Attaching a bow eye to a fiberglass boat requires careful preparation and the right tools to ensure a secure and durable installation. This guide will provide a step-by-step process for successfully mounting a bow eye, including preparing the boat's surface, selecting the appropriate hardware, and following best practices for installation. By following these instructions, you can enhance the functionality and aesthetics of your boat with a well-fitted bow eye.

What You'll Learn

- Preparation: Clean and prepare the boat's surface for the bow eye

- Material Selection: Choose the right adhesive and hardware for fiberglass

- Installation Technique: Follow a step-by-step process for secure attachment

- Reinforcement: Use additional support for a strong and durable connection

- Testing: Ensure the bow eye is tight and secure before use

Preparation: Clean and prepare the boat's surface for the bow eye

Before you begin the process of attaching a bow eye to your fiberglass boat, it's crucial to ensure that the surface is clean and prepared correctly. This step is often overlooked but is essential for a successful and long-lasting installation. Here's a detailed guide on how to prepare the boat's surface for the bow eye:

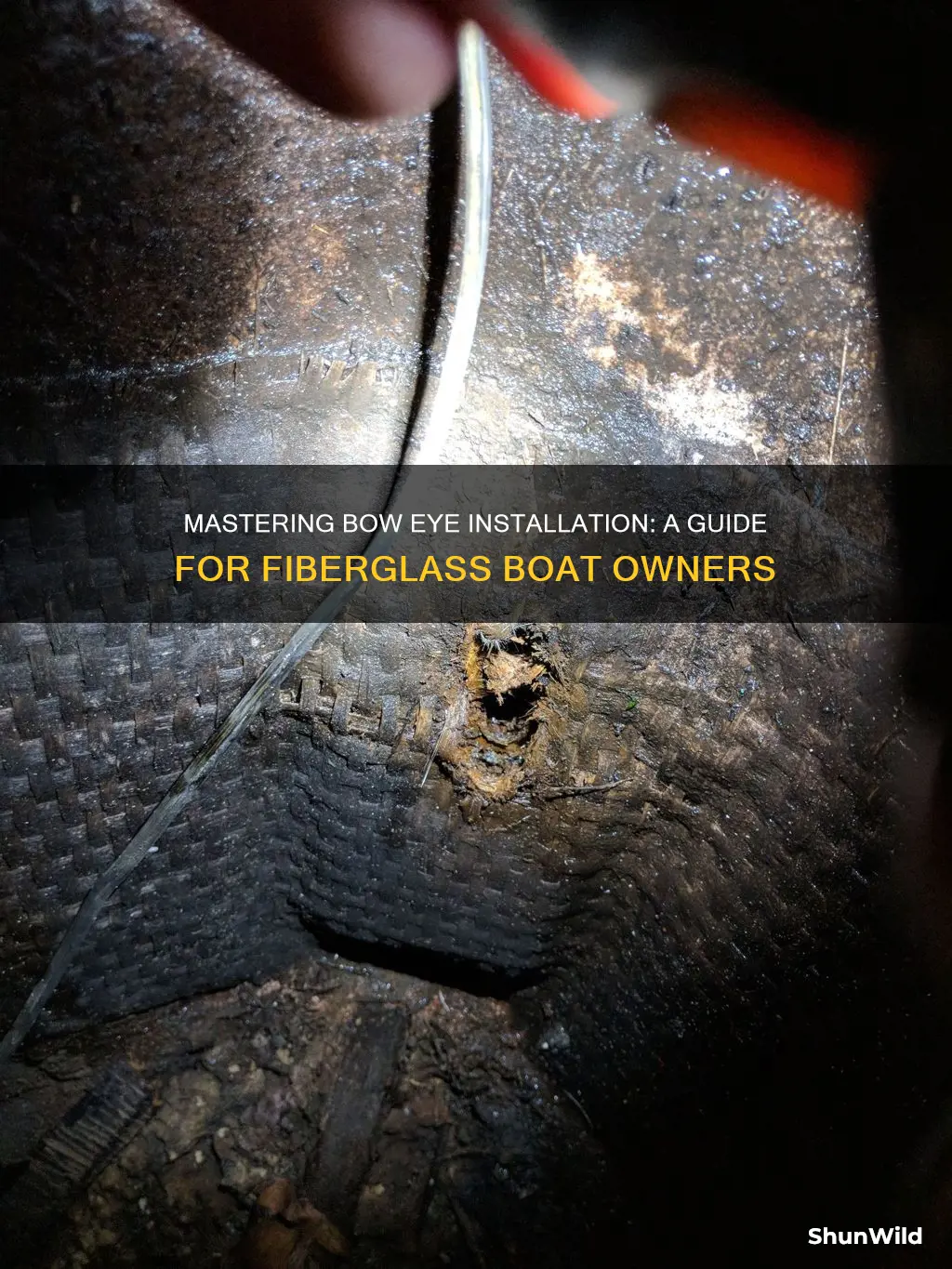

Cleaning the Surface: Start by thoroughly cleaning the area where the bow eye will be attached. Use a mild detergent or boat cleaner specifically designed for fiberglass to remove any dirt, grime, or old paint. Rinse the surface with fresh water to ensure no residue remains. Pay close attention to any existing damage, such as scratches or small holes, as these areas may require additional preparation.

Etching the Fiberglass: Fiberglass is a smooth surface, and creating a rough texture is necessary for the adhesive to bond effectively. You can use a variety of methods for etching. One common technique is to use fine-grit sandpaper (600-1200 grit) to lightly sand the surface. This process should be done carefully to avoid scratching the fiberglass beyond repair. Alternatively, you can use a specialized fiberglass etch or a chemical etch, following the manufacturer's instructions for application and drying times.

Filling and Sanding: After etching, any remaining imperfections should be filled to create a smooth and even surface. Use a fiberglass filler or putty, applying it sparingly and following the product's guidelines. Once the filler is dry, sand it down to a smooth finish using fine-grit sandpaper. Ensure that the entire area is free of dust and debris before proceeding.

Final Inspection: Before attaching the bow eye, inspect the prepared surface one last time. Check for any remaining imperfections and ensure the area is completely clean and dry. This thorough preparation process will ensure a strong bond between the bow eye and the boat, minimizing the risk of future issues.

