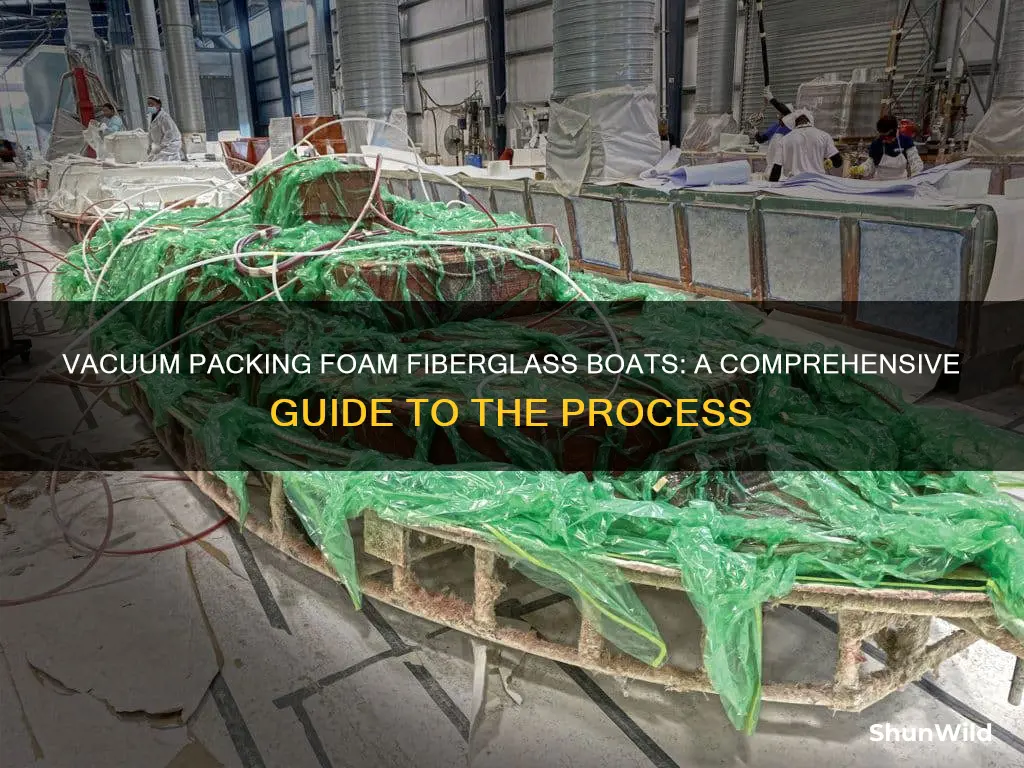

Vacuum packing foam fiberglass boats can be a challenging task due to the delicate nature of the materials involved. The process requires careful handling to ensure the boat remains intact and free from damage during the packing and sealing stages. This process involves a series of steps that demand precision and attention to detail, making it a complex and potentially tricky endeavor. Understanding the specific techniques and tools required to effectively vacuum pack a foam fiberglass boat is essential for a successful outcome.

| Characteristics | Values |

|---|---|

| Material | Fiberglass, Foam |

| Vacuum Packing | Yes, possible but challenging |

| Difficulty Level | High |

| Tools Required | Vacuum sealer, heavy-duty bags, gloves, protective gear |

| Time Commitment | Several hours, depending on boat size |

| Safety Precautions | Wear gloves, goggles, and a respirator to avoid skin and eye irritation, and inhaling fiberglass dust |

| Environmental Impact | Proper disposal of used vacuum bags and foam is essential to minimize environmental harm |

| Cost | Relatively low for materials, but labor costs may apply if hiring professionals |

| Success Rate | High if done carefully, but potential for damage if not handled properly |

What You'll Learn

- Vacuum Packing: A method to remove air and compress fiberglass, enhancing boat storage and transport

- Fiberglass Handling: Careful techniques to avoid damage during the vacuum packing process

- Boat Preparation: Cleaning and drying the boat before vacuuming to ensure a successful process

- Vacuum System: Choosing the right vacuum system for effective air removal from the boat

