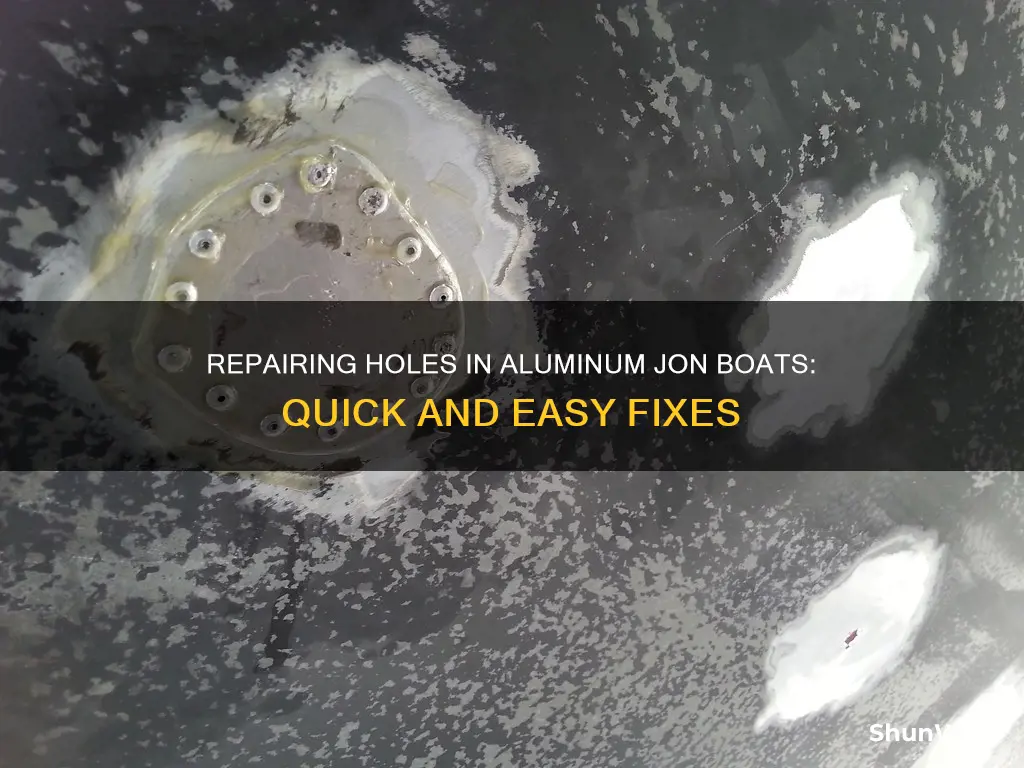

Owning a boat can be a lot of fun, but it also comes with maintenance and repair work. If you have a hole in your aluminium jon boat, there are a few ways to fix it. The most popular methods include using epoxy putty, JB Weld, or welding. For small holes, you can use epoxy putty or JB Weld to seal the hole. Start by hammering the area flat to close the hole as much as possible, then sand or grind the area and clean it with acetone solvent. Mix the two-part marine-grade epoxy putty or JB Weld and apply it to the hole, smoothing it out from both sides if possible. For larger holes, welding may be the best option. You can take your boat to a weld shop and have them weld the hole with a TIG welder. To prevent future leaks, it's important to clean and prepare the area before applying any sealant or welding. This includes sanding, drilling, and cleaning the surface with acetone to ensure a strong bond.

What You'll Learn

Using a welder to fix a hole in an aluminium jon boat

Welding aluminium can be challenging, especially for beginners. Aluminium is a porous metal with a low melting point, making it susceptible to contamination and requiring a higher heat for welding. It is also easy to burn through, so welding must be done quickly.

If you are set on welding your jon boat, it is recommended to use the TIG welding method, as this offers greater control over the heat and is less likely to burn through the thin aluminium. You will also need to use Argon gas to weld aluminium.

Before welding, it is important to thoroughly clean the area to be welded. Use a stainless steel wire brush to remove any oxide from the aluminium surface. You may also need to grind the area to be welded to ensure a smooth surface. Drill small holes at each end of any cracks to prevent them from spreading.

When welding, ensure that you have good ventilation and wear appropriate safety gear, including a welding helmet, gloves, and long sleeves. Work quickly and confidently, as hesitation can lead to mistakes. If you are not confident in your welding skills, it may be best to seek the help of a professional welder or consider alternative repair methods such as riveting or epoxy putty.

Protecting Your Boat: Preventing Corrosion While Docked

You may want to see also

Epoxy putty as a repair method

Epoxy putty is a reliable and convenient solution for repairing holes in aluminum jon boats. It is easy to use, with a simple kneading and application process that does not require specialized tools. This user-friendly method is suitable for both professionals and DIY enthusiasts.

Before applying the putty, it is essential to prepare the surface by sanding or grinding the area around the hole. Clean the area with an acetone solvent to ensure that the putty adheres effectively. For cracks, it is recommended to drill small holes at each end to prevent further spreading.

When using epoxy putty, ensure you have a sufficient amount to cover the hole and its surrounding area. Mix the two-part, marine-grade epoxy putty by rolling equal parts of the resin and hardener together until a uniform color is achieved. This putty usually has a fast curing time, so it is important to work quickly. Press and smooth the putty into the hole, ensuring it adheres well to the aluminum surface.

Once applied, the epoxy putty will cure within a few hours, depending on the temperature. After curing, you can sand, drill, or paint the repaired area for a seamless finish. The repaired area will be strong and durable, capable of withstanding high temperatures and pressure.

Epoxy putty is an effective and accessible solution for repairing holes in aluminum jon boats. It requires minimal tools and offers a fast and permanent fix. With proper application and curing, your boat will be ready for many more adventures on the water.

