Marine battery charging systems are a must-have for many boat owners, and installing an onboard charger is a fairly simple project. Before the advent of multi-stage battery chargers, batteries were frequently damaged by over- or under-charging while on shore power. Today, quality marine chargers use multi-stage charging to monitor the voltage in the batteries and can be left on continuously if installed correctly.

When selecting a marine battery charger, it is important to look for one that is built to ABYC (American Boat and Yacht) and UL standards. The charger should also offer multiple options for charging voltages and be able to create a custom charging profile for different battery types. It is also important to size the charger correctly for your battery or battery bank, with a general rule of thumb being to choose a charger with an output that is at least 10% of your battery capacity.

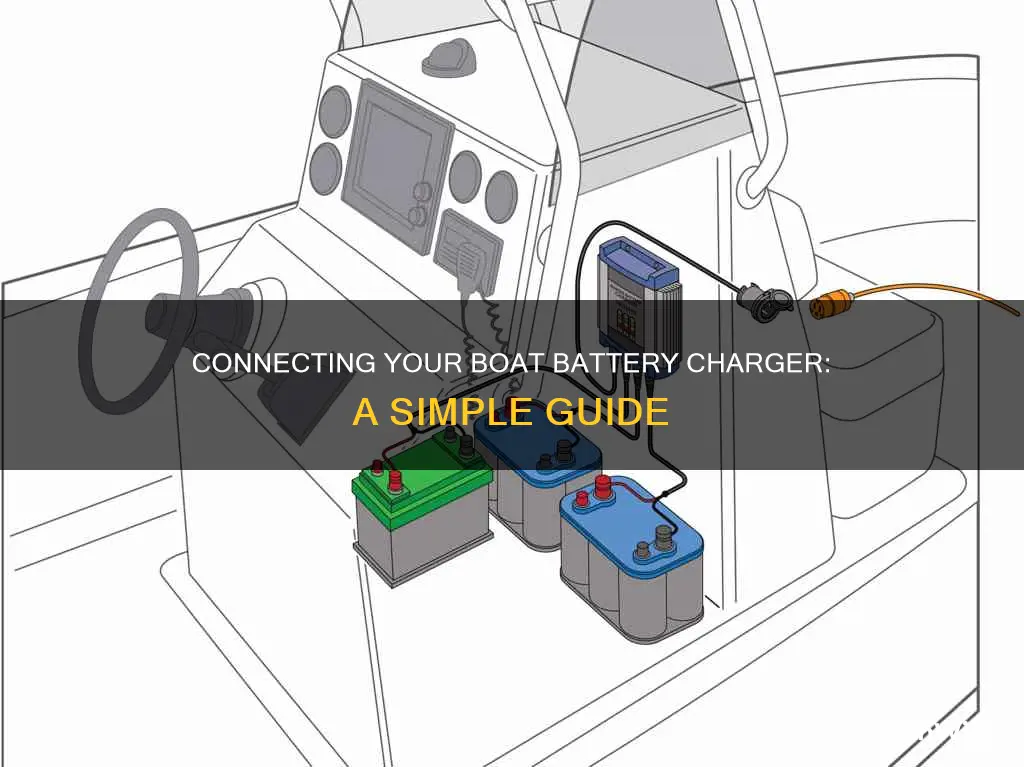

When installing a marine battery charger, it is important to select a mounting area that stays dry and allows for adequate ventilation. The charger should not be mounted directly over the batteries, as this can expose it to corrosive gases. The wiring for the charger is fairly straightforward, with the DC wiring going from the charger to the batteries, and the AC wiring coming from the AC distribution panel to the charger. It is critical to use the manufacturer's suggested wire size to ensure optimal performance.

| Characteristics | Values |

|---|---|

| Location | Should be in a cool, dry area with adequate ventilation. Higher up is better due to better ventilation and protection from the corrosive humidity of the bilge. |

| Distance from batteries | Not too close to the batteries, but also not too far. |

| Weight | If the charger weighs more than a few pounds, it should be through-bolted. |

| Mounting hardware | Marine-grade stainless steel. |

| Wiring | AC and DC wiring is required. The DC wiring should be sized according to the manufacturer's recommendations, which is based on the distance between the charger and the battery. |

| Wire connections | Wire-to-wire connections should be made using marine-grade butt splices, preferably those with heat-shrink tubing. |

| Clamps/clips | If the charger DC wire terminates in spring clamps or alligator clips, cut them off and replace with proper, marine-grade ring terminals. |

| Power source | For a more permanent install, a grounded AC power inlet can be installed, which accepts a standard extension-cord plug. |

| Circuit breaker | If the boat has an AC system, the charger can be powered from the main AC distribution panel using an unused circuit breaker of the amperage called for by the charger manufacturer (typically 15 to 20 amps). |

What You'll Learn

Selecting a marine battery charger

Battery Type and Compatibility

First, determine the type of battery you have. The most common types are AGM (Absorbent Glass Mat), flooded, and gel batteries. The charger you choose should be compatible with your battery type. Smart chargers, for instance, have customised charging profiles tailored to different battery chemistries.

