An inboard boat transmission is a crucial component in the propulsion system of watercraft, converting the engine's rotational energy into forward motion. This system operates by transmitting power from the engine to the propeller through a series of gears and shafts, allowing the boat to move efficiently through the water. The transmission's design enables precise control over speed and torque, ensuring optimal performance and handling. Understanding the mechanics of this transmission is essential for boat owners and enthusiasts to maintain and troubleshoot their vessels effectively.

What You'll Learn

- Engine Power Transfer: Mechanical or hydraulic systems transfer engine power to the propeller

- Gear Ratios: Multiple gears change speed and torque to optimize performance and efficiency

- Propeller Control: Thrust and speed are adjusted by varying propeller pitch or speed

- Cooling Systems: transmissions require cooling to prevent overheating, often using oil or water

- Control Mechanisms: Throttle, shift levers, or electronic controls adjust transmission operation

Engine Power Transfer: Mechanical or hydraulic systems transfer engine power to the propeller

The power transfer system in an inboard boat engine is a critical component that ensures efficient and effective propulsion. This system is responsible for transmitting the engine's power to the propeller, which then drives the boat forward. The method of power transfer can vary, but the primary goal remains the same: to convert the engine's rotational energy into forward motion.

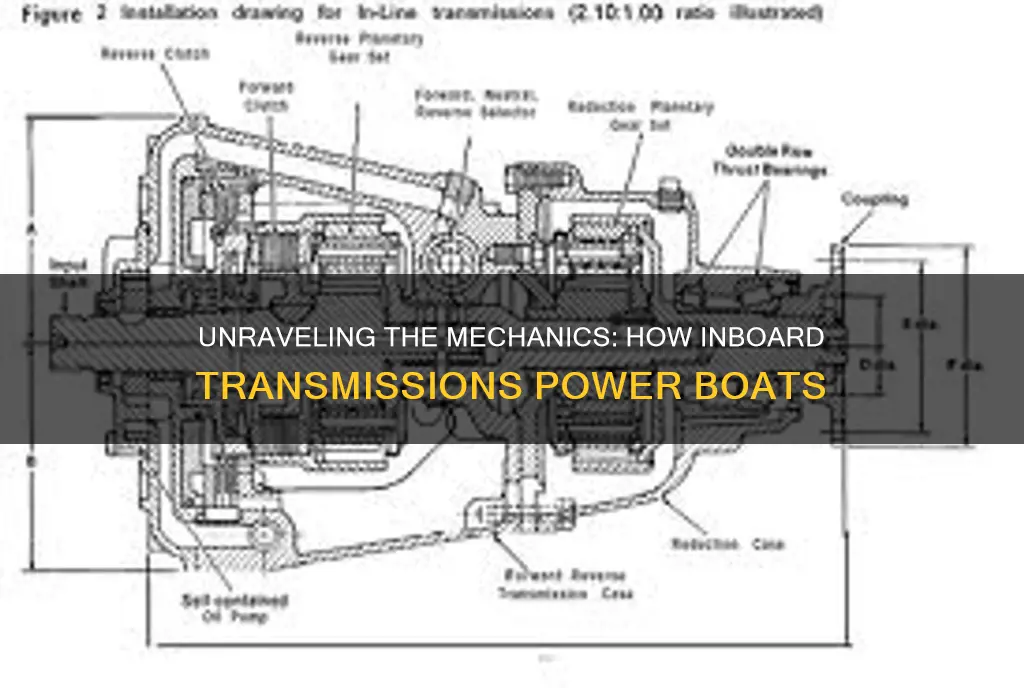

Mechanical systems are commonly used in inboard boat transmissions. These systems utilize a series of gears and pulleys to transfer power from the engine to the propeller shaft. The engine's output shaft is connected to a gear, which then meshes with another gear on the propeller shaft. This mechanical connection allows for a direct transfer of power, ensuring a smooth and efficient propulsion system. The gears are carefully designed to match the engine's speed and torque requirements, providing the optimal power output to the propeller.

Hydraulic systems offer an alternative approach to power transfer. In this method, hydraulic fluid is used to transmit power from the engine to the propeller. The engine's output shaft is connected to a hydraulic pump, which creates pressurized fluid. This pressurized fluid then travels through a series of lines and valves, ultimately reaching the propeller shaft. The hydraulic system provides a flexible and adaptable power transfer, allowing for variations in speed and torque. By adjusting the fluid flow and pressure, the system can accommodate different operating conditions, ensuring optimal performance.

Both mechanical and hydraulic systems have their advantages and are chosen based on specific boat requirements. Mechanical systems are known for their simplicity and reliability, making them a popular choice for many inboard boat applications. They provide a direct and efficient power transfer, ensuring a smooth and responsive propulsion system. On the other hand, hydraulic systems offer increased flexibility and the ability to fine-tune power output, making them suitable for boats that require variable speed and torque adjustments.

In summary, the engine power transfer process in an inboard boat transmission is a crucial aspect of boat propulsion. Whether using mechanical or hydraulic systems, the goal is to efficiently convert engine power into forward motion. These systems play a vital role in ensuring the boat's performance, speed, and overall functionality, allowing for a smooth and enjoyable boating experience.