- Storage and Transportation: Vacuum packing for easy storage and safe transportation of the fiberglass boat

Vacuum Packing: A method to remove air and compress fiberglass, enhancing boat storage and transport

Vacuum packing is a valuable technique for boat owners and enthusiasts, especially when dealing with materials like foam fiberglass, which can be bulky and challenging to store or transport. This method involves creating a vacuum environment to remove air and compress the material, making it more manageable and space-efficient. Here's an overview of the process and its benefits:

The process begins with acquiring a vacuum sealer and bags specifically designed for the task. These bags are typically made of a sturdy, flexible material that can withstand the suction pressure. It is crucial to choose the right size and thickness of the bag to accommodate the fiberglass boat's dimensions. Once the bags are prepared, the boat is carefully placed inside, ensuring it is positioned correctly to allow for even compression. The vacuum sealer is then used to create a strong suction force, pulling out the air from the bag and around the boat. This process requires some practice and technique to ensure all air is removed without causing any damage.

As the vacuum seal is applied, the air is extracted, and the fiberglass begins to compress. This compression is a key advantage of vacuum packing. It significantly reduces the volume of the boat, making it easier to store in tight spaces or transport in smaller vehicles. For example, a boat that would typically occupy a large trailer can be compressed to fit into a smaller trailer or even a car trunk, making it more convenient for travel and storage. The compression also helps to minimize the risk of damage during transport, as the boat is securely held in place without the need for excessive padding.

One of the critical aspects of vacuum packing fiberglass boats is the use of appropriate accessories. This includes specialized straps or ties to secure the boat within the bag, preventing it from shifting during the vacuuming process. Additionally, some vacuum sealers offer features like adjustable suction power, allowing users to control the level of compression. This control is essential to ensure the boat remains intact and avoids any potential damage.

In summary, vacuum packing offers a practical solution for boat owners, particularly those with fiberglass boats made of foam. By removing air and compressing the material, this method simplifies storage and transport, making it an attractive option for those seeking efficient ways to manage their watercraft. With the right equipment and techniques, boat owners can easily handle the process, ensuring their boats remain in excellent condition while being moved or stored.

Filling Holes in Your Boat: Perfect Electronics Installation

You may want to see also

Fiberglass Handling: Careful techniques to avoid damage during the vacuum packing process

When dealing with vacuum packing foam fiberglass boats, it's crucial to employ careful techniques to prevent any damage to the delicate material. Fiberglass, known for its strength and durability, can be susceptible to damage if not handled properly during the packing process. Here are some essential guidelines to ensure the integrity of the boat remains intact:

Preparation: Begin by ensuring the boat is clean and free from any debris or contaminants. Moisture is a particular concern, so it's imperative to thoroughly dry the surface before proceeding. Any residual moisture can lead to mold or deterioration during the packing process. Additionally, inspect the boat for any existing damage; this will help you identify areas that require extra care.

Vacuum Packing Technique: The key to successful vacuum packing lies in the technique. Start by placing the boat on a flat surface, ensuring it is centered and secure. Use a high-quality vacuum sealer designed for delicate materials. Apply the vacuum gently and evenly across the boat's surface, avoiding any sudden movements or excessive force. The goal is to create a tight seal without putting pressure on the fiberglass. Take your time and be methodical to ensure a thorough vacuum.

Handling with Care: Once the vacuum packing is complete, handle the boat with utmost care. Avoid any sharp or abrupt movements that could potentially scratch or dent the surface. Use padded gloves or cloth to touch the boat, as human skin can leave oils that may damage the fiberglass over time. Lift and move the boat using its sides or the transom, ensuring you distribute the weight evenly.

Storage and Unpacking: After the packing process, store the boat in a controlled environment, preferably in a dry and temperature-regulated space. This is crucial to prevent any further damage. When you're ready to unpack, follow the reverse process, slowly releasing the vacuum and carefully opening the package. Inspect the boat for any signs of damage during and after the unpacking process, addressing any issues promptly.