Voltage

The voltage of the charger must match the output voltage of your battery. If you have a 12V battery, you need a 12V charger. If you have multiple batteries in a series setup, the voltage is added together, and you'll need a charger that matches the total voltage. For example, two 12V batteries in series require a 24V charger.

Amp Rating

The amp rating depends on the size and type of your battery. Higher amp ratings will result in faster recharging. To determine the amp rating you need, consider the battery's capacity, measured in ampere-hours (Ah). A charger's amperage output should be around 10-20% of the battery's capacity. For instance, a 100Ah battery would require a charger with an output of 10-20 amps.

Outdoor Temperatures

The ambient outdoor temperature of the environment you'll be boating in also plays a role. If you plan to operate your boat in temperatures higher than 90°F, you'll need a lower charging voltage. Conversely, if you'll be boating in temperatures below 40°F, a higher charging voltage is necessary.

Number of Batteries

If you have more than one battery, you'll need a charger that can handle multiple connections. The term "bank" refers to a single connection from the battery to the charger. So, a six-bank charger can simultaneously charge six batteries.

Onboard or Portable Charger

You'll also need to decide between an onboard charger, which is permanently installed and connected to the boat's electrical system, or a portable charger, which is compact and versatile. Onboard chargers offer the convenience of automatic charging, while portable chargers provide flexibility and are generally more cost-effective. Your choice will depend on factors such as boating habits, frequency of use, and budget.

Charger Capacity and Input Voltage

Consider the charger capacity and input voltage requirements. The number of outputs on the charger should match the number of batteries or battery banks you need to charge. Additionally, check the input voltage—most marine battery chargers operate on either 120 or 230 VAC.

Smart Chargers

Smart chargers are an excellent option for marine use due to their advanced technology. They employ a multi-stage charging approach, including bulk, absorption, and float stages, which optimises the charging process and prolongs battery life. They automatically adjust the charging voltage and current based on the battery's state, preventing overcharging.

Safety and Maintenance

Look for safety features such as reverse polarity protection, short circuit protection, and overcurrent protection. Additionally, follow the manufacturer's instructions for battery maintenance, storage, and charging guidelines to ensure optimal performance and longevity.

Understanding Boat Engine Seizures: Common Causes and Prevention

You may want to see also

Installing the console

Installing a charger isn't too complicated, and a competent DIYer with an average toolbox should be able to complete the job easily in a weekend. The instructions here are for a small center console that isn't equipped with shore power. If you have a larger vessel or you already have shore power, the installation will be similar, but you can connect the charger directly to a spare 115-volt breaker on the AC panel.

Some chargers come with an AC lead already connected to the charger. While it's possible simply to tuck this out of the way and plug it into an extension cord when you need to use the charger, it's not the best way. For a neat and tidy job, add a 20-amp socket to the outside of the console as shown; now a regular extension cord can be connected to keep the batteries charged.

Start by deciding where you want the battery charger installed. Ideally, the closer to the batteries, the better, but it's a bad idea to install the charger directly above the batteries, where escaping gas can compromise it. Wire runs should be kept as short as possible and use the correct gauge to avoid voltage drop. The instructions that come with the charger should give some guidance if you're unsure.

It's essential to have some form of circuit protection between the charger and the battery. Most chargers have internal overcurrent protection for the DC side built into the charger itself, but this leaves the cabling between the charger and battery unprotected. A short circuit in the wires between the charger and battery could be catastrophic, so a fuse should be installed in the positive lead as close as possible to the battery. The American Boat & Yacht Council suggests that this be no farther than seven inches from the battery's positive terminal. This isn't always possible in practice, but the fuse should be as close to the battery as you can reasonably mount it.

Mount the charger using self-tapping screws or, better yet, stainless-steel nuts and bolts in a dry, well-ventilated location. We mounted our charger under the center console, keeping it away from the compass because mounting it closer than a couple of feet is likely to cause some compass deviation.

