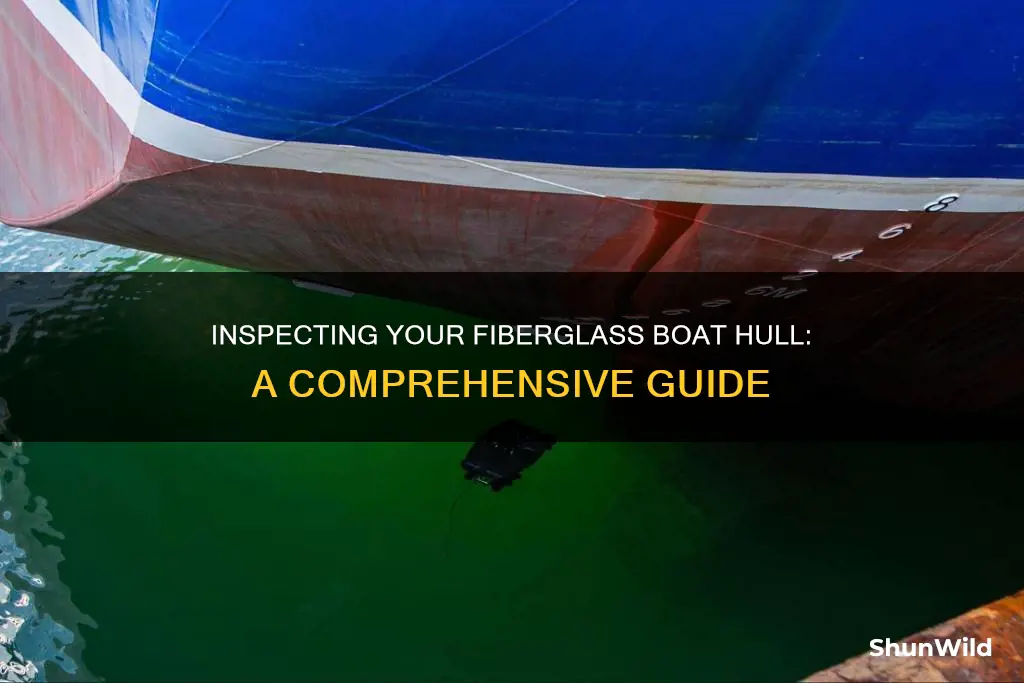

Checking the hull of a fiberglass boat is an essential part of maintenance and can help identify potential issues early on. This guide will provide a step-by-step process for inspecting the hull, including how to look for signs of damage, such as cracks, delaminations, or discolored areas, and how to use tools like a flashlight and a mirror to get a thorough examination. It will also cover the importance of regular inspections and how to maintain the boat's structural integrity.

What You'll Learn

- Visual Inspection: Look for cracks, delamination, or discolored areas

- Moisture Detection: Use a moisture meter to identify wet spots

- Structural Integrity: Check for warping or structural damage

- Gelcoat Condition: Inspect for fading, chalking, or damage

- Repair Techniques: Learn methods for filling, sanding, and bonding repairs

Visual Inspection: Look for cracks, delamination, or discolored areas

A visual inspection is a crucial step in assessing the condition of a fiberglass boat hull. It allows you to identify potential issues that may not be immediately apparent through other methods. Here's a detailed guide on how to perform this inspection:

Start by carefully examining the entire hull for any visible signs of damage or deterioration. Look for cracks, which can vary in size and appearance. Some cracks may be hairline-thin, while others might be more pronounced and visible to the naked eye. Pay close attention to areas where the hull joins other components, such as the transom, stringers, and bulkheads. These areas are more susceptible to stress and potential cracking over time. Delamination is another critical issue to look out for. It occurs when the layers of fiberglass separate, often due to damage or a compromised bond. Inspect the hull surface for any lifting or bubbling of the gelcoat, which could indicate delamination. These lifted areas might feel spongy or soft when pressed.

