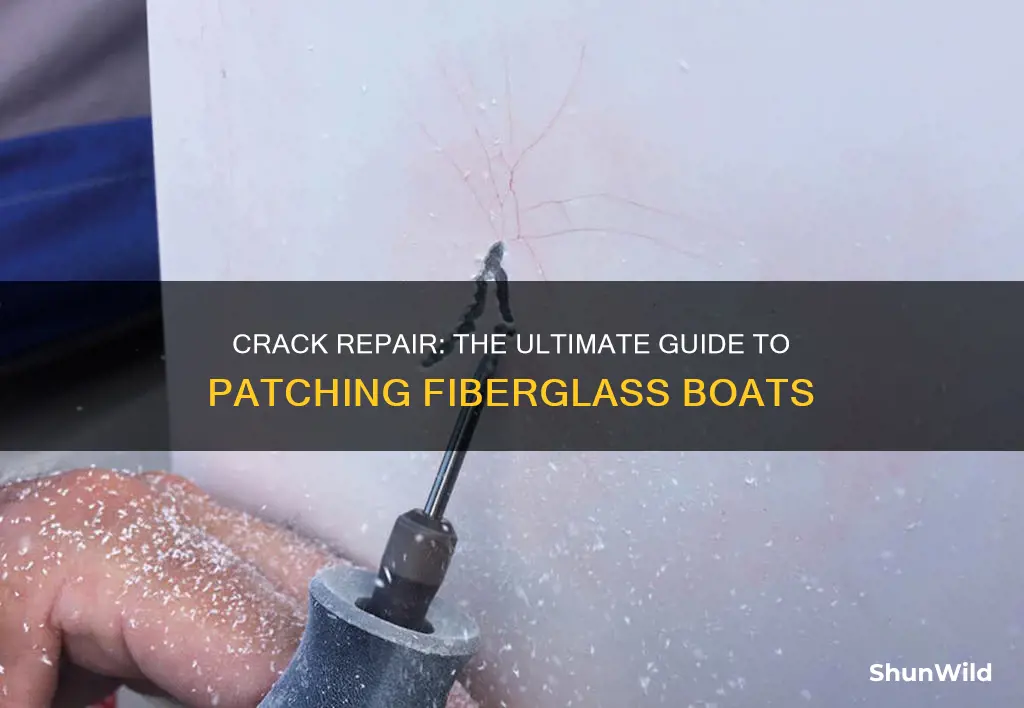

Patching cracks in a fiberglass boat can be a challenging task, and the difficulty level depends on the size, depth, and location of the crack. Fiberglass is a lightweight and durable material, but it can be prone to damage from impact, corrosion, or age. Repairing these cracks requires a careful approach to ensure the structural integrity of the boat is maintained. This process involves cleaning the area, applying a suitable filler or resin, and carefully smoothing it to match the surrounding surface. While it is possible to perform these repairs yourself, it is often recommended to seek professional help to ensure a successful and long-lasting fix.

What You'll Learn

- Patching Process: Step-by-step guide for effective crack repair

- Materials Needed: Essential tools and supplies for fiberglass repair

- Preparation: Cleaning and preparing the crack area for patching

- Adhesives: Choosing the right adhesive for fiberglass reinforcement

- Finishing Touches: Sanding and painting for a seamless repair

Patching Process: Step-by-step guide for effective crack repair

Before you begin the patching process, it's crucial to understand the nature of the crack and the extent of the damage. Inspect the fiberglass boat thoroughly to assess the size and depth of the crack. Small, shallow cracks can often be repaired with a simple patch, while deeper or more extensive damage may require more advanced techniques. Gather the necessary tools and materials, including fiberglass repair kit, epoxy resin, hardener, cloth or mesh, and a heat gun or hairdryer for curing.

Step 1: Clean the Area: Start by cleaning the crack and its surrounding area. Use a mild detergent or soap mixed with water to remove any dirt, grime, or old filler. Rinse the area thoroughly and allow it to dry completely. This step ensures that the patch adheres properly to the fiberglass surface.