The wires are terminated with crimp-on ring terminals. Before crimping, slip a length of heat-shrink tubing down to cover the joint, then warm it using a hot-air gun or hair dryer to make the connection waterproof.

Use a hot-air gun or hair dryer if possible, to warm heat-shrink tubing. A small portable torch or even a match works, but tends to leave soot marks, which look unsightly.

The heat-shrink tubing also supplies some measure of strain relief to the wire. Either use one of the less-expensive all-in-one crimp-on tools or invest in the ratchet-type double crimpers, which do a far better job.

Cables must be adequately supported, at least every 18 inches. I used plastic clips and cable ties, but other types are available.

Yacht Drawbacks: What Boat Owners Should Consider

You may want to see also

Mounting the charger

When mounting the charger, you should select a mounting area that stays dry and provides adequate ventilation. The location should also be higher up and away from the engine compartment to avoid high temperatures. It is also important to ensure that the mounting surface can support the weight of the charger. Use the supplied template or instruction manual to mark the mounting holes, and use a screwdriver and the supplied mounting screws to attach the charger, bedding each screw with marine sealant. For smaller chargers being mounted to a thick bulkhead or structure, screws are acceptable, but if the charger weighs more than a few pounds, it should be through-bolted. Remember to use marine-grade stainless steel for all mounting hardware.

Additionally, it is crucial to maintain a safe distance between the charger and the batteries. While keeping the DC cables between the charger and the batteries short is important, batteries emit gases during charging that can cause corrosion and shorten the life of the charger. Therefore, avoid mounting the charger directly above the batteries and ensure there is sufficient space between them.

Finally, when securing the charger, ensure that the DC cords can reach the batteries and that the AC cord is accessible for plugging into a power source.

A River Boat Mystery: What Really Happened?

You may want to see also

Wiring the charger

The wiring for the charger is fairly straightforward, with the DC wiring going from the charger to the batteries, and the AC wiring coming from the AC distribution panel to the charger, or an outlet box adjacent to it.

Good wiring practice is to hook up from the device toward the source. In this case, the battery is the source. The idea is to limit one's exposure to a live circuit. Thus, we hook up the source—the batteries—last.

It is critical to use the manufacturer's suggested wire size between the battery and the charger. This will have a disproportionately large impact on how well your battery charger works. The wire size required will be based on the distance from the charger to the batteries; longer runs require proportionally larger wire. If the wire is too small, the resulting voltage drop can cause the battery to be chronically undercharged and increase charging time.

Most marine chargers do not have separate voltage-sensing inputs. They depend on measuring the voltage inside the charger for the “sense” voltage used to control the charger output. If the wire is sized for three per cent drop at full current and the charge voltage is 14.0V, that means there would be 0.42V drop in the wire alone. Thus, the battery would be at 13.58V, not the desired 14.0V. This problem is most severe during high-current charging.

The DC cables should be connected to the charger as directed by the manufacturer. Wire nuts, common in household applications, must not be used. If a wire-to-wire connection must be made, it should be done using a butt splice, preferably one with adhesive heat-shrink tubing and secured inside the wiring compartment on the charger. If the charger is a potted type and has cables embedded in it, do not extend the wires. If the DC wiring is terminated with alligator clips, they should be cut off and terminated with proper ring terminals to prevent the alligator clips from causing a spark, which could lead to a battery explosion.

When connecting the wires to the battery, put the charger wire on top of the big battery cables, not under them. Spray or coat the terminals with a corrosion preventative. Try to use closed barrel terminals and heat shrink or tape over the terminal. The most common wiring failure is corrosion caused by acid and gas wicking up the wire, leading to eventual failure. Sealing, corrosion preventatives and routing wires so the terminals are away from the battery caps help forestall failures due to corrosion. If your system uses a shunt in the negative of the battery system, do not connect the charger negative directly to the battery. It must connect on the same side of the shunt as all the loads and sources on the boat. There should only be one cable between the shunt and the battery.

The AC wiring can be as simple as plugging the charger into an extension cord and running that to an outlet in your garage. This would be appropriate for a fishing boat, ski boat or runabout. If a permanent installation is desired, it is likely to fall into one of two categories:

- The charger is the only load on the boat and is wired from the shore power inlet to the charger.

- The boat has a distribution panel (AC breaker panel) and the charger is wired to a breaker in the panel.

