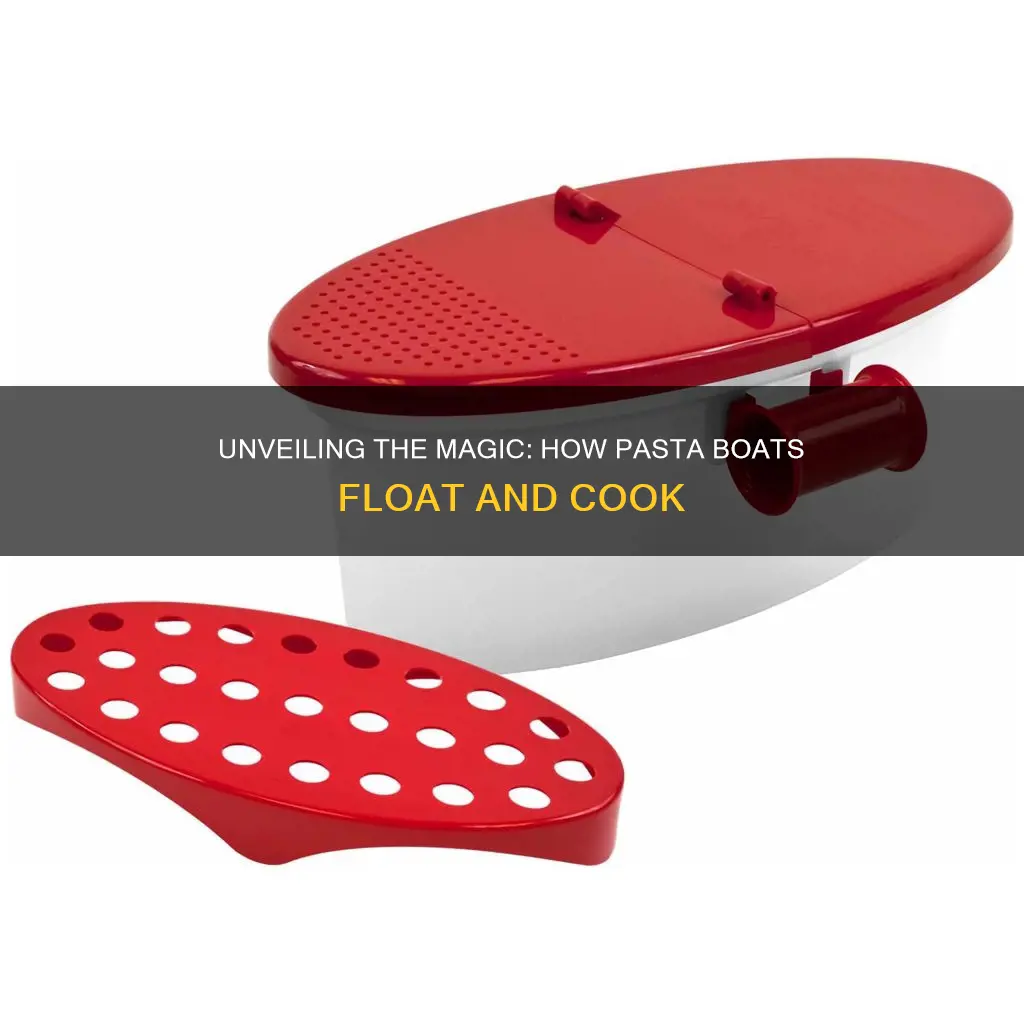

The Pasta Boat, an innovative kitchen appliance, revolutionizes the pasta-making process by offering a unique and efficient method. This device, often referred to as a pasta maker or pasta press, operates by utilizing a boat-like structure to cook pasta directly in water. The process involves placing pasta into the boat, which is then submerged in boiling water, allowing the pasta to cook evenly and retain its shape. The boat's design facilitates the separation of cooked pasta from the water, ensuring a quick and easy draining process. This method is particularly popular for making fresh pasta, offering a convenient and time-saving alternative to traditional cooking methods.

