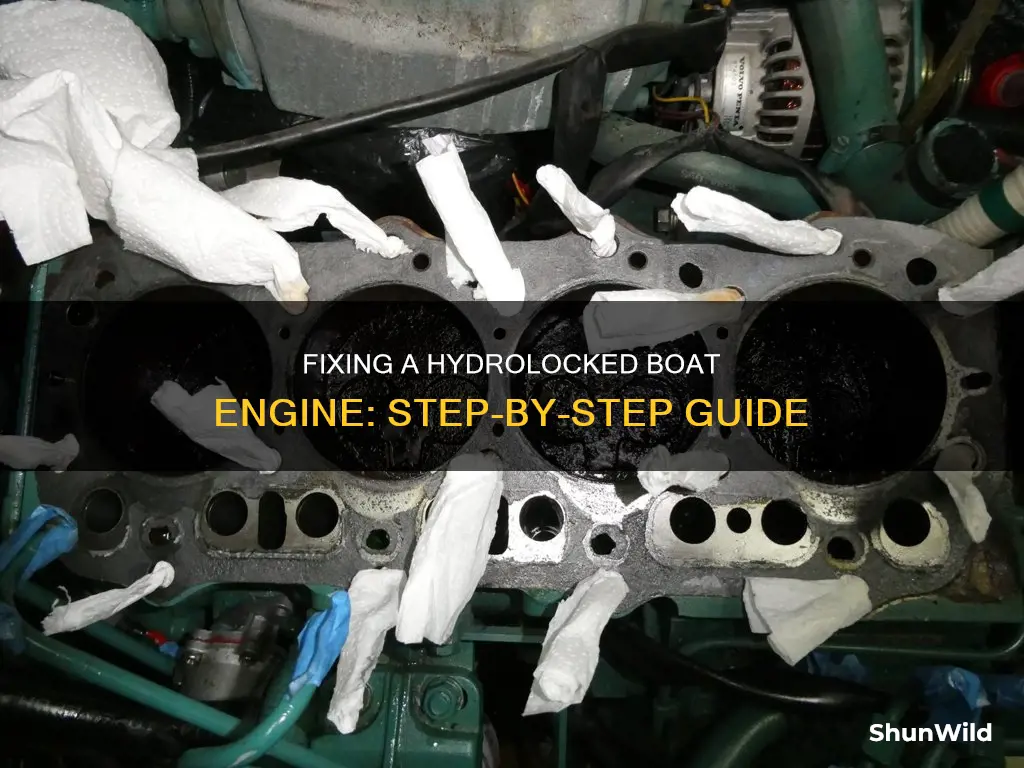

A hydrolocked boat engine is a serious issue that can ruin your day out on the water. It occurs when water enters the engine cylinders, causing the pistons to seize. This can be due to engine timing issues, large waves, or water in the intake, among other things. To fix a hydrolocked boat engine, you must first remove the kill switch lanyard (if present) and then the spark plugs. Then, crank the engine with the plugs removed to expel the water from the cylinders. Dry the plugs, put them back in, and reconnect the wires. Finally, start the engine and investigate the cause of the issue to prevent it from happening again.

| Characteristics | Values |

|---|---|

| What is a hydrolocked engine? | A condition that occurs when a significant amount of liquid enters the engine's cylinders or combustion chambers, causing the pistons to seize. |

| What causes it? | Driving through deep water, internal coolant or oil leaks, a malfunctioning or damaged head gasket, a cracked engine block or cylinder head, submerging the engine's air intake in water, engine timing issues, large waves, or water in the intake. |

| Signs of a hydrolocked engine | The engine won't start, clunking noises, the engine not turning over, crashing or knocking noises, abnormal amounts of water coming from the exhaust, engine stalling after driving through water. |

| What to do if your engine is hydrolocked | Do not try to start the engine again, get to safety if necessary, disconnect the battery, check the air filter, call a professional mechanic. |

| Can a hydrolocked engine be fixed? | Yes, in most cases. The extent of damage and cost of repairs depend on how long the engine was hydrolocked and the type of liquid involved. Fixes may include draining the engine, replacing damaged components, and various other car services. |

What You'll Learn

Remove the kill switch lanyard

A hydrolocked boat engine can be a challenging issue to resolve, and it occurs when excessive water enters the engine cylinders, causing the pistons and other components to seize up instantaneously. While it is possible to repair a hydrolocked engine, the process can be time-consuming and costly, depending on the severity of the damage.