Discolored areas on the hull can also provide valuable insights. Check for any stains, fading, or unusual colors that deviate from the original finish. Discoloration can result from various factors, including UV damage, water intrusion, or chemical exposure. Note any patterns or specific locations where the discoloration is concentrated, as this could indicate underlying issues. It's important to remember that the color of the gelcoat can change over time due to environmental factors, so a comparison with the boat's original color chart is essential.

When inspecting, move your eyes across the hull's surface, noticing any deviations from a smooth and uniform appearance. Feel the hull with your hands to detect any soft or spongy spots, which could indicate delamination or damage. A thorough visual inspection should take note of any unusual textures or changes in the hull's integrity.

Remember, the goal of this visual inspection is to identify any signs of structural compromise that may require further investigation or repair. Regular visual checks are an essential part of boat maintenance, ensuring the hull's longevity and safety.

Fort Hamer Boat Ramp: Open or Closed?

You may want to see also

Moisture Detection: Use a moisture meter to identify wet spots

Checking the moisture content in a fiberglass boat hull is a critical step in ensuring its structural integrity and longevity. Moisture can lead to various issues, including corrosion, mold growth, and structural weakness. Here's a detailed guide on how to use a moisture meter to detect wet spots on your boat's hull:

Understanding the Moisture Meter:

A moisture meter is a handy tool designed to measure the moisture content in various materials, including fiberglass. It typically consists of a probe or sensor that can be inserted into the material or gently touched against the surface. The meter provides a reading in percentage, indicating the moisture level. Look for a meter with a range suitable for wood or composite materials, as this will give you accurate readings for the hull.

Preparation and Safety:

Before beginning the inspection, ensure you have the necessary safety gear, especially if working near the waterline or in areas with potential water exposure. Wear gloves and eye protection to avoid any contact with sharp edges or potential hazards. It's also a good idea to have a helper assist you during the process, especially when using the meter.

Step-by-Step Process:

- Clean the Hull: Start by thoroughly cleaning the hull's surface. Remove any visible dirt, grime, or old paint. This step ensures accurate readings and helps identify areas that might have been missed during cleaning.

- Dry the Hull: Allow the hull to dry completely before proceeding. Moisture on the surface can interfere with the reading. You can use fans or air blowers to speed up the drying process.

- Insert the Probe: Gently insert the moisture meter's probe into the fiberglass hull. Ensure it makes good contact with the material. You might need to apply slight pressure to get a reading. The meter will display the moisture percentage.

- Read the Results: Take multiple readings at different locations across the hull. Focus on areas that are more prone to moisture accumulation, such as below the waterline, near bilge areas, and in compartments. Aim for a moisture content of less than 1% for optimal dryness.

- Identify Wet Spots: Compare the readings to identify areas with higher moisture levels. Wet spots may indicate potential issues, such as leaks, poor ventilation, or water intrusion. Mark these areas for further investigation and repair.

Interpreting the Results:

A moisture meter reading above the acceptable threshold indicates the presence of excess moisture. This could be a sign of a leak, poor sealing, or inadequate ventilation. Address these issues promptly to prevent further damage. If the readings are consistently high, consider consulting a marine specialist or a professional boat repairer for a thorough assessment.

Remember, regular moisture checks are essential for maintaining a healthy fiberglass boat. By using a moisture meter, you can proactively identify and resolve potential problems, ensuring your boat remains in top condition.

Wyatt's Portrayal in Fresh Off the Boat: Unraveling the Actor

You may want to see also

Structural Integrity: Check for warping or structural damage

When inspecting a fiberglass boat hull for structural integrity, warping, and damage, there are several key areas and methods to focus on. Firstly, examine the hull's overall shape and curvature. Fiberglass can be prone to warping, especially in older boats, so look for any noticeable deviations from the intended shape. Warping may present as a visible curve or distortion along the hull's surface, often more pronounced near the waterline. Use a straight edge or a long ruler to check for any inconsistencies in the hull's curvature.

