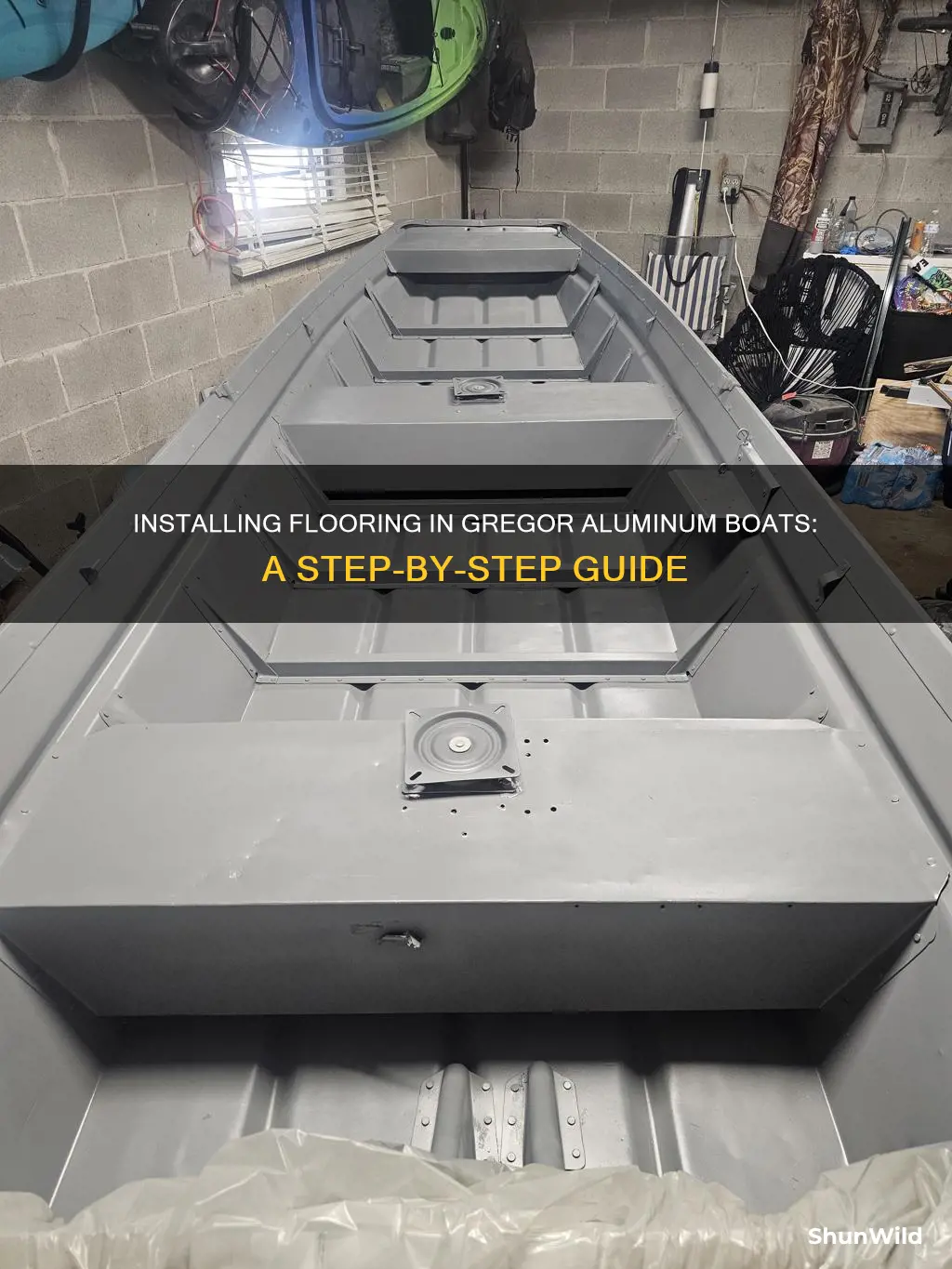

Adding a floor to an aluminium boat is a great way to increase space and comfort. In this article, we will explore the process of adding a floor to a Gregor aluminium boat, including the materials needed, the steps to follow, and the benefits of this modification. Whether you're an experienced boater or a novice, adding a floor to your Gregor aluminium boat can be a rewarding project that enhances your boating experience. So, get ready to roll up your sleeves and dive into the world of boat customisation!

What You'll Learn

Removing the bench seats

Assess the Structure and Purpose:

Before starting, it is crucial to understand the role of the bench seats in the boat's structure. In many cases, bench seats provide bracing and strength to the boat's sidewalls, and they may also contain flotation foam for safety. Therefore, removing them can impact the boat's rigidity and buoyancy.

Decide on the Scope:

Determine how many bench seats you want to remove. Removing all the bench seats at once can significantly impact the boat's structure. Consider removing one bench seat at a time and assessing the boat's performance and stability before proceeding further.