Now, let's focus on the kill switch lanyard and its role in addressing a hydrolocked boat engine. The kill switch, also known as the emergency cut-off switch, safety lanyard, or engine cut-off switch, is a crucial safety feature on any boat. In an emergency, such as the driver being thrown from the boat, it is designed to stop the engine and prevent the propeller from turning.

To ensure the safety of the boat's operator, it is essential to remove the kill switch lanyard. Here are some detailed instructions and considerations regarding this process:

Understanding the Kill Switch Lanyard:

The kill switch lanyard is typically a red, coiled lanyard attached to the kill switch. It is designed to be worn by the boat operator and is clipped to their life jacket or clothing. In an emergency, such as the operator being thrown from the helm, the lanyard pulls the switch to the "off" position, stopping the engine and preventing further acceleration.

Federal Regulations and Requirements:

It is important to be aware of the federal regulations regarding the use of the kill switch lanyard. As of April 1, 2021, a federal law mandates that the operator of a motorized recreational vessel with three or more horsepower and less than 26 feet in length must attach the kill switch lanyard to their person while the boat is in motion.

When to Remove the Lanyard:

There are specific scenarios when you should remove the kill switch lanyard. If your boat is idling, docking, or moving at a slow speed, you are not required by law to have the lanyard attached. However, if the boat is travelling at a faster speed or is on plane, you must securely attach the lanyard.

Best Practices and Recommendations:

Consider the following tips for safe boating practices related to the kill switch lanyard:

- Have an extra lanyard clip on board: In case of an emergency, such as needing to retrieve the operator from the water, it is helpful to have a spare lanyard clip readily available.

- Manual override: Install a kill switch with a manual override option to provide an additional layer of safety.

- Floating key chain: Attach a floating key chain to your lanyard to prevent it from sinking if it falls into the water.

- Professional installation: If your boat does not have a kill switch, consider having one professionally installed to ensure it meets safety standards.

Alternatives to the Lanyard:

While the lanyard-style kill switch is widely used and cost-effective, there are alternative options available. One such alternative is a wireless man-overboard alarm system, which is often more suitable for larger boats or those with a full crew. These systems use electronic fobs that sense when the operator is too far from the helm or submerged in water, activating the engine cut-off switch.

Remember, safety should always be a top priority when operating a boat. By following the instructions and considerations outlined above, you can help ensure the safe use of your boat and effectively address any issues related to a hydrolocked engine.

Boat Licensing in Florida: What's the Requirement?

You may want to see also

Remove spark plugs

Removing the spark plugs is an essential step in fixing a hydrolocked boat engine. This is because the spark plugs provide access to the cylinders, which are the components that become filled with water or other fluids in a hydrolocked engine.

To begin the process of removing the spark plugs, you will need to locate them first. The number and position of spark plugs can vary depending on the engine type and model, so it is important to refer to your boat engine's manual or seek guidance from a marine mechanic if you are unsure. Once you have located the spark plugs, follow these steps:

- Make sure the engine is cool before starting work to avoid the risk of burns or injury.

- Prepare the necessary tools, such as a spark plug socket wrench, a torque wrench, and a gap tool. These tools are specifically designed for working with spark plugs and can often be found in marine tool kits.

- Disconnect the spark plug wires. This step is crucial as it ensures that no power is transmitted to the spark plugs during the removal process, reducing the risk of injury.

- Using the spark plug socket wrench, carefully loosen and remove each spark plug one by one. Place them in a safe location, keeping them separate from any other engine parts or debris.

- Once all the spark plugs have been removed, you will be able to inspect the cylinders for signs of water or fluid damage. This is an important diagnostic step to confirm hydrolocking.

- If water or fluid is present in the cylinders, you will need to drain it. Turn the engine over several times to allow the water to drain out. You may need to repeat this process until all the water is removed.

- After draining the water, dry the cylinders thoroughly using clean cloths or compressed air to remove any remaining moisture.

- Reinstall the spark plugs by gently threading them back into their corresponding cylinders by hand. Ensure they are securely tightened using the torque wrench, following the manufacturer's specifications for torque settings.

By following these steps, you will be able to successfully remove, inspect, and reinstall the spark plugs, which is a crucial aspect of repairing a hydrolocked boat engine.

Truckers' Lottery Wins: A Boat to Retirement

You may want to see also

Crank the engine with plugs removed

If you suspect that your boat engine is hydrolocked, it is important to act quickly to prevent further damage. One of the key steps in the process of fixing a hydrolocked boat engine is cranking the engine with the spark plugs removed. This step helps to remove the water that has entered the engine's cylinders, which is the main cause of hydrolock.