Patching Boat Hulls: A Comprehensive Guide to Hull Maintenance

You may want to see also

Drilling and deburring to prevent cracks from spreading

Drilling and deburring at the ends of cracks in your aluminum jon boat is an important step to prevent the cracks from spreading. This process involves creating a rounded edge at the end of the crack, which helps to distribute stress and prevent the crack from growing. Here is a step-by-step guide on how to do this effectively:

Step 1: Identify the Crack

Locate the crack in your aluminum jon boat that needs to be addressed. It is important to repair cracks as soon as they are noticed to prevent them from spreading and causing further damage.

Step 2: Gather Your Tools and Materials

You will need a drill with the appropriate drill bits, as well as a deburring tool. The drill bits should be slightly smaller than the width of the crack. You may also want to have some sandpaper or a metal file on hand to smooth out any rough edges.

Step 3: Drill Holes at the Ends of the Crack

Using your drill and the selected drill bit, create a hole at each end of the crack. The holes should be drilled perpendicular to the crack and should not be too deep. The goal is to create a rounded feature that will help distribute stress and prevent the crack from growing.

Step 4: Deburr the Edges

Use your deburring tool, or a metal file, to smooth out any sharp edges or burrs created by the drilling process. This step is important to ensure that the crack does not catch on anything and to create a clean, finished look.

Step 5: Clean the Area

Once you have drilled and deburred the ends of the crack, clean the area thoroughly. Remove any debris, grease, or oil that may be present. This step is important to ensure a good surface for the next steps.

Step 6: Apply Sealant or Epoxy

After cleaning, apply a marine-grade sealant or epoxy to the drilled and deburred area. This will help create a watertight seal and provide additional strength to the repair. Follow the instructions on your chosen product for the best results.

Step 7: Monitor and Inspect Regularly

Even after repairing the crack, it is important to keep an eye on the area. Inspect the repair periodically to ensure that the crack has not continued to spread. If you notice any changes or further cracking, address them promptly.

Remember, safety should always be a priority when working with power tools and making repairs to your boat. Take your time, follow the instructions provided with your chosen products, and seek professional advice if you are unsure about any aspect of the repair process.

Ski Boat Carpet Alternatives: Comfort and Style

You may want to see also

Using a patch to fix a hole in an aluminium jon boat

If you have a hole in your aluminium jon boat, you can fix it with a patch. Here is a step-by-step guide on how to do it:

First, assess the size of the hole. If it is small, you can buy some JB Weld to seal it. If the hole is bigger, you will need a patch. For tears or long cracks, you will need to drill and debur at the ends of the cracks to stop them from spreading further. Clean the area with acetone solvent to remove any oil or grease.

Next, you will need to prepare the patch. Cut a piece of aluminium that is larger than the hole and round off the corners to prevent snagging. Drill holes every 2.5 cm (1 inch) around the patch. You can also use a damaged street sign, which tends to be made of heavy-gauge aluminium.

Now it's time to attach the patch. Place it over the hole and mark the holes on the boat. Drill the holes and use rivets to attach the patch. Make sure the rivets are tight and sealed with a marine sealant such as 3M 5200 or 3M 4000UV.

Finally, apply a coating to the inside of the boat to prevent corrosion and leakage. You can use a product like Gluvit or SteelFlex. Follow the instructions on the product for proper application.

Your aluminium jon boat is now patched and ready to be used again!

Launching a Boat Canvas Business: Getting Started

You may want to see also

Sanding and cleaning the area around the hole

Before you begin to repair a hole in an aluminium jon boat, it is important to sand and clean the area around the hole. This will ensure that the repair is effective and long-lasting.

First, use a hammer and an auto-body bucking dolly to get the hull close to its original shape. If the hole is the result of a tear, use a hammer to flatten the tear as much as possible. Next, use a coarse 3M® Roloc™ Bristle Disc to remove paint and soften the edges of the aluminium around the hole. You can also use 120-grit sandpaper to achieve this. If the hole is the result of a tear, be careful not to remove too much material as the metal is already thin. Drilling stopper holes at the end of each tear can help to prevent the crack from spreading.

Once you have shaped and softened the area around the hole, it is important to clean the surface. Use a solvent such as acetone to clean the area and remove any oil or grease. Even oil from your fingers that you can't see will hamper how well the repair mixture sticks to the surface around the hole.

Preventing Boat-to-Dock Collisions: Tips for Safe Docking

You may want to see also

Frequently asked questions

Small holes in an aluminium boat can be fixed with epoxy putty. Start by hammering the area flat to close the hole as much as possible. Then sand or grind the area and clean with acetone solvent. Mix the two-part, marine-grade epoxy putty, by rolling equal parts of A and B together until it is a uniform colour. Press and smooth the putty into the hole and surrounding area, from both sides if possible.

For larger holes, you will need to patch the hole with a piece of aluminium. Drill stopper holes at the ends of each tear to reduce the potential for crack propagation. Softening the edges of the aluminium with 120-grit sandpaper and use a coarse 3M Roloc Bristle Disc to remove paint, giving yourself plenty of bonding surface area around the hole. Wet sand with 80-grit to prep the surfaces prior to bonding. Cut a piece of aluminium to use as a patch, allowing approximately 2" of overlap around the hole. Brush both surfaces with G/flex epoxy, taking care to work the adhesive into the scratches and small dings. Place the patch over the hole and smooth into the thickened mixture.

JB Weld, PC-11, 3M 5200, 3M 4000UV, G/flex Epoxy, and Marine Tex are all recommended products for fixing holes in aluminium boats.