Next, inspect the hull for any signs of structural damage. Fiberglass is a strong material, but it can still be susceptible to impact damage, especially around the boat's chines (where the hull meets the transom) and the waterline areas. Look for any visible cracks, chips, or delaminations in the fiberglass. These issues may be more challenging to spot, so a thorough inspection is crucial. Pay attention to the boat's interior as well; check for any signs of water intrusion, such as discolored or warped interior panels, which could indicate previous damage or poor maintenance.

A comprehensive visual inspection is essential. Look for any discolored or faded areas on the hull surface, as these might indicate previous repairs or potential weak spots. Inspect the hull's attachment points, such as where the deck or cabin structures are bolted on, for any signs of corrosion or damage. Corrosion can weaken the structural integrity of the boat, so addressing any issues is vital.

In addition to visual checks, consider using a stethoscope or a similar tool to listen for any unusual sounds when tapping on the hull. This method can help identify areas of potential damage or weakness. If you suspect warping or structural issues, it's advisable to consult a marine engineer or a professional boat inspector who can provide a detailed assessment and recommend any necessary repairs.

Remember, regular maintenance and inspections are crucial to ensuring the long-term structural integrity of your fiberglass boat. By being proactive and addressing any issues promptly, you can keep your boat in optimal condition and ensure a safe and enjoyable boating experience.

Bass Tracker Classic: A Worthy Boat?

You may want to see also

Gelcoat Condition: Inspect for fading, chalking, or damage

When inspecting the gelcoat of a fiberglass boat hull, it's crucial to look for signs of wear and damage that can affect the boat's appearance and structural integrity. Gelcoat, a protective layer applied to the fiberglass, can deteriorate over time due to various factors such as UV exposure, chemical damage, and physical impact. Here's a detailed guide on how to check the gelcoat condition for fading, chalking, or damage:

Fading: Start by examining the gelcoat for any signs of color loss or fading. UV radiation from the sun is a primary culprit in gelcoat fading. Look for areas where the color has become lighter or has taken on a dull appearance compared to the surrounding areas. Fading can be more noticeable in areas exposed to direct sunlight, such as the bow, stern, and sides of the hull. Pay attention to the transition between different colors or patterns on the boat, as these areas are more susceptible to fading.

Chalking: Chalking is a common issue that occurs when the gelcoat loses its glossy finish and becomes powdery or flaky. This happens due to the breakdown of the gelcoat's surface layer. Inspect the hull for any white or grayish powder-like residue, especially in areas where the gelcoat has been exposed to harsh weather conditions or frequent cleaning. Chalking can lead to further damage if left untreated, as it creates a rough surface that can attract dirt and grime, making the boat more susceptible to corrosion.

Damage: Inspect the gelcoat for any visible cracks, chips, or scratches. These types of damage can occur due to impacts, improper maintenance, or environmental factors. Look for areas where the gelcoat has cracked or become separated from the underlying fiberglass. Small cracks may not be immediately noticeable, but they can progress and lead to more significant issues over time. Additionally, check for any signs of delamination, where the gelcoat has lifted or separated from the fiberglass, which can be a serious structural concern.

To assess the extent of the damage, consider the following:

- Depth of Damage: Use a sharp object, like a knife or a small screwdriver, to gently probe the damaged areas. If you can easily penetrate the gelcoat or reach the underlying fiberglass, it indicates severe damage that may require professional repair.

- Size and Location: Note the size and location of any damage. Small, isolated issues might be repairable with a gelcoat repair kit, while larger or more widespread damage may require professional fiberglass repair techniques.

Regularly inspecting the gelcoat condition is essential for maintaining the boat's appearance and ensuring its longevity. Addressing issues like fading, chalking, and damage promptly can prevent further deterioration and costly repairs in the future.