Mystery of Richard Sharp's Boat Mayaluga's Disappearance

You may want to see also

Gear Ratios: Multiple gears change speed and torque to optimize performance and efficiency

In the world of inboard boat transmissions, gear ratios play a pivotal role in optimizing performance and efficiency. These ratios are the result of a carefully calculated arrangement of multiple gears, each with a specific size and number of teeth. The primary function of these gears is to alter the speed and torque of the engine, ensuring that the boat operates at its most efficient and effective level.

The concept is simple yet powerful: by engaging different gear combinations, the transmission can either increase or decrease the rotational speed of the propeller, directly impacting the boat's speed and performance. For instance, a lower gear ratio provides more torque, enabling the boat to accelerate quickly or overcome heavy loads. Conversely, a higher gear ratio increases speed, allowing the boat to cruise efficiently at higher velocities. This versatility is crucial for various boating activities, from leisurely cruising to high-speed water sports.

The design of these gear ratios is intricate and often tailored to specific engine and boat configurations. Manufacturers consider factors such as engine power, boat weight, and intended use to determine the optimal gear ratio setup. This customization ensures that the transmission not only enhances performance but also provides a smooth and efficient power transfer from the engine to the propeller.

In practice, when a boat is at rest or moving slowly, the transmission might default to a higher gear ratio, maximizing efficiency by reducing the engine's speed and fuel consumption. As the boat gains speed, the transmission can seamlessly shift to a lower gear ratio, providing the necessary torque to maintain or increase velocity. This dynamic adjustment is a hallmark of advanced inboard boat transmissions, ensuring a responsive and efficient driving experience.

Understanding gear ratios is essential for boat owners and operators, as it empowers them to make informed decisions about their vessel's performance. By recognizing the impact of different gear ratios, they can optimize their boating experience, whether it's for recreational cruising, fishing, or water sports. The intricate dance of gears and ratios within the inboard transmission is a testament to the engineering prowess that enables boats to navigate the waters with precision and efficiency.

Best Places to Install a Power Inverter on Your Boat

You may want to see also

Propeller Control: Thrust and speed are adjusted by varying propeller pitch or speed

Propeller control is a critical aspect of inboard boat transmission systems, allowing for precise adjustments in thrust and speed. This control mechanism is designed to optimize performance and efficiency, ensuring that the boat operates at its best in various conditions. The primary method of achieving this control is by manipulating the propeller's pitch or its rotational speed.

Pitch, in the context of propellers, refers to the angle of the blades relative to the horizontal plane. By adjusting the pitch, the boat's engine can control the amount of thrust generated. A higher pitch results in a steeper angle, creating more lift and forward force, which increases thrust. Conversely, a lower pitch angle reduces lift, decreasing thrust and allowing for a more efficient, slower speed. This adjustment is particularly useful when a boat needs to maintain speed while carrying heavy loads or when navigating through varying water conditions.

The speed of the propeller is another crucial factor in propeller control. By altering the rotational speed, the engine can directly impact the boat's speed. Increasing the propeller speed boosts the boat's velocity, while decreasing it slows down the vessel. This method of control is often used in conjunction with pitch adjustment to fine-tune the boat's performance. For instance, a boat might use a higher pitch for maximum thrust during acceleration and then switch to a lower pitch and higher propeller speed for cruising at a steady pace.

Inboard boat transmissions often employ advanced systems that automatically adjust propeller pitch and speed based on the boat's operating conditions. These systems use sensors to monitor factors such as engine speed, water temperature, and load. By making real-time adjustments, the transmission ensures optimal performance, fuel efficiency, and longevity of the propeller and engine. This level of control is essential for modern boats, especially those designed for specific tasks like fishing, cruising, or high-speed water sports.

Understanding and utilizing propeller control allows boat owners and operators to maximize the efficiency and performance of their vessels. It enables them to adapt to different environments and tasks, ensuring a smooth and controlled ride. Whether it's adjusting pitch for varying loads or changing propeller speed for different speeds, this control mechanism is a key component in the overall functionality of inboard boat transmissions.

The Gallant Lady: Mystery of Ownership

You may want to see also

Cooling Systems: transmissions require cooling to prevent overheating, often using oil or water

Inboard boat transmissions, which are a type of marine propulsion system, rely on efficient cooling mechanisms to maintain optimal performance and prevent damage. These transmissions are designed to transmit power from the engine to the propeller, and without proper cooling, they can overheat, leading to reduced efficiency, premature wear, and potential failure.

The primary cooling method for inboard transmissions is through the use of hydraulic oil. The transmission's internal components, including gears, bearings, and the torque converter, are lubricated and cooled by this oil. As the transmission operates, the oil circulates through a series of passages and channels, absorbing heat from the components. This heated oil then passes through a cooler, which can be either an oil-to-air or oil-to-water heat exchanger. In the cooler, the oil releases its heat to the surrounding environment or water, thus cooling down and being recirculated back into the transmission. This continuous cooling process ensures that the transmission's operating temperature remains within safe limits.