By adhering to these careful techniques, you can significantly reduce the risk of damage to the foam fiberglass boat during the vacuum packing process, ensuring its longevity and structural integrity. It is an art that requires practice and attention to detail, but the rewards are a well-preserved boat ready for its intended use.

Boat Parade Start Time in Palm Beach

You may want to see also

Boat Preparation: Cleaning and drying the boat before vacuuming to ensure a successful process

Before you begin the process of vacuuming a foam fiberglass boat, proper preparation is crucial to ensure a successful and effective outcome. Cleaning and drying the boat is an essential step that should not be overlooked, as it directly impacts the quality of the vacuum-sealing process. Here's a detailed guide on how to prepare your boat for vacuuming:

Cleaning the Boat: Start by giving your boat a thorough cleaning. This step is vital as it removes any dirt, debris, or contaminants that could interfere with the vacuum-sealing process. Use a mild detergent or a specialized boat cleaner to wash the entire surface of the boat, including the hull, deck, and any interior compartments. Pay extra attention to areas where dirt or grime tends to accumulate, such as the bilge or beneath the seats. Rinse the boat thoroughly with freshwater to ensure no soap residue remains. For foam fiberglass boats, it's especially important to clean the surface because the foam's texture can easily trap dirt, making it harder to achieve a tight vacuum seal.

Drying the Boat: After cleaning, the boat must be completely dry before vacuuming. Moisture can lead to issues during the vacuum-sealing process, such as mold growth or reduced vacuum effectiveness. Use a high-pressure water blaster or a powerful shop vacuum to remove any remaining water from the boat's surface. Ensure that all areas, including hard-to-reach spots, are thoroughly dried. You can also use a soft cloth or a shop towel to wipe down the boat, but be cautious not to scratch the fiberglass surface. Proper drying is critical, especially in the case of foam fiberglass, as it requires a dry environment to maintain its structural integrity.

Additionally, consider using a desiccant-based drying agent, such as calcium chloride or silica gel, to further ensure dryness. These agents can be placed in sealed bags or containers within the boat to absorb any remaining moisture. This extra step is particularly useful if the boat has been in a humid environment or has experienced water damage.

By taking the time to thoroughly clean and dry your boat, you create an optimal environment for the vacuum-sealing process. This preparation step is often overlooked but is essential for achieving a successful and long-lasting vacuum-packed boat repair or restoration project. It ensures that the vacuum seal adheres properly to the boat's surface, providing the necessary support and protection.

A River Boat Mystery: What Really Happened?

You may want to see also

Vacuum System: Choosing the right vacuum system for effective air removal from the boat

When it comes to vacuum packing a foam fiberglass boat, the choice of the right vacuum system is crucial for effective air removal and a successful outcome. The goal is to create a tight, compact package that will protect the boat during storage or transportation, ensuring it remains in top condition. Here's a guide to help you select the appropriate vacuum system for this task:

Consider the Size and Type of the Boat: The first step is to assess the dimensions and structure of your boat. Foam fiberglass boats can vary significantly in size and shape. For smaller boats or those with limited space, a compact, handheld vacuum pump might be sufficient. These pumps are portable and easy to maneuver, making them ideal for tight spaces. However, for larger boats or those with more complex structures, a more powerful and robust industrial vacuum system might be necessary. Industrial vacuums often come with larger capacity tanks and stronger suction power, ensuring that even the smallest air pockets are removed.

Look for High Suction Power and Efficiency: The key to effective air removal is a vacuum system with strong suction power and high efficiency. When choosing a vacuum, consider the maximum suction force (usually measured in watts or horsepower) and the efficiency of the motor. A higher suction force will enable the vacuum to pull out more air, especially from the intricate nooks and crannies of the boat's structure. Look for vacuums with advanced filtration systems to ensure that even small particles and dust are removed, leaving the boat clean and ready for packing.

Choose a System with Adjustable Settings: Different materials and structures may require varying levels of suction and air removal techniques. Opt for a vacuum system that offers adjustable settings, allowing you to customize the suction power and air flow. This feature is particularly useful when dealing with different parts of the boat, such as the hull, deck, or interior compartments, each requiring a tailored approach to air removal.

