the main bearing caps one at a time, taking note of the location of the tangs on the bearing shells. Clean the shells with solvent and wipe them dry. Examine the shells for any scars, debris, or copper showing. Drag your fingernail lightly across the surface to feel for any abnormalities. If you notice extreme wear or damage, it indicates a significant issue that needs to be addressed.

Lubricate and reassemble the main bearings:

Lubricate the shell surface and the crank journal. Reinstall the main bearing caps and tighten the bolts or nuts to the specified torque (typically around 40 ft/lbs for the inner and outer mains, and 100 ft/lbs for the thrust main).

Set the crankshaft end play:

Before adjusting the crankshaft end play, it is crucial to measure the initial value. The standard end play for a crankshaft is typically between .005" and .010". Adjust the crankshaft to match these specifications.

Check the rod bearings for side clearance:

Grab the rod caps and try to slide them back and forth on the rod journal. They should move easily with a slight audible click. This indicates proper side clearance, which is essential for smooth engine operation.

Reinstall the oil pump and accessories:

Once you have completed the bearing inspections and adjustments, carefully reinstall the oil pump, front cover, fuel pump, oil pan, and any other accessories that were removed.

Torque the main and rod bolts/nuts:

As a final step, use a torque wrench to re-check and confirm the torque on the main and rod bolts/nuts. This step is crucial to ensure the integrity and longevity of your engine.

By following these steps, you can effectively check the pin and rod bearings of your boat engine. Regular maintenance and inspections can help identify potential issues before they become major problems, ensuring the reliable operation of your boat engine.

Lewes Fire Boat: What Happened to Delaware's Watercraft?

You may want to see also

Frequently asked questions

Boat engines can seize due to rust from sitting idle for too long, excessive heat from a lack of coolant or oil, or mechanical problems such as a foreign object in the cylinder or a crankshaft bearing failure.

Remove the spark plugs and try rotating the engine. If you can't rotate it, the engine is likely seized.

If the engine is seized due to rusted cylinder walls, you can try using penetrating oil. Spray the oil into the cylinder through the spark plug hole and wait a couple of hours. Then try to rotate the crankshaft. If this doesn't work, you may need to pull the cylinder apart and remove the cylinder head and crankshaft.