What You'll Learn

- Engine Power: How the engine's power is transferred to the propeller

- Propeller Design: The role of the propeller in generating thrust

- Hydrodynamics: Pasta boat's movement through water explained

- Stability Systems: Mechanisms that keep the boat steady

- Fuel Efficiency: Optimizing fuel use for long voyages

Engine Power: How the engine's power is transferred to the propeller

The power generated by the engines of a pasta boat is a critical component of its operation, enabling the vessel to move efficiently through the water. This power is transferred to the propeller, which is the primary component responsible for propulsion. The process involves a series of mechanical steps that convert the rotational energy of the engines into the forward motion of the boat.

At the heart of this system is the engine, typically a diesel or gasoline engine, which produces mechanical energy through the combustion of fuel. This energy is initially transferred to a transmission, which acts as a gear box, allowing for the adjustment of speed and torque. The transmission's output shaft is connected to a driveshaft, a robust and flexible component designed to transmit power over long distances without significant loss.

The driveshaft's power is then directed to a reduction gear, a crucial component that slows down the rotational speed of the driveshaft while increasing its torque. This reduction in speed is necessary to match the propeller's optimal rotational velocity for efficient propulsion. The reduction gear is often a planetary gear set, which provides high torque and precision in speed control.

Finally, the powered driveshaft rotates a propeller, usually a three- or four-blade design, which is positioned at the stern of the boat. The propeller's blades are shaped to create a lift force as they rotate through the water, generating thrust. This thrust propels the boat forward, overcoming water resistance and allowing for movement. The propeller's design and angle are carefully engineered to optimize performance, ensuring that the boat's engines are efficiently utilized.

In summary, the engine's power is transferred to the propeller through a series of mechanical components, each playing a vital role in the process. This intricate system ensures that the boat's engines are effectively harnessed to provide the necessary force for movement, demonstrating the sophisticated engineering behind the simple act of sailing a pasta boat.

Repairing Vinyl Boat Seats: Fixing Holes Like a Pro

You may want to see also

Propeller Design: The role of the propeller in generating thrust

The propeller is a critical component of any watercraft, including the unique 'pasta boat' concept. Its design and functionality are essential to understanding how these vessels generate thrust and move through the water efficiently. Propellers work on the principle of creating a forward force by rotating blades in a specific manner. When a boat's engine drives the propeller, it spins, creating a pressure differential between the water and the air. This pressure difference results in a lift force, which is the primary means of propulsion.

The design of the propeller is intricate and involves several key elements. Firstly, the shape and angle of the blades are crucial. Propeller blades are typically curved and angled to form an 'angle of attack,' which is the angle at which the blade meets the water. This angle is carefully calculated to optimize the lift force generated. The blades are also designed with a specific pitch, which refers to the distance a blade travels in one complete revolution. A higher pitch means the blades are more efficient at creating thrust, especially at higher speeds.

As the propeller rotates, it creates a vortex of water, which is essentially a spinning column of water. This vortex is directed backward, and according to Newton's third law of motion, an equal and opposite reaction occurs, pushing the boat forward. The efficiency of this process depends on the propeller's design, including its diameter, pitch, and number of blades. A larger diameter propeller can move more water, providing more thrust, but it may also be less efficient at lower speeds.

The number of blades on a propeller also plays a significant role in its performance. Typically, a propeller with two or three blades is common, but designs with four or more blades are also used. More blades can provide better control and efficiency, especially at lower speeds, as they help maintain a more consistent flow of water. The design also considers the material used, with lightweight, durable materials being preferred to reduce the overall weight of the boat without compromising performance.

In the context of a 'pasta boat,' understanding propeller design is crucial for optimizing its performance. Engineers would need to consider the specific requirements of the vessel, such as its size, intended speed, and the type of pasta it will carry. By tailoring the propeller's design, including blade shape, pitch, and material, engineers can ensure efficient thrust generation, allowing the pasta boat to navigate waters effectively while maintaining the unique characteristics of its design.

