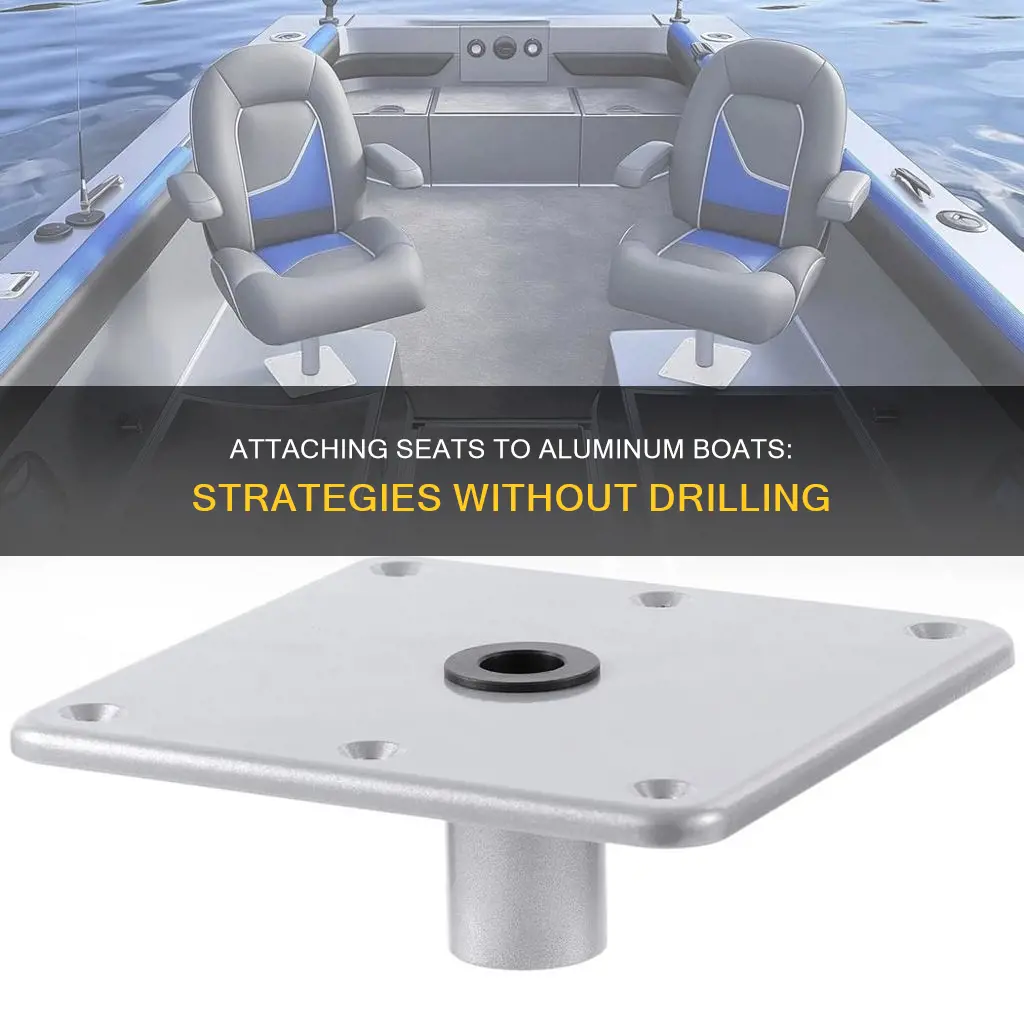

Installing seats on an aluminium boat can be a challenging task, especially if you don't have access to the underside of the bench. While some people suggest cutting a hole in the bench to access the underside, others recommend using plywood as a base for the seats. This method involves bolting the plywood to the bench and then attaching the seats to the plywood. It is important to avoid using treated lumber as the copper in it can eat through the aluminium. Instead, you can treat the plywood with a sealant or a coating of fibreglass resin. Another option is to use interlocking aluminium extrusions or a product called blind nuts to attach the seats without drilling through the bench.

What You'll Learn

Using stainless steel bolts and nuts

Stainless steel is a great option for mounting seats in an aluminium boat. Stainless steel is highly resistant to corrosion, which is essential in marine environments. However, when stainless steel and aluminium are in direct contact, there is a risk of galvanic corrosion, which can shorten the life of the fastener. This is more likely to occur in saltwater.

To avoid galvanic corrosion, you can use non-conductive materials such as plastic, nylon, or Teflon between the stainless steel and the aluminium. For example, you could use plastic or nylon washers and spacers.