Following our good practice of working from the load to the source during hookup, we first make up the charger. It will probably have an attached AC wiring box for connections. Typically, these boxes have knockouts that allow the cable to enter from a variety of directions. It is best to enter from the bottom, if possible, with the sides as the second choice. Top entry should be the last choice since it makes it easier for water to enter the wiring compartment. Be sure to use strain relief connectors; do not run the AC cable through the knockout alone, as it might chafe. Do not overtighten the strain relief, as it can crush the insulation and cause a short or a hot spot. All it has to do is hold the cable in place.

As with the DC connections, the AC connections should be made with crimp-type connections—not wire nuts. For extra protection, apply tape on top of the connections or use butt splices with adhesive-lined heat-shrink tubing. When folding the wires into the wiring box, be sure they are not pinched or rubbing against screws or fittings in such a way as to cause chafe.

Now to the AC panel. Be sure the cable is securely fastened along its length and as it enters the panel space. Tie it into the wire loom such that it does not bind the panel as it is opened. Locate the AC neutral and ground and connect the white and green wires, respectively. The black wire will connect to the circuit breaker.

Waterless Boat Race Mystery at Dixie Speedway

You may want to see also

Testing the charger

Check Connections and Voltages:

Before turning on the charger, carefully inspect all your connections. Ensure that the wiring is secure and there are no loose connections. Double-check the battery voltage as a reference point. This will help you identify any significant deviations during the testing process.

LED Indicator Check:

Connect the charger to an extension cord and plug the extension into a GFCI 120-volt AC power outlet. Observe the LED indicator panel. Look for a blue LED, which indicates a successful connection to AC power. Keep an eye out for red, amber, and green LEDs, which provide information about the charging status of each battery. If a red fault LED illuminates, it could indicate a loose wiring connection, reverse polarity, or a DC over- or under-voltage issue.

Test Charging Cycle:

Allow the charger to go through a complete charge cycle. Note the maximum voltage during the acceptance stage and the final float voltage. Compare these values with the manufacturer's specifications for your batteries. If there are significant deviations, you may need to adjust the charge regimen or check for voltage drop issues.

Check for Voltage Drop:

If your boat has heavy loads, test for voltage drop under full load at both the charge voltage and the float voltage. Measure the voltage at the charger and the batteries. The values should be within 0.1 volts of each other. If there is a larger disparity, you may have a voltage drop issue in your wiring.

Verify Charging Output:

To ensure the charger meets its rating, turn on a DC load equal to the current rating of the charger. Observe if it can maintain the charging voltage. Ideally, the charger should be able to sustain its full-rated output at both the acceptance and float voltages. If it can't, reduce the load to about 75% of the rating and test again.

Monitor Initial Operation:

It is recommended to be present during the first few hours of operation for any new charging source. This allows you to verify that the batteries are being charged correctly and to address any potential issues promptly.

Check for Over-Voltage:

Before starting your boat's engine, disconnect the battery charger. With today's voltage-critical, digitally controlled marine engines, failing to do so may result in an over-voltage situation that could damage sensitive digital circuitry and electronic components.

Consult Troubleshooting Guides:

If you encounter any issues during testing, such as LED fault indicators or voltage discrepancies, refer to the troubleshooting section of your charger's installation guide. This will provide specific guidance on resolving common problems.

Remember, safety should always be a top priority when working with electrical systems. Ensure all power sources are turned off before making or checking connections, and always follow the manufacturer's instructions and safety guidelines.

The Enigmatic Rule 91: What Boat Type Is It?

You may want to see also

Frequently asked questions

The charger should be placed in a cool, dry area with adequate ventilation. Higher up is generally better due to better ventilation and protection from the corrosive humidity of the bilge. Avoid high-temperature locations such as your engine compartment, if possible.

For smaller chargers being mounted to a thick bulkhead or structure, screws are an acceptable option. If the charger weighs more than a couple of pounds, however, it should be through-bolted. Regardless, make sure you use marine-grade stainless steel for all mounting hardware.

You need to connect the charger, which involves installation of both AC (to power the charger) and DC wiring (between the charger and the battery). DC wiring should be sized according to the manufacturer’s recommendations, which is based on the distance between the charger and the battery. The longer the wire run, the larger-diameter wire you’ll need to offset loss due to voltage drop. Wires should be routed as directly as possible and provided with support and chafe protection as needed. Once the wire runs are in place, connect them to the battery charger as per the owner’s manual.

Cut them off and replace them with proper, marine-grade ring terminals.

For smaller boats or watercraft without a permanently installed AC system, hooking up the AC side can be as simple as plugging the battery charger into a suitable extension cord. For a more permanent installation, you can add a 20-amp socket to the outside of the console.