To begin cranking the engine, first remove the kill switch lanyard (if your boat has one) to disable the ignition system. This is an important safety step to ensure that the engine does not accidentally turn on while you are working on it.

Next, carefully remove all the spark plugs from the engine. It is important to label the wires connected to the spark plugs to ensure that you can replace them in the correct order later. With the spark plugs removed, you are now ready to crank the engine.

Turn the key to start the engine, being careful to only crank the engine for a few seconds at a time. As the engine is cranked, the water in the cylinders will be expelled through the spark plug holes. Continue this process until no more water comes out of the cylinders. This step is crucial as it helps to remove the water that has caused the engine to seize up.

Once you have removed as much water as possible, use a clean cloth or towel to dry off the spark plugs. It is important to ensure that they are completely dry before reinstalling them. Carefully screw the spark plugs back into the engine, making sure they are tight, and reconnect the wires in the correct order.

Now that the water has been removed and the spark plugs replaced, you can attempt to start the engine. Turn the key and listen for any unusual noises. If the engine starts and sounds normal, then you have successfully fixed the hydrolocked engine. However, it is important to keep an ear out for any strange noises, as this could indicate that there is still water in the engine or other damage has occurred.

Boat Mooring: How Far is Too Far?

You may want to see also

Dry off plugs, put them back in

Drying off the plugs and putting them back in is the fourth step in recovering from a hydrolocked boat engine. Before this, you must remove the kill switch lanyard (if your boat has one) to disable the ignition system, then remove all spark plugs (ensuring you label the wires so you remember the correct order when reassembling).

The third step involves cranking the engine with the plugs removed. You should notice water being expelled from the cylinders through the spark plug holes. You should do this for several seconds until no more water is being expelled.

Once the cylinders are clear of water, you can dry off the plugs and put them back in. You should then reconnect the wires and start the engine. Hopefully, everything will sound normal. However, it is important to then find out why the hydrolocking occurred in the first place.

Sailing a Boat: Is It Really That Difficult?

You may want to see also

Find the cause

Finding the cause of a hydrolocked boat engine is important to prevent it from happening again. Here are some of the most common reasons for a boat engine to hydrolock:

Engine Timing Issues: This is the most common cause of hydrolock. Incorrect timing can cause the engine to turn backward almost a full revolution when shut down, especially if the shutdown occurs unexpectedly at higher RPMs. This causes the system to run backward, sucking water up into the exhaust manifold and cylinders instead of expelling exhaust gases. Advancing the timing to gain more performance is a prime cause of this issue.

Large Waves: A large wave approaching a boat from the stern when the engine is shut down could create enough pressure to push water up through the exhaust and into the cylinders. While this is less frequent, there have been recorded instances of this happening.

Water in the Intake: Any incident that causes water to enter the air intake will result in water entering the cylinders. This could be due to the vessel being overtaken by a large wave or water entering the bilge by other means.

Submerged Engine Air Intake: Submerging the engine's air intake in water while off-roading or driving through a flooded area can cause hydrolock. This often occurs when driving through deep water, such as during heavy storms or through deep puddles.

Internal Coolant or Oil Leaks: A malfunctioning or damaged head gasket, a cracked engine block or cylinder head, or damaged seals or gaskets can allow coolant or oil to leak into the combustion chamber, leading to hydrolock.

To prevent hydrolock, it is crucial to address these issues and ensure proper engine maintenance. Remember, hydrolock can cause significant damage to your engine, so taking preventive measures and promptly addressing any signs of hydrolock are essential.

Traveling from Menethil to Darnassus: Which Boat to Take?

You may want to see also

Frequently asked questions

A hydrolocked engine is when a significant amount of liquid enters the engine's combustion chambers, preventing the pistons from completing their compression stroke. This liquid can be water, coolant, or engine oil, and it causes the engine to seize up and stop running.

A hydrolocked boat engine is often caused by driving through deep water, or large waves approaching the boat from the stern. Engine timing issues, internal leaks, and submerging the engine's air intake in water can also cause hydrolocking.

The most apparent sign is that the engine won't start. Other signs include the engine not turning over, crashing or knocking noises, abnormal amounts of water coming from the exhaust, and engine stalling after driving through water.

First, do not try to start the engine again as this can cause further damage. Disconnect the battery to prevent electrical damage and check the air filter to confirm water entered the intake system. Then, call a professional mechanic for assistance in locating and fixing the source of the hydrolock.