Step 2: Prepare the Crack: For small cracks, you can use a simple filling technique. Clean the crack again and lightly sand the edges to create a smooth surface. Remove any loose fibers or debris from the crack. If the crack is more extensive, consider using a fiberglass repair kit specifically designed for boat repairs. These kits often include a gel coat or primer to prepare the surface.

Step 3: Apply the Patch: Cut a piece of fiberglass cloth or mesh slightly larger than the crack. Dip it into the epoxy resin and press it onto the prepared area. Ensure the cloth is smooth and flush with the surface. Apply a thin layer of hardener over the cloth and the surrounding area to create a strong bond. Use a heat gun or hairdryer to gently heat the area, facilitating the curing process.

Step 4: Smooth and Sand: Once the epoxy has cured, inspect the patch. If it's smooth and flush with the surrounding fiberglass, you're on the right track. If not, carefully sand the patch to create a seamless finish. Use fine-grit sandpaper to avoid damaging the surrounding fiberglass. Clean the area again after sanding to remove any dust.

Step 5: Finish and Protect: Apply a new layer of gel coat or primer to the entire repaired area, following the manufacturer's instructions. This step adds strength and protection to the repair. Once cured, the boat is ready for further use. Remember to regularly inspect and maintain the repair to ensure its longevity.

Paddling on the Lake: Is It Possible?

You may want to see also

Materials Needed: Essential tools and supplies for fiberglass repair

Before diving into the repair process, it's essential to gather the right tools and materials to ensure a successful fiberglass boat repair. Here's a comprehensive list of what you'll need:

Fiberglass Repair Kit: This is the cornerstone of your repair endeavor. A fiberglass repair kit typically includes a range of essential components:

- Fiberglass Resin: Choose a two-part epoxy resin system specifically designed for marine applications. This resin will act as the bonding agent for the repair.

- Fiberglass Mat or Woven Glass Fabric: Select a mat or fabric with a weave size suitable for your repair. It should be slightly larger than the crack to ensure proper coverage.

- Catalyst: Also known as a hardener, the catalyst is mixed with the resin to initiate the curing process.

- Stir Sticks and Mixing Cups: These tools are necessary for mixing the resin and catalyst accurately.

- Putty Knife or Spreader: Used for applying the resin and shaping the repair.

- Masking Tape: Useful for temporarily securing the repair area and creating a clean edge.

Adhesives and Bonding Agents:

- Epoxy Adhesive: In addition to the resin and catalyst, consider having a separate epoxy adhesive for bonding the repair to the existing fiberglass.

- Super Glue or Instant Bond: For smaller cracks, a strong adhesive like super glue can be applied to create a temporary bond before the final repair.

Sanding and Grinding Tools:

- Sandpaper: Fine-grit sandpaper (600-1200 grit) is ideal for smoothing the repair area and blending it with the surrounding surface.

- Electric Grinder: A small angle grinder with a diamond-coated disc can be useful for aggressive sanding and removing damaged material.

Cleaning and Preparation Supplies:

- Isopropyl Alcohol: Used to clean the repair area, remove any dirt or contaminants, and ensure proper adhesion.

- Solvent: A suitable solvent, like acetone or methyl ethyl ketone (MEK), can be used to thin the resin and facilitate application.

Safety Gear:

- Goggles and Gloves: Protect your eyes and hands from resin, catalyst, and any potential debris during the repair process.

- Ventilation: Work in a well-ventilated area or use a fume hood to minimize exposure to fumes from the resin and catalyst.

Additional Supplies:

- Rags and Cloths: For cleaning and applying solvents.

- Tape Measure: To ensure accurate measurements for the repair.

- Safety Wire: Useful for temporarily securing the repair area.

Having all these materials ready will empower you to tackle the fiberglass repair with confidence. Remember, proper preparation is key to a successful and long-lasting repair.