Remember, taking the time to properly clean and prepare the surface is a critical step that will impact the overall success of your project. It's an essential foundation for a secure and long-lasting attachment.

Boat Ramps in Wisconsin: Open or Closed?

You may want to see also

Material Selection: Choose the right adhesive and hardware for fiberglass

When it comes to attaching a bow eye to a fiberglass boat, material selection is crucial for a secure and long-lasting installation. The right combination of adhesive and hardware can make all the difference in ensuring a strong bond and preventing damage to the boat's structure. Here's a detailed guide on choosing the appropriate materials:

Adhesive Selection:

For fiberglass boats, epoxy-based adhesives are highly recommended. These adhesives form a strong, flexible bond with the material, making them ideal for marine environments. Look for epoxy systems specifically designed for bonding composites, as they offer excellent adhesion and resistance to water and chemicals. The key is to find an epoxy that cures at room temperature, ensuring a convenient and efficient process. Some manufacturers offer two-part epoxy systems, which provide precise control over the curing process and result in a robust bond.

Hardware Considerations:

The hardware you choose should complement the adhesive and provide the necessary strength and support. For fiberglass boats, stainless steel or aluminum hardware is often preferred due to their corrosion resistance and lightweight properties. Bow eyes typically require a combination of screws and pins. Opt for stainless steel screws with a length suitable for your boat's thickness. These screws should have a fine thread to ensure a tight grip. Additionally, consider using aluminum or stainless steel pins, which can be inserted into pre-drilled holes to secure the bow eye in place.

Bonding Process:

Start by cleaning the fiberglass surface to remove any dirt or contaminants. Apply a thin layer of the chosen adhesive, ensuring complete coverage. Press the hardware components firmly into the adhesive, following the manufacturer's instructions for curing time. Allow sufficient time for the adhesive to cure before subjecting the installation to any stress or load.

Remember, the goal is to create a strong, invisible bond that integrates seamlessly with the boat's structure. Proper material selection and application techniques will result in a secure bow eye attachment, ensuring the boat's performance and longevity. Always refer to the specific requirements of your boat model and consult with experts or manufacturers for the best results.