When mounting seats, it is essential to ensure that the bolts are strong enough to hold the weight and that the mounting surface is reinforced to prevent the bolts from pulling through the aluminium. One way to do this is to use stainless steel reinforcing plates on both the top and bottom of the mounting surface. If you cannot access the underside of the mounting surface, you can use hardwood or plywood as a reinforcing material instead.

Another option is to bolt wood across the length of the bench and then attach the seats to the wood. This will reduce flex and provide a more secure mounting surface. If you go this route, be sure to use untreated lumber, as the copper in treated lumber can eat through the aluminium. Seal the wood with a product like Johnson's Water Seal or coat it with fibreglass resin.

When drilling holes in aluminium, be careful not to strip the threads, as aluminium is a soft metal. It is also important to use the correct type of bolts and washers. Hex head bolts, Allen head bolts, and carriage bolts are all suitable options. Flat washers, fender washers, lock washers, and finish washers can be used depending on the specific application.

Finally, consider the environment in which you will be using your boat. Stainless steel is highly corrosion-resistant, but it is not completely immune to corrosion. If you will be using your boat in saltwater, it is essential to take extra precautions to protect your fasteners. A zinc coating can provide additional protection, but it may not be suitable for warm saltwater environments as the chlorides can corrode the zinc. Grade 316 stainless steel is a better option for saltwater applications as it is more resistant to pitting and saltwater corrosion.

Jacksonville's Dragon Boat Races: Dates and Highlights

You may want to see also

Drilling holes and adding plywood

When attaching seats to an aluminum boat, one common method involves drilling holes and securing plywood as a base for the seats. This method provides a sturdy and durable foundation for the seats, ensuring a safe and comfortable boating experience. Here's a step-by-step guide on how to attach seats to an aluminum boat using this technique:

Step 1: Gather Materials and Measurements

Before beginning the installation process, ensure you have all the necessary materials, including plywood, drill bits, screws, and any additional hardware. Measure the intended area for the seats to determine the appropriate size and placement of the plywood base. It's crucial to have accurate measurements to ensure a snug fit for the seats.

Step 2: Prepare the Plywood

Cut the plywood to size, ensuring it fits the intended area for the seats. Sand the edges of the plywood to smooth out any rough surfaces. This step is important for both safety and aesthetics. Consider staining or sealing the plywood to protect it from moisture and extend its lifespan.

Step 3: Mark and Drill Holes

Place the plywood in the desired position inside the boat and use a pencil to mark the locations for drilling holes. Carefully remove the plywood and select a drill bit that matches the size of screws you will be using. Drill holes through the marked spots on the plywood, being cautious not to apply too much pressure to avoid damaging the wood.

Step 4: Attach the Plywood

Position the plywood back into place and secure it to the aluminum boat using screws and washers, if needed. Ensure that the screws are long enough to provide a secure hold but not so long that they protrude and cause discomfort or safety hazards. Tighten the screws firmly but be cautious not to over-tighten, as this could strip the screws or damage the plywood.

Step 5: Install the Seats

With the plywood base securely attached, you can now mount the seats directly onto the plywood. Utilize appropriate screws or bolts to attach the seats, following the manufacturer's instructions or the provided guidance. Ensure that the seats are firmly in place and capable of withstanding expected loads.

By following these steps and carefully drilling holes and adding plywood, you can securely attach seats to your aluminum boat. This method provides a stable and long-lasting solution for seating, enhancing the functionality and enjoyment of your boat. Remember to work carefully and double-check all attachments before taking your boat out on the water.

The Ultimate Guide to Replacing Boat Floor Stringers

You may want to see also

Using interlocking aluminium extrusions

Step 1: Gather the Materials

You will need to source two interlocking aluminium extrusions from a boat dealer. One piece will fasten to the front of your seats, while the other will be used to bolt the seat and swivel. Make sure you also have pop rivets or sheet metal screws for fastening.

Step 2: Prepare the Aluminium Extrusions

Before you begin, check that you have the necessary tools for the assembly. You may need tools like a drill, screwdriver, or rivet gun, depending on your preferred fastening method. Ensure the aluminium extrusions are the correct size and fit together securely.

Step 3: Fasten the First Extrusion

Take the first piece of the aluminium extrusion and fasten it to the front of your seat using pop rivets or sheet metal screws. Ensure that the fit is secure and that the fasteners you use are suitable for aluminium and resistant to corrosion.

Step 4: Attach the Seat

Now, take the second piece of the aluminium extrusion and bolt your chosen seat and swivel to it. This will allow you to remove or adjust the seat by lifting up on the rear without cutting into the bench seat.

Step 5: Test and Adjust

Once you have attached the seat, test the stability and security of the assembly. Ensure that the seat does not wobble or shift and that the fasteners are tight and secure. Make any necessary adjustments to ensure a safe and comfortable seating experience.