Water cooling is another effective method employed in some inboard transmissions. This system utilizes the boat's engine cooling water, which is typically a separate circuit from the engine's cooling system. The transmission's housing or certain components are designed to accept this water flow, allowing for efficient heat exchange. As the water passes through the transmission, it absorbs heat, and then it is directed to a cooler, often located near the engine, where it cools down and is recirculated. Water cooling is advantageous as it provides excellent heat dissipation, especially in high-performance or large-displacement transmissions.

Both oil and water cooling systems are designed to maintain the transmission's temperature within a narrow range, ensuring optimal performance and longevity. Overheating can lead to several issues, such as increased friction, reduced component life, and even permanent damage to the transmission. Therefore, efficient cooling is crucial for inboard boat transmissions to operate reliably and efficiently in marine environments.

In summary, inboard boat transmissions rely on cooling systems that utilize hydraulic oil and, in some cases, engine cooling water to prevent overheating. These cooling methods are essential to maintain the transmission's performance, efficiency, and overall reliability, especially in the demanding conditions of marine applications.

Boat Insurance Basics: What Does Your Policy Cover?

You may want to see also

Control Mechanisms: Throttle, shift levers, or electronic controls adjust transmission operation

Inboard boat transmissions rely on various control mechanisms to manage the transfer of power from the engine to the propeller. These control systems play a crucial role in determining the boat's speed, torque, and overall performance. Here's an overview of the primary control mechanisms used in inboard boat transmissions:

Throttle Control: The throttle is a fundamental component in any engine-driven system, including inboard boat transmissions. It functions as a variable resistor or a throttle body, which regulates the amount of air-fuel mixture entering the engine's combustion chamber. By adjusting the throttle, the driver can control the engine's speed and power output. In inboard transmissions, the throttle is typically connected to the engine's throttle body or carburetor, allowing for precise control over the engine's performance. When the throttle is opened, more air-fuel mixture is allowed into the engine, increasing power and speed. Conversely, closing the throttle reduces power and slows down the boat. This mechanism is often controlled by a pedal or a lever, providing the operator with a direct and intuitive way to manage the boat's speed.

Shift Levers: In manual or semi-automatic inboard transmissions, shift levers are used to change gear ratios. These levers are typically mounted on the boat's dashboard or floor, providing the operator with easy access. When the driver wants to increase or decrease speed, they engage the shift lever, which moves the transmission's gears up or down. This action changes the gear ratio, affecting the amount of torque and speed delivered to the propeller. For example, shifting to a lower gear provides more torque, making it easier to accelerate or climb steep inclines. Higher gears offer increased speed and efficiency for cruising. The shift levers are designed to provide a tactile and audible feedback system, ensuring the operator knows when a gear change is complete.

Electronic Controls: Modern inboard boat transmissions often incorporate electronic controls, which offer enhanced precision and convenience. These systems use sensors, actuators, and microprocessors to manage the transmission's operation. Electronic controls can include throttle bodies with electronic sensors, shift actuators, and advanced control units. By utilizing electronic sensors, the system can monitor engine parameters, such as speed, load, and temperature, and adjust the transmission accordingly. For instance, electronic controls can automatically shift gears based on engine load, providing optimal performance and fuel efficiency. Some systems even offer cruise control, allowing the driver to maintain a set speed without constant throttle input. Electronic controls often feature user-friendly interfaces, such as touchscreens or buttons, making it easier for operators to adjust settings and monitor transmission performance.

The combination of throttle control, shift levers, and electronic systems allows inboard boat transmissions to provide efficient power transfer and precise speed control. These control mechanisms enable operators to navigate various water conditions, from calm lakes to challenging offshore environments, ensuring a smooth and responsive boating experience. Understanding these control systems is essential for boat owners and operators to maximize the performance and longevity of their inboard transmissions.

Docking Techniques for Medieval Sailors: A Historical Guide

You may want to see also

Frequently asked questions

An inboard boat transmission is a type of transmission system used in boats to transfer power from the engine to the propeller. It is located inside the boat's hull, hence the term "inboard." This design allows for a more compact and efficient layout, as the transmission is protected from the elements and can be positioned closer to the engine.

The key difference lies in their mounting location. Inboard transmissions are mounted inside the boat, typically near the engine, while outboard transmissions are mounted on the outside, often on the transom or the side of the hull. Inboard transmissions offer better weight distribution and a lower center of gravity, contributing to improved boat handling and stability.

An inboard transmission system consists of several key components. These include the transmission case, which houses the gears and provides a protective enclosure; the input shaft, which connects to the engine's output; the output shaft, which delivers power to the propeller; various gears and clutches that enable speed and torque adjustments; and the propeller shaft, which transmits power to the propeller.

The gear system in an inboard transmission is designed to provide different speed and torque ratios to optimize boat performance in various conditions. It typically includes a range of gears, such as forward, neutral, and reverse, which are selected by the operator. The gears are meshed with the input and output shafts, allowing for efficient power transfer and enabling the boat to move forward, reverse, or remain stationary.