Boat battery cables are essential for a smooth sailing experience. They are responsible for powering everything from navigation systems to fishing electronics. To ensure a carefree day on the water, it's crucial to periodically inspect and maintain these cables. The most common issues with boat battery cables include fraying, splitting, and corrosion, which can lead to severe damage, power surges, and electrical issues. Regular inspections can help identify these problems early on, preventing further complications. Additionally, factors such as cable material, size, insulation, flexibility, and certifications play a vital role in the performance and safety of your boat's electrical system. By paying attention to these aspects and addressing any issues promptly, you can keep your boat in excellent shape and enjoy stress-free boating adventures.

| Characteristics | Values |

|---|---|

| Material | Stranded copper conductors |

| Size and Gauge | Bigger is often better; should be chosen based on the boat's electrical load |

| Insulation and Protection | Robust insulation that protects from moisture, heat, and UV radiation; "marine-grade" or "UV-resistant" labels |

| Flexibility and Durability | Flexible and durable design to accommodate movement and vibrations |

| Certification and Standards | UL (Underwriters Laboratories) approved |

| Environmental Factors | Insulation quality, heat shrink tubing, proper sealing, cable pathway management, regular inspection, secure connections, overload protection |

| Danger Signs | Weak starting performance, hot cables, odd odours, resistance when bent, voltmeter reading of more than 14.5 volts, high resistance on multimeter ohm scale |

What You'll Learn

Check for fraying and splitting

Checking for fraying and splitting is a simple and effective way to identify whether your boat battery cables need replacing. Fraying or splitting of the cables is a clear sign of severe degradation and damage, which is usually caused by corrosion or overuse without maintenance.

Boat lift cables wear both internally and externally. Internal cable wear occurs when strands work against each other, often under heavy loads, such as when cables are hauled across pulleys or sheaves. Internal wear is caused by nicking and appears almost scalloped on internal strands. External wear, on the other hand, is more apparent and results from metal being slowly worn away over time. As the crowns of each wire flatten, the strength of the cable gradually decreases.

To check for fraying and splitting, use leather gloves or another form of hand protection and examine the cables closely for any signs of damage. Look for broken strands, especially in excess, and keep an eye out for any flattening of the wire crowns. If you notice any fraying or splitting, stop using the cables immediately and replace them.

It is recommended that you inspect your boat lift cables at least once a month to ensure they are in good condition. Additionally, consider replacing your cables every couple of years, even if you only notice slight wear or fraying. Attempting to extend the life of your cables beyond two years could be dangerous.

Choosing the Right Anchor Weight for Your Small Boat

You may want to see also

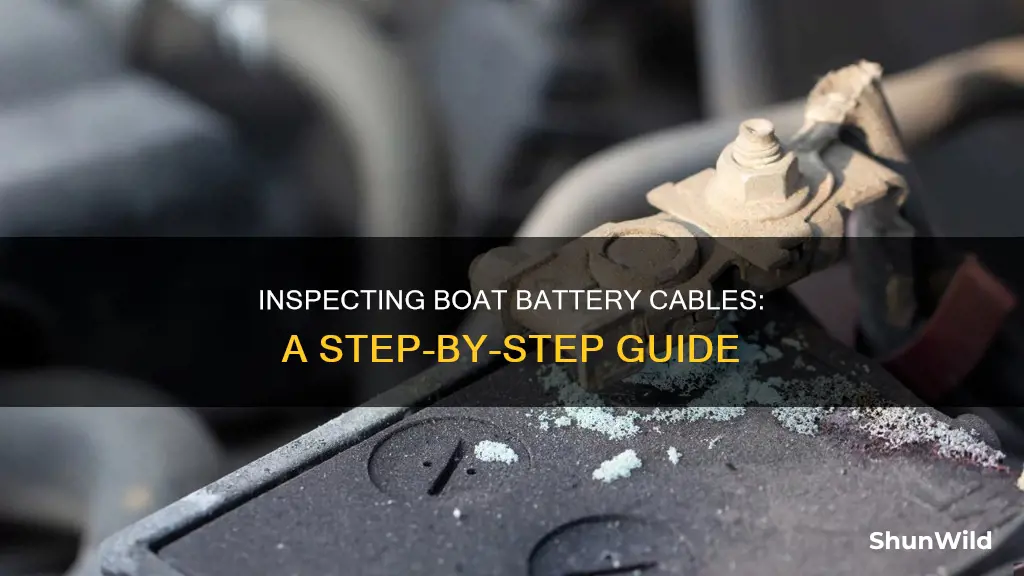

Inspect for corrosion

Inspecting your boat battery cables for corrosion is an essential aspect of boat maintenance. Corrosion is a common issue in marine environments, and it can cause severe damage to your boat's electrical system. To inspect for corrosion, follow these steps:

First, it is important to wear protective gear. Corrosive residue can be harmful to your skin, so don gloves and other necessary protective equipment before handling the cables.

Begin your inspection by looking for any white or greenish crust or powder around the battery cable connectors. This discolouration is a tell-tale sign of corrosion. Corrosion occurs when the electrolyte (sulfuric acid) releases hydrogen gas, which then collides with the air and moisture, leading to a chemical reaction that causes corrosion.

Pay close attention to the cable connectors and the area where the boat battery cables attach to the battery itself. Corrosion commonly occurs in these areas and can cause severe damage to both the cables and the battery.

Inspect the wires and connection points thoroughly. Corrosion may not always be visible, so it is important to check for any signs of degradation or moisture exposure. Look for any cracks or splits in the insulation, as this can lead to increased moisture intrusion and accelerate corrosion.

