Understanding how your boat's gas takes work is essential for ensuring a smooth and efficient boating experience. Gas-powered boats rely on a complex system that involves the combustion of fuel to generate power. This process begins with the engine's fuel injection system, which precisely measures and injects gasoline into the engine's cylinders. The fuel is then ignited by a spark plug, causing a controlled explosion that drives the pistons and ultimately propels the boat forward. This intricate process is a delicate balance of timing, pressure, and precision, all working in harmony to provide the necessary thrust for your vessel.

What You'll Learn

- Engine Operation: Gasoline powers the engine, driving the propeller for propulsion

- Fuel Injection: Gas is injected into the engine's cylinders for combustion

- Combustion Process: Gas ignites, creating power to move the boat

- Exhaust System: Gas exhaust is released through the boat's tailpipe

- Gas Tank: Stores gasoline, which is pumped to the engine when needed

Engine Operation: Gasoline powers the engine, driving the propeller for propulsion

The operation of a boat's engine is a fascinating process that relies on the combustion of gasoline to generate power and propel the vessel. When you ignite the fuel, a series of intricate mechanisms come into play, transforming the chemical energy into mechanical force. This force is then transferred to the propeller, which in turn moves the boat through the water.

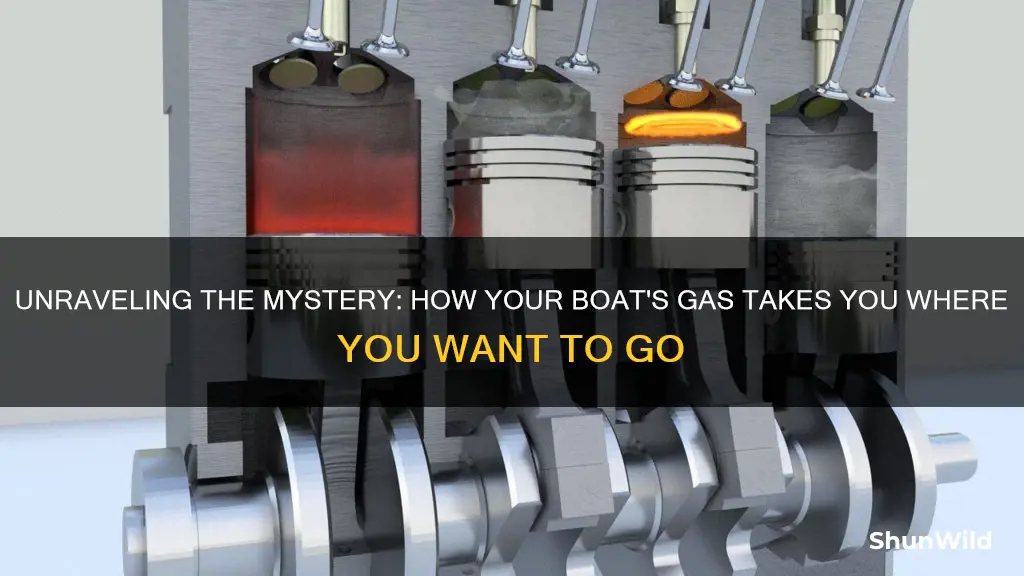

At the heart of this system is the internal combustion engine, a complex assembly of components that work in harmony. When gasoline is injected into the engine's cylinders, it is carefully timed and mixed with air. This mixture is then ignited by a spark plug, causing a rapid combustion process. The explosion creates a significant amount of energy, which is harnessed to drive the engine's pistons. These pistons are connected to a crankshaft, a vital component that converts the linear motion of the pistons into rotational energy.

The rotational force generated by the crankshaft is then transferred to the propeller shaft. This shaft is typically connected to the engine via a series of gears or a belt drive system. As the propeller shaft rotates, it drives the propeller, which is often located at the rear of the boat. The propeller's blades are designed to create a hydrodynamic force when they rotate, pushing water backward and generating thrust in the opposite direction, propelling the boat forward.

The timing and synchronization of these components are crucial for efficient operation. The engine's fuel injection system ensures that the gasoline is delivered precisely when and where it is needed, optimizing combustion. Additionally, the engine's management system monitors various parameters, such as temperature, pressure, and speed, to maintain optimal performance and prevent damage. This intricate dance of mechanical precision allows the boat to navigate the waters with power and control.

