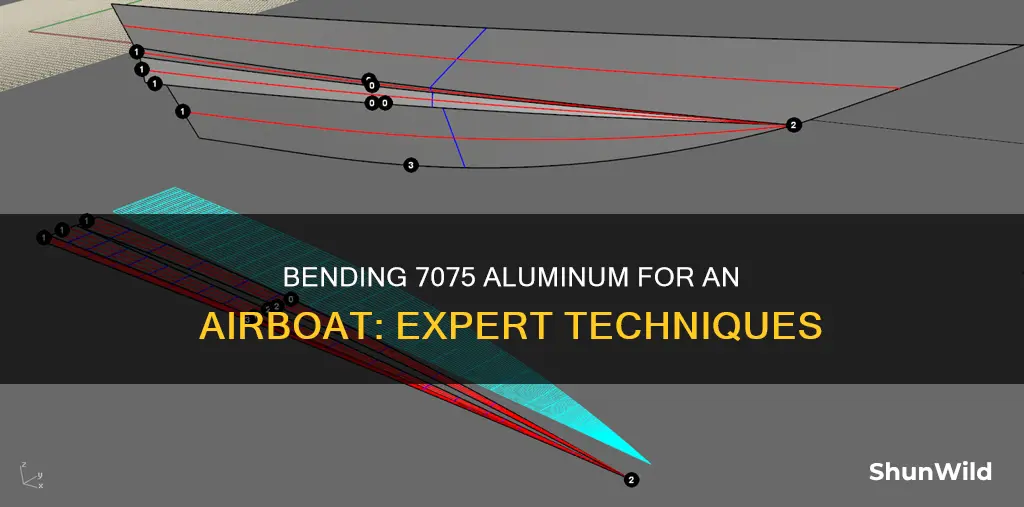

Bending 7075 aluminium for an airboat requires careful consideration of the metal's properties and the right tools. 7075 aluminium is one of the strongest alloys available, comparable to many types of steel, and is commonly used in aircraft structures. It is challenging to bend due to its hardness and tendency to crack, especially when bending more than 90 degrees or with a small radius. To successfully bend 7075 aluminium, it is recommended to heat the metal to a certain temperature in an oven for a specific duration, and then work with it within a limited time frame before it starts to harden again. This process can be complemented by post-bend age-hardening to enhance its tensile strength. Alternatively, one could consider using a different alloy, such as 5052 or 6061, which are more suitable for bending and commonly used in fabrication.

What You'll Learn

- Heat 7075 aluminium to 450°C for 4 hours before bending

- After bending, leave it to cool to room temperature

- You will have 30 minutes to work with it before it starts to harden

- To artificially age-harden, heat to 120°C for 72 hours

- If you don't need to bend it too much, you can use a softer aluminium alloy such as 5052

Heat 7075 aluminium to 450°C for 4 hours before bending

Heating 7075 aluminium to 450°C for four hours is a process known as solution heat treatment. This is a method of annealing the metal, which softens it and makes it easier to bend. After this process, the aluminium will be malleable for 30 minutes before it starts to harden again. It will reach full hardness in around three weeks.

To straighten a bent piece of 7075 aluminium, it is recommended to re-heat treat it to reform the grain structure and straighten it within 30 minutes of reaching room temperature. This can be prolonged by placing the part in a deep freeze at -18°C.

The aluminium can be artificially aged and hardened by heating to 120°C for 72 hours. This is known as age hardening and will give the aluminium peak tensile strength.

When bending 7075 aluminium, it is important to note that it is a challenging alloy to work with. It is more difficult to bend than other aluminium alloys, such as 5052 or 6061. It is also important to bend the metal against the grain to avoid cracking.

- Heat the aluminium to 450°C for four hours.

- Allow the aluminium to cool to room temperature.

- You will now have 30 minutes to bend the aluminium before it starts to harden again.

- Use a bending tool or jig to bend the aluminium to the desired angle.

- If you need more time to work with the aluminium, place it in a deep freeze at -18°C.

- If you are satisfied with your bends, artificially age the aluminium by heating it to 120°C for 72 hours to harden it.

Note: This process may not be suitable for all applications, as it will change the temper of the aluminium and may require heat-treating to restore the original temper.

The Historic Route of the Boat Race

You may want to see also

After bending, leave it to cool to room temperature

After bending, it is important to leave 7075 aluminium to cool to room temperature. This is because 7075 aluminium is only malleable for 30 minutes after it has been heated to the appropriate temperature and before it begins to harden again. If you need to prolong the time you have to work with the aluminium, you can place the part in a deep freeze at -18°C; this will keep it malleable.

After bending, you should also be aware of the tendency of 7075 aluminium to crack. This is because the process of bending breaks apart the metal grain structure, and attempting to straighten it will only pull the grain structure apart further, weakening it and potentially causing micro-cracking. If the bend is slight, it is best to leave it as it is. If the bend is more severe, you will need to reheat-treat the aluminium to reform the grain structure.

To cool the aluminium effectively, you can use air cooling or leave it at room temperature. However, if you wish to harden the aluminium after working on it, you can leave it at 120°C for three days.