If you suspect corrosion, gently flex the battery cables. A cracking noise could indicate internal damage caused by corrosion. However, be careful not to over-flex the cables, as this can lead to unnecessary damage.

Additionally, use your sense of smell to detect any acrid or burning rubber odours. These smells could indicate critical degradation due to corrosion or overheating.

If you find signs of corrosion, it is important to act quickly. Corrosion can rapidly worsen and lead to more severe problems, including power loss, electrical issues, and even fires. Replace any corroded cables and clean the battery terminals and connections with a baking powder and water solution to neutralize the acid. Once cleaned, rinse and dry the battery thoroughly before applying a protective spray or coating to prevent future corrosion.

To prevent corrosion, use only marine-grade wire approved by the ABYC. These wires have individually tinned copper strands to protect against corrosion. Additionally, ensure proper charging habits, as overcharging can increase hydrogen gas production and contribute to corrosion. Keep batteries clean, dry, and stored in a well-ventilated area away from saltwater and extreme temperatures.

Repairing a Leaky Inflatable Boat Valve: A Step-by-Step Guide

You may want to see also

Use your senses

Checking your boat's battery cables with your senses is a quick and easy way to identify potential issues. Here are some tips on how to use your senses to inspect your boat's battery cables:

Touch

Feel each battery cable after a day on the water. If one of the cables feels hot to the touch, this is an indication that something is wrong and requires further investigation. It is important to pay attention to any temperature abnormalities as they can signal underlying problems.

Smell

Overheating cables tend to give off a distinct odour. If you detect any unusual or foul odours coming from your battery or cables, it is crucial to address the issue promptly. Burning rubber or acrid smells can indicate critical degradation that warrants immediate attention.

Hearing

Listen for any unusual noises coming from the battery cables. During a routine inspection or when experiencing electrical problems, gently flex the cables. If you hear a cracking noise, it suggests that the interior of the cable has sustained damage. Be cautious not to over-flex the cables as it can lead to preventable damage.

Sight

Keep a close eye on your voltmeter readings. If the output exceeds 14.5 volts, it is an indication of a problem. Additionally, pay attention to any visible signs of degradation, such as fraying, splitting, or corrosion on the cables and connectors. Corrosion often appears as a white crust around the battery cable connectors. Always wear heavy-duty work gloves when inspecting for corrosion to protect your skin.

Boat Registration Transferability in Georgia: What You Need to Know

You may want to see also

Ensure cable flexibility and durability

To ensure the flexibility and durability of your boat battery cables, you should consider the following:

Material

Flexible conductor materials such as copper alloy or aluminum alloy are usually best for battery connection cables. These materials offer good flexibility and conductive properties, ensuring the cable won't break when bent or twisted.

Wire Diameter

The wire diameter will also affect the flexibility of the cable. A thinner wire diameter allows the cable to bend more, increasing its flexibility.

Insulation and Sheathing

Soft insulation and thinner jackets can increase the cable's flexing capabilities and durability.

Special Designs

Some cables use special designs, such as braiding or spiral structures, to increase their flexibility and tensile properties.

Multi-Stranded Wires

Multi-stranded wires are more tolerant of mechanical vibration, movement, and flexibility. This means they will last longer and are less likely to fail.

Cable Size

The length of the cable is an important factor, as it determines the performance. Longer wires offer a higher voltage range, but they also have more resistance and voltage drop.

Cable Connectors/Terminals

Battery connectors are essential to the system's functionality, as they regulate the current flow between the battery and other components.

Tinned Copper

Tinned copper will add extra protection against corrosion at the exposed terminals.

Outer Jacket

The outer jacket will protect the cable in the event of a current surge and lessen the chance of engine fires.

Boat Reel Development: Who Owns the Innovation?

You may want to see also

Check for proper sealing

To ensure the proper sealing of your boat battery cables, you must inspect the cable entry points into your boat's electrical compartments. These entry points should be well-sealed to prevent water ingress, which can be achieved through the use of rubber grommets and cable glands. Proper sealing is crucial as it protects the cables from exposure to moisture, saltwater, and other environmental factors.

Additionally, you can apply heat shrink tubing over the cable connections. This adds an extra layer of protection against moisture and contaminants, reducing the risk of corrosion. Corrosion is a common issue, especially around the cable connectors, and it can cause severe damage to both the cables and the battery.

By regularly inspecting your marine battery cables for signs of wear, corrosion, or damage, you can promptly replace any compromised sections and prevent further issues. This proactive approach ensures the safety and reliability of your boat's electrical system, which is critical for a carefree day on the water.

Remember, the cables play a vital role in powering your navigation systems, fishing electronics, and other equipment. By paying attention to proper sealing and maintenance, you can avoid complications and fully enjoy your boating adventures.

Boat Fuel Types: Understanding Your Boat's Appetite

You may want to see also

Frequently asked questions

Check for any signs of fraying, splitting, or corrosion on the cables. Fraying or splitting is often caused by corrosion or a lack of maintenance. Corrosion usually occurs around the cable connectors and appears as a white crust. It can cause severe damage to the cables and the battery itself.

Use your senses. If you smell something acrid or burning rubber, or hear a cracking noise when gently flexing the cables, these are signs of degradation.

The most reliable marine battery cables are made with stranded copper conductors. Copper is an excellent conductor of electricity and highly resistant to corrosion.

You can test for resistance using the ohm function of a multimeter. More than an ohm means there's trouble. Also, feel each cable after a run. If one feels hot, there could be a problem.