Understanding the engine's operation is essential for boat owners and operators to ensure proper maintenance and troubleshooting. By grasping the fundamental principles of gasoline combustion and its role in driving the propeller, one can appreciate the complexity and beauty of marine propulsion systems. This knowledge empowers individuals to make informed decisions regarding their boat's care and ensures a smooth and efficient journey across the waters.

Wednesday's Boat Race Victory: What Went Down?

You may want to see also

Fuel Injection: Gas is injected into the engine's cylinders for combustion

Fuel injection is a critical component of modern boat engines, ensuring efficient and powerful performance on the water. This system is designed to precisely control the amount of fuel delivered to the engine's cylinders, optimizing combustion and power output. Here's a detailed explanation of how fuel injection works in the context of boat engines:

In a fuel-injected boat engine, the process begins with the fuel injection system, which is responsible for delivering the correct amount of gasoline to the engine's cylinders. This system consists of several key components. Firstly, there is the fuel pump, which draws fuel from the tank and pressurizes it to ensure a consistent flow. The pressurized fuel then travels through a series of fuel injectors, which are strategically positioned near the engine's cylinders. These injectors are the heart of the fuel injection process.

Each fuel injector is designed to spray a precise amount of fuel into the engine's combustion chamber at a specific time. This timing is crucial for optimal engine performance. The injectors use high-pressure fuel to create a fine mist, ensuring efficient mixing with the air-fuel mixture. This mist is then injected into the cylinders, where it combines with the air-fuel mixture created by the intake process.

The timing of fuel injection is controlled by the engine's electronic control unit (ECU). This sophisticated computer system monitors various engine parameters, such as temperature, speed, and load, to determine the ideal fuel-air mixture ratio. By adjusting the fuel injection timing and amount, the ECU ensures that the engine operates efficiently, delivering the right amount of power when needed. This precision in fuel delivery results in improved performance, better fuel efficiency, and reduced emissions, making it an essential feature for modern boat engines.

The process of fuel injection is a complex yet highly efficient method of feeding the engine. It ensures that the gasoline is delivered directly to the combustion chambers, where it mixes with air and ignites, producing the power that propels the boat. This system's sophistication and precision make it a cornerstone of modern marine engineering, providing boat owners with reliable and powerful engines for their aquatic adventures.

Boat Shoes for Men: Are Sperrys Still in Style?

You may want to see also

Combustion Process: Gas ignites, creating power to move the boat

The combustion process is a fascinating and powerful mechanism that lies at the heart of how boats propel themselves through the water. When you ignite the gas in a boat's engine, a series of rapid and controlled chemical reactions occur, resulting in a significant release of energy. This energy is then harnessed to create the necessary force to move the vessel forward.

In the context of a boat's engine, the combustion process typically involves a mixture of fuel (gas) and air being drawn into the engine's cylinders. This mixture is carefully composed to ensure optimal combustion, as the right balance of fuel and air is crucial for efficient power generation. Once the mixture is ignited, a spark plug creates a spark, which rapidly ignites the fuel-air mixture. This ignition process is a critical step, as it initiates the controlled burning of the fuel, releasing a tremendous amount of energy in a very short time.

As the gas ignites, it undergoes a rapid and intense burning process, which can be likened to a controlled explosion. This explosion creates a high-pressure and high-temperature environment within the cylinder. The force generated by this combustion event is then transferred to the engine's pistons, causing them to move rapidly. This movement of pistons is a key mechanical advantage, as it converts the thermal energy from combustion into mechanical energy, which is essential for propelling the boat.

The power generated by the combustion process is further amplified by the engine's design. As the pistons move, they are connected to a crankshaft, which converts the linear motion into rotational motion. This rotational force is then transferred to the boat's propeller, which is positioned at the rear of the vessel. The propeller's design and rotation create a forward thrust, pushing the boat through the water. This intricate process showcases the brilliance of marine engineering, where the controlled combustion of gas is transformed into the kinetic energy that propels boats across oceans and rivers.

Understanding the combustion process is essential for boat owners and enthusiasts, as it highlights the importance of maintaining and optimizing engine performance. Regular maintenance, such as checking spark plug condition and fuel injection systems, ensures that the combustion process remains efficient and reliable. By grasping the science behind this process, boat owners can appreciate the intricate dance of chemistry and mechanics that occurs every time they ignite the engine, ultimately enabling their vessel to navigate the waters with power and precision.

Boat Navigation at Night: Is It Legal?