Ranger Bass Boat: Unlocking the Speed Limits

You may want to see also

Preparation: Cleaning and preparing the crack area for patching

Before you begin the patching process, it's crucial to thoroughly clean and prepare the cracked area on your fiberglass boat. This step is essential to ensure the patch adheres properly and the repair is long-lasting. Here's a detailed guide on how to prepare the crack:

Step 1: Remove Debris and Old Material

Start by carefully removing any loose debris, dirt, or old fiberglass material from the crack. Use a sharp knife or a small blade to gently scrape away any frayed or damaged fibers. Take your time and be meticulous to avoid causing further damage. If the crack is deep, you might need to carefully cut away a small section of the fiberglass around the crack to create a clean, flat surface for the patch.

Step 2: Wet the Area

Moisture is your friend during this process. Spray the cracked area generously with water to keep it damp. This step helps to soften the existing fiberglass and makes it easier to work with. Ensure the water is not too excessive, as you want to avoid creating a slippery mess. The goal is to create a pliable surface that can be shaped and molded.

Step 3: Apply a Release Agent (Optional)

Consider using a release agent or a non-stick spray to further facilitate the patching process. This step is especially useful if the crack is narrow or deep. The release agent will prevent the fiberglass resin from sticking to the area, making it easier to apply the patch and ensuring a smooth finish. Apply the agent sparingly, focusing on the crack and the surrounding area.

Step 4: Roughen the Surface

Once the area is clean and damp, use a fine-grit sandpaper (around 120-150 grit) to lightly sand the surface. This step creates a rough texture that will provide better adhesion for the patch. Be careful not to sand too aggressively, as you might remove the gelcoat or damage the underlying structure. After sanding, wipe away any dust or debris with a damp cloth.

Step 5: Inspect and Re-evaluate

Take a moment to inspect the prepared crack. Ensure that all debris has been removed, the surface is clean, and the area is damp. Re-evaluate the depth and extent of the crack to determine the appropriate patch size and material. This preparation stage is critical to the success of the repair, as it ensures a solid foundation for the patch to adhere to.

Tracker Boats: Are They Worth the Hype?

You may want to see also

Adhesives: Choosing the right adhesive for fiberglass reinforcement

When it comes to repairing cracks in a fiberglass boat, choosing the right adhesive is crucial for a successful and long-lasting fix. Fiberglass is a composite material that requires specific adhesives to bond effectively, as the wrong choice can lead to poor adhesion, premature failure, and potential safety hazards. Here's a guide to help you select the appropriate adhesive for your fiberglass reinforcement project:

Understanding Fiberglass Structure: Fiberglass is composed of a matrix of resin and fibers, typically glass fibers. The resin acts as a binder, holding the fibers together and providing structural integrity. When repairing a crack, the goal is to create a strong bond between the existing fiberglass and any new materials or patches added. This requires an adhesive that can penetrate and adhere to both the resin and the fibers.

Types of Adhesives: There are several types of adhesives suitable for fiberglass reinforcement:

- Epoxy Resins: Epoxy-based adhesives are highly recommended for fiberglass repairs. They form a strong, durable bond with the fiberglass matrix. Look for two-part epoxy systems, as they offer better control over the curing process and provide excellent adhesion. Ensure you follow the manufacturer's instructions for mixing and application.

- Polyester Resins: Polyester resins are another viable option, especially for smaller repairs. They are less expensive and easier to work with compared to epoxies. However, polyester resins may not provide the same level of strength and durability, so they are better suited for cosmetic repairs or temporary fixes.

- Acrylic Adhesives: Acrylic adhesives are known for their quick curing time and ease of use. They are suitable for minor repairs and can provide a strong bond. However, they may not be as resistant to chemicals and UV radiation as epoxy or polyester resins.

Application Considerations:

- Surface Preparation: Proper surface preparation is essential. Clean the crack area thoroughly, removing any dirt, grease, or old adhesive residue. Roughen the surface slightly to provide better adhesion.

- Mixing and Application: Follow the adhesive manufacturer's instructions for mixing ratios and application techniques. Proper mixing ensures optimal bonding. Apply the adhesive in a thin, even layer, ensuring full coverage of the crack and any new materials.