Exploring Trieste and Venice: A Boat Trip Away

You may want to see also

Hydrodynamics: Pasta boat's movement through water explained

The concept of a "pasta boat" might seem unusual, but it's an intriguing idea that combines culinary delights with fluid dynamics. This innovative design aims to optimize the movement of pasta through water, which is an interesting challenge given the unique properties of pasta and the principles of hydrodynamics.

When a pasta boat glides through water, it showcases the fascinating interplay between shape, material, and fluid. The boat's design is crucial, as it needs to minimize drag and maximize stability. The hull, for instance, should be streamlined to reduce resistance, allowing the boat to cut through the water efficiently. This is where the principles of hydrodynamics come into play. By understanding the behavior of fluids, engineers can design boats that minimize the force opposing their motion, known as drag.

The shape of the pasta boat is critical. A typical pasta boat might feature a long, slender hull with a rounded front and a slightly flatter rear. This design reduces the water's resistance, enabling the boat to move smoothly. The boat's weight distribution is also essential; a well-balanced boat will sit lower in the water, reducing the impact of waves and improving stability. This balance ensures that the boat glides effortlessly, almost as if it's skimming the surface.

Hydrodynamics also explains the boat's ability to navigate through water. As the boat moves, it creates a flow pattern around it. The water's velocity and pressure change around the hull, with higher pressure on the bottom and lower pressure on the top. This pressure difference creates a lift force, which helps the boat stay afloat and move forward. The design of the boat's propeller is also crucial, as it needs to generate enough thrust to overcome drag and propel the boat efficiently.

In essence, the pasta boat's movement through water is a result of careful engineering and an understanding of hydrodynamics. By optimizing shape, weight distribution, and fluid interaction, engineers can create vessels that move with grace and efficiency, even when carrying a load of delicious pasta. This concept not only showcases the beauty of science but also inspires innovative designs in various industries.

Understanding Boat Propulsion: Z-Drive Technology Explained

You may want to see also

Stability Systems: Mechanisms that keep the boat steady

The 'Pasta Boat' is an innovative concept that combines the principles of hydrostatic lift and buoyancy to create a unique watercraft design. At its core, the boat utilizes a system of interconnected water-filled bags or compartments, often referred to as 'hydrostatic stability cells'. These cells are strategically placed and designed to maintain the boat's equilibrium and stability on the water's surface.

One of the key mechanisms for stability is the distribution of weight and the concept of hydrostatic lift. The boat's design ensures that the weight of the vessel and its passengers is evenly distributed across the water-filled compartments. This even distribution creates a stable platform, preventing the boat from capsizing due to uneven weight distribution. The hydrostatic lift principle comes into play as the water pressure increases with depth, providing an upward force that counteracts the boat's weight, thus maintaining stability.

Additionally, the Pasta Boat may employ various stabilization systems to enhance its performance and safety. One such system is the use of adjustable buoyancy controls. These controls allow operators to fine-tune the boat's buoyancy, adjusting it to different water conditions and loads. By altering the water level in the stability cells, the boat can be made more stable in calm waters and less stable (with a deeper draft) in rougher conditions, providing better control and safety.

Another critical aspect of stability is the boat's design and shape. The hull of the Pasta Boat is often designed with a wide, flat bottom and a rounded hull shape. This design minimizes the boat's tendency to roll, especially in side winds or when navigating through waves. The flat bottom provides a stable platform, while the rounded hull reduces drag and allows the boat to glide smoothly over the water's surface.

Furthermore, advanced stability systems might include dynamic stabilization technologies. These systems use sensors and actuators to actively adjust the boat's orientation and balance in real-time. By continuously monitoring the boat's motion and making rapid adjustments, these systems can counteract any external forces or movements, ensuring a smooth and stable ride. This technology is particularly useful in dynamic water conditions and can significantly improve the overall performance and safety of the Pasta Boat.

