The global basketball industry produces an astonishing number of basketballs annually, catering to the demands of professional leagues, amateur players, and enthusiasts worldwide. With an estimated production of over 100 million basketballs per year, the manufacturing process involves intricate craftsmanship and rigorous quality control to ensure optimal performance and durability. This paragraph sets the stage for an exploration of the intricate production process, the factors influencing the demand for basketballs, and the impact of this massive production on the sports equipment market.

| Characteristics | Values |

|---|---|

| Total Basketballs Made Annually | Approximately 100 million |

| Basketballs per Second | 1.7 (based on a 24-hour day) |

| Basketballs per Minute | 102 |

| Basketballs per Hour | 6120 |

| Basketballs per Day | 146,880 |

| Basketballs per Week | 1,028,160 |

| Basketballs per Month (assuming 4 weeks) | 4,112,640 |

| Basketballs per Year | 49,351,680 |

What You'll Learn

- Manufacturing Process: Breakdown of materials and assembly steps for basketball production

- Global Production: Regional distribution and leading manufacturers of basketballs worldwide

- Demand and Sales: Factors influencing annual basketball sales and market trends

- Quality Control: Standards and testing methods for ensuring basketball performance and durability

- Environmental Impact: Sustainable practices and waste reduction in basketball manufacturing

Manufacturing Process: Breakdown of materials and assembly steps for basketball production

The production of basketballs involves a meticulous process that combines various materials and precise assembly techniques to ensure the final product meets the high standards required by players and manufacturers alike. Here is a detailed breakdown of the manufacturing process, focusing on the materials and assembly steps involved.

Materials:

- Outer Cover: The most visible part of a basketball is its outer cover, typically made from high-quality rubber or composite materials. Natural rubber is a traditional choice, known for its durability and bounce. However, modern basketballs often use synthetic rubber compounds or composite materials, which offer improved consistency and reduced weight. These materials are carefully selected to withstand the impact and wear during intense gameplay.

- Bladders: Inside the outer cover, a small, flexible bladder is inserted. This bladder is usually made from latex or butyl rubber, providing the ball with its shape and feel. The bladder's thickness and composition can vary, affecting the ball's responsiveness and grip.

- Inserts: Some basketballs feature an additional layer called an insert, typically made from a lightweight foam or rubber compound. This insert is placed between the bladder and the outer cover, enhancing the ball's structure and performance. Inserts can be designed to provide a specific feel, such as increased grip or a softer touch.

- Thread and Cord: The outer cover is then securely attached to the bladder using a strong, flexible thread or cord. This assembly process ensures the ball's structural integrity and allows for the necessary tension to be applied.

Assembly Steps:

- Material Selection: The manufacturing process begins with the careful selection of materials based on the desired specifications. Different grades of rubber or composite materials are chosen to meet performance, durability, and cost requirements.

- Outer Cover Formation: The outer cover material is carefully processed and formed into a spherical shape. This step involves precise molding techniques to ensure the cover's uniformity and consistency.

- Bladder Insertion: The latex or butyl rubber bladder is then inserted into the partially formed outer cover. This process requires skill to ensure the bladder is centered and properly positioned.

- Assembly and Inflation: The bladder is inflated to the desired pressure, and the thread or cord is used to securely attach the cover to the bladder. This assembly step demands precision to maintain the ball's structural integrity.

- Insert Installation (if applicable): If an insert is included, it is carefully placed between the bladder and the outer cover. This layer can be customized to provide specific performance characteristics.

- Final Inspection and Quality Control: Each basketball undergoes rigorous inspection to ensure it meets the required standards. This includes checking for proper inflation, uniform color, and overall craftsmanship.

- Packaging and Distribution: After passing quality control, the basketballs are packaged, labeled, and distributed to retailers and sports equipment suppliers.

The manufacturing process of basketballs is a complex art, requiring precision, skill, and an understanding of materials to produce a high-performance product. Each step contributes to the overall quality and performance of the basketball, ensuring an optimal playing experience for athletes.

Maximizing Your Fantasy Basketball: The Optimal Point Guard Count

You may want to see also

Global Production: Regional distribution and leading manufacturers of basketballs worldwide

The global production of basketballs is a significant industry, with an estimated 100 million basketballs manufactured annually worldwide. This number can vary depending on factors such as market demand, the time of year, and the availability of raw materials. The production process involves several key steps, including material sourcing, design, manufacturing, quality control, and distribution.

Regionally, the United States is a major player in the basketball manufacturing sector. The country boasts a robust domestic market and a strong presence in international trade. Companies like Wilson Sports, a leading manufacturer, produce a significant portion of their basketballs in the U.S., catering to both professional and recreational players. Other regional hubs for basketball production include China, which has become a significant player in the global market due to its low production costs and large-scale manufacturing capabilities. Chinese brands like Li-Ning and Anta have gained recognition for their basketball products.