The Deadly Voyage: Boats and the Holocaust

You may want to see also

Repair Techniques: Learn methods for filling, sanding, and bonding repairs

When it comes to repairing a fiberglass boat hull, understanding the process of filling, sanding, and bonding is crucial for a successful restoration. Here's a detailed guide on the techniques you can employ:

Filling Repairs:

Start by identifying the damage and assessing the extent of the repair needed. For small holes or imperfections, you can use a fiberglass repair kit specifically designed for marine applications. These kits typically include a resin, hardener, and a filler material. Carefully clean the damaged area to remove any dirt or debris. Then, mix the resin and hardener according to the manufacturer's instructions, ensuring you have the right consistency. Apply the filler material over the damaged area, using a putty knife to spread it evenly. Allow it to cure according to the kit's guidelines, which may involve covering it with a plastic bag or a clear tape to protect it from dust and moisture. Once cured, sand the filled area gently with fine-grit sandpaper to blend it seamlessly with the surrounding surface.

For larger repairs or significant damage, you might need to use a fiberglass cloth or tape to reinforce the area. Cut the cloth or tape to the appropriate size and shape, ensuring it covers the damaged area and extends slightly beyond it. Apply a thin layer of the mixed resin over the cloth or tape, then carefully lay the cloth or tape onto the hull, smoothing out any air bubbles. This step creates a strong bond and provides structural support. After curing, you can sand and finish the repair as described above.

Sanding Techniques:

Sanding is a critical step to ensure a smooth and professional finish. Always work with the grain of the fiberglass when sanding. Use a variety of sandpaper grades, starting with a coarse grit to remove any residual filler or old repairs, and gradually moving to finer grits for a smooth surface. Pay close attention to the edges and contours of the hull, as these areas require precise sanding. Avoid excessive pressure to prevent scratching the surface. After sanding, wipe away any dust with a damp cloth to prepare the surface for the next step.

Bonding Repairs:

Strong and durable bonds are essential for long-lasting repairs. Before bonding, ensure both the old and new materials are clean and free of contaminants. Use a suitable primer designed for marine environments to prepare the surfaces. Apply the primer evenly, allowing it to dry according to the manufacturer's instructions. Then, carefully mix the bonding agent or epoxy resin, following the instructions provided. Apply a thin layer of the bonding agent to the prepared surface, and quickly position the repair piece, ensuring proper alignment. Hold the pieces together for the recommended curing time, which may involve clamping or using specialized bonding agents. Once cured, you can sand and finish the bonded area.

Remember, practice and patience are key when mastering these repair techniques. It's essential to take your time and follow the specific guidelines for each product used. With proper preparation and technique, you can effectively restore and repair your fiberglass boat hull.

Connecting Boat Batteries Backwards: Potential Electrical Hazards

You may want to see also

Frequently asked questions

Checking the hull for damage is an essential part of boat maintenance. Start by visually inspecting the entire surface for any visible cracks, chips, or delaminations. Look for areas where the gelcoat (the clear outer layer) might be faded or discolored, as this could indicate underlying damage. Pay close attention to areas around the propeller, anchor, and any areas that have previously been repaired. If you notice any issues, consider taking a closer look with a magnifying glass or even a small flashlight to get a better view of the surface.

Yes, using the right tools can make the inspection process more efficient. A wet/dry vacuum can help remove any dirt or debris that might obscure potential issues. A putty knife or a small spatula can be useful for gently lifting the gelcoat to check for any voids or blisters. You can also use a marine-grade soap and water solution to clean the hull, making it easier to identify any imperfections. Remember to dry the hull thoroughly after cleaning to avoid any water spots.

If you discover any issues, it's best to consult a professional marine technician or a fiberglass repair specialist. They can provide an accurate assessment and recommend the appropriate repairs. Minor damage might be fixable with a simple fill and sand, but more severe issues could require a full re-fairing or even a replacement of the affected area. Always ensure that any repairs are done by qualified professionals to maintain the structural integrity of your boat.

Regular inspections are crucial for the long-term health of your boat. It's recommended to perform a thorough inspection at least once a year, or more frequently if you frequently use your boat or if it's an older vessel. Look out for any changes in the hull's appearance, such as new scratches, changes in color, or the appearance of mold or mildew. Any unusual noises or vibrations while operating the boat could also indicate potential hull issues. Regular maintenance and inspections will help ensure your boat remains safe and reliable.