The Bayliner Boat: A Comprehensive Overview

You may want to see also

Fuel Efficiency: Optimizing fuel use for long voyages

The 'Pasta Boat', as you might have learned from your research, is a fascinating concept in marine engineering, designed to optimize fuel efficiency and reduce emissions for long-distance voyages. This innovative vessel is a testament to the power of human ingenuity in tackling the challenges of sustainable transportation. Here's a detailed exploration of how fuel efficiency can be maximized for such a vessel:

Design and Construction: The foundation of fuel efficiency lies in the design and construction of the Pasta Boat. Engineers must consider the vessel's overall shape, size, and weight. A streamlined hull, similar to that of a hydrofoil boat, can significantly reduce drag, allowing the boat to cut through water more efficiently. The use of lightweight materials, such as advanced composites, can also minimize the vessel's weight, reducing the power required to propel it forward. Additionally, the design should incorporate features like water-tight compartments and efficient ventilation systems to ensure structural integrity and reduce unnecessary weight.

Propulsion System: The propulsion system plays a critical role in fuel efficiency. For the Pasta Boat, a hybrid propulsion system could be employed, combining diesel engines for high-speed cruising and electric motors for low-speed maneuvers and maneuvering. This dual-power system allows for efficient energy use, as electric motors are highly efficient at lower speeds, reducing fuel consumption during port maneuvers and slow-speed transit. Additionally, the use of advanced propellers or waterjets can provide better propulsion efficiency, minimizing fuel wastage.

Navigation and Route Planning: Efficient fuel use is also about strategic navigation and route planning. The Pasta Boat's crew should be trained in optimizing routes, taking into account factors like water currents, wind patterns, and sea conditions. By planning routes that take advantage of favorable currents and winds, the vessel can reduce the power required to maintain speed. Advanced navigation systems and real-time weather data can assist in making informed decisions, ensuring the boat stays on an efficient course.

Maintenance and Operation: Regular maintenance is essential to ensure the vessel's systems operate optimally. This includes routine checks of the propulsion system, engines, and fuel tanks to identify and rectify any inefficiencies. Proper fuel management, such as using fuel-efficient driving techniques and avoiding rapid acceleration or deceleration, can also significantly impact fuel consumption. Additionally, implementing a comprehensive monitoring system that tracks fuel usage, engine performance, and vessel speed can provide valuable data for further optimization.

Renewable Energy Integration: To further enhance fuel efficiency, the Pasta Boat could incorporate renewable energy sources. Solar panels on the deck or wind turbines integrated into the design can generate electricity to power certain systems, reducing the reliance on diesel engines. This approach not only improves fuel efficiency but also contributes to a more sustainable and environmentally friendly operation.

By focusing on these aspects, the Pasta Boat can achieve remarkable fuel efficiency, making it a more sustainable and cost-effective solution for long-distance maritime transportation. This approach not only benefits the environment but also ensures a more efficient and economically viable operation for the vessel's owners and operators.

The Mayflower: A Vessel for Puritan Dreams

You may want to see also

Frequently asked questions

The pasta boat, also known as a pasta maker or pasta machine, is a kitchen appliance designed to automate the process of making pasta. It works by feeding a long strip of dough through a series of rollers or blades, which cut and shape the dough into the desired pasta shape, typically long noodles or fettuccine. The machine can adjust the thickness of the pasta by selecting different settings or adjusting the roller width, allowing for customization based on personal preference or recipe requirements.

A pasta boat can create a variety of pasta shapes, including spaghetti, fettuccine, lasagna sheets, fettuccine rigate (with ridges), and even cavatelli. Some models may offer additional attachments or settings to create different shapes and sizes, providing versatility for various recipes and culinary creations.

Using a pasta boat is generally straightforward and user-friendly. Here's a simple process: First, prepare the dough according to your recipe, ensuring it's soft and pliable. Feed the dough into the machine, typically by placing it on a designated area or through a feeding tube. Adjust the settings to control the thickness and shape. Once the pasta is formed, carefully remove it from the machine and cook it according to the package instructions or your preferred method.

Yes, a pasta boat is an excellent tool for making fresh pasta at home. Fresh pasta, when made with high-quality ingredients and properly prepared, offers a superior texture and taste compared to store-bought dried pasta. The machine ensures consistent shaping and thickness, resulting in al dente pasta with a smooth texture. Additionally, making fresh pasta allows for customization of ingredients, such as adding herbs, spices, or vegetables to the dough, creating unique and personalized pasta dishes.