In Europe, countries like Germany and Italy have a strong tradition of sports equipment manufacturing, and some companies in these regions produce basketballs, often focusing on high-quality, premium products. Additionally, the Asia-Pacific region, including countries like India and Vietnam, has seen an increase in basketball manufacturing facilities due to favorable labor costs and proximity to major markets.

The leading manufacturers of basketballs worldwide often have a diverse product range, catering to various sports and skill levels. For instance, Wilson Sports, apart from its basketballs, also produces footballs, baseballs, and other sports equipment. Similarly, Chinese brands like Nike and Adidas have a global presence and offer a wide array of basketball products, including specialized shoes and apparel.

The distribution of basketballs is a complex process, often involving a network of distributors, retailers, and online platforms. Major manufacturers typically have established distribution channels that reach customers worldwide, ensuring that basketballs are accessible to players and enthusiasts across different regions.

The Art of Absurd: Basketball's Wildest Trick Shots

You may want to see also

Demand and Sales: Factors influencing annual basketball sales and market trends

The global basketball market is a thriving industry, with annual sales figures reaching impressive heights. The demand for basketballs is influenced by various factors, both internal and external, which shape the market trends and sales performance. Understanding these factors is crucial for manufacturers, retailers, and enthusiasts alike to navigate the dynamic landscape of basketball production and consumption.

One of the primary drivers of annual basketball sales is the popularity of the sport itself. Basketball is a widely played and followed sport, with a massive global fan base. The sport's popularity is further bolstered by its inclusion in major international events like the Olympics and the NBA Finals, attracting a vast audience. As a result, the demand for basketballs increases, especially during peak sports seasons or tournaments. For instance, the lead-up to the NBA playoffs often sees a surge in basketball sales as fans and players alike prepare for the high-stakes games.

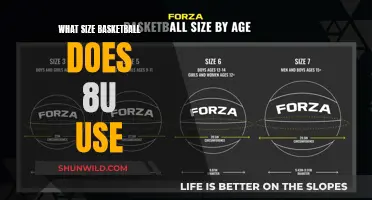

Demographic factors also play a significant role in shaping the market. Age is a critical consideration, as different age groups have distinct preferences and needs. Younger players might opt for smaller, lighter balls, while older players or professionals may require larger, more durable options. Additionally, the gender of the player can influence ball choice, with some brands offering specialized designs for men, women, or youth. Market research often reveals that certain age groups or demographics are more inclined to purchase specific brands or types of basketballs, further emphasizing the importance of understanding target audiences.

The availability and accessibility of basketballs are other key factors. Retailers and online stores play a vital role in meeting consumer demand by offering a wide range of basketballs at various price points. The introduction of new technologies and materials in ball manufacturing has led to the creation of high-performance, durable basketballs that cater to professional and amateur players alike. For instance, the use of innovative rubber compounds and advanced inflation systems has resulted in balls that provide better grip, control, and longevity, thus increasing their appeal and sales.

Furthermore, the influence of social media and celebrity endorsements cannot be overlooked. Influencers and celebrities often promote specific basketball brands or models, creating a buzz and generating interest among their followers. This word-of-mouth marketing can significantly impact sales, especially for niche or emerging brands. Additionally, collaborations between sports brands and celebrities or athletes can lead to limited-edition releases, which often become highly sought-after items, driving up sales and creating a sense of exclusivity in the market.

In conclusion, the annual sales and market trends of basketballs are shaped by a combination of factors, including the sport's popularity, demographic preferences, product availability, and marketing strategies. Manufacturers and retailers must stay attuned to these influences to meet the ever-evolving demands of the basketball industry. By understanding the dynamics of the market, they can ensure a steady supply of high-quality basketballs to cater to the global audience of basketball enthusiasts.

Purdue's 2023 Basketball Recruiting Class: A Deep Dive into the Top Prospects

You may want to see also

Quality Control: Standards and testing methods for ensuring basketball performance and durability

Quality control is an essential aspect of the basketball manufacturing process, ensuring that each ball meets the required standards for performance, durability, and player safety. The standards and testing methods employed in this process are rigorous and comprehensive, covering various aspects of the basketball's construction and materials. Here's an overview of the key considerations and testing procedures:

Performance Standards: Basketballs must adhere to specific performance criteria to ensure optimal gameplay. The primary focus is on the ball's bounce, which should be consistent and responsive. Manufacturers often use specialized equipment to measure the rebound height and velocity, ensuring it meets the industry standards. Additionally, the ball's weight is critical; it should be within a narrow range to provide a balanced feel during play. Testing involves precise weight measurements to guarantee uniformity across the production run.