It is also important to note that the process of bending 7075 aluminium can be tricky due to its strength and hardness. It is one of the strongest alloys available and is comparable to many types of steel. Therefore, the bending process may require a lot of tooling, time and effort to achieve the desired bend.

Essential First Aid Kit Items for Boaters

You may want to see also

You will have 30 minutes to work with it before it starts to harden

When working with 7075 aluminium, you will have a very limited time frame to work with it once it has cooled down to room temperature. You will have 30 minutes to work with it before it starts to harden again. After this, it will take around three weeks to reach full hardness.

This is an important window of time to be aware of when working with this alloy. If you need to straighten a bent piece of 7075 aluminium, it must be re-heated and straightened within 30 minutes of reaching room temperature. This is because the process of bending breaks the metal grain structure apart, and straightening it pulls this structure even further apart, weakening it and causing micro-cracking.

To prolong the time you have to work with the alloy, you can place the part in a deep freeze at -18°C. While frozen, it will remain malleable, but it will start to harden again once it returns to room temperature.

If you are working with 7075 aluminium, it is important to be aware of this time limitation and plan your work accordingly.

Boat Engine Compliance: California's Emissions Hang Tag Law

You may want to see also

To artificially age-harden, heat to 120°C for 72 hours

To artificially age-harden 7075 aluminium, you need to heat it to 120 °C for 72 hours. This process, also known as precipitation hardening, is a specialised heat treatment that modifies the aluminium's mechanical, electrical, and/or corrosion properties. It is done at low temperatures and is used to improve the aluminium's mechanical properties.

The process of age-hardening aluminium involves forming dispersed precipitants throughout the aluminium's microstructure, which obstructs dislocation movements. These fine particles offer heightened resistance to deformation, increasing overall hardness and tensile strength. The degree of precipitation and the morphology of the precipitate are controlled by the aging time and temperature.

It is important to note that the aluminium should be in its solution annealed state before the age-hardening process is started. Additionally, if the aluminium has strict straightness specifications, straightening procedures should be completed before age-hardening.

The benefits of age-hardening include augmented strength and hardness, an optimised grain structure, superior wear and corrosion resistance, stable dimensions, and tailored mechanical properties. It is also an economic and efficient way to enhance the properties of aluminium.

The age-hardening process is usually executed at temperatures ranging from 225 °F to 350 °F (approximately 107 °C to 163 °C). The material is sustained at the specified temperature for a duration typically spanning between 5 and 36 hours, depending on the specific material.

In the case of 7075 aluminium, heating it to 120 °C for 72 hours will result in peak tensile strength, providing the ideal mechanical performance. This process will give the aluminium its highest strength and hardness while only slightly reducing its ductility.

Overall, age-hardening is a valuable technique for enhancing the properties of aluminium, and when combined with precise guidelines and state-of-the-art facilities, it can provide consistent and reliable outcomes.

Manufacturing Boat Brands: Their Names and Significance

You may want to see also

If you don't need to bend it too much, you can use a softer aluminium alloy such as 5052

Aluminium alloy 7075 is notoriously difficult to bend due to its strength and hardness. It is used in aircraft engineering for structural parts that need to be very strong and not flex or bend. If you try to bend a 7075 aluminium chassis, you risk breaking the metal grain structure, which can cause micro-cracking that will worsen over time due to vibration and flexing.

If you don't need to bend your aluminium too much, you can opt for a softer aluminium alloy such as 5052. This alloy is far more malleable and can be bent to form a variety of shapes and structures. 5052 aluminium is widely used for cooking utensils, food processing equipment, storage tanks, truck and trailer components, aircraft components, boat hulls, and much more.

One of the benefits of 5052 aluminium is that it has good weldability and excellent corrosion resistance. It is also highly fatigue-resistant, which is why it is often used in architectural facades exposed to high vibration. It is also used in marine environments, as it is resistant to corrosion from seawater and salt spray.

Another benefit of 5052 aluminium is its high rate of work hardening. It is the strongest non-heat-treatable aluminium sheet and plate in common use. However, it is worth noting that 5052 aluminium is not as strong as 7075 aluminium. If you need something with higher strength and lower formability, 6061 aluminium is a heat-treatable alloy that is commonly used in structural and engineering applications.

In summary, if you don't need to bend your aluminium too much, 5052 aluminium alloy is a good choice due to its malleability, weldability, corrosion resistance, and fatigue strength. It is widely used across various industries and applications and offers excellent value for money.

Finding Land-Based Roles in the Boating Industry

You may want to see also

Frequently asked questions

Bending 7075 aluminium is a tricky process. It is one of the strongest alloys available and is comparable to many types of steel. To bend 7075 aluminium, you can either anneal the aluminium to reduce its hardness and then quench and temper it to restore its hardness, or you can weld the jig and then perform CNC machining. Either way, the aluminium sections can be heat-treated before the bending process to simplify it.

7075 aluminium is prone to cracking, especially when bending more than 90 degrees or with a very small R angle. To avoid cracking, you should anneal the aluminium to reduce its hardness before bending and then quench and temper it to restore its strength.

When bending 7075 aluminium tubing, it is important to use lubrication on the dies to minimise galling. A hydro bender can be used to bend the tubing, and the galled spots can be cleaned up with a tubing sander that uses a belt of 3M Scotchbrite.