- Curing and Handling: Allow sufficient curing time for the adhesive to set properly. Avoid handling or subjecting the repair to stress until the adhesive is fully cured.

Additional Tips:

- Consider the environmental conditions and the load-bearing requirements of the repair. For high-stress areas or marine environments, epoxy-based adhesives are generally preferred for their superior strength.

- Practice on a small section of the boat or a test piece before applying the repair to ensure you are satisfied with the results.

- Always wear appropriate personal protective equipment (PPE) when working with adhesives, including gloves, respirators, and protective eyewear.

By carefully selecting the right adhesive and following proper application techniques, you can effectively reinforce fiberglass boat cracks, ensuring a durable and long-lasting repair. Remember, the key to success is understanding the unique properties of fiberglass and choosing adhesives that complement its structure.

Dragon Boat Racing: China's Ancient Cultural Tradition

You may want to see also

Finishing Touches: Sanding and painting for a seamless repair

When it comes to repairing a crack in a fiberglass boat, the finishing touches are crucial to ensure a seamless and professional-looking result. After the initial patch job, you'll need to focus on sanding and painting to restore the boat's original appearance. Here's a step-by-step guide to help you through this process:

Sanding: Start by allowing the repair area to dry completely. Then, use a fine-grit sandpaper (600-1200 grit) to gently sand the patched area. This step is essential to create a smooth surface and blend the repair into the surrounding fiberglass. Work in small sections, applying light pressure and following the direction of the boat's existing fibers. If the patch is new, you might need to sand it down to match the surrounding surface. Be careful not to over-sanding, as it can lead to a rough texture. After sanding, wipe away any dust with a tack cloth to ensure a clean surface for the next step.

Filling and Sanding Again: Once the sanding is complete, it's time to fill any remaining imperfections. Use a two-part epoxy filler or a fiberglass repair kit, following the manufacturer's instructions. Apply the filler sparingly, only where needed, to avoid a lumpy appearance. After it dries, sand the filled area again with a finer grit (1000-1500 grit) to create a smooth transition between the repair and the original surface. This step is critical to ensure the paint adheres properly and looks seamless.

Priming and Painting: Before painting, apply a suitable primer designed for marine environments. This step helps the paint adhere better and provides a protective barrier. Use a small brush or a spray gun to apply the primer evenly. Allow it to dry completely, then sand lightly with a fine-grit paper to create a smooth surface for painting. Finally, choose a marine-grade paint that is durable and resistant to UV rays. Apply the paint in thin, even coats, allowing sufficient drying time between each layer. This process ensures the repair blends seamlessly with the rest of the boat's exterior.

Remember, patience and attention to detail are key during this stage. Take your time with each step, and don't rush the sanding and filling process. Proper preparation will result in a high-quality finish that will make the repair nearly invisible.

Gambling Boat Operations in Indiana: Open for Business?

You may want to see also

Frequently asked questions

Patching a crack in a fiberglass boat can be a challenging task, but with the right tools and some patience, it is definitely achievable. The difficulty level depends on the size and location of the crack, as well as the skill of the person performing the repair.

You will need a few essential tools for the job. These include a fiberglass repair kit, which typically includes a filler or resin, a catalyst, and a hardener. Additionally, you'll need a putty knife or a similar tool for applying the filler, a sandpaper or a fine-grit abrasive for smoothing, and a primer to ensure proper adhesion.

For small to medium-sized cracks, a DIY repair is possible. However, for larger or more complex damage, it is recommended to consult a professional marine technician or a fiberglass repair specialist. They have the expertise and experience to ensure a proper and long-lasting fix.

The time required for the repair can vary. For a small crack, it might take a few hours, including preparation, application, and curing time. Larger repairs could take a day or more, depending on the extent of the damage and the complexity of the boat's design.

Yes, there are a few tips to simplify the process. Ensure the boat is clean and dry before starting. Follow the manufacturer's instructions for the repair kit carefully. Take your time and work in a well-ventilated area. Practice good sanding techniques to create a smooth surface for the filler.