Durability Testing: To assess the durability of basketballs, manufacturers employ various methods. One common approach is to simulate game conditions and subject the balls to extensive wear and tear. This includes exposing the balls to repeated impacts, abrasion, and even extreme temperatures to mimic different weather conditions. By doing so, manufacturers can identify potential weaknesses in the ball's construction, such as seams that may come loose or materials that are prone to tearing.

Material Inspection: The materials used in basketball construction are carefully selected and inspected. Manufacturers scrutinize the quality of rubber or composite materials used for the ball's outer cover, ensuring they are free from defects and meet the required specifications. The inner bladder or air chamber is also tested for its ability to retain air pressure over time, which is crucial for consistent performance.

Abrasion Resistance: Testing the abrasion resistance of basketballs is vital to ensure they can withstand the wear and tear of regular use. This involves subjecting the ball's surface to controlled abrasion tests, where it is rubbed against various surfaces to simulate the effects of playing on different courts. The goal is to ensure that the ball's cover remains intact and does not show excessive wear, maintaining its appearance and performance.

Seam Strength: The strength of the ball's seams is another critical aspect of quality control. Manufacturers use specialized machines to test the seams' resistance to separation, ensuring they can withstand the stress of ball handling and the impact of shooting and dribbling. This testing process helps identify any potential issues with the stitching or bonding of the ball's components.

By implementing these rigorous testing methods, manufacturers can guarantee that each basketball produced meets the highest standards of performance, durability, and safety. This level of quality control is essential to maintain the integrity of the game and ensure player satisfaction.

Unveiling the Air 1 Basketball Shot: A Guide to the Perfect Swish

You may want to see also

Environmental Impact: Sustainable practices and waste reduction in basketball manufacturing

The global production of basketballs is a significant aspect of the sports industry, with an estimated 100 million basketballs manufactured annually. This massive output has a substantial environmental impact, primarily due to the materials used and the manufacturing processes employed. The environmental consequences of basketball production are multifaceted, ranging from resource depletion to waste generation and pollution.

One of the primary environmental concerns in basketball manufacturing is the use of non-renewable resources. Basketballs are typically made from rubber, a material derived from natural latex. The extraction of latex involves tapping rubber trees, which can lead to deforestation and habitat destruction, especially in regions where rubber trees are indigenous. Additionally, the production of rubber requires significant amounts of energy and water, contributing to resource depletion and potential water scarcity issues.

The manufacturing process itself is energy-intensive, often relying on fossil fuels, which release greenhouse gases and contribute to climate change. The use of chemicals in the production of basketballs, such as vulcanizing agents and accelerators, can also result in water pollution if not properly managed. These chemicals, if released into water bodies, can have detrimental effects on aquatic ecosystems and potentially harm human health.

To address these environmental challenges, sustainable practices and waste reduction strategies are crucial. Firstly, manufacturers can explore the use of renewable resources and alternative materials. For instance, some companies are now using recycled rubber from old tires, reducing the demand for new latex and minimizing waste. This approach not only conserves natural resources but also diverts waste from landfills.

Implementing more efficient manufacturing processes is another key strategy. Optimizing production techniques can reduce energy consumption and minimize waste generation. For example, adopting precision engineering methods can ensure that basketballs are produced with minimal excess material, reducing waste and the associated environmental impact. Additionally, implementing closed-loop recycling systems can help recover and reuse materials, further decreasing the industry's environmental footprint.

In summary, the environmental impact of basketball manufacturing is significant, primarily due to resource depletion and pollution. However, through the adoption of sustainable practices, such as using renewable materials and efficient manufacturing processes, the industry can significantly reduce its ecological footprint. By embracing these changes, basketball manufacturers can contribute to a more sustainable future, ensuring that the sport's popularity does not come at the expense of the environment.

The Evolution of the Basketball: From Dribble to Dunk

You may want to see also

Frequently asked questions

The exact number of basketballs manufactured each year is difficult to pinpoint due to the vast production volume and the involvement of numerous manufacturers worldwide. However, estimates suggest that over 100 million basketballs are produced annually, catering to the demands of professional leagues, amateur players, and the global sports market.

Yes, basketball production varies significantly by region. Countries like China, the United States, and India are among the top producers, with China being the largest manufacturer due to its vast sports equipment industry. Regional variations also exist in terms of the types of basketballs produced, with different materials and designs catering to various skill levels and playing conditions.

Demand plays a crucial role in determining production numbers. Peak demand periods often coincide with major sporting events, such as the NBA playoffs or the Olympics, where the need for official-quality balls increases. Additionally, the growth of basketball popularity in emerging markets can significantly boost production and sales, leading to higher annual production figures.