Where to Buy Boat Anchor Paint?

You may want to see also

Installation Technique: Follow a step-by-step process for secure attachment

The process of attaching a bow eye to a fiberglass boat requires precision and attention to detail to ensure a secure and durable installation. Here is a step-by-step guide to help you achieve this:

- Preparation: Begin by cleaning the surface of the boat's hull where the bow eye will be attached. Remove any dirt, grease, or old paint to ensure a proper bond. You can use a mild abrasive cleaner or sandpaper for this step. Ensure the surface is smooth and free of debris.

- Layout and Marking: Decide on the position of the bow eye, considering factors like boat design, intended use, and clearance from other components. Use a straight edge or a ruler to draw a straight line on the hull, marking the center of the bow eye's intended location. This step is crucial for accurate placement.

- Drilling: Using a drill with a suitable bit for fiberglass, carefully create a pilot hole at the marked position. The hole should be slightly smaller in diameter than the bow eye's attachment. Take your time to avoid cracking the fiberglass. Ensure the drill bit is centered to avoid any misalignment.

- Insertion and Alignment: Carefully insert the bow eye into the pilot hole, ensuring it is aligned correctly. You can use a small piece of masking tape or a temporary marker to check the alignment. Make sure the eye is level and centered. If needed, adjust the position slightly to achieve the desired orientation.

- Bonding and Securing: Apply a suitable marine-grade adhesive or epoxy specifically designed for fiberglass bonding. Follow the manufacturer's instructions for application and curing time. Once the adhesive is set, use stainless steel screws or bolts to secure the bow eye firmly in place. Tighten the fasteners evenly to avoid any uneven pressure that could damage the boat.

- Final Touches: After the fasteners are tightened, inspect the installation. Ensure there are no visible gaps or movement in the bow eye. You can use a small amount of filler or putty to fill any remaining gaps and smooth the surface. Once cured, sand the area to a smooth finish, blending it seamlessly with the surrounding hull.

Remember, when working with fiberglass, it's essential to take your time and follow safety precautions. Always wear protective gear, and ensure proper ventilation when using adhesives or solvents. This step-by-step process will help you achieve a secure and long-lasting attachment for your bow eye.

Removing Scum from Your Aluminum Boat: A Step-by-Step Guide

You may want to see also

Reinforcement: Use additional support for a strong and durable connection

When attaching a bow eye to a fiberglass boat, reinforcement is key to ensuring a strong and durable connection. The unique properties of fiberglass, such as its lightweight nature and susceptibility to impact damage, require careful consideration during the installation process. Here's a detailed guide on how to reinforce the attachment for a secure and long-lasting result:

Choose the Right Reinforcement Material: Select a reinforcement material that complements the strength of your fiberglass boat. Carbon fiber or Kevlar fabric is an excellent choice due to their high tensile strength and ability to distribute loads evenly. These materials can be woven or layered over the attachment area to provide additional structural support. Alternatively, you can opt for specialized epoxy-based adhesives designed for marine applications, which offer excellent bonding strength and resistance to water intrusion.

Prepare the Surface: Begin by thoroughly cleaning the surface where the bow eye will be attached. Remove any dirt, grease, or old adhesives using a suitable cleaner and a wire brush. Ensure the surface is smooth, dry, and free from contaminants. If necessary, lightly sand the area to create a rough texture for better adhesion. This step is crucial to ensure the reinforcement material adheres firmly to the boat's surface.

Apply the Reinforcement: Start by laying the chosen reinforcement material over the prepared surface, ensuring complete coverage of the attachment area. For fabric reinforcements, overlap the edges slightly and secure them temporarily with tape or clamps. Then, carefully apply the epoxy adhesive, following the manufacturer's instructions for mixing and application. Spread the adhesive evenly, ensuring it fills any gaps or voids between the reinforcement and the boat's surface. Allow the adhesive to cure partially, creating a temporary bond.

Attach the Bow Eye: Once the adhesive has cured sufficiently, carefully position the bow eye onto the reinforced area. Ensure it is aligned correctly and securely fastened using the appropriate hardware, such as stainless steel screws or bolts. Tighten the fasteners firmly but avoid over-tightening to prevent damage to the fiberglass. The reinforcement layer now provides additional strength to withstand the forces exerted by the bow eye, ensuring a secure and long-lasting connection.