Boat Dealers: Trade-Ins and What You Should Know

You may want to see also

Using treated plywood to reduce flex

When installing seats on an aluminium boat, it is important to consider the material used to reinforce the structure and reduce flex. While plywood is a common choice, it is essential to select the right type to ensure durability and structural integrity.

In the context of boat construction and repair, plywood is typically graded based on the quality of its plies. Marine-grade plywood, often found in home improvement stores, usually features an A-grade outer ply and a B-grade inner ply, with a total of seven plies made from Douglas fir bonded together with waterproof glue. This high ply count contributes to the overall strength and stiffness of the material, making it suitable for boat structures.

However, when considering plywood for an aluminium boat, it is crucial to avoid using treated lumber or pressure-treated plywood. The copper present in treated lumber can react with aluminium and cause corrosion. Instead, opt for untreated plywood and treat it with a sealant or a coating of fibreglass resin to protect it from moisture.

When attaching plywood to an aluminium boat, mechanical fasteners such as blind rivets (pop rivets) can be used for a secure and removable installation. It is recommended to install rivets around the perimeter of the plywood, ensuring a rock-solid connection. Additionally, stainless steel bolts and nuts can be used for mounting, providing a strong and durable solution.

By following these guidelines and selecting the appropriate grade and treatment of plywood, you can effectively reduce flex and create a sturdy foundation for mounting seats in your aluminium boat.

Flipping a Boat: The Safe Way to Turn Over a Hull

You may want to see also

Using a swivel base for ease of movement

Using a swivel base for your boat seats is a great option if you're looking for ease of movement and flexibility. Swivel bases allow you to pivot and rotate your seats with ease, providing a more dynamic and comfortable seating experience. Here's a step-by-step guide to help you through the process of installing boat seats using a swivel base:

Step 1: Choosing the Right Swivel Base

First, you'll need to select a suitable swivel base for your boat seats. There are a variety of options available, such as the Swivl-Eze brand, which offers a range of adjustable seat pedestals, bases, and mounts. Consider the type of seat you have, the mounting surface, and your desired level of adjustability. The Swivl-Eze website provides detailed instructions and guidelines for choosing the right base for your specific needs.

Step 2: Preparing the Mounting Surface

Before installing the swivel base, ensure that the mounting surface is clean and free of any debris. If you're mounting the base onto an aluminium bench or deck, you may want to consider reinforcing it with wood or stainless steel reinforcing plates, as aluminium can be soft and prone to tearing. This will provide a stronger foundation for your seats.

Step 3: Installing the Swivel Base

Refer to the instructions provided with your chosen swivel base for specific installation steps. Typically, you will need to securely mount the base to the boat's surface, ensuring that it is firmly attached. The Swivl-Eze Lock’N-Pin ¾-Inch Pedestal Package, for example, includes a pedestal and base plate, requiring only the addition of your chosen seat and hardware.

Step 4: Attaching the Seats

Once the swivel base is securely installed, you can attach your chosen boat seats to the top of the swivel mechanism. Make sure the seats are compatible with the swivel base and follow the manufacturer's instructions for a safe and proper installation. For example, the Titan Swivel system comprises a base and a top, with the base locking onto the bench using rubber anchors, and the top attaching to the seat.

Step 5: Testing and Maintenance

After installing your boat seats with swivel bases, test them thoroughly to ensure they provide stable and smooth movement. Check for any signs of wobbling or accidental spinning, as safety is a priority. Additionally, regular maintenance will ensure the longevity and optimal performance of your swivel seats. Clean the components with mild soap and water, and periodically inspect the connections and moving parts.

By following these steps and choosing a suitable swivel base, you can enjoy the benefits of ease of movement and flexibility with your boat seats. Remember to refer to specific product instructions and guidelines for a safe and successful installation.

Plywood Boat Painting: A Step-by-Step Guide

You may want to see also

Frequently asked questions

You can use a clamp-on bracket, which is the most common way to attach seats without drilling. However, some people have reported that clamp-on brackets are not very sturdy and can be unsafe.

You can drill holes and use screws, bolts, or rivets to secure the seats. It is recommended to use stainless steel or stainless bolts and nuts and to reinforce the mounting surface with stainless plates or wood.

It is recommended to use untreated wood and seal it with a product like polyurethane or fiberglass resin. Do not use treated lumber, as the copper in it will eat through the aluminum.

Yes, you can use a product called blind nuts or rivnuts, which are designed for thin metals and can be installed without accessing the backside of the bench.

Always use stainless steel hardware and make sure the seats are securely attached to handle the torque and weight of a person. Reinforcing the bench seat with wood or aluminum sheeting can provide additional support.