Consider Portability and Ease of Use: Depending on your specific needs, you might prefer a vacuum system that is easy to transport and set up. For instance, if you plan to move the boat frequently or work in various locations, a lightweight, portable vacuum with a long power cord will be more convenient. Alternatively, for a one-time project, a more permanent setup might be acceptable, focusing on power and efficiency over portability.

Safety and Maintenance: Always prioritize safety when operating a vacuum system. Ensure that the vacuum is properly grounded and that all connections are secure. Regular maintenance, such as cleaning the filters and checking for any blockages, will also ensure optimal performance and longevity.

Freeing a Seized GW Invader Engine: A Step-by-Step Guide

You may want to see also

Storage and Transportation: Vacuum packing for easy storage and safe transportation of the fiberglass boat

Vacuum packing is an excellent method to ensure the safe storage and transportation of a fiberglass boat, especially when dealing with the unique challenges of handling foam fiberglass. This technique involves removing air from a bag or container, creating a compact and secure environment for the boat. Here's a step-by-step guide on how to effectively vacuum pack your fiberglass boat for easy storage and safe transit:

Preparation: Before you begin, ensure the boat is clean and free of any debris. Remove all accessories, such as seats, covers, or any loose items that might interfere with the packing process. This step is crucial to ensure the boat fits snugly in the vacuum bag and prevents potential damage during transportation.

Choose the Right Vacuum Bag: Select a vacuum bag specifically designed for boat storage. These bags are typically made of durable, tear-resistant materials that can withstand the suction force. Look for bags with a strong seal to ensure no air escapes during the vacuuming process. The bag should be large enough to accommodate the boat's dimensions, allowing for a tight fit without excessive stretching.

Packing Process: Place the boat inside the vacuum bag, ensuring it is centered and secure. Use straps or ties to hold the boat in place, preventing it from shifting during vacuuming. Close the bag, leaving a small opening for the vacuum attachment. Apply a strong suction force to remove all the air, ensuring the boat is tightly compressed. This process might require some effort, especially for larger boats, but it is essential for effective packing.

Transportation and Storage: Once vacuum packed, the boat becomes incredibly compact and easy to transport. You can now load it into a trailer, truck, or storage facility with minimal space requirements. The vacuum-sealed boat will remain protected from dust, moisture, and potential damage during transit. For long-term storage, consider keeping the boat in a climate-controlled environment to prevent any adverse effects on the fiberglass material.

Vacuum packing offers a convenient and safe way to store and transport your foam fiberglass boat. It eliminates the risks associated with traditional storage methods, such as stacking or crating, which can lead to scratches or damage. By following these steps, you can ensure your boat remains in excellent condition, ready for its next adventure on the water.

Repairing Holes Left by Boat Electronics: A Step-by-Step Guide

You may want to see also

Frequently asked questions

Vacuum packing a foam fiberglass boat can be a manageable task, but it requires some technical knowledge and the right equipment. The process involves creating a vacuum-sealed environment to remove air and moisture, which helps in preserving the boat's structure and preventing damage.

You'll need a vacuum sealer, preferably a commercial-grade one with a high-quality pump. Additionally, a vacuum bag or container specifically designed for the boat's size is essential. Some enthusiasts also use a heat gun to melt the bag's seams for a more secure seal.

While it is possible to vacuum pack a boat yourself, especially for smaller boats, it is generally recommended to seek professional assistance for larger or more complex vessels. Professionals have the expertise and equipment to ensure a thorough and effective vacuum-sealing process.

Vacuum packing helps in moisture management, preventing mold and mildew growth. It also aids in maintaining the boat's structural integrity by removing air bubbles that could compromise the fiberglass layers. This process can extend the boat's lifespan and ensure its longevity.

One potential challenge is ensuring an airtight seal, especially around the boat's openings and seams. Inadequate sealing might lead to moisture intrusion. Additionally, the process requires careful handling to avoid damaging the boat's surface or compromising its structural integrity.