Final Steps: After the fasteners are in place, inspect the entire assembly for any signs of movement or looseness. Make any necessary adjustments and retighten the fasteners as required. Finally, apply a marine-grade sealant around the fasteners and the bow eye to further protect against water intrusion and corrosion. This reinforcement technique ensures that the bow eye attachment is robust and capable of withstanding the stresses of boating operations.

The Open Boat: Fateful Ending Foreshadowed by a Lifeless Object

You may want to see also

Testing: Ensure the bow eye is tight and secure before use

When attaching a bow eye to a fiberglass boat, ensuring its tightness and security is crucial for safe and effective use. Here's a detailed guide on how to test and verify the installation:

Initial Inspection: Before testing, conduct a thorough visual inspection. Check for any visible signs of damage or imperfections around the attachment point. Look for cracks, chips, or any areas where the fiberglass might be compromised. Ensure that the surface is clean and free from debris or old adhesive residue.

Tightness Check: The primary goal is to ensure the bow eye is tightly secured. Start by gently pulling on the eye from various angles and directions. It should feel firmly attached and not move excessively. Pay attention to any play or movement; if you notice any looseness, it indicates that additional tightening is required. Use a torque wrench if available to measure the tightening force and ensure it meets the manufacturer's specifications.

Water Testing: Submerging the boat in water is an effective way to test the bow eye's integrity. Fill the boat with water and ensure it is properly sealed. Then, apply pressure to the bow eye and observe if there are any leaks or signs of water intrusion. A secure installation should prevent any water from entering the boat through the attachment point.

Load Testing: To further validate the security, consider performing a load test. Attach a heavy object to the bow eye and simulate real-world conditions. This could involve pulling the object horizontally, vertically, or at an angle to mimic various scenarios. The bow eye should hold firm without showing signs of strain or damage. If any issues arise, it's a clear indication that the installation needs improvement.

Documentation and Maintenance: After confirming the bow eye's tightness and security, document the process for future reference. Keep records of the tightening torque and any adjustments made. Regularly inspect and retighten the bow eye, especially after exposure to harsh conditions or frequent use. This maintenance ensures the long-term reliability of the attachment.

By following these testing procedures, you can guarantee that the bow eye on your fiberglass boat is securely installed, providing peace of mind during your boating adventures. Remember, proper testing and maintenance are essential to the overall safety and functionality of your vessel.

Lofting a Boat Hull: A Step-by-Step Guide to Success

You may want to see also

Frequently asked questions

Attaching a bow eye to a fiberglass boat is a straightforward process that requires a few tools and materials. First, ensure you have the right size and type of bow eye that fits your boat's specifications. Clean the surface of the boat where the bow eye will be attached to remove any dirt or debris. Then, apply a suitable adhesive or epoxy to the boat's surface and the bow eye, following the manufacturer's instructions. Press the bow eye firmly onto the boat, holding it in place for the recommended curing time. Finally, check the attachment regularly and reinforce it if needed to ensure it remains secure.

You will need a few essential tools to attach a bow eye to your fiberglass boat. These include a clean cloth or rag for surface preparation, a suitable adhesive or epoxy specifically designed for marine applications, a pair of gloves for protection, and a mallet or rubber mallet to help with the installation. Additionally, having a small brush or paintbrush can be helpful for applying the adhesive evenly.

Yes, when working with fiberglass boats, there are a few important considerations. Ensure that the fiberglass surface is clean, dry, and free of any contaminants. Fiberglass can be more sensitive to moisture, so it's crucial to use an adhesive or epoxy that is compatible with marine environments and can withstand the exposure to water. Follow the manufacturer's guidelines for application and curing times to ensure a strong bond.

To ensure the longevity and security of the bow eye attachment, regular maintenance and inspections are key. Check the bond periodically and touch up the adhesive or epoxy if necessary. Avoid placing heavy objects or pressure directly on the attached bow eye to prevent any stress or damage. Additionally, consider using a protective covering or pad over the bow eye to minimize friction and potential wear.