Prepare the Work Area:

Gather the necessary tools and materials, such as a drill, center punch, and rivets. Ensure you have a clear and safe workspace to avoid any accidents during the removal process.

Remove the Bench Seats:

Start by center-punching the rivets holding the bench seats in place. This will create a small indentation that guides your drill and prevents it from slipping. Carefully drill out the rivets, being mindful not to damage the boat's hull. Once the rivets are removed, the bench seats should come off easily.

Reinforce the Structure:

As the bench seats provide structural support, it is essential to reinforce the boat's structure after their removal. Consider adding a heavy-wall aluminum L-channel or a similar structure along the gunnel, extending a few feet both fore and aft. This will help restore longitudinal rigidity and prevent the hull from flexing or folding.

Address Buoyancy:

If the bench seats contained flotation foam, consider adding buoyancy elsewhere in the boat. You can use spray foam under the new floor or add additional flotation devices to ensure the boat remains afloat even if it flips or takes on water.

Test and Refine:

After removing the bench seats and making the necessary structural modifications, take the boat out on the water to test its performance. Observe how the boat handles, paying close attention to any flexing or stability issues. If problems arise, you may need to reinstall the bench seats or make further structural enhancements.

Remember, removing bench seats from an aluminum boat is a significant modification, and it is crucial to prioritize the boat's safety and performance. Always exercise caution and seek advice from boating professionals or forums if you are unsure about any aspect of the process.

Uncover Boat Liens: A Comprehensive Guide to Ownership Checks

You may want to see also

Adding braces to help with structure

Adding braces to your Gregor aluminum boat can help improve its structure and rigidity. Here are some detailed instructions and considerations for this project:

Planning and Materials

Before starting, it is important to assess the specific structure of your boat and plan the placement of the braces accordingly. Additionally, consider the weight of the materials you will be using. While adding structural rigidity is important, you don't want to add too much weight to your boat. Aluminum tubing or square tubing can be a good choice for braces as they are strong yet lightweight.

Attaching Braces

When attaching wooden cross members or braces, it is recommended to use bolts and nuts instead of screws for a sturdier and more secure hold. Seal all screws and bolts with 3M 5200 to ensure a watertight seal. If you are skilled in metalworking, you can create composite beams by drilling or punching holes in aluminum sheet metal and riveting them together.

Flooring

When adding a floor to your boat, consider using treated plywood or composite lumber. Cut the plywood to fit snugly between the sides of the boat, and secure it with short stainless steel screws. You can also use aluminum angle riveted to the sides of the boat for the top deck to screw into.

Flotation and Safety

Remember that the bench seats in your boat likely contain flotation foam for safety. If you remove these seats, consider adding additional flotation devices or foam to your boat to maintain its buoyancy in case of emergencies.

Corrosion Prevention

Be cautious when mixing metals in your boat, as this can lead to galvanic corrosion. Avoid using treated wood in direct contact with aluminum, as the copper in the treated wood can react with and corrode the aluminum. Seal any treated wood surfaces that will be in contact with aluminum, and regularly inspect for signs of corrosion.

Decoding Boat Hull ID: RTC004MBJ788 Explained

You may want to see also

Using aluminium to frame up a floor support

Aluminium is a great material to use for framing up a floor support, especially for a Gregor aluminium boat. Aluminium is a durable and lightweight material, which makes it ideal for boats. Here are some steps and tips to help you frame up a floor support using aluminium:

Planning and Design

Before starting any work, it's important to plan and design the floor support structure. Measure the dimensions of the boat and determine the layout of the floor support. Consider the weight of the floor and any additional weight it needs to bear. Ensure that your design does not overload the boat's capacity. It is also essential to consider the safety aspects, such as ensuring the boat remains buoyant even if it flips or gets a hole.

Materials and Tools

To frame up a floor support using aluminium, you will need aluminium sections or profiles with the appropriate dimensions. Standard extruded aluminium sections are commonly used for construction. Additionally, you will require fasteners, screws, and other fixing elements. It is recommended to use steel screws for fixing aluminium frames. You may also need tools like a cutter, screwdriver, and a level platform for installation.

Construction and Installation

When constructing the floor support frame, ensure that the aluminium members are straight both horizontally and vertically. Avoid using chisels for cutting and opt for a cutter to get the required lengths. For fixing the frame, follow the specific instructions depending on whether you are installing it on a brick masonry, concrete surface, or woodwork. Ensure that the floor support is securely attached to the boat's structure.

Finishing and Protection

Before installing the aluminium floor support, apply a coat of clear transparent lacquer to protect the aluminium surface from wet cement. After installation, fill any gaps with mastic cement and plaster. You can also add buoyancy foam to the structure for added safety.

By following these steps and tips, you can effectively frame up a floor support using aluminium for your Gregor aluminium boat. Remember to take your time, work carefully, and ensure that all measurements and fixings are accurate.

Boat Owners: Who Has the Pleasure of Sailing?