You may want to see also

Exhaust System: Gas exhaust is released through the boat's tailpipe

The exhaust system on a boat is a crucial component that manages the release of combustion gases from the engine. When the engine operates, it burns fuel, and the resulting gases, primarily carbon dioxide and water vapor, are expelled through the exhaust system. This system is designed to efficiently remove these gases from the engine compartment and release them safely into the environment.

The process begins with the exhaust manifold, which is a metal pipe that connects multiple cylinders of the engine. After the fuel-air mixture is ignited and burned, the hot gases produced travel through the exhaust manifold and into the exhaust pipe. This pipe is typically made of sturdy materials like stainless steel or aluminum to withstand the high temperatures and pressures involved.

As the gases move through the exhaust pipe, they are directed towards the boat's tailpipe, often located at the rear of the vessel. The tailpipe is an essential component as it provides a controlled and directed path for the exhaust gases to exit the boat. It is designed with a specific diameter and length to ensure optimal flow and minimize backpressure, allowing the gases to escape efficiently. When the gases reach the tailpipe, they are released into the atmosphere through a small opening, often with a muffler or silencer to reduce noise.

The exhaust system's design is critical to ensure the boat's engine operates efficiently and meets environmental regulations. Proper exhaust system maintenance, including regular inspections and cleaning, is essential to prevent blockages and ensure the boat's performance and longevity. Additionally, understanding the exhaust system's function can help boat owners identify potential issues and make informed decisions regarding their vessel's maintenance.

Nitro RC Boats: Kick-Starting Your Racing Adventure

You may want to see also

Gas Tank: Stores gasoline, which is pumped to the engine when needed

The gas tank is a crucial component of your boat's fuel system, serving as the primary storage unit for gasoline. Its primary function is to hold the fuel that powers your boat's engine, ensuring a steady supply of gasoline when you're out on the water. This tank is typically located beneath the boat, often in a central position, and is designed to withstand the rigors of marine environments.

When you fill up your boat's gas tank, it's filled with gasoline, a volatile liquid that requires careful handling due to its flammable nature. The tank is sealed to prevent any leaks and is often made of durable materials like steel or aluminum to ensure it can withstand the pressure and potential impact of waves. Inside the tank, you'll find a fuel pump, which is responsible for transferring gasoline from the tank to the engine when it's required. This pump is a critical component, as it ensures a consistent and controlled flow of fuel, preventing any potential issues with the engine.

The process begins when the engine requires fuel. The fuel pump activates, drawing gasoline from the tank and sending it through a series of fuel lines to the engine. These fuel lines are carefully designed to minimize resistance and ensure a smooth, efficient flow of fuel. The engine then uses this gasoline to power its various components, such as the cylinders and pistons, which convert the chemical energy of the fuel into mechanical energy, propelling your boat forward.

It's important to note that the gas tank is not just a passive storage unit. It is equipped with various safety features to prevent accidents. These include fuel level indicators, which show how much gasoline is left in the tank, and safety valves that release pressure if the tank becomes overfilled or if there's a malfunction. Additionally, many boats have fuel filters to ensure that contaminants don't enter the engine, which could cause damage.

Regular maintenance of the gas tank is essential to ensure its longevity and the efficient operation of your boat's engine. This includes checking for any signs of corrosion or damage, replacing the fuel filter at recommended intervals, and ensuring that the fuel pump is functioning correctly. Proper care will help you avoid issues like fuel contamination, engine misfires, or even engine damage, all of which can be costly to repair.

Fire Extinguishers: Boat Requirements and Safety

You may want to see also

Frequently asked questions

The gas system in a boat is designed to store and supply fuel to the engine. It typically consists of a fuel tank, a fuel pump, and a fuel line. When you start the engine, the pump activates to send gas from the tank to the carburetor or fuel injection system, where it mixes with air and is ignited to power the engine.

Monitoring the gas level is crucial to ensure your boat's engine operates efficiently and avoids running out of fuel. Regular checks help you plan refueling stops, especially for longer voyages or when navigating in unfamiliar waters. It also allows you to identify any potential issues with the fuel system, such as leaks or contamination.

It's generally recommended to use the type of fuel specified by the boat manufacturer. Different engines may require specific octane levels or fuel blends. Using the wrong gas can lead to engine performance issues, reduced efficiency, or even damage. Always refer to your boat's manual for fuel recommendations.

If the gas gauge is faulty, it's essential to estimate the fuel level manually. You can do this by regularly checking the fuel level at various points during your journey. Additionally, keep track of the distance traveled and fuel consumption to estimate when you'll need to refuel. It's a good practice to carry extra fuel when the gauge is unreliable.