You may want to see also

Replacing plywood transom with UHMW or HDPE plastic

Adding a floor to an old Gregor aluminum boat is a great project to take on during the winter. Before you begin, it's important to note that the bench seats in your boat may provide bracing and strength to the sidewalls, so removing them could potentially affect the hull's integrity. It's also worth mentioning that the foam in these bench seats is meant to provide flotation for safety reasons. With that in mind, let's dive into the process of replacing the plywood transom with UHMW or HDPE plastic.

First, you'll need to gain access to the transom by carefully cutting through the liner or sole. Make sure you don't damage the outside fiberglass skin, but if you do, reinforce it with an extra layer of fiberglass before proceeding. Next, completely remove the old plywood core using tools like a reciprocating demo saw, grinder, hammer, and chisel. An air hammer can also be useful if you have access to an air compressor.

At this point, you should create a template of the transom using cardboard or cheap plywood. This template will be crucial for cutting your new core and tracing the wide fiberglass pieces that will form the new inside transom skin. When installing the new core, ensure that its total thickness matches the original plywood. You can use UHMW or HDPE plastic sheets for this, but keep in mind that bonding these materials together is challenging, and they may not provide the same rigidity as plywood.

To attach the new core, consider through-bolting it to the aluminum sheet of the transom. You can also use epoxy to laminate multiple layers of UHMW or HDPE together, creating a thicker and stronger structure. Fill any gaps between the new core and the sides/bottom of the hull with epoxy putty. Additionally, make a fillet of putty around the joint for a smoother transition.

The next step is to tab the transom core to the sides and bottom of the hull using 12 oz Biaxial fiberglass tape. This tape is stronger than traditional woven tape and is epoxy-compatible. Finally, laminate a new inside transom fiberglass skin using multiple layers of wide biaxial cloth. Each layer should overlap the previous one by a few inches, creating a strong and durable transom.

Remember to take precise measurements throughout the process and seek advice from boat repair forums or experts if needed. Good luck with your Gregor aluminum boat restoration project!

Boat Ownership: Calculating Annual Costs and Expenses

You may want to see also

Installing a sealed floor

Step 1: Remove Old Flooring and Clean the Boat

Start by removing any existing flooring or decking, including the bench seats. Be careful not to damage the underlying structure. Power wash the inside of the boat to remove any dirt, grime, or residue.

Step 2: Assess the Support Structure

Check the support structure of your boat. Look for ribs, stringers, or angles that you can attach your new floor to. If there is a lack of support, consider adding aluminium tubing or angles to provide a stable surface for the new floor.

Step 3: Choose Your Flooring Material

You have a few options for flooring material. Plywood, particularly exterior-grade plywood, is a popular choice. If you go with plywood, consider sealing it with epoxy, floor paint, or fibreglass resin for added protection. Another option is to use synthetic lumber, such as Starboard, which is long-lasting and doesn't require treatment.

Step 4: Create a Gap Between the Floor and Hull

When installing the new floor, leave a small gap between the wood and the aluminium hull. This will allow water to drain and not get trapped underneath the flooring.

Step 5: Add Flotation and Drainage

Use flotation foam or blocks strategically placed underneath the floor to enhance buoyancy and drainage. Avoid using materials that block water flow, and instead, opt for pool noodles or blue/pink foam board, which aid in drainage.

Step 6: Seal the Wood

To protect your wood flooring, seal both sides with a suitable treatment. You can use oil-based paint, fibreglass resin, or epoxy. This will help prevent water damage and prolong the life of your new floor.

Step 7: Consider Your Covering

Instead of carpet, consider using marine vinyl for your floor covering. Carpet tends to soak up water and hold it, whereas vinyl allows for better drainage. If you prefer carpet for comfort, opt for indoor/outdoor carpet with a rubber backing.

Remember to always consult with boating professionals or experts for advice specific to your boat model before making any modifications.

Fresh Off the Boat: Appropriate or Offensive?

You may want to see also

Frequently asked questions

Adding a floor to your Gregor aluminum boat can provide several benefits, such as maximizing floor space, creating enclosed storage compartments, and improving the overall aesthetics of the boat. Additionally, you can customize the floor to include features like in-floor rod storage, LED lighting, and pedestal seating.

When adding a floor to your Gregor aluminum boat, consider using materials such as plywood, marine carpeting, aluminum, and insulation. For the deck, you can use plywood sealed with a spar urethane finish. To reduce weight, opt for 3/8" plywood instead of 1/2". Use marine-grade carpeting and an exterior carpet adhesive to carpet the deck and hatches. Aluminum angles, brackets, and rivets can be used for framing and securing the floor to the boat. Finally, insulation can be added between the ribs under the floor for added protection.

Yes, it is important to consider the impact on hull integrity and buoyancy before adding a floor to your Gregor aluminum boat. Removing bench seats may affect the bracing and strength of the sidewalls, so adding additional support structures or flotation devices might be necessary. Consult a professional or seek advice from boat modification forums to ensure your